LED surface light source light engine based on honeycomb arrangement and production method thereof

A honeycomb, light source technology, applied in the field of lighting, can solve problems such as low glare value and low service life, and achieve the effects of long service life, small light decay, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art of the present invention can easily implement the present invention.

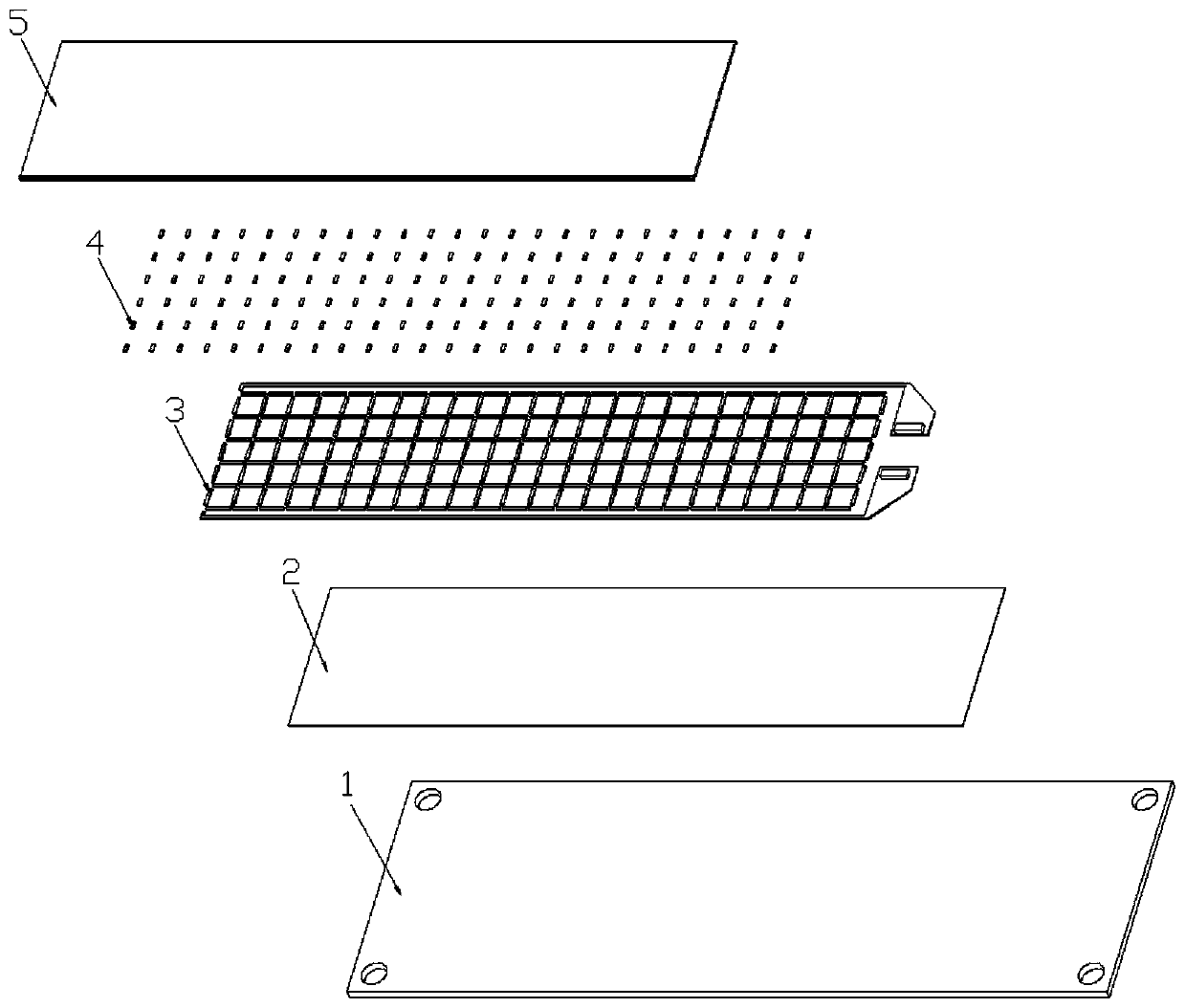

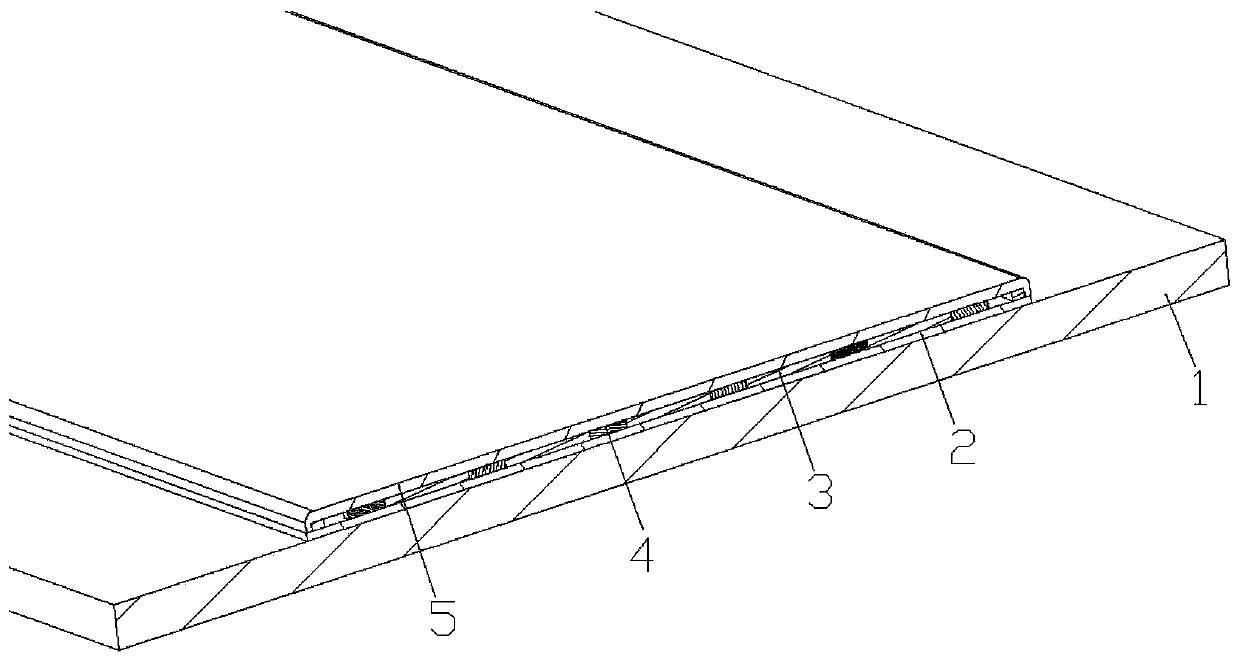

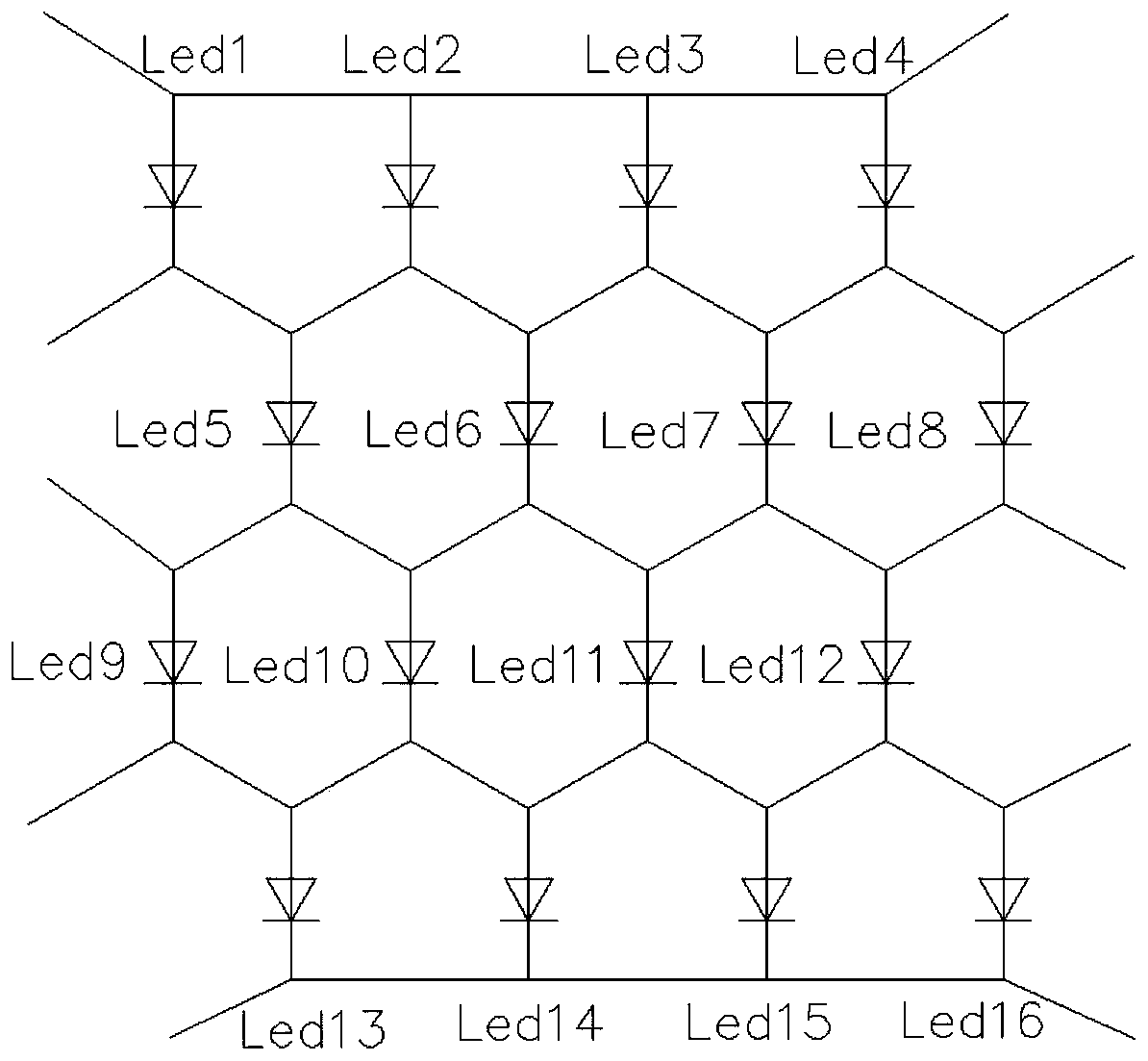

[0033] Such as Figure 1-2 As shown, it is a structural schematic diagram of the present invention. The present invention provides a LED surface light source light engine based on honeycomb arrangement, which is composed of LED lamp beads 4, aluminum substrate 1, fluorescent layer 5, insulating layer 2 and conductive copper foil 3. The aluminum substrate 1 is the physical carrier of the light engine, located at the bottom layer, which can effectively and quickly dissipate the heat generated by the LED lamp bead 4 during operation; the thickness of the aluminum substrate 1 can be 0.5mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm , pure aluminum plates with thermal conductivity of 1.0, 2.0, 3.0; the aluminum substrate 1 can also be replaced by a flexible circuit board, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com