Modeling method for multi-point grounding fault of wound iron core under inter-chip short circuit

A multi-point grounding and modeling method technology, which is applied in the direction of instruments, calculations, electrical digital data processing, etc., can solve the problems of inaccurate judgment and analysis of fault current, increased core loss, and short circuit between chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The implementation process of the present invention will be further described in detail below in conjunction with the accompanying drawings.

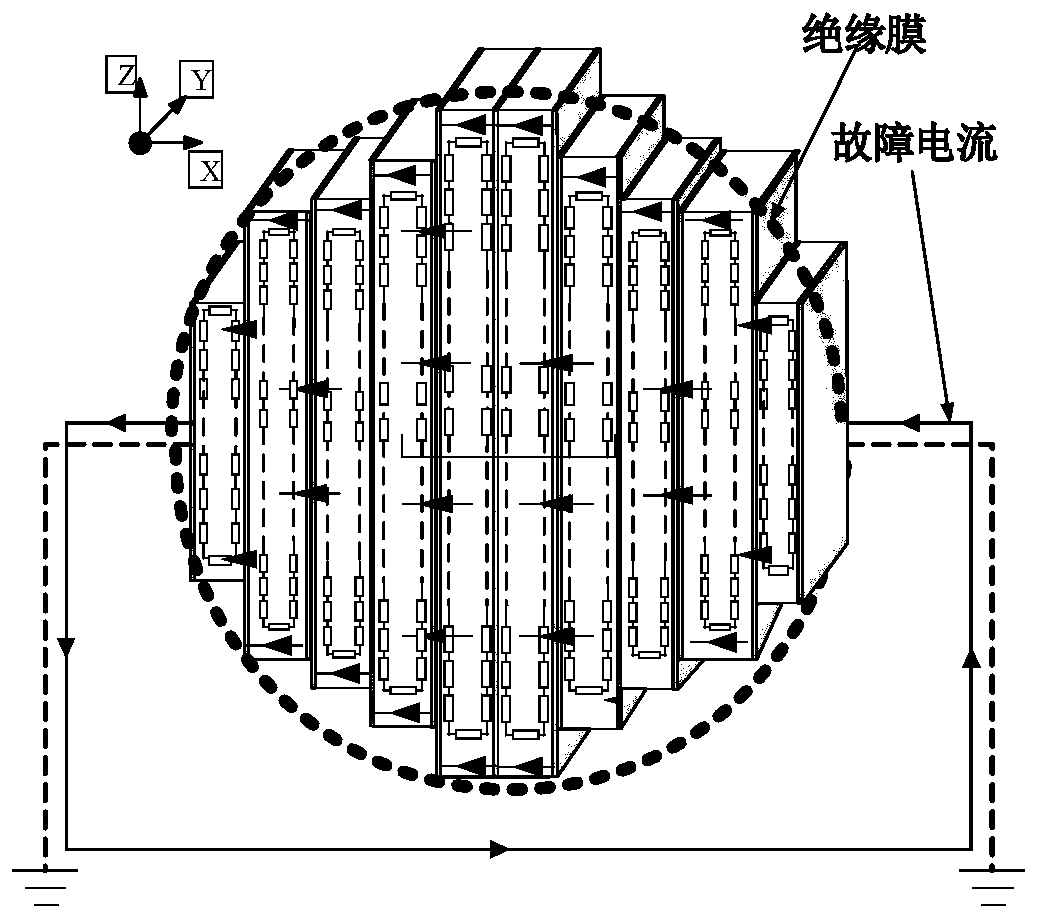

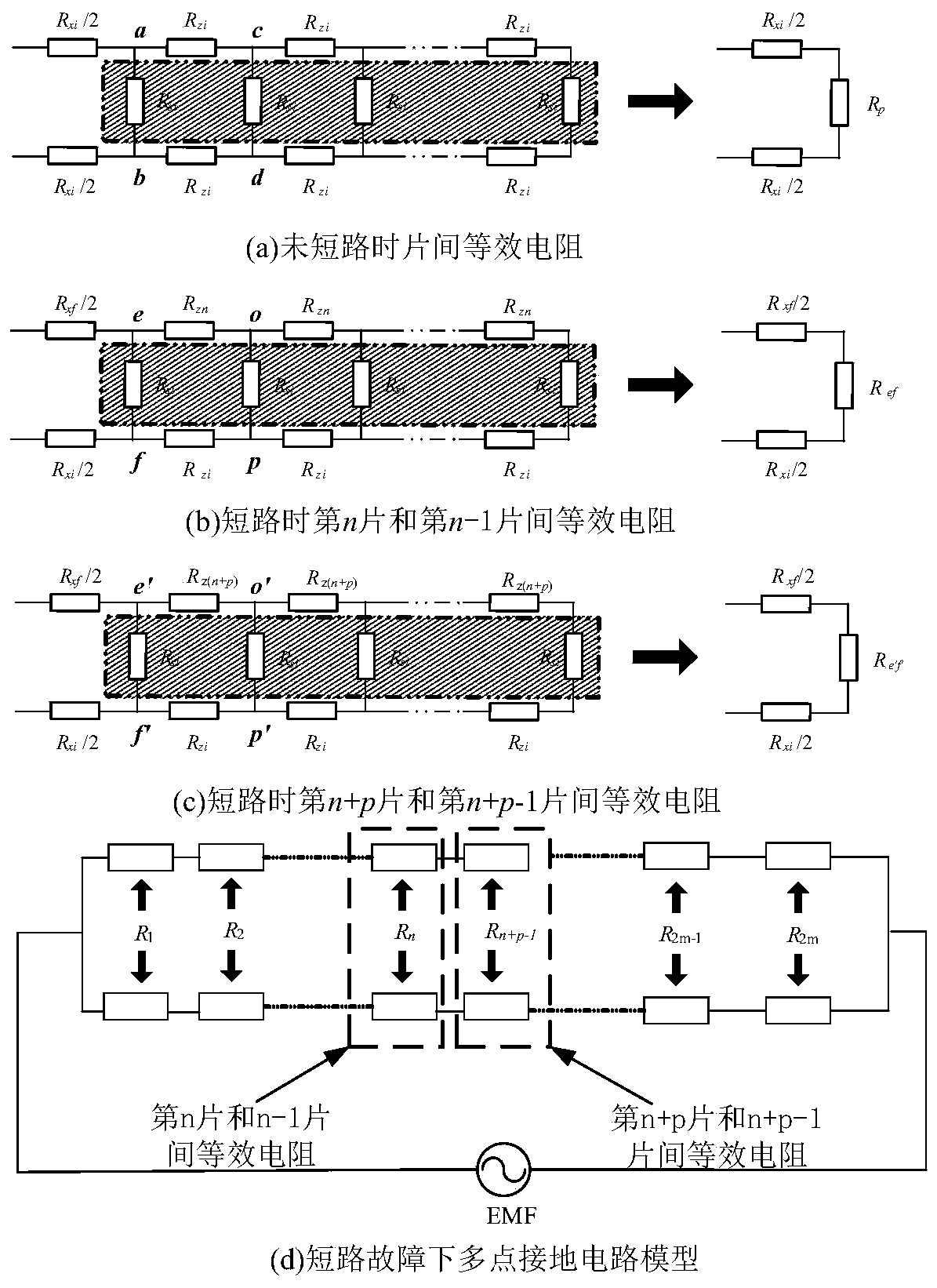

[0045] figure 1 It is a schematic diagram of the multi-point grounding fault current flowing in different directions of the cross section of the wound iron core of the present invention. When a multi-point grounding short circuit fault occurs in the iron core, the iron core forms a loop through the earth, and a current will be generated on this loop in the alternating electromagnetic field, and its flow direction is as follows: figure 1 Shown are primarily along the x and z directions. Due to the influence of the skin effect, the current will only flow on both sides of the silicon steel sheets. The equivalent resistance parameters between each level of silicon steel sheets are derived. The current flow area should be obtained from the skin depth δ, and the resistance calculation formula must also consider each level. Winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com