Liquid-liquid extraction phase separator

A phase separator and extraction technology, applied in the fields of chemical industry, mining, metallurgy, food production, and pharmaceuticals, can solve the problems of low utilization rate of clarifiers, affecting production efficiency, long time consumption, etc., to improve equipment utilization rate and production efficiency, Simple structure, fully mixed extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

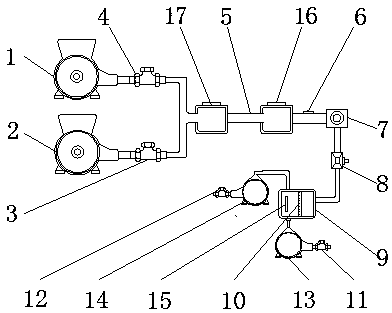

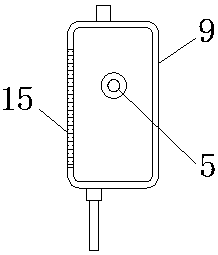

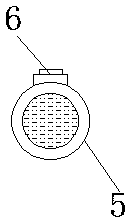

[0019] see Figure 1-3 , the present invention provides a technical solution: a liquid-liquid extraction phase separator, including a light phase feed pump 1, a horizontal tubular extraction phase separation pipe 5 and a horizontal split tank 9, the light phase feed pump 1 below A heavy-phase feed pump 2 is provided, and a heavy-phase feed valve 4 is connected to the right side of the light-phase feed pump 1, and a mixer 17 is arranged on the right side of the heavy-phase feed valve 4. Horizontal tubular extraction and phase separation The pipe 5 is installed on the right side of the mixer 17, and the right side of the horizontal tubular extraction phase-splitting pipe 5 is connected with a coalescence packing unit 16, and the right side of the coalescence packing unit 16 is provided with a sight glass 7, and the sight glass 7 The bottom of the extraction phase-splitting pipe discharge valve 8 is connected, and the horizontal splitter tank 9 is installed on the lower left side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap