Loudspeaker

A loudspeaker and bottom surface technology, applied in the field of loudspeakers, can solve problems such as reducing the acoustic performance of products, and achieve the effect of increasing the bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

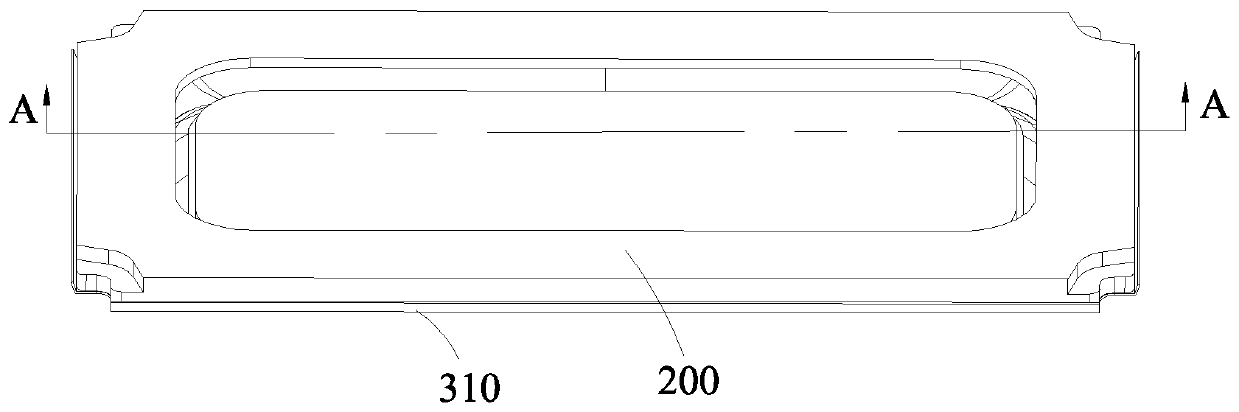

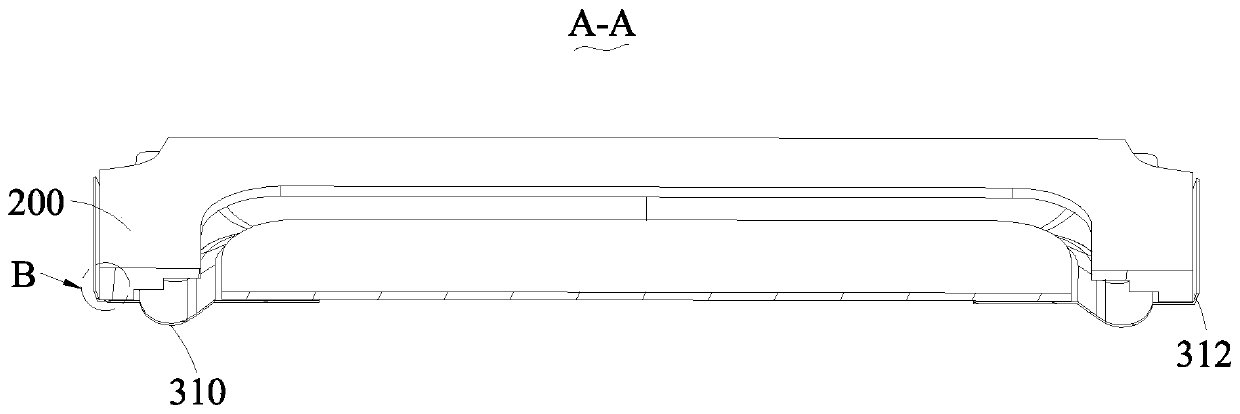

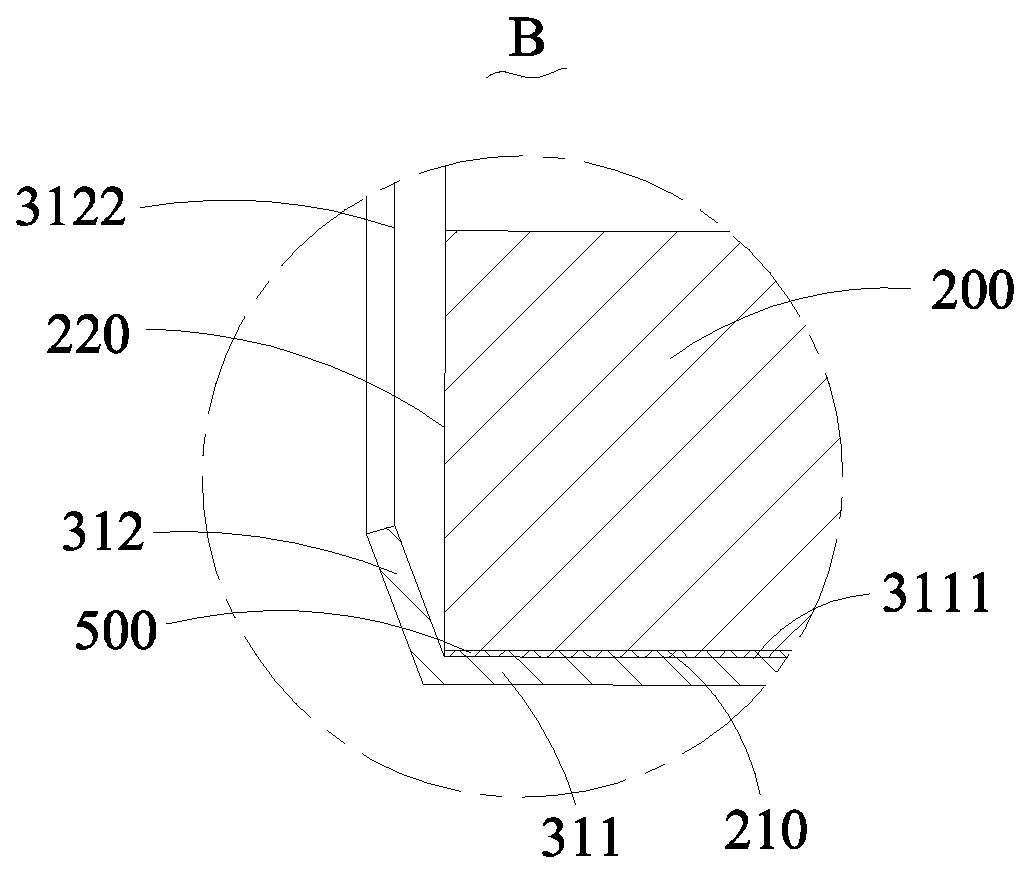

[0041] see Figure 1-10 , the loudspeaker provided by the embodiment of the present invention includes a basin frame 100, a front cover 200, a vibration system 300 and a magnetic circuit system 400, the basin frame has a storage space 120, the vibration system 300 and the magnetic circuit system 400 are accommodated in the storage space 120, the vibration system 300 includes a diaphragm 310 fixed on the frame 100 and a voice coil 320 supported on one side of the diaphragm 310 , the front cover 200 is stacked on the diaphragm 310 , and the diaphragm 310 is disposed between the front cover 200 and the frame 100 . The magnetic circuit system 400 includes a magnetic bowl 410 fixed on the side of the basin frame 100 away from the diaphragm 310, and a main magnet 420 and a side magnet 430 fixed to the magnetic bowl 410. The side magnets 430 are located on opposite sides of the main magnet 420. The side and the main magnetic steel 420 are spaced apart to form a magnetic gap 440 , and...

Embodiment 2

[0056] refer to Figure 11-13 As shown, the difference between the loudspeaker provided in this embodiment and the first embodiment lies in the structure of the front cover 200, which is specifically reflected in: in this embodiment, the bottom surface 210 of the front cover 200 is provided with several grooves distributed at intervals 230, the adhesive layer 500 is further filled between the groove 230 and the adhesive surface 3111, the adhesive layer 500 specifically includes the first adhesive layer 510 filled between the adhesive surface 3111 and the bottom surface 210 and the first adhesive layer 510 filled on the adhesive surface 3111 and the second adhesive layer 520 between the groove 230 . The groove 230 is specifically recessed and formed from the bottom surface 210 toward a direction away from the bonding portion 311 . In this embodiment, the vibrating membrane 310 is provided with a groove 230 on the bottom surface 210 of the front cover 200 for bonding with the v...

Embodiment 3

[0063] refer to Figure 14 and Figure 15 As shown, the difference between the speaker and the mobile terminal device provided by this embodiment and the second embodiment is mainly that the arrangement of the groove 230 is different, which is specifically reflected in: in this embodiment, the groove 230 is arranged around the bottom surface 210 And the annular groove is arranged at intervals between the outer ring edge 211 and the inner ring edge 212 , and the adhesive layer is further filled between the annular groove and the bonding part. The arrangement of the annular groove in this embodiment can also achieve the purpose of further increasing the amount of local glue between the front cover 200 and the diaphragm and improving the deep waterproof performance without reducing the acoustic performance of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com