A wide-band reflective coating and reflective device

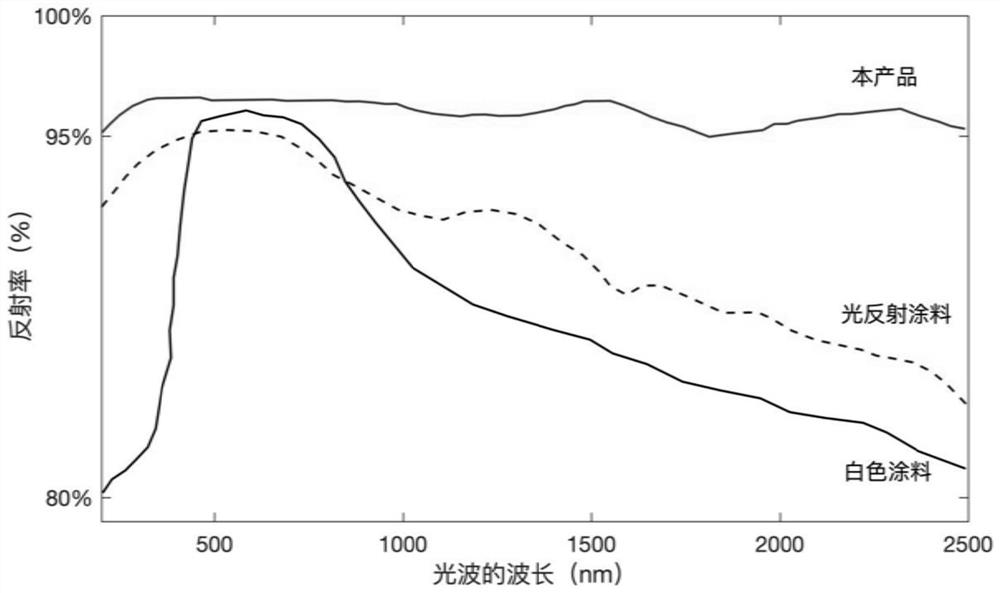

A reflective paint, broadband technology, applied in the field of paint, can solve problems such as relatively few studies, and achieve the effect of high reflectivity and wide reflection band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

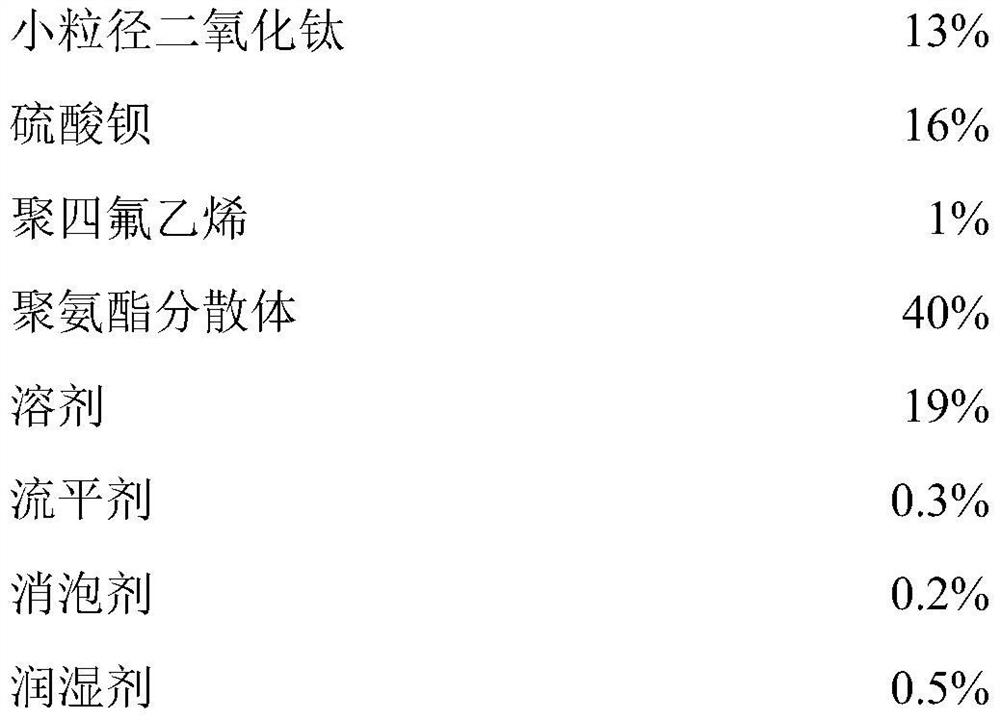

[0031] A broadband reflective paint, comprising the following components according to the total mass of the paint:

[0032]

[0033]

[0034] Among them, the reflective powder accounts for 40% of the total mass of the coating, including 10% of large particle size titanium dioxide (that is, 25% of the total mass of the reflective powder), 13% of small particle size titanium dioxide (that is, 25% of the total mass of the reflective powder) 32.5%), 16% of barium sulfate (that is, 40% of the total mass of the reflective powder) and 1% of polytetrafluoroethylene (that is, 2.5% of the total mass of the reflective powder).

[0035] This embodiment also provides a method for preparing the above-mentioned broadband reflective coating: wherein, the method for preparing titanium dioxide with a small particle size and titanium dioxide with a large particle size specifically includes (this embodiment takes the surface of titanium dioxide particles coated with silicon dioxide as an exa...

Embodiment 2

[0048] A kind of broadband reflective coating, the difference with embodiment 1 is that the concrete ratio of each component is different, specifically as follows:

[0049]

[0050] Among them, the reflective powder accounts for 37% of the total mass of the coating, including 8% of large particle size titanium dioxide (that is, 21.6% of the total mass of the reflective powder), 12% of small particle size titanium dioxide (that is, 21.6% of the total mass of the reflective powder) 32.4%), 15% of barium sulfate (that is, 40.6% of the total mass of the reflective powder) and 2% of polytetrafluoroethylene (that is, 5.4% of the total mass of the reflective powder).

Embodiment 3

[0052] A kind of broadband reflective coating, the difference with embodiment 1 is that described aqueous resin selects epoxy resin, simultaneously, comprises 16% deionized water and 1% leveling agent, 1% defoamer and 1% of wetting agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com