A kind of extra-soft cow fiber leather preparation process

A preparation process, a technology of fiber skin, applied in the direction of fabric kneading/softening, textile and papermaking, fabric surface trimming, etc. Not high problems, to achieve the effect of improving hand feel, improving physical properties, and improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The following examples are for more clearly explaining the technical solutions of the present invention without limiting the scope of the invention.

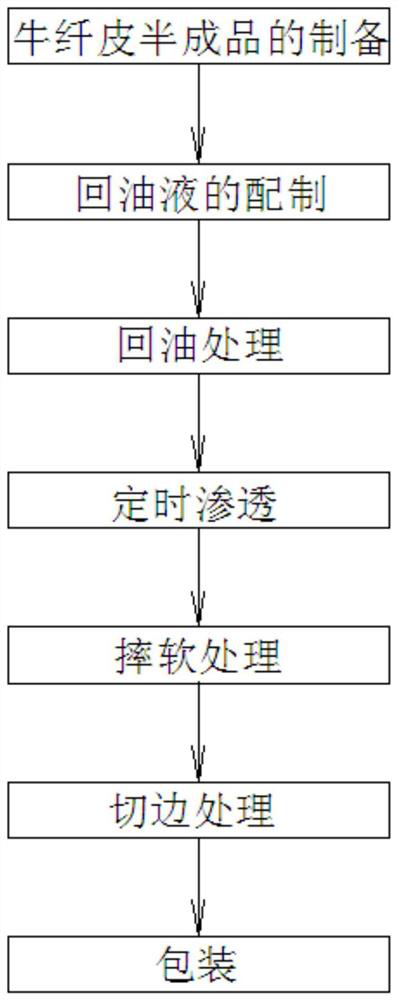

[0045] like Figure 1 to 3 The present invention is shown in a special soft cow leather fiber manufacturing process embodiment, comprising the process steps:

[0046]Step 10, preparing bovine leather semifinished fiber: fiber by bovine Pi Jibu PU film and bonding process, the film obtained after bovine semifinished fiber skin;

[0047] Step 20, back to the oil formulation: The deionized water, softened leather softening oil, lanolin, penetrating agents, mildew oil mixture, formulated as oil back;

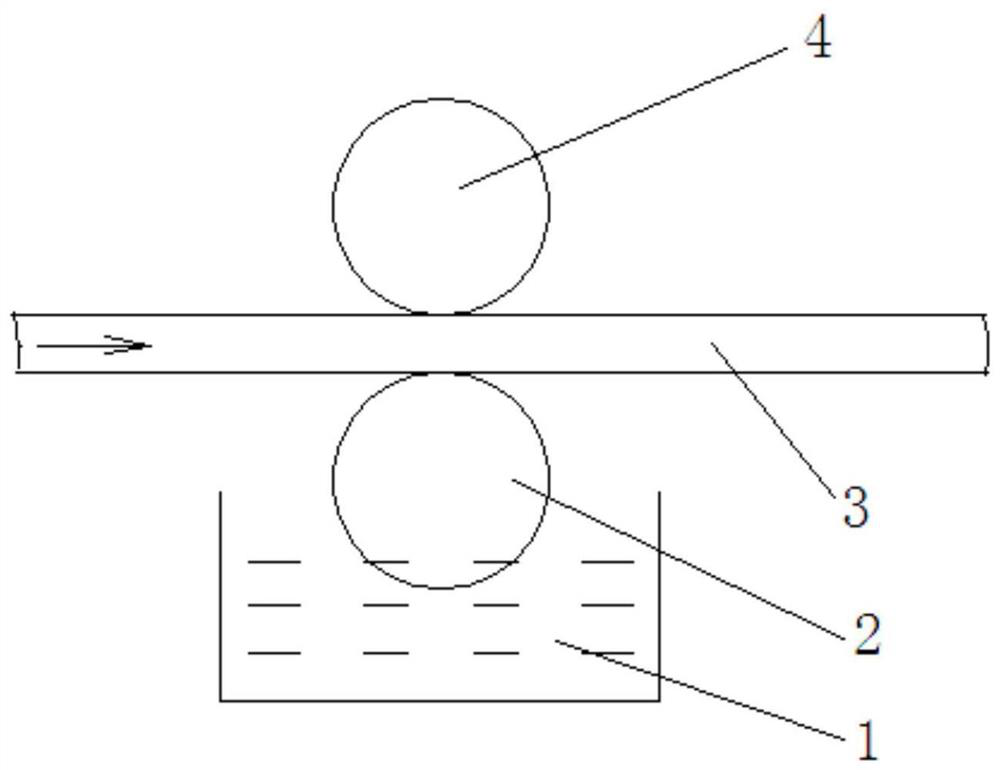

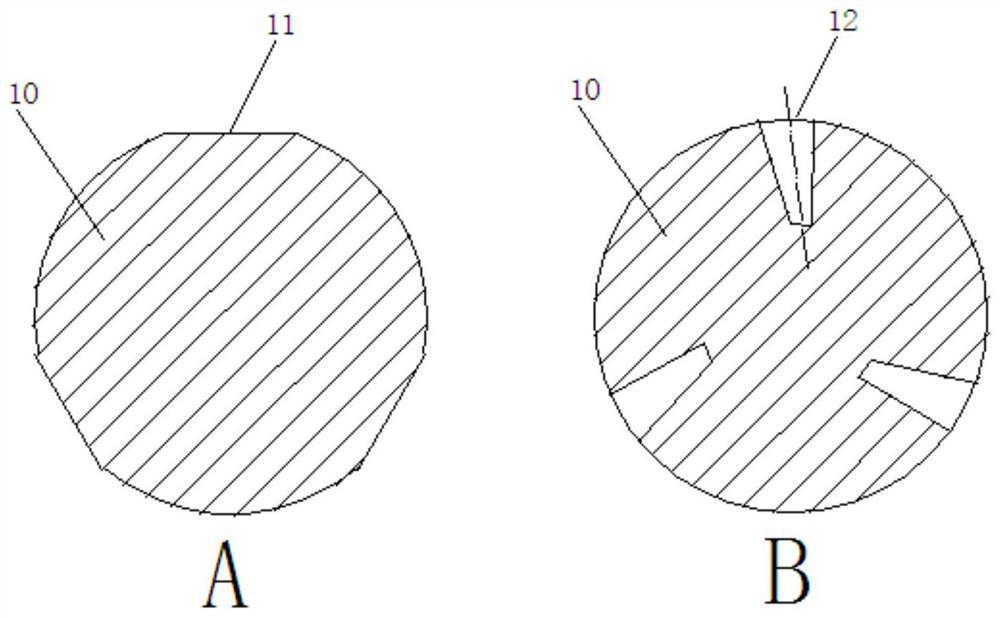

[0048] Step 30, back to the oil treatment: The back roller and fluid and equipment, the surface of the bovine leather semifinished simplex fiber treated with oil, the one surface treated with oil refers to oil back semifinished fiber skin applied to cattle the reverse side (i.e. the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com