Flexible tool used for grinding and grinding method

A flexible tooling and flexible technology, applied in machine tools suitable for grinding workpiece planes, grinding workpiece supports, grinding/polishing equipment, etc., to achieve the effect of improving parallelism and flatness accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

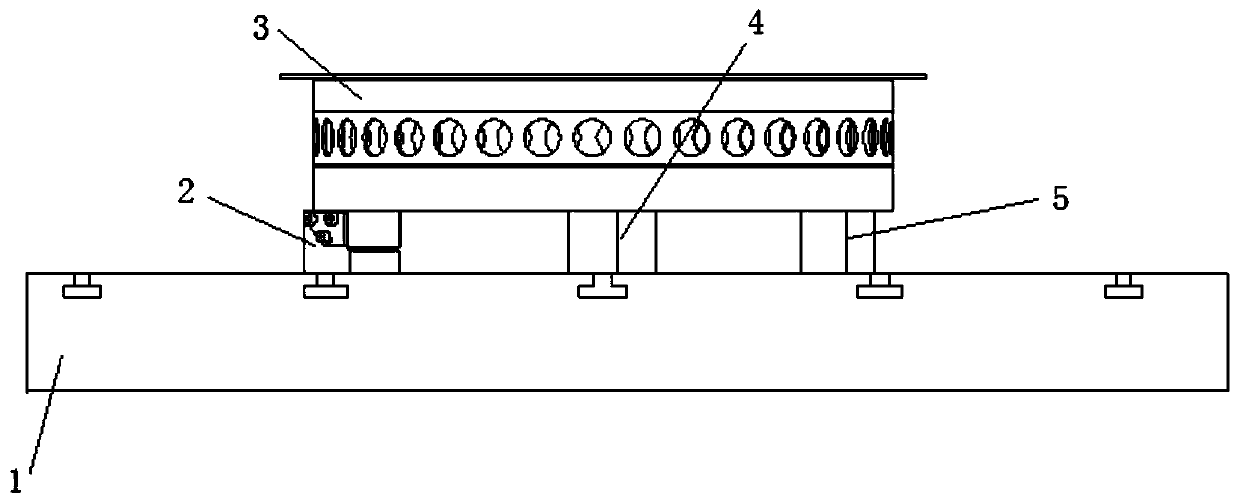

[0020] The flexible tooling of the present invention, such as figure 2 As shown in Fig. 1, a worktable with magnetic attraction 1, a flexible standard block 2, a first fixed standard block 4 and a second fixed standard block 5 are used. When grinding a part, three points are used to determine a surface. The flexible standard block 2, the first fixed standard block 4 and the second fixed standard block 5 provide support to the parts between the workbench 1, and the deformation of the parts caused by magnetic attraction is reduced by using the flexible standard block 2. Fixing bolt 15 fixes the flexible standard block on the workbench.

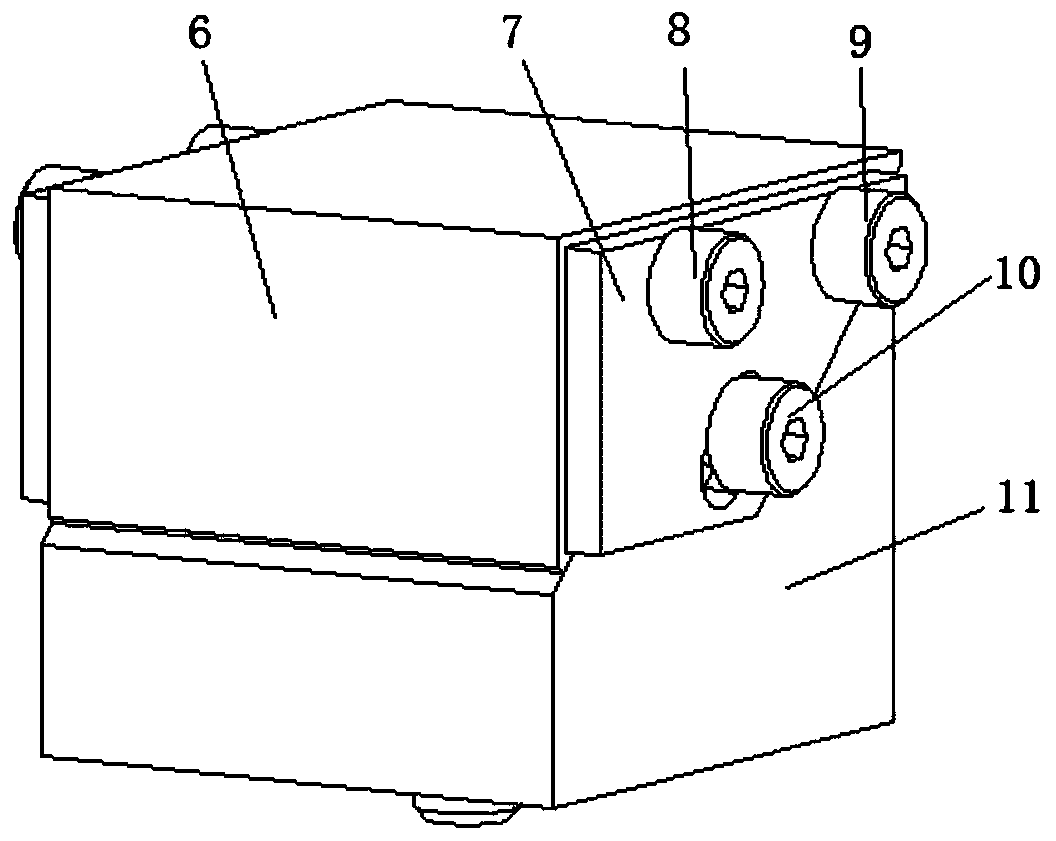

[0021] Flexible standard block 2 mainly comprises movable cushion block 6, cushion block base 11, compression spring 13 and guide plate 7 etc., movable cushion block 6 and cushion block base 11 use magnetic permeability strong material to make; The contact surface of the tooth-shaped structure is adopted to form the first sliding mating surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com