Sewage pipeline adjuster

A technology of sewage pipes and regulators, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of large labor consumption, increased workload, and low efficiency of sewage pipe handling, so as to reduce labor force and prevent self-moving , Improve the effect of handling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

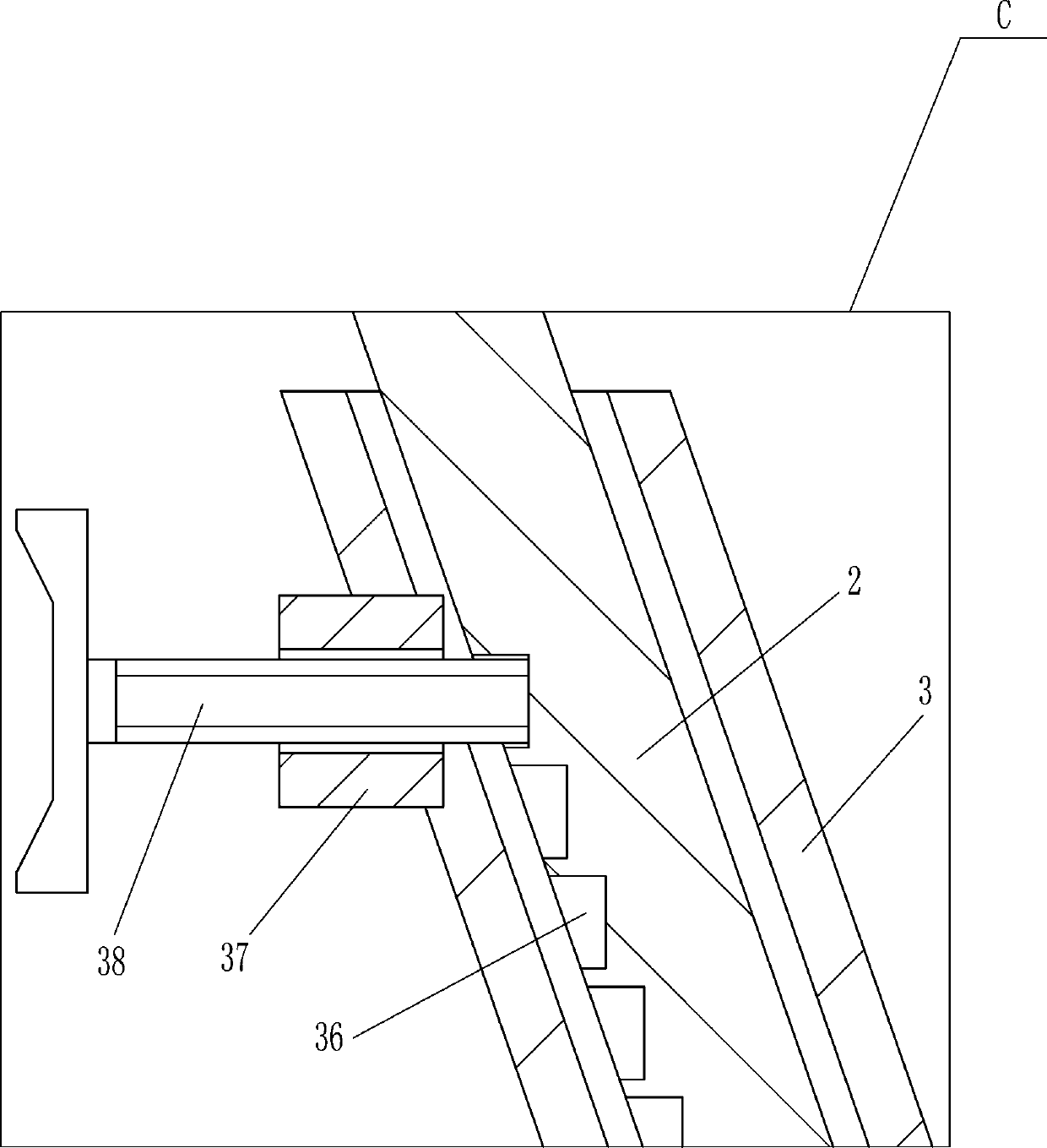

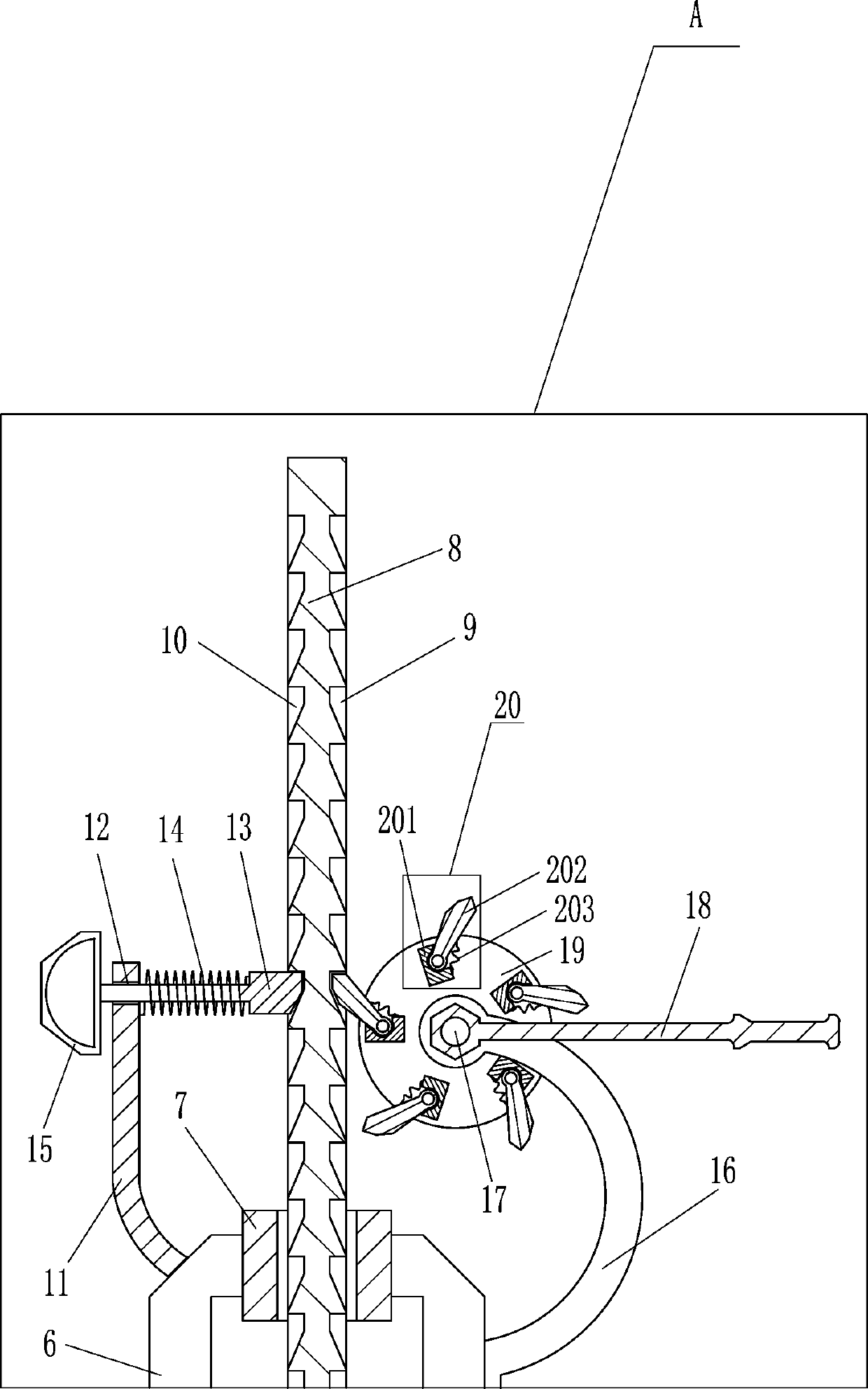

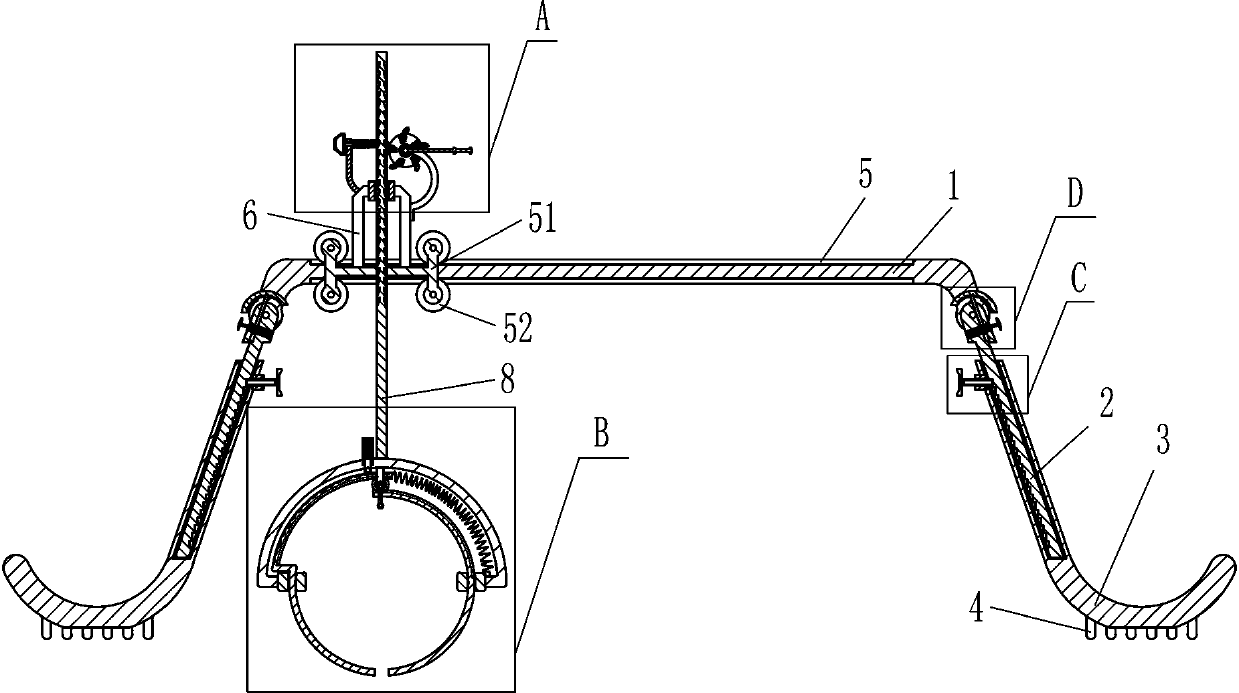

[0018] A sewage pipe regulator such as Figure 1-3 As shown, it includes a first bracket 1, a first sliding rod 2, a first sliding tube 3, a tapered nail 4, a first pole 51, a roller 52, a second pole 6, a first sliding sleeve 7, a second Slide bar 8, third pole 11, first guide bar 13, first spring 14, first handle 15, second support 16, first rotating shaft 17, second handle 18, turntable 19, swing device 20, arc bar 21. The fourth pole 22, the second rotating shaft 23, the handle 24, the gear 25, the second sliding sleeve 26, the arc-shaped sliding rod 27, the first arc-shaped rack 28, the second arc-shaped rack 29 and the third Spring 30, the left and right sides of the bottom of the first bracket 1 are all rotatably connected with the first slide bar 2 that plays a supporting role, the first slide bar 2 is slidably provided with the first slide tube 3, and the bottom of the first slide tube 3 There are a plurality of tapered nails 4 for fixing, the upper and lower sides o...

Embodiment 2

[0020] A sewage pipe regulator such as Figure 1-3As shown, it includes a first bracket 1, a first sliding rod 2, a first sliding tube 3, a tapered nail 4, a first pole 51, a roller 52, a second pole 6, a first sliding sleeve 7, a second Slide bar 8, third pole 11, first guide bar 13, first spring 14, first handle 15, second support 16, first rotating shaft 17, second handle 18, turntable 19, swing device 20, arc bar 21. The fourth pole 22, the second rotating shaft 23, the handle 24, the gear 25, the second sliding sleeve 26, the arc-shaped sliding rod 27, the first arc-shaped rack 28, the second arc-shaped rack 29 and the third Spring 30, the left and right sides of the bottom of the first bracket 1 are all rotatably connected with the first slide bar 2 that plays a supporting role, the first slide bar 2 is slidably provided with the first slide tube 3, and the bottom of the first slide tube 3 There are a plurality of tapered nails 4 for fixing, the upper and lower sides of...

Embodiment 3

[0023] A sewage pipe regulator such as Figure 1-3 As shown, it includes a first bracket 1, a first sliding rod 2, a first sliding tube 3, a tapered nail 4, a first pole 51, a roller 52, a second pole 6, a first sliding sleeve 7, a second Slide bar 8, third pole 11, first guide bar 13, first spring 14, first handle 15, second support 16, first rotating shaft 17, second handle 18, turntable 19, swing device 20, arc bar 21. The fourth pole 22, the second rotating shaft 23, the handle 24, the gear 25, the second sliding sleeve 26, the arc-shaped sliding rod 27, the first arc-shaped rack 28, the second arc-shaped rack 29 and the third Spring 30, the left and right sides of the bottom of the first bracket 1 are all rotatably connected with the first slide bar 2 that plays a supporting role, the first slide bar 2 is slidably provided with the first slide tube 3, and the bottom of the first slide tube 3 There are a plurality of tapered nails 4 for fixing, the upper and lower sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com