Microwave heating cavity for carbon fiber graphitization

A microwave heating cavity and heating cavity technology, which is applied in the fields of fiber chemical characteristics, textiles and paper making, can solve the problem of low cost of high-strength or high-modulus carbon fiber, mass continuous production, low heating efficiency, and short working life. And other problems, to achieve the effect of wide application range, convenient processing, and avoid disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

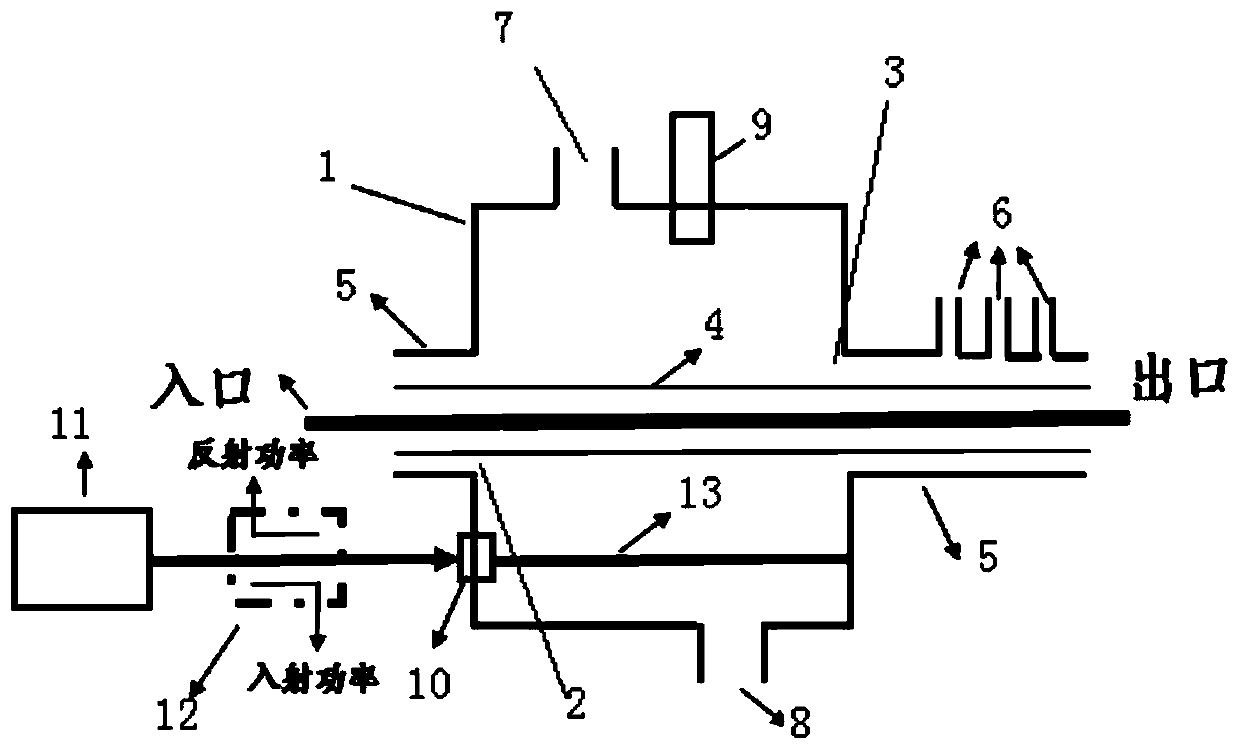

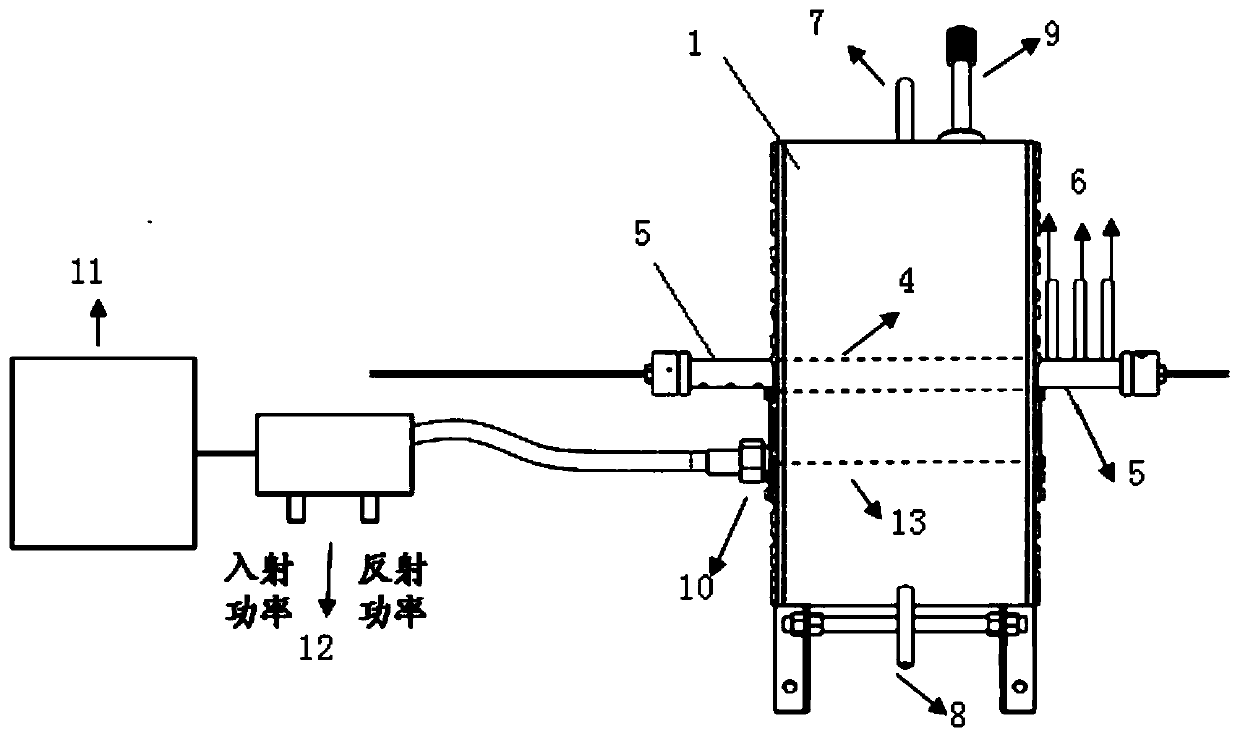

[0021] Such as figure 1 , 2 As shown, a microwave heating chamber for carbon fiber graphitization includes a heating chamber 1, and a carbon fiber inlet 2 and a carbon fiber outlet 3 are respectively provided on the left and right sides of the heating chamber 1, and between the carbon fiber inlet and the carbon fiber outlet A glass tube 4 is arranged between them, and a heating chamber transition pipe 5 is respectively connected to the carbon fiber inlet 2 and the carbon fiber outlet 3, and a plurality of temperature measuring holes 6 are opened on the heating chamber transition pipe 5 of the carbon fiber outlet 3, through which the infrared probe Observing the temperature, an air inlet 7 and an air outlet 8 are respectively opened above and below the heating chamber 1, the air inlet 7 is connected with an inert gas source, and a tuning screw 9 is also installed on the heating chamber 1, and the heating chamber A feed port 10 is also provided on the left side of the body 1, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical bandwidth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com