Grid fin device

A grid rudder and unlocking device technology, applied to projectiles, self-propelled bombs, offensive equipment, etc., can solve the problem that there is no improvement plan for the pin shaft limit scheme of the pin puller, and achieve easy welding quality and high reliability , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

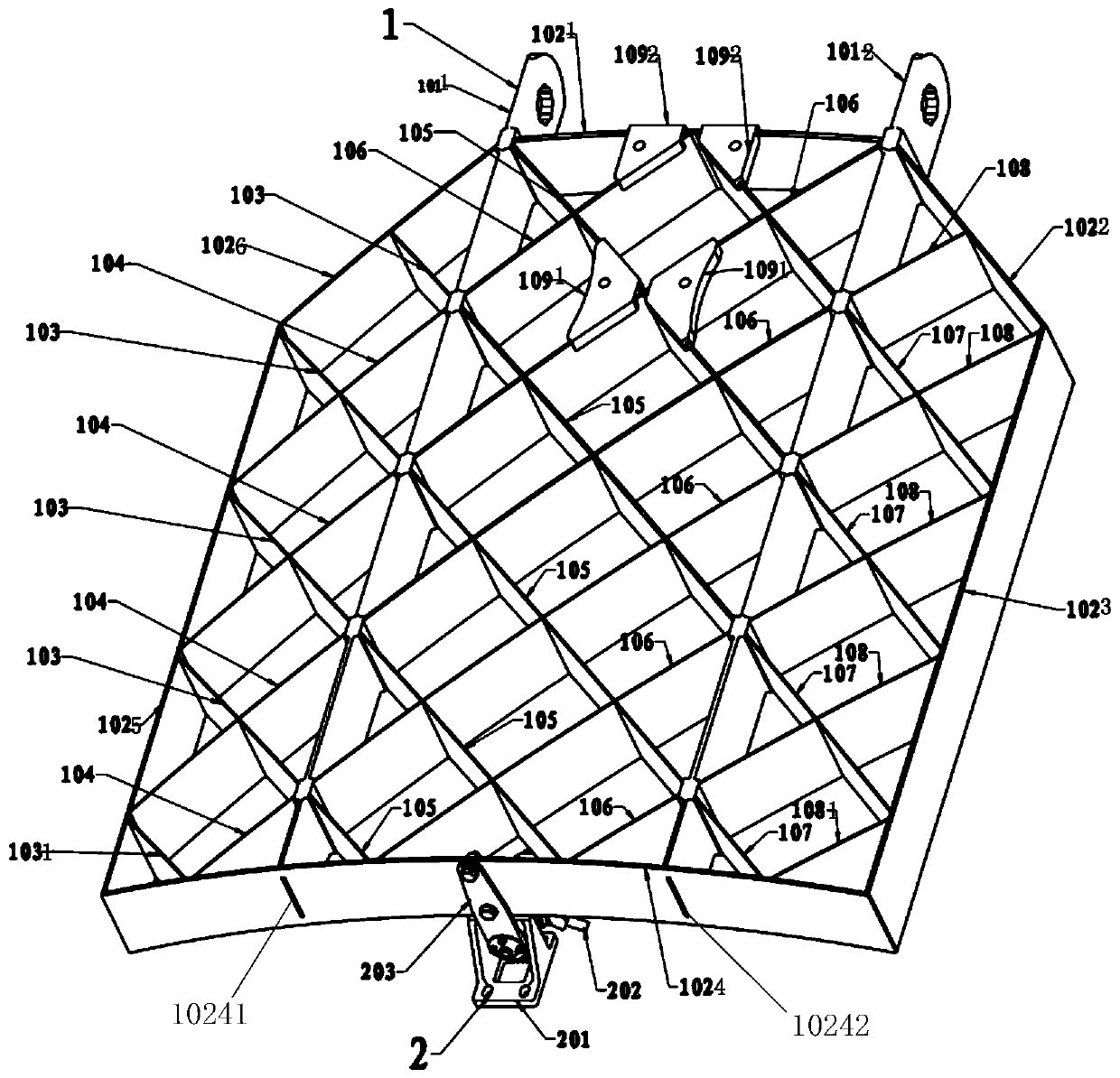

[0049] The invention provides a grid rudder device, such as figure 1 As shown, it includes a rudder surface structure 1 and a locking and unlocking device 2 .

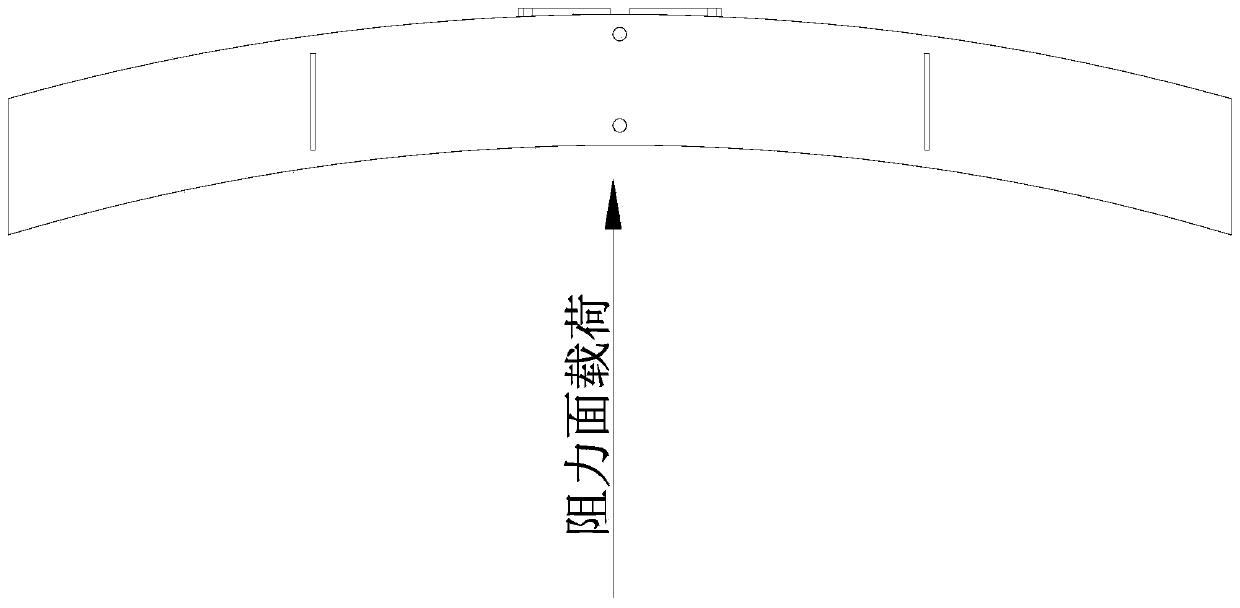

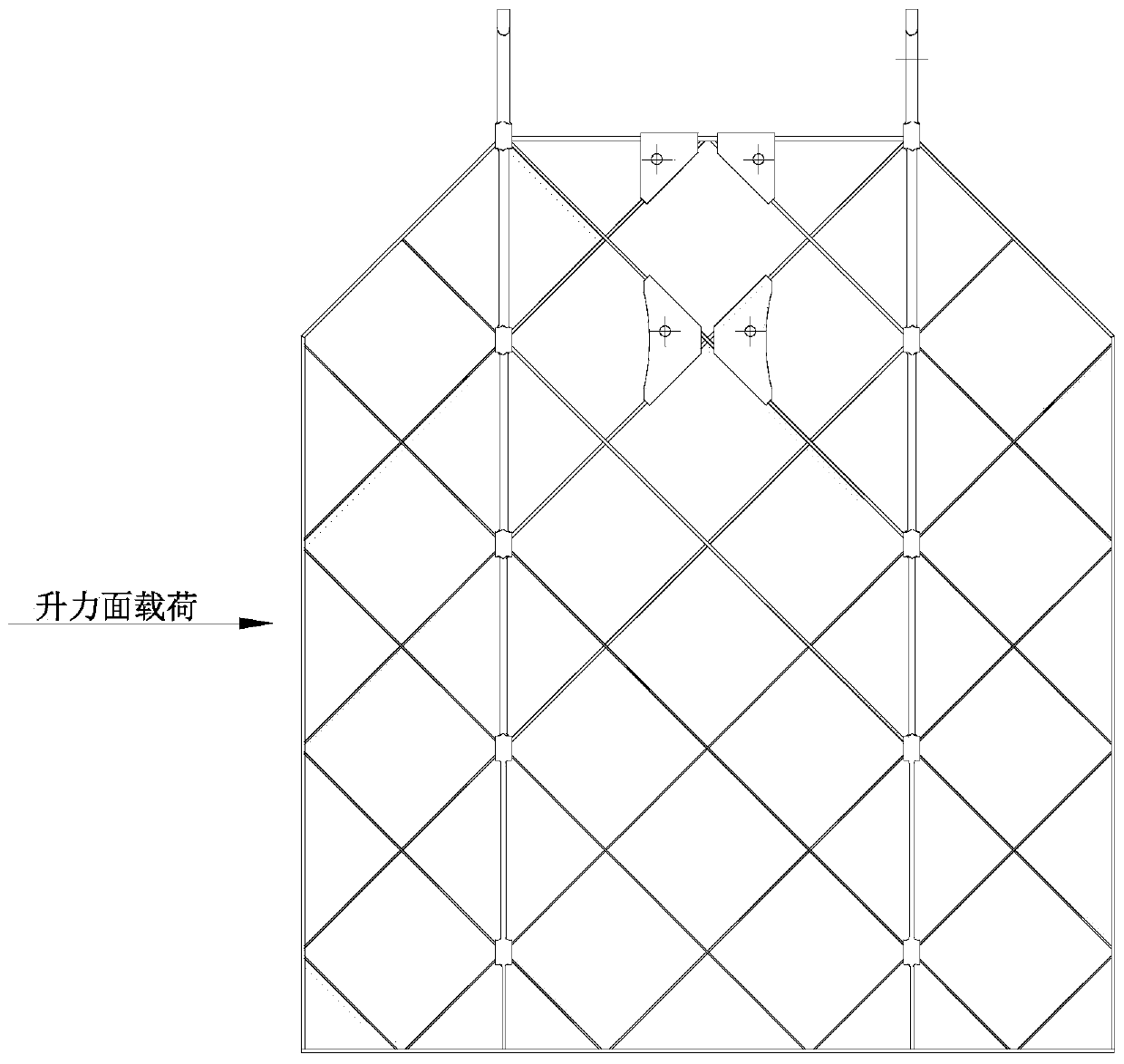

[0050] The rudder surface structure 1 comprises: a first rudder root 1011, a second rudder root 1012, a rudder frame 102, a first blade 103, a second blade 104, a third blade 105, a fourth blade 106, a fifth blade 107, a Six blades 108, adapter plate 109. The joints of the rudder root 101, rudder frame 102, blades 103-108, and adapter plate 109 are all designed with ±45° U-shaped semi-through grooves. After being inserted into each other and positioned, the overall welding is formed, such as figure 1 As shown; the load carried by the rudder surface structure is two major parts of the lift surface and the resistance surface load, such as figure 2 , image 3 , Figure 4 shown;

[0051] The rudder root 101 has a gradual cross-sectional thickness structure, which is thinner near the locking device side and thicker ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com