Spatial position tracking method and system for target

A space position and tracking system technology, applied in the field of target space position tracking method and system, can solve the problem of conflict between area and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0024] An embodiment of the present application provides a method for tracking a spatial position of a target, and the method is applied to a planar capacitive sensor array, and the planar capacitive sensor array includes M*N electrodes.

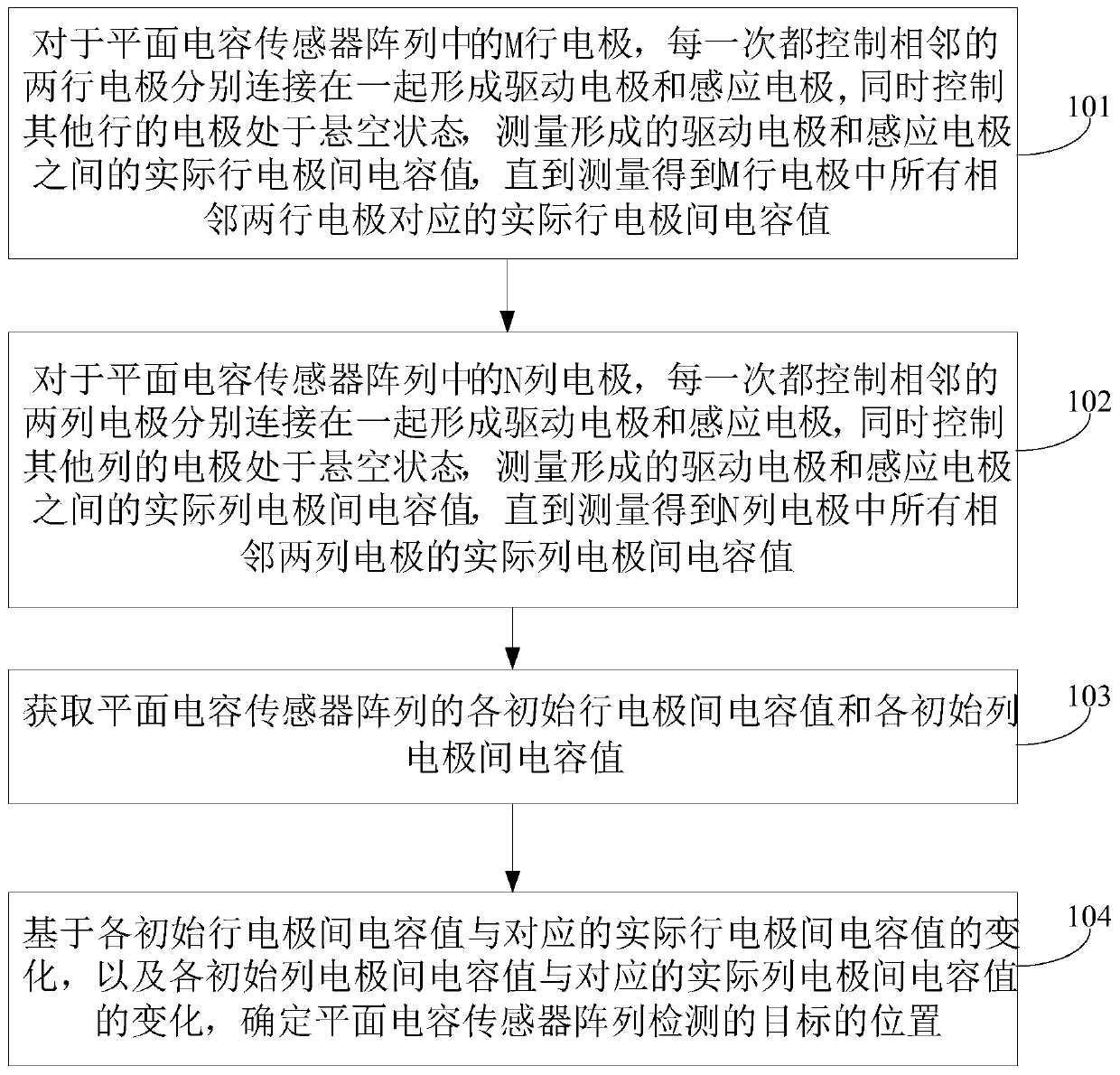

[0025] see figure 1 , the spatial position tracking method of the target includes:

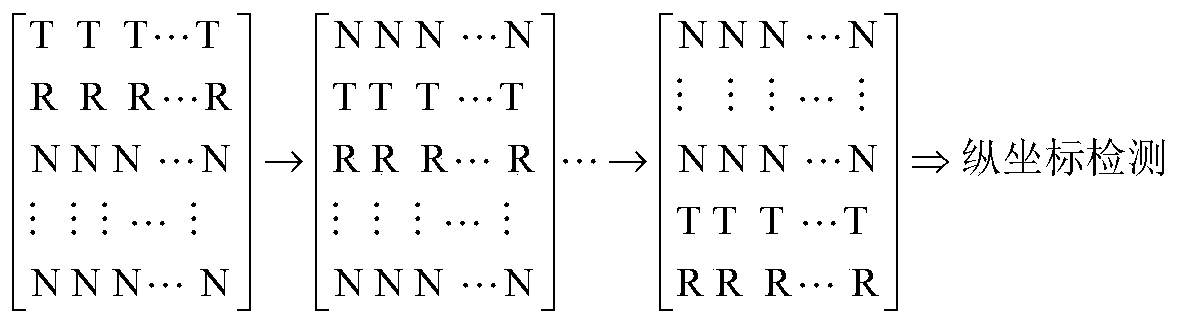

[0026] Step 101, for M rows of electrodes in the planar capacitive sensor array, each time control two adjacent rows of electrodes to be connected together to form driving electrodes and sensing electrodes, and simultaneously control the electrodes of other rows to be in a floating state, and measure the formed driving electrodes and the actual row-electrode capacitance value between the sensing electrodes, until the actual row-electrode capacitance value corresponding to all the adjacent two row electrodes in the M row electrodes is measured, wherein, for all the adjacent two-row electrodes, the upper A row of electrodes is connected together to form the s...

no. 2 example

[0066] see Image 6 , the present embodiment proposes a spatial position tracking system of a target, the system comprising: a planar capacitive sensor array and a control device connected to the planar capacitive sensor array, the planar capacitive sensor array includes M*N electrodes, and the control device includes:

[0067] The row electrode control module 601 is used to control the electrodes of the M rows in the planar capacitive sensor array to connect two adjacent rows of electrodes to form the driving electrodes and the sensing electrodes, and to control the electrodes of other rows to be in a suspended state, Measure the actual row-electrode capacitance between the formed driving electrodes and the sensing electrodes until the actual row-electrode capacitance corresponding to all two adjacent row electrodes in the M row electrodes is measured, wherein, for all the adjacent two-row electrodes , the upper row of electrodes are connected together to form the same type o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com