Permanent magnet synchronous motor resolver zero position calibration circuit

A permanent magnet synchronous motor, zero calibration technology, applied in motor control, electronic commutation motor control, electrical components and other directions, can solve the problem of inability to adapt to the influence of resolver angle deviation, inability to achieve real-time self-calibration learning, complex implementation, etc. problem, to achieve the effect of small footprint, prevention of zero position change of resolver, and low circuit cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

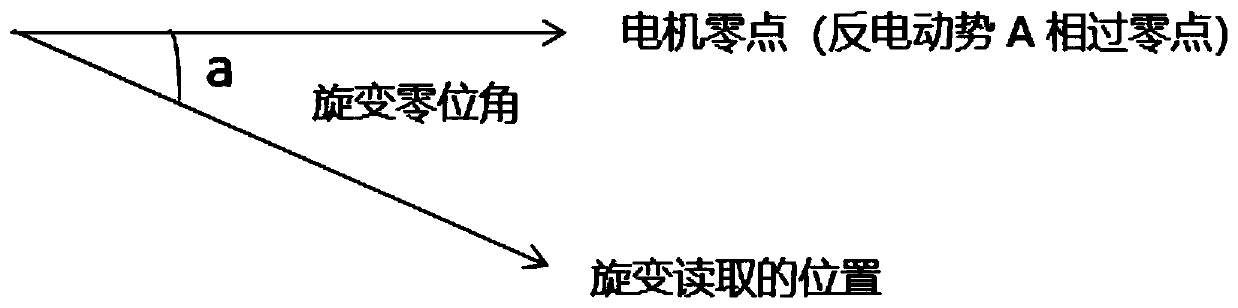

[0024] The principle of the present invention is to determine the current position of the rotor according to the size of the counter electromotive force, such as figure 1 As shown, when phase A descends to the zero point, the rotor is at the 0 degree position (the position of the D axis), when the B phase descends to the zero point, the rotor is at the position of 120 degrees, and when the C phase descends to the zero point, the rotor is at 240 degree position.

[0025] u a =-ωΨ f sin(ωt)

[0026] u b =-ωΨ f sin(ωt-2*π / 3)

[0027] u c =-ωΨ f sin(ωt-4*π / 3)

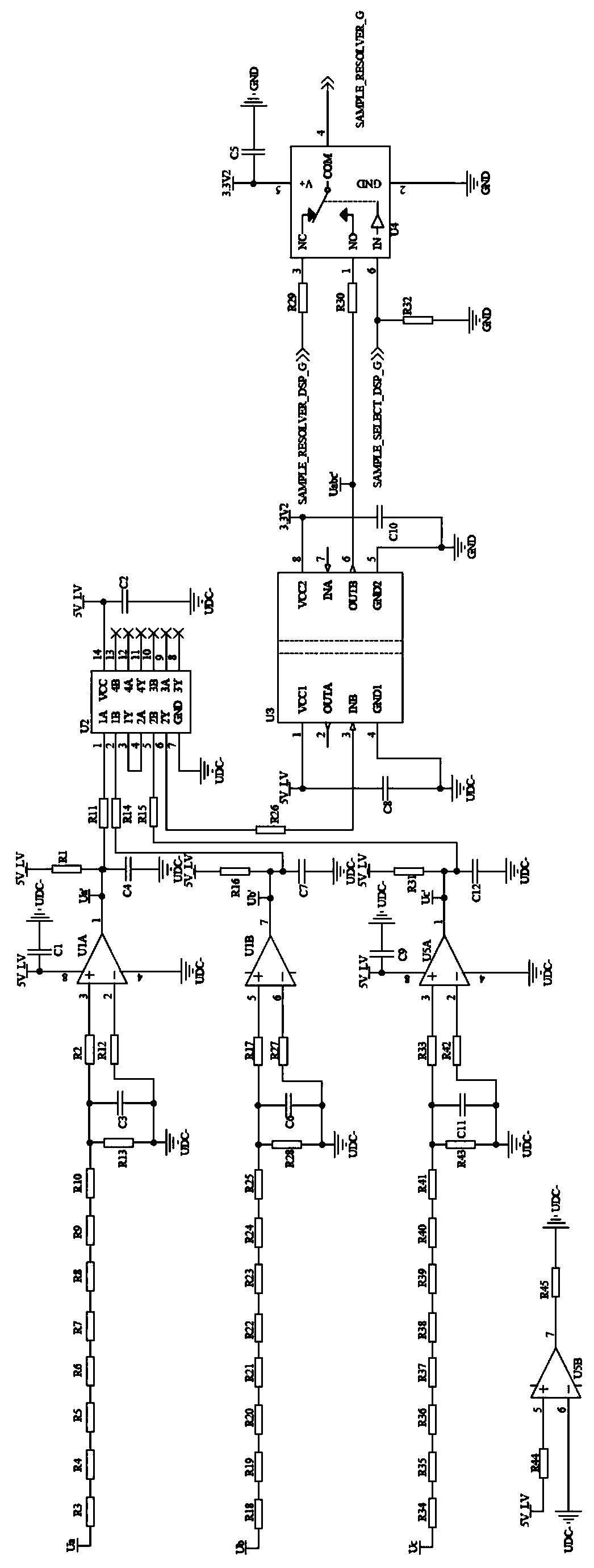

[0028] Utilizing the characteristics of AD2S1210 resolver decoding chip to update the position information at the falling edge of SAMPLE, the current rotor position is read through AD2S1210 resolver decoding chip when the counter electromotive force crosses zero, so as to obtain the resolver zero angle.

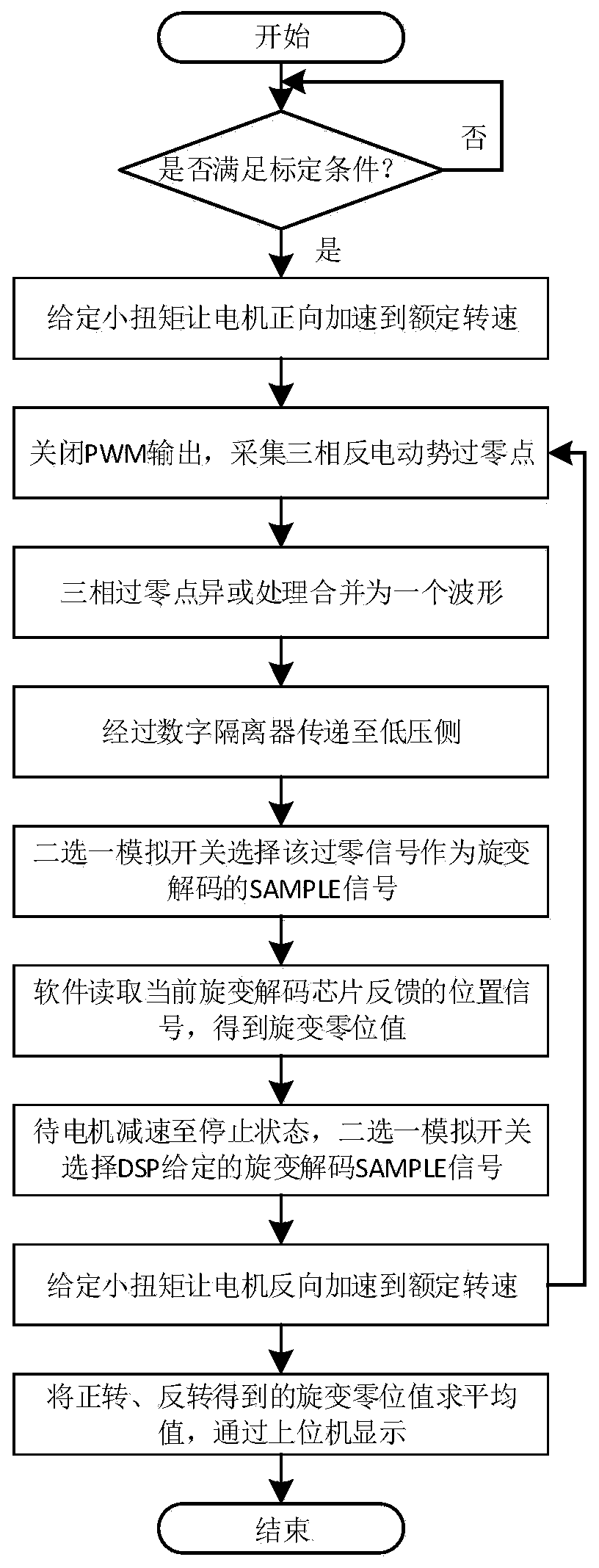

[0029] The specific implementation steps are as figure 2 Shown: First, a small torque is given to accelerate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com