Handheld screwing device

A screwing, hand-held technology, applied in the field of hand-held screwing devices, can solve the problems of low screwing efficiency, hand injury, consumption, etc., and achieve the effect of saving manpower and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

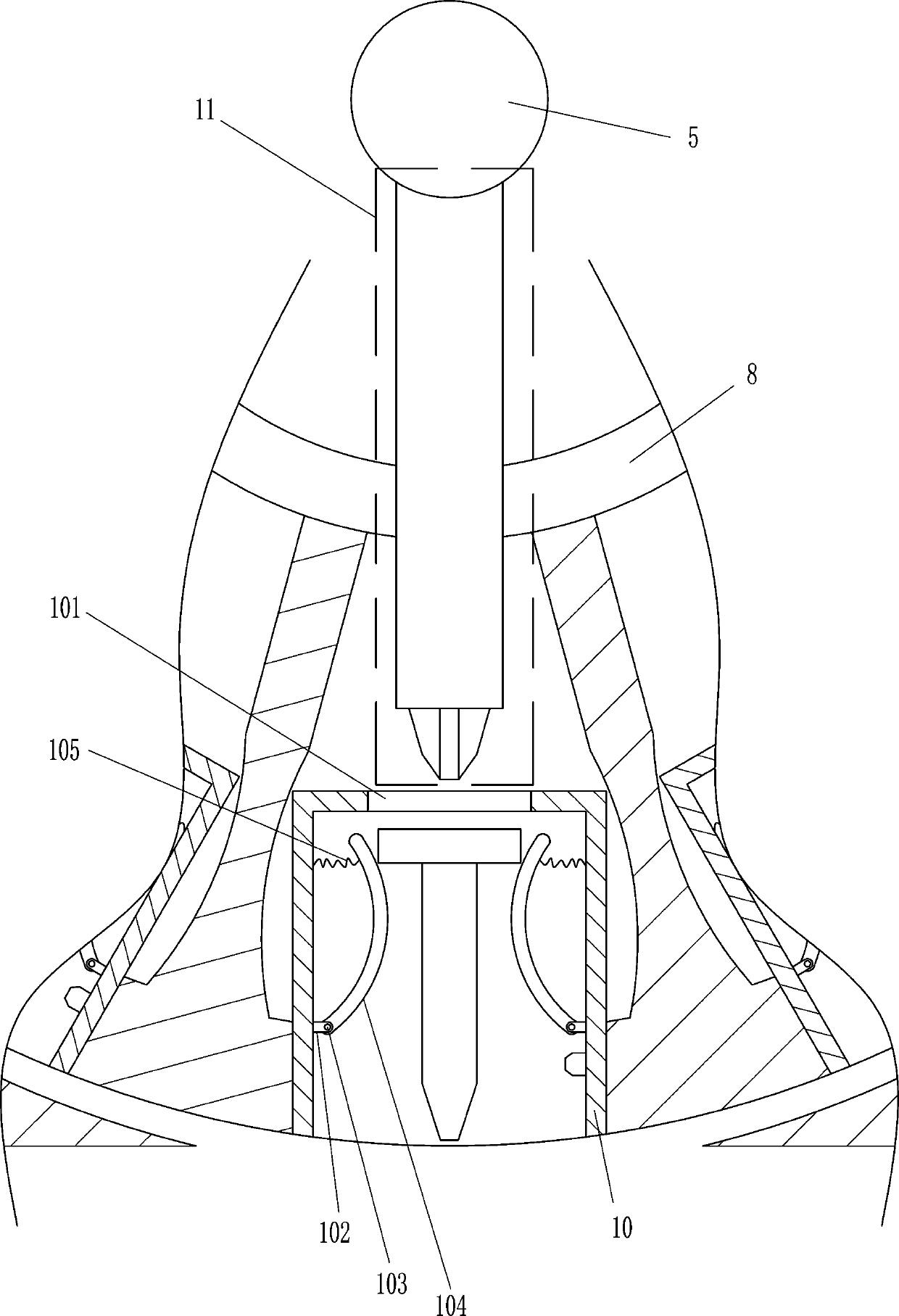

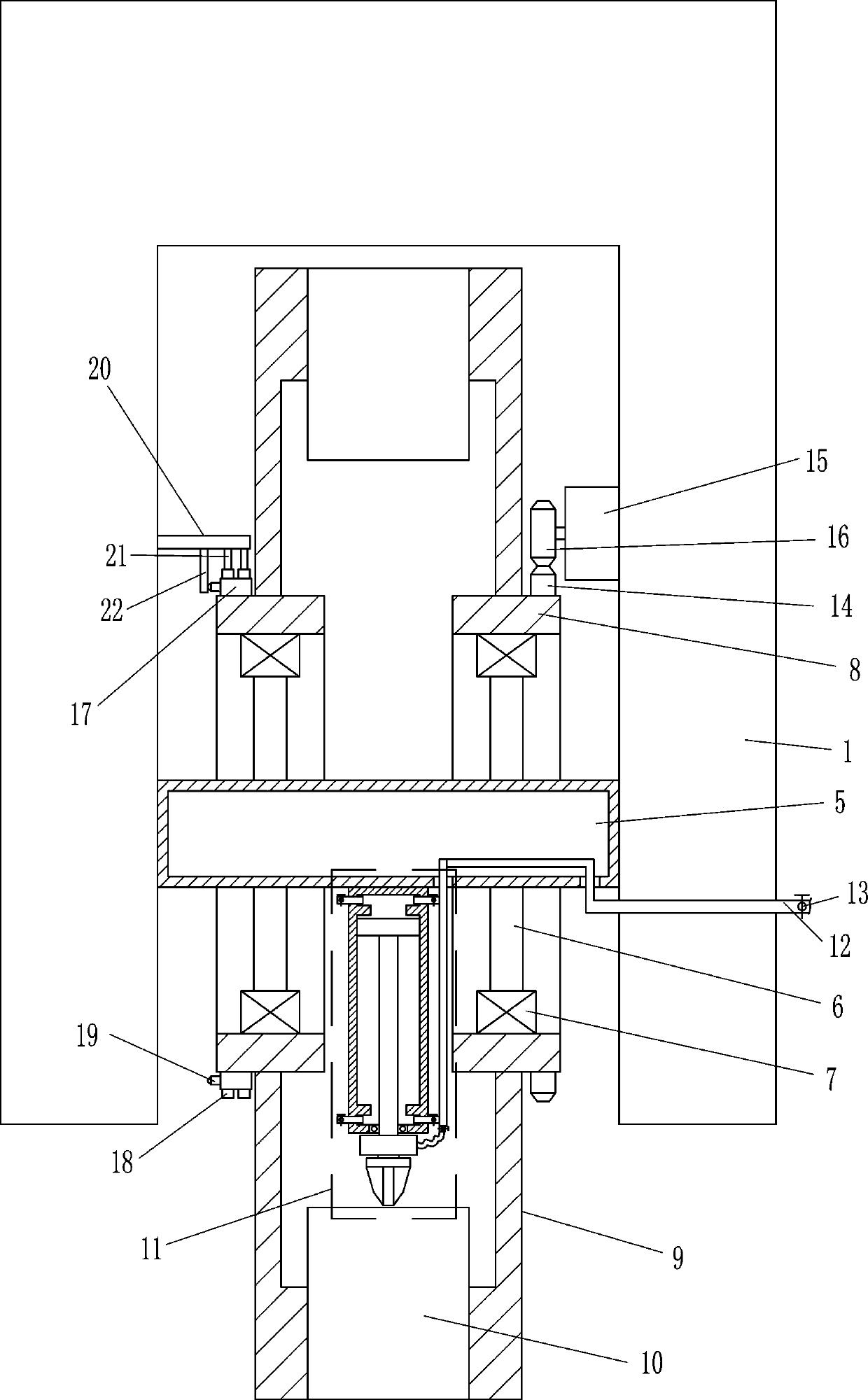

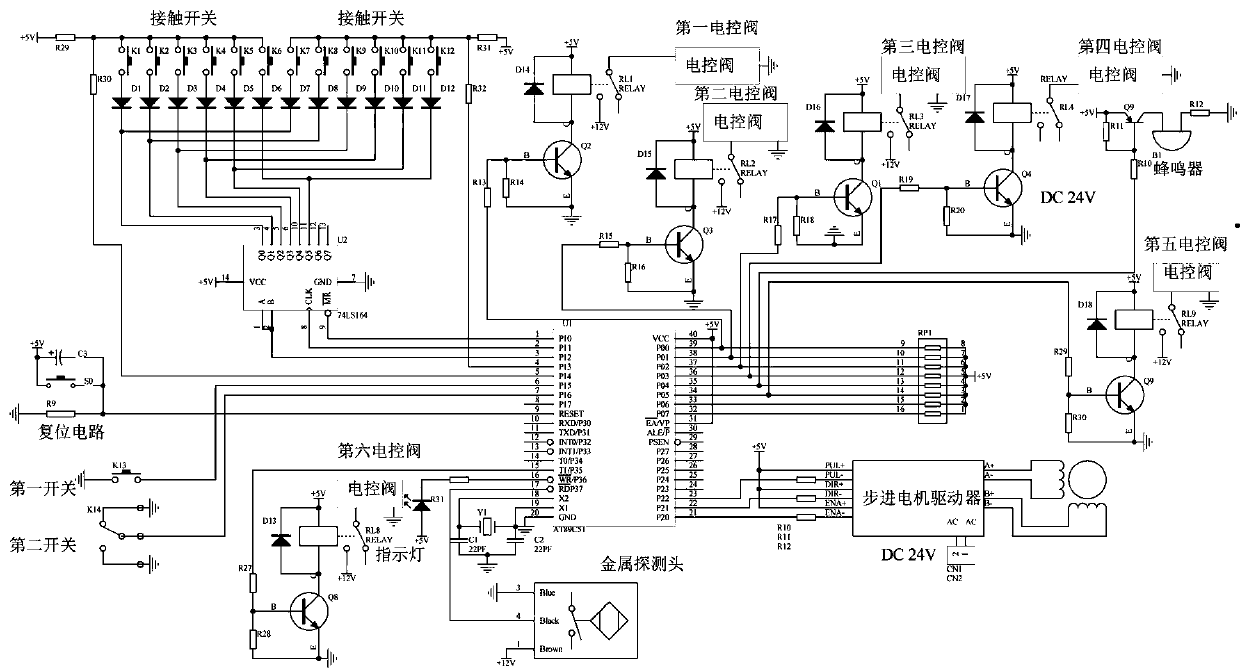

[0026] A handheld screwdriver, such as figure 1 , figure 2 , image 3 , Figure 4As shown, it includes a hand grip 1, an external hose 2, a first switch 3, a second switch 4, a middle round box 5, an extension rod 6, a bearing seat 7, a rotating ring 8, a connecting ring frame 9, and a storage box 10 , shaft seat 102, rotating shaft 103, arc rod 104, spring 105, impact screwing device 11, connecting air pipe 12, first electric control valve 13, first gear 14, servo motor 15, second gear 16, mounting plate 17 , receiving coil 18, contact switch 19, connecting block 20, electrode 21 and bump 22, the right side of hand-held device 1 is connected with external hose 2, and external hose 2 is provided with power cord and external trachea, hand-held The lower side of the middle part of the device 1 is connected with a first switch 3, and the upper side of the middle part of the handheld device 1 is connected with a second switch 4. The second switch 4 is a three-speed switch, and...

Embodiment 2

[0029] On the basis of Example 1, such as Figure 5 As shown, the impact screwing device 11 includes a cylinder 111, a piston 112, a push rod 113, a sealing ring 114, an air motor 115, a screw head 116, a tap pipe 117, a second electric control valve 118, a connecting air hose 119, The first air intake pipe 1110, the third electric control valve 1111, the second air intake pipe 1112, the fourth electric control valve 1113, the first exhaust pipe 1114, the fifth electric control valve 1115, the second exhaust pipe 1116 and the sixth electric Control valve 1117, a cylinder 111 is connected in the middle of the bottom of the middle circular box 5, a piston 112 is arranged in the cylinder 111, a push rod 113 is connected in the middle of the top of the piston 112, a sealing ring 114 is embedded in the middle of the bottom of the cylinder 111, and the push rod 113 wears Through the sealing ring 114, the bottom end of the push rod 113 is connected with the air motor 115, and the pus...

Embodiment 3

[0032] On the basis of Example 2, such as figure 1 , image 3 , Image 6 , Figure 7 , Figure 8 As shown, a metal detector 301 and an indicator light 302 are also included. The metal detector 301 is connected to the right side of the placement box 10. The metal detector 301 is located under the shaft seat 102. The front side of the placement box 10 is connected to an indicator light 302. , the metal detector head 301 and the indicator light 302 are connected to the control module through lines.

[0033] Also include a first connecting rod 311, an upper protective cover 312, a second connecting rod 314 and a lower protective cover 315, the upper left side of the hand grip 1 is connected with the first connecting rod 311, the bottom left of the first connecting rod 311 The side is connected with an upper protective cover 312, the first connecting rod 311 is connected with the upper protective cover 312 by means of bolt connection, the right part of the upper protective cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com