Remote monitoring system for medical disinfection machine

A technology of a remote monitoring system and a sterilizer, applied in the field of medical devices, can solve the problems of poor sterilization effect, difficult management, inconvenient access, etc., and achieve the effect of good sterilization effect and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

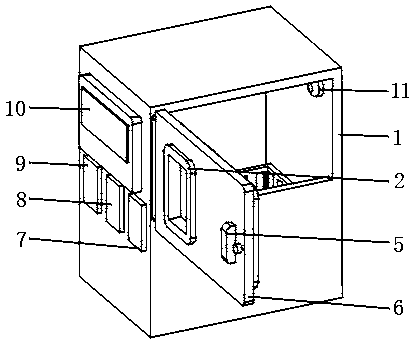

[0020] A remote monitoring system for a medical disinfection machine, comprising a monitoring host and a plurality of disinfection machine main bodies 1, the monitoring host is connected to at least two disinfection machine main bodies 1 through a network, and the left side of the disinfection machine main body 1 is located near the upper surface. There is a PLC controller 10, the PLC controller 10 controls the operation of the sterilizer main body 1 and sends its work data to the monitoring host, the left side of the sterilizer main body 1 is provided with a memory 9, and the memory 9 is used to store the data of the sterilizer main body 1 Work data, record the time and disinfection status of each disinfection of the sterilizer through the memory 9 and the PLC controller 10, the left side of the sterilizer main body 1 is provided with a GPS locator 8 near the position of the memory 9, and the GPS locator 8 uses To locate the position of the sterilizer main body 1 and determine...

Embodiment 2

[0022] The difference between this embodiment and embodiment 1 is:

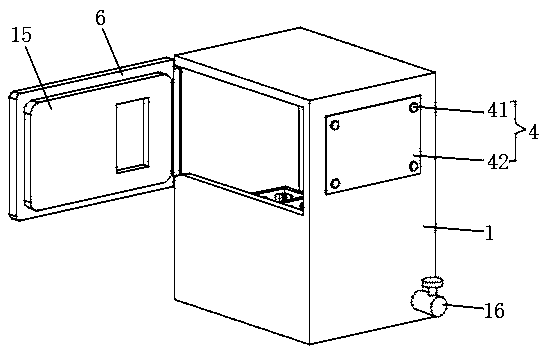

[0023] In this embodiment, a handle 5 and a safety lock are provided on the outer side of the closed door 6 near the edge, a sealing backing plate 15 is provided on the inner side of the closed door 6, and a through groove is provided on the outer side of the closed door 6. Transparent glass observation window 2 is installed.

[0024] Specifically, such setting facilitates the opening and closing of the door 6, which is more convenient to use and convenient to observe the disinfection status of the medical equipment.

Embodiment 3

[0026] The difference between this embodiment and embodiment 1 is:

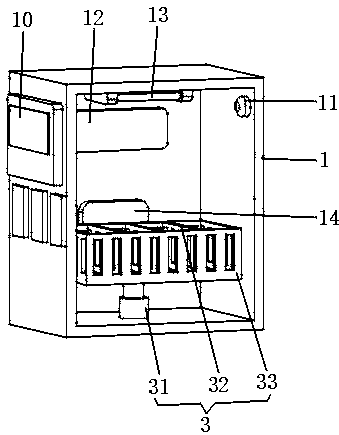

[0027] In this embodiment, the medical equipment placement mechanism 3 includes an electric push rod 31 arranged at the bottom of the disinfection pool, a placement frame 33 is provided on the top of the electric push rod 31, and a partition plate 32 is provided at the bottom of the cavity of the placement frame 33. The input end of the rod 31 is electrically connected to the output end of the PLC controller 10. After preliminary cleaning and disinfection, the electric push rod 31 drives the placement frame 33 to rise, so that the medical equipment is separated from the disinfectant, and is dried by the drying fan 12. The disinfection machine A drying fan 12 is provided on the side of the inner cavity of the main body 1 close to the upper surface, and the input end of the drying fan 12 is electrically connected to the output end of the PLC controller 10 .

[0028] Specifically, such a setting is convenient fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com