Design optimization method for porous elastic pavement mixture

An optimization method and technology of mixing materials, which are applied in the analysis of materials, strength characteristics, and the use of repetitive force/pulse force to test the strength of materials, etc., to achieve the effect of good pavement performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

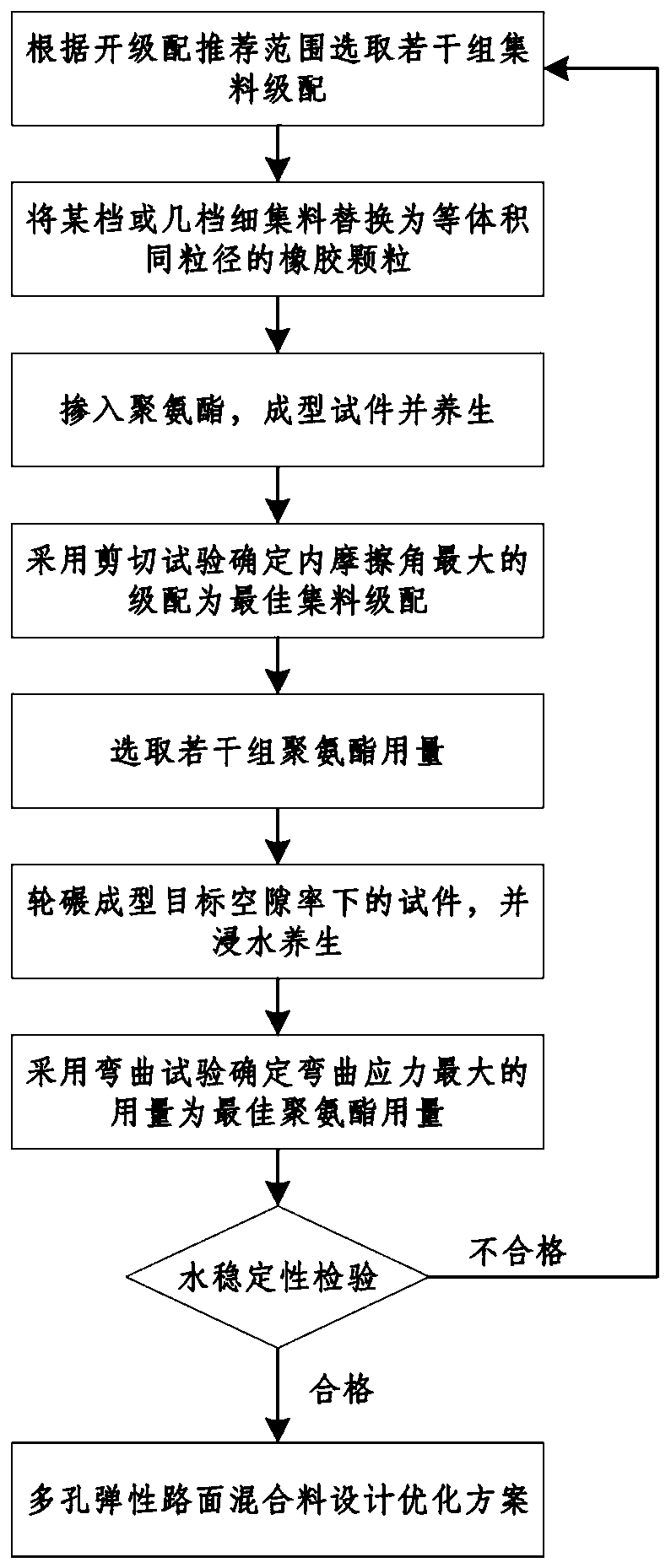

Method used

Image

Examples

Embodiment

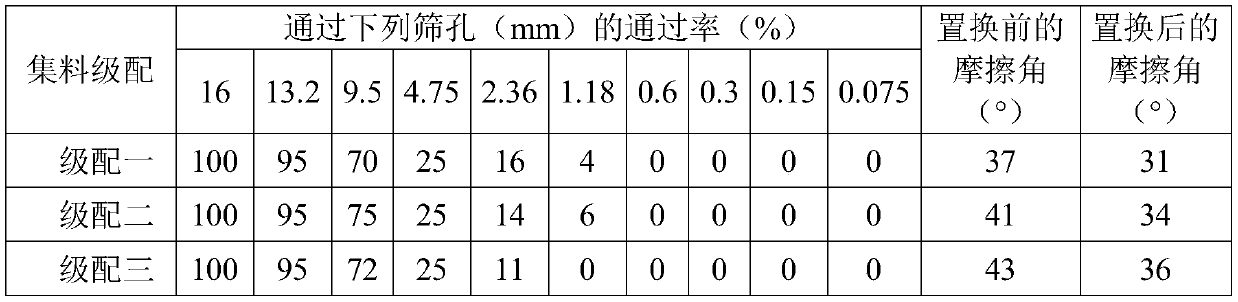

[0044] Poroelastic pavement mixture specimens use 25% rubber particles (that is, replace all fine aggregates below 4.75mm), 20% porosity, three selected gradations, friction angle values before and after equal volume replacement of rubber particles (mixed Polyurethane content 5% in the material) as table 2. According to the results in Table 2, gradation 3 is selected as the best aggregate gradation.

[0045] Select polyurethane content of 4%, 4.5%, 5%, 5.5%, choose aggregate gradation 3, use wheel rolling test to determine the number of wheel rolling under 20% void ratio is 24 times, form three-point bending test specimen, after 60 After 72 hours of health preservation in an incubator at ℃, put them in water at 20℃ for 24 hours, and perform a three-point bending test. The test results are shown in Table 3.

[0046] Table 2 Aggregate gradation and friction angle of three kinds of poroelastic mixtures

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com