Metal baseplate provided with LED and manufacturing method thereof

A technology of metal substrates and manufacturing methods, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as difficult current transmission, achieve the effects of reducing light attenuation, good stability, and reducing light attenuation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

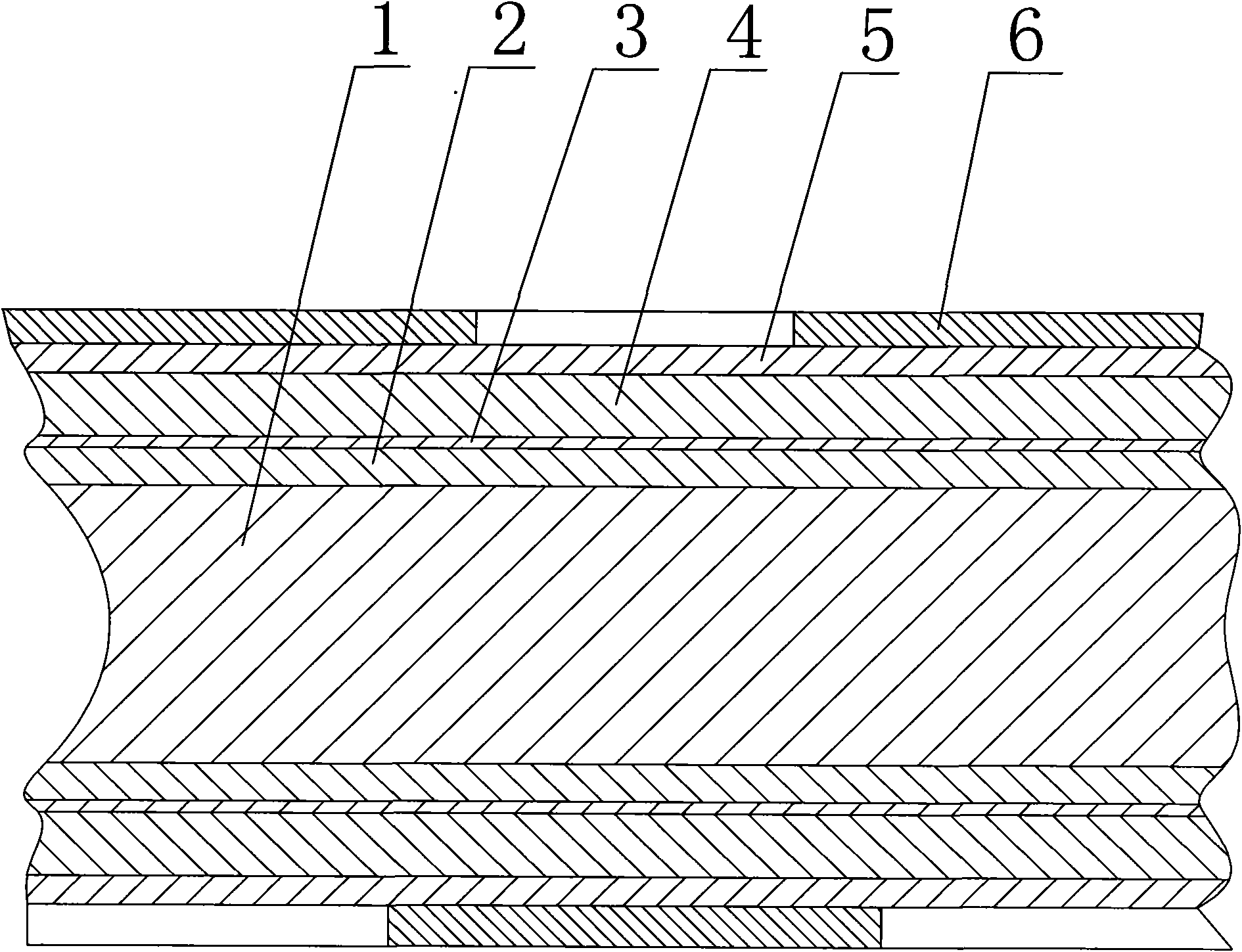

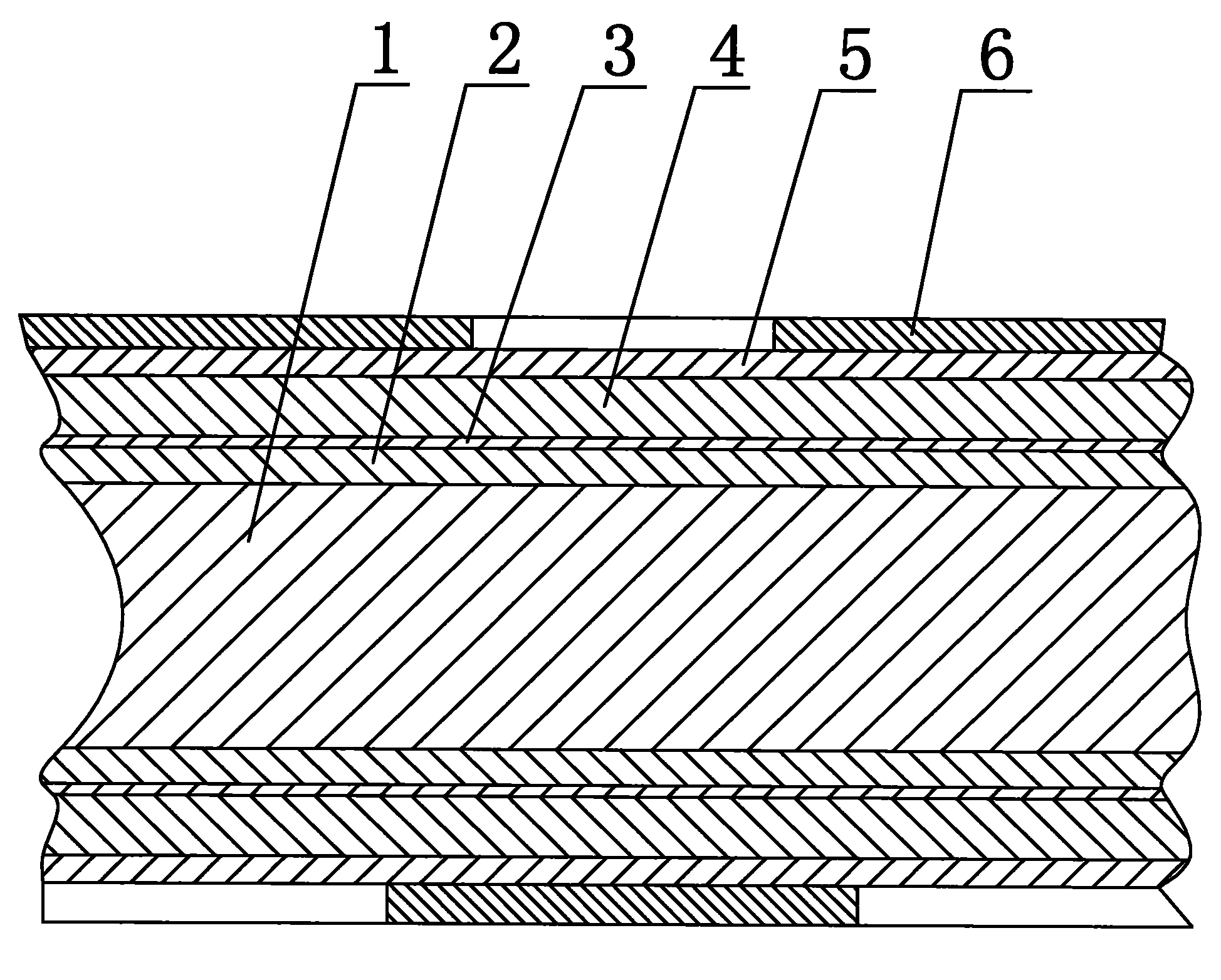

[0029] Take the production of aluminum substrates installed with LEDs as an example:

[0030] 1. Cut the 1050, 5052 or 6061 aluminum plate into a size of 550×700×T2.0 (0.385m2).

[0031] 2. Oxidize the surface of the aluminum plate into alumina with a thickness of 20-30 μm in the electrolyte with an oxygen electrode, and then seal the micro-holes left in the alumina with water vapor. Or use high molecular polymers, such as PET, to fill the pores of the aluminum oxide layer. The thickness of the polymer is about 100 nanometers.

[0032] 3. Under vacuum conditions, the aluminum substrate is treated in diamond-like carbon containing 1 / 4-1 / 2 atomic ratio of H, N, O, F or Si for 10 minutes, and the thickness of the formed diamond-like carbon film is 1 μm.

[0033] 4. Sputter carbonizable metals, such as magnesium, silicon, chromium, vanadium or titanium, on the diamond-like carbon film, with a thickness of 200nm-1000nm.

[0034] 5. A layer of copper is sputtered outside the carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com