Pulp blending electrical control system

An electrical control system and slurry mixing technology, which is applied in general control systems, control/regulation systems, non-electric variable control, etc., can solve problems such as waste of resources, difficulty in supervision, and difficulty in grasping the situation of slurry mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

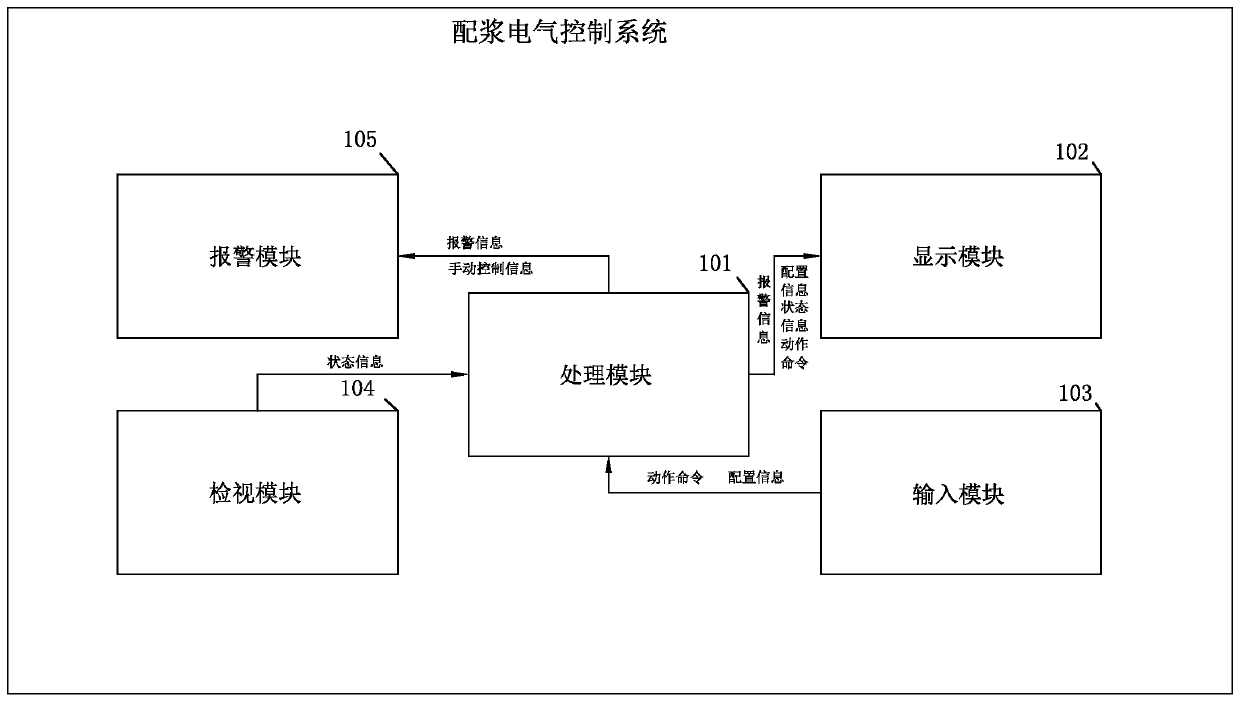

[0019] Depend on figure 1 It can be seen that a pulp mixing electrical control system is disclosed, including a processing module 101, an input module 103, a display module 102 and a viewing module 104, the processing module 101, the input module 103, the display module 102 and the viewing module 104, the The input module 103 is used to input configuration information, and sends the action command and configuration information to the processing module 101; the inspection module 104 is used to obtain status information, and send the status information to the processing module 101; the processing module 101 is used to Receive configuration information and action commands from the input module 103, receive status information from the inspection module 104, and form production actions according to the configuration information or action commands, for sending configuration information, action information and status information to the display module 102; The display module 102 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com