Plane gate system

A plane gate and gate technology, which is applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve problems such as deformation of high shafts and shafts, large amount of concrete works, and large investment in civil engineering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

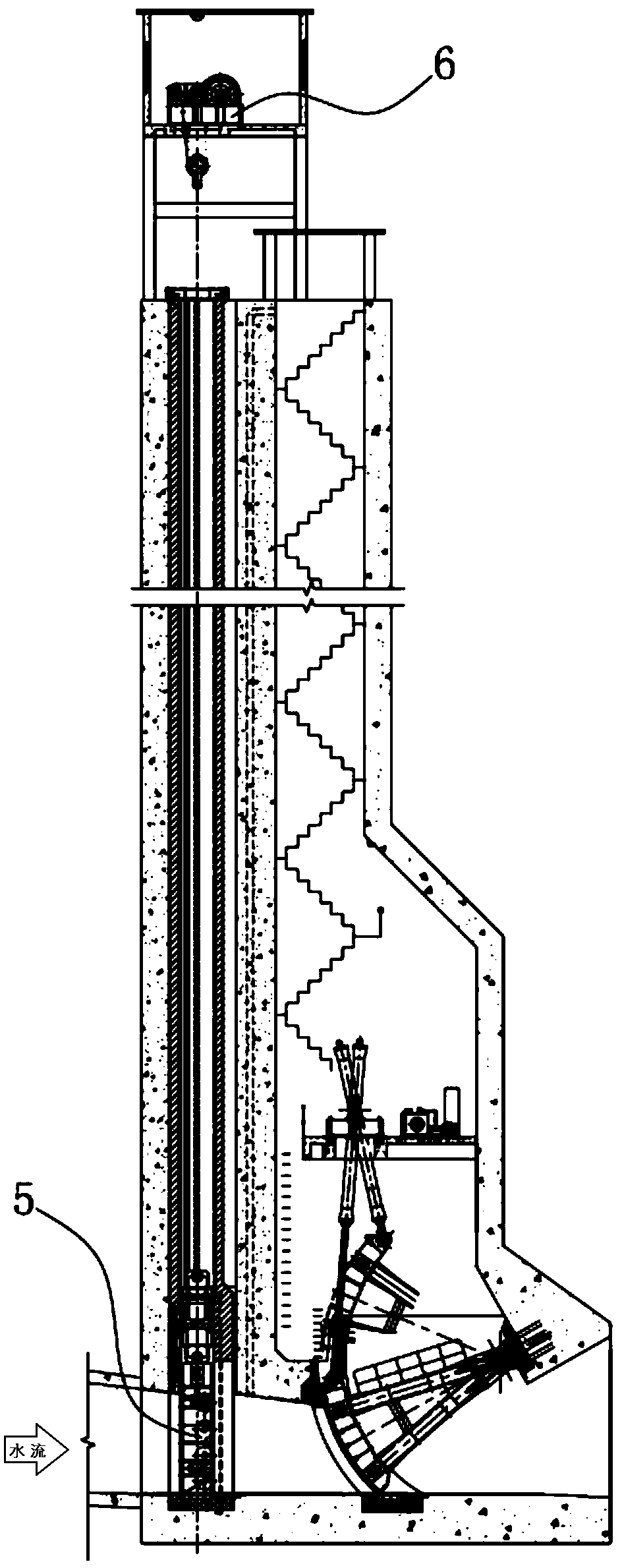

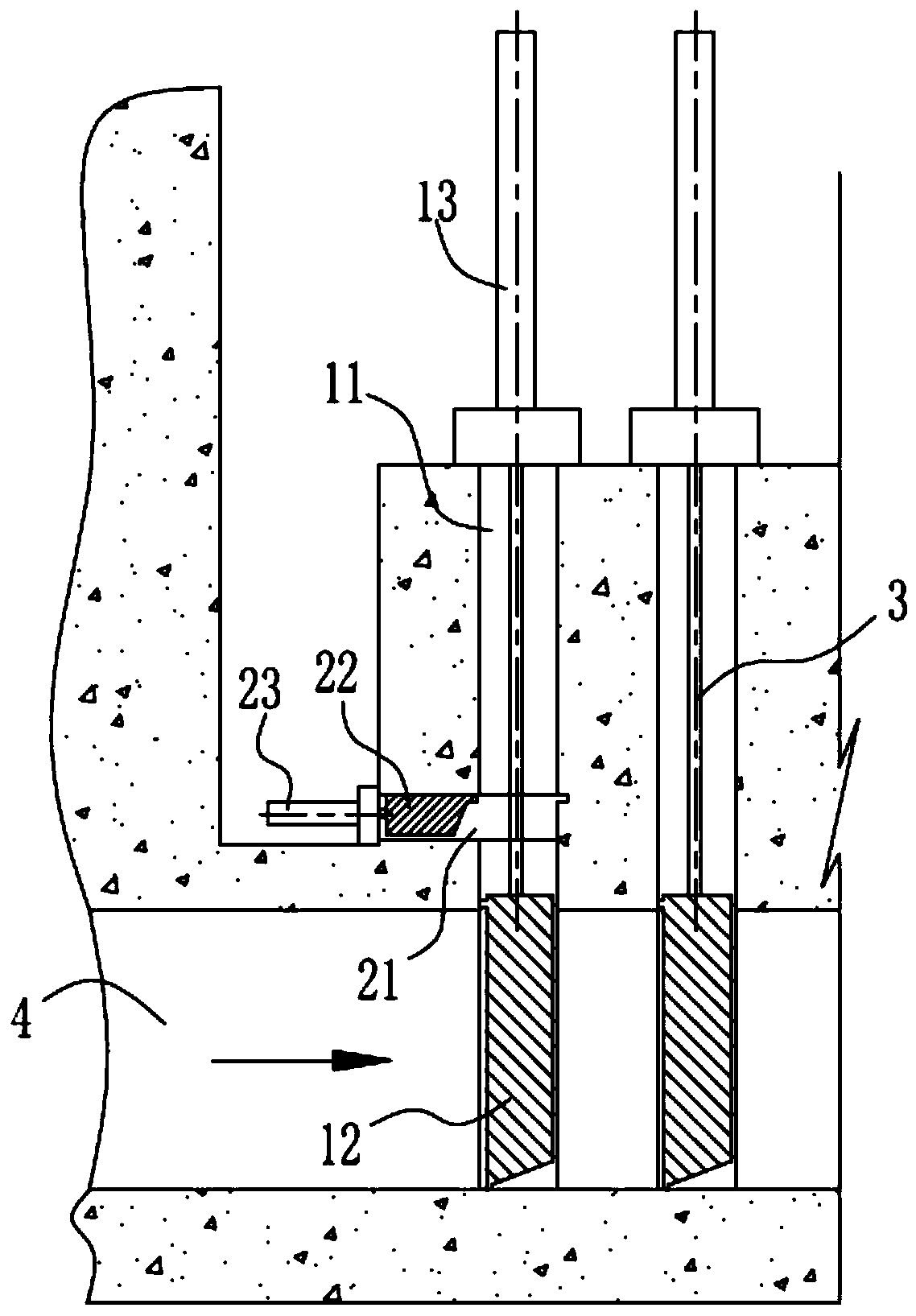

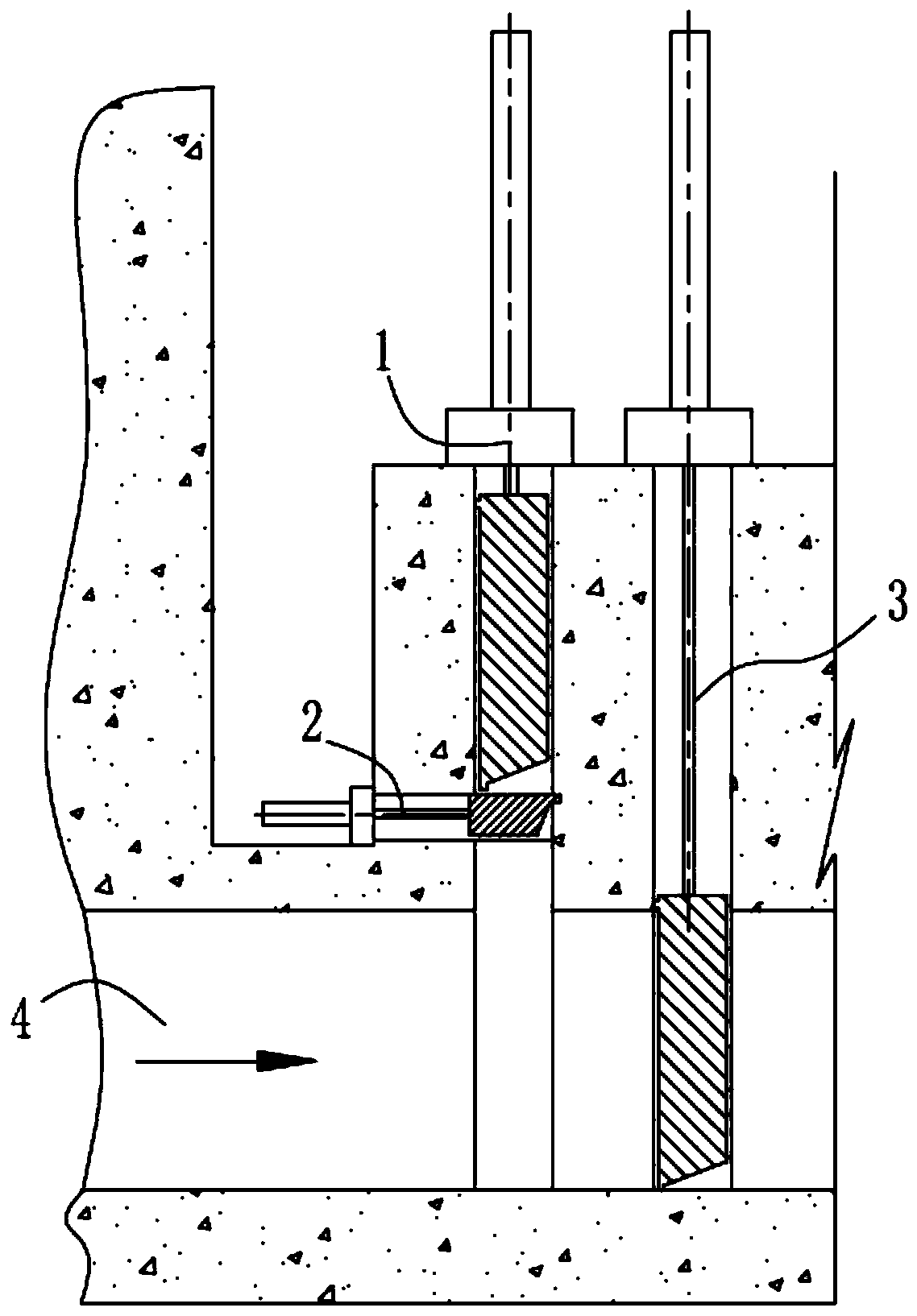

[0014] Such as figure 1 with figure 2 As shown in , the planar gate system of the present invention includes a main gate 1 and a horizontal gate 2, the main gate 1 includes a main gate groove 11 and a main gate leaf 12, and the main gate leaf 12 can be positioned on the main gate Move in the slot 11, the horizontal gate 2 includes a horizontal door slot 21 and a horizontal door leaf 22, the horizontal door leaf 22 can move in the horizontal door slot 21, the horizontal door slot 21 and the main door slot 11 are arranged in an orthogonal cross connection, and the horizontal door leaves 22 can extend into the middle of the main door slot 11 to block the main door slot 11 .

[0015] The main gate 1 of the present invention and the horizontal gate 2 can provide anhydrous and pressure-free conditions as the maintenance of the other side. as att...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap