Brick tea automatic blending control system and method

A technology of control system and brick tea, which is applied in general control system, control/adjustment system, program control, etc., can solve the problems of increased secondary pollution of tea, long batching time, scattered tea, etc., to reduce the probability of secondary pollution, The effect of improving batching efficiency and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

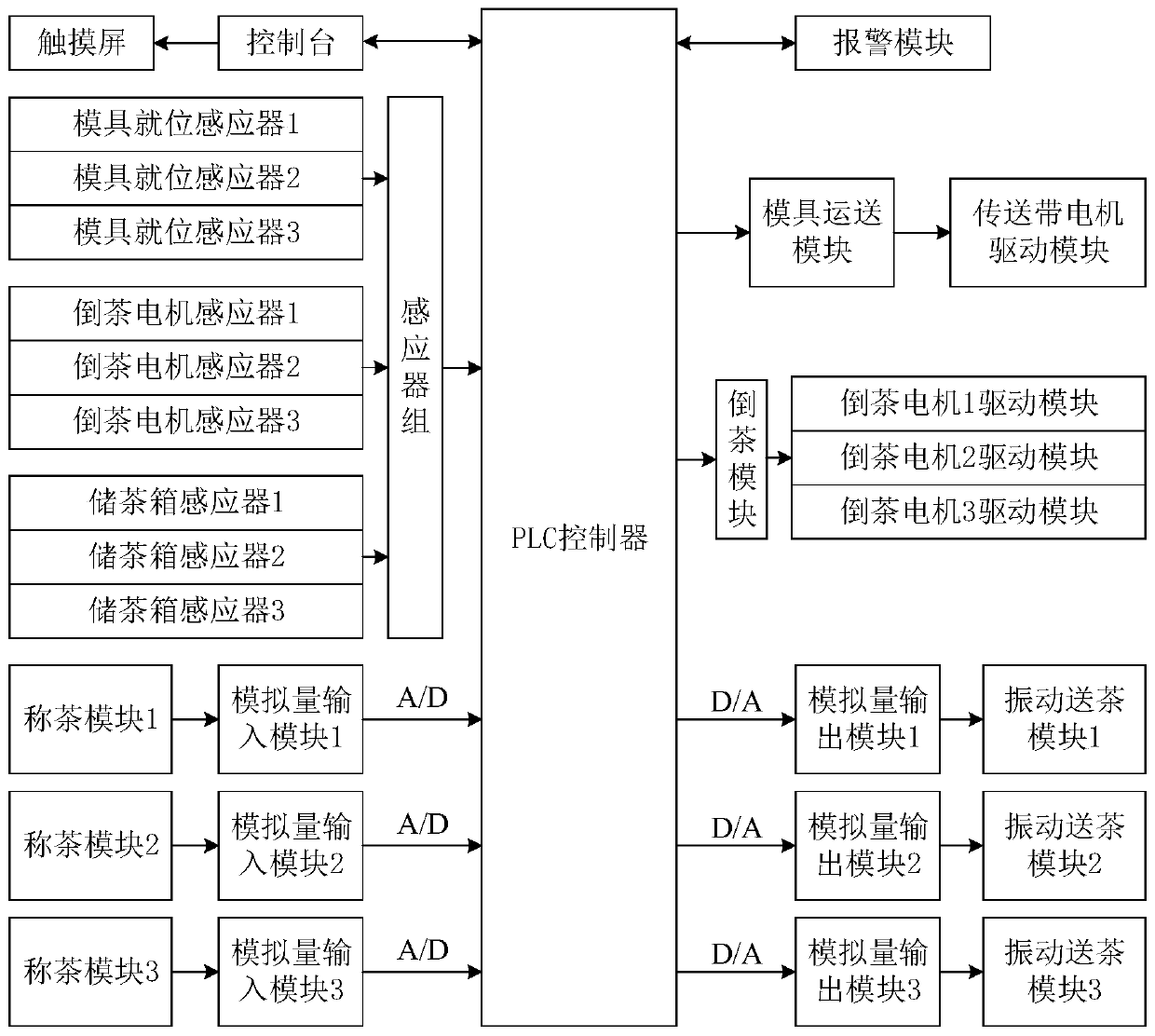

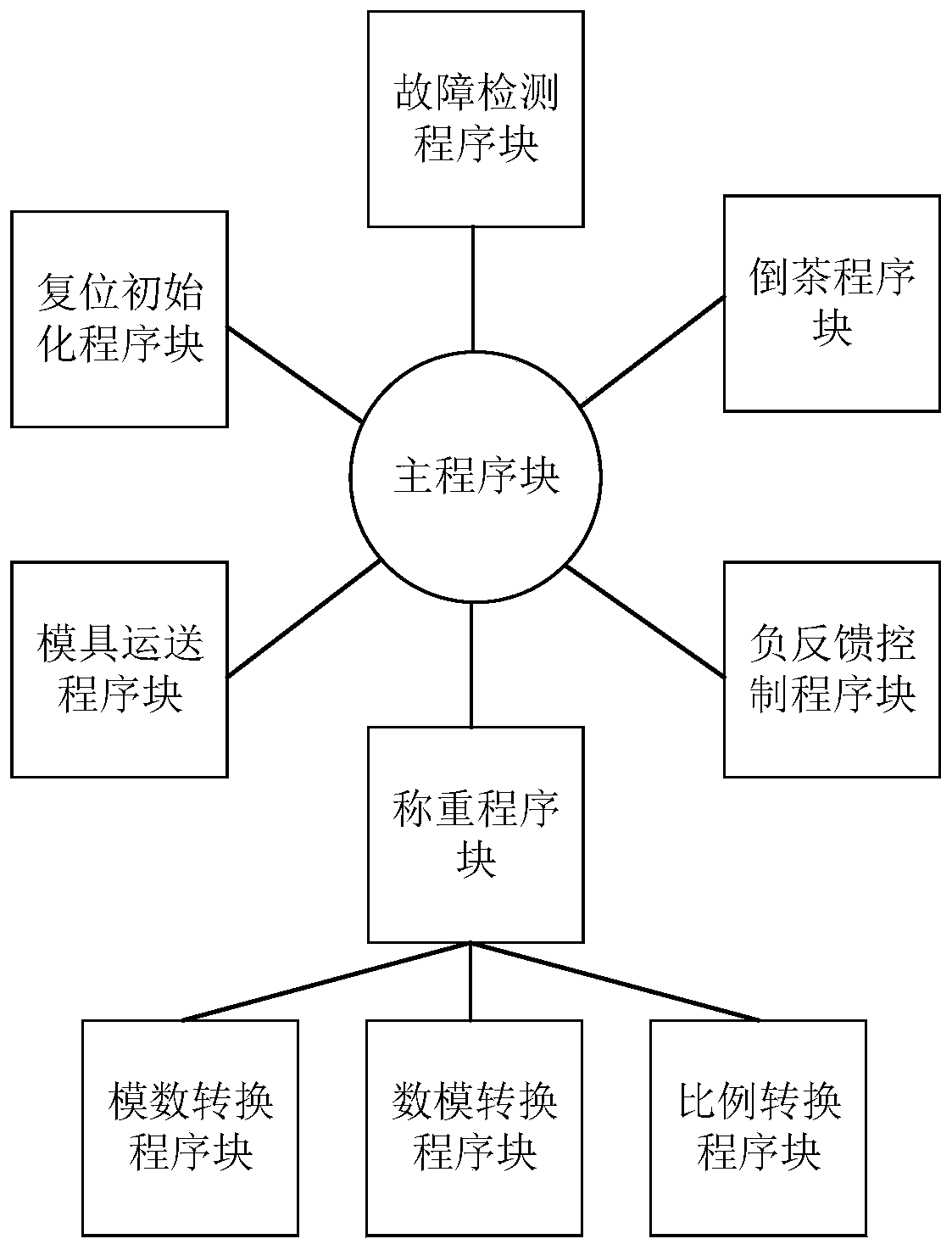

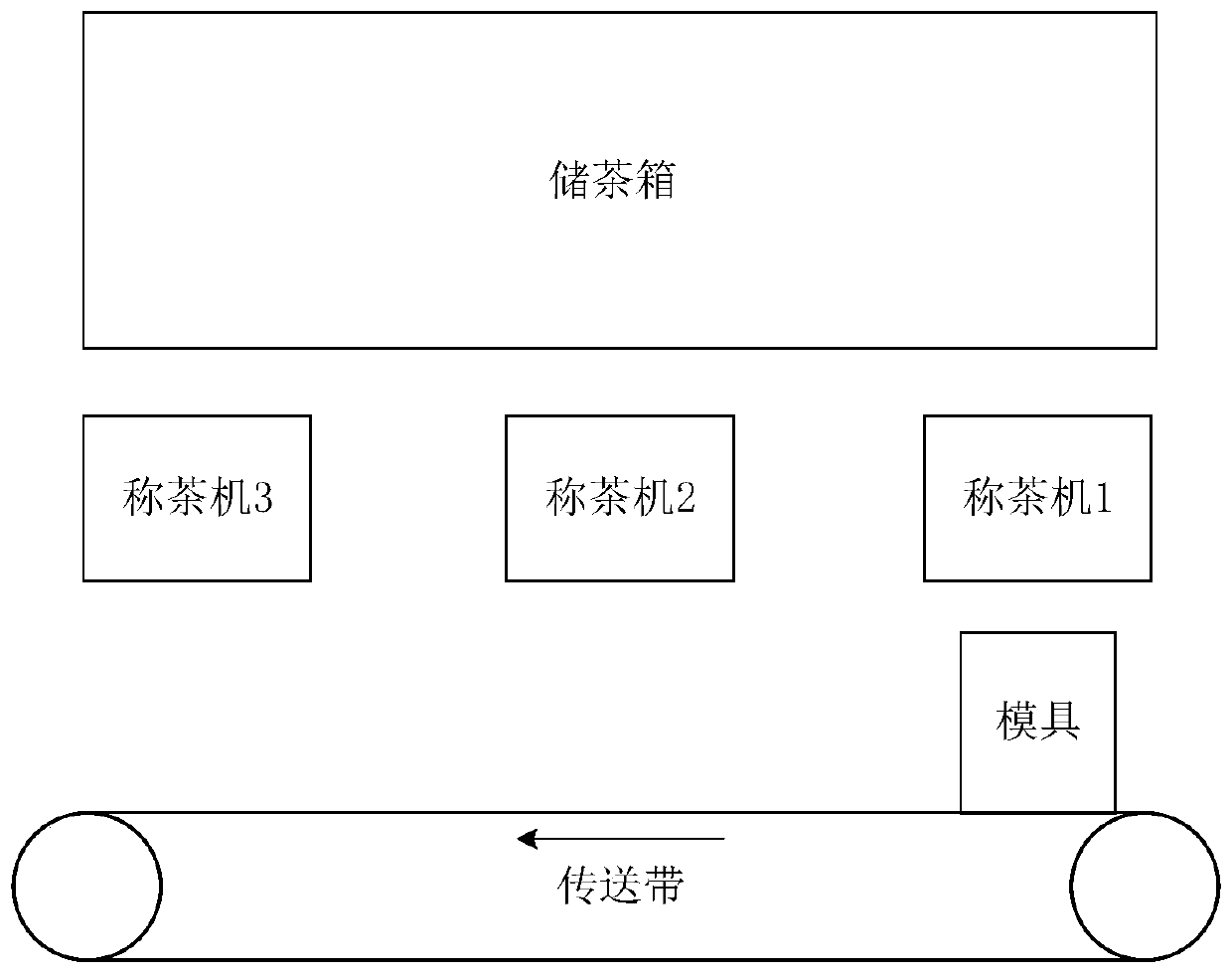

[0041] Such as figure 1 As shown, an automatic batching control system for brick tea of the present invention includes a PLC controller, a console, a sensor group, a tea weighing module group, an analog input module group, an analog output module group, a vibration tea delivery module group, and a tea pouring module group. module, mold delivery module and alarm module;

[0042] The PLC controller internally stores a logic control program, which is used to respond to the control signal transmitted by the console, collect the state information of the sensor group, process and convert the digital signal input by the analog input module group, and output Digital signals control the vibration tea delivery module group, control the start and stop of the tea pouring module group, control the mold delivery module to transfer the mold to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com