Tunnel lining quality detection mechanical hand

A manipulator and lining technology, used in manipulators, electromagnetic wave detection, tool manufacturing, etc., can solve problems such as hidden dangers, labor consumption, long detection distance, etc., and achieve the effect of high transmission ratio, compact structure and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

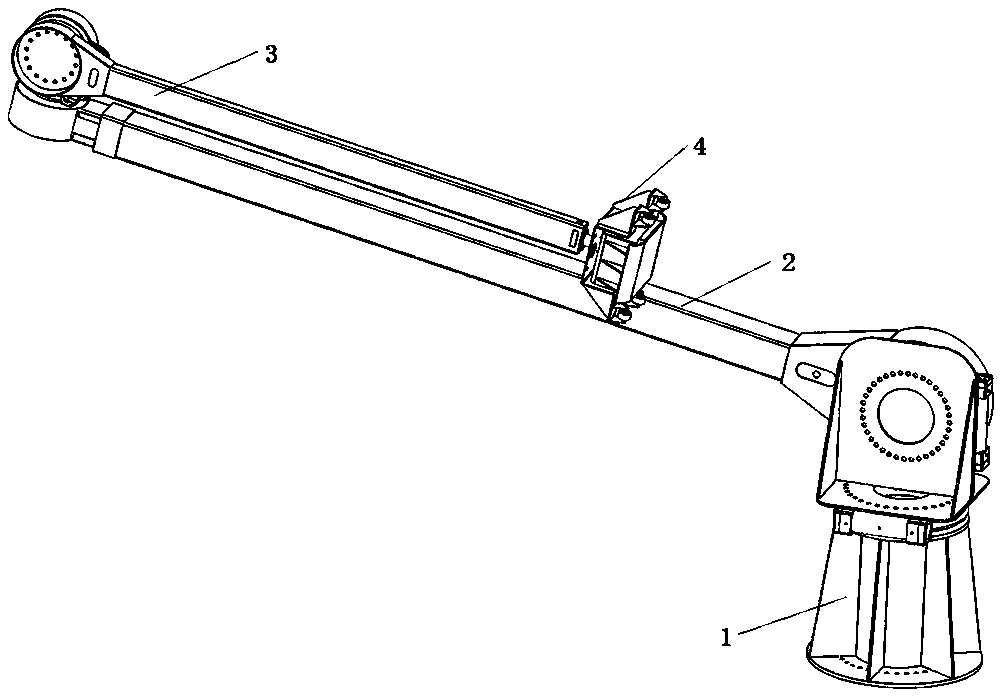

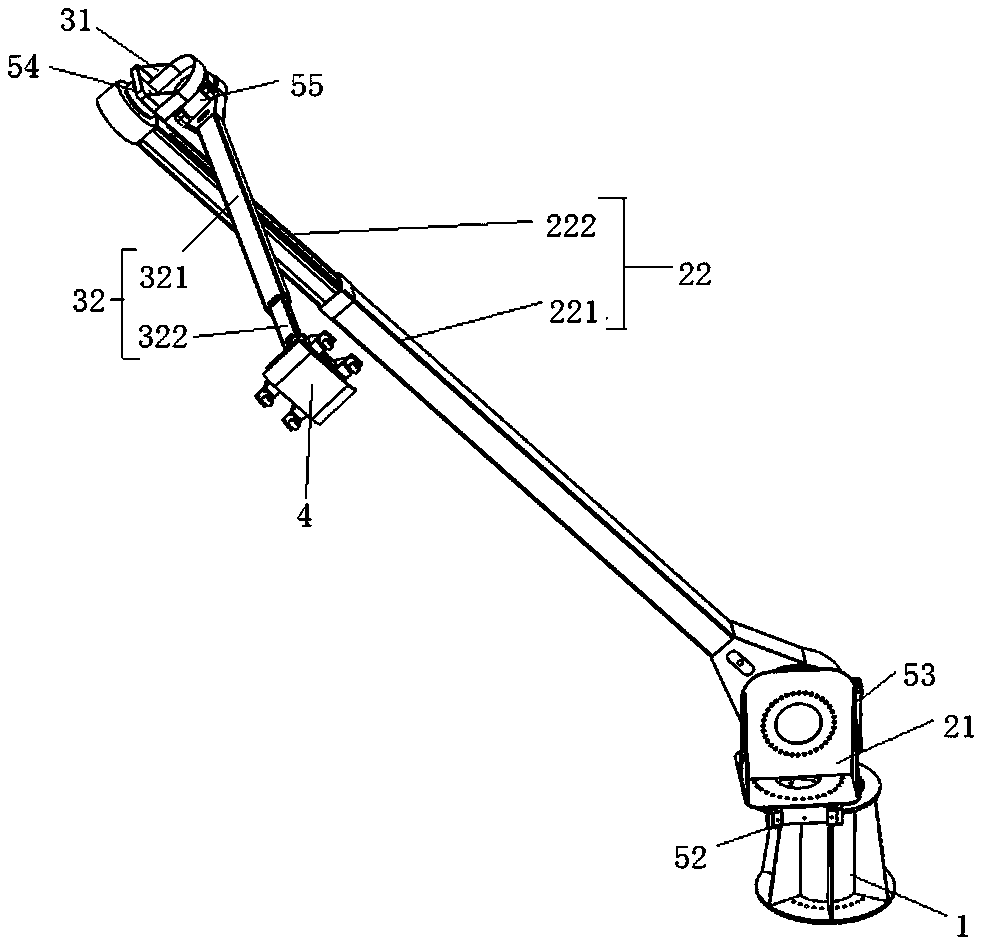

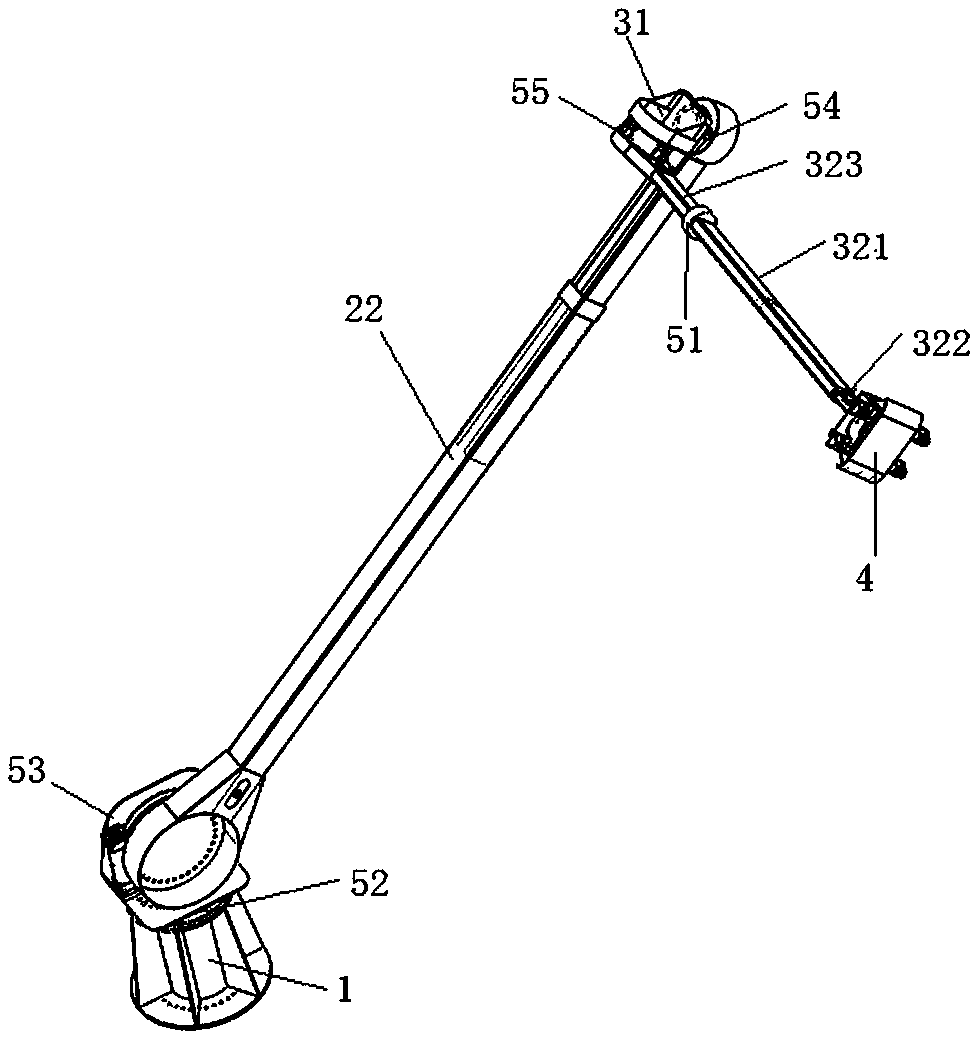

[0034] like Figure 1 to Figure 4 As shown, a tunnel lining quality inspection manipulator includes a base 1 , a first rotary telescopic arm mechanism 2 , a second rotary telescopic arm mechanism 3 and a floating antenna box device 4 .

[0035] The first rotary telescopic arm mechanism 2 includes a rotary seat a21 and a telescopic arm a22, and the second rotary telescopic arm mechanism 3 includes a rotary seat b31 and a telescopic arm b32.

[0036] One end of the telescopic arm a22 is rotatably connected to the swivel seat b31, and one end of the telescopic arm b32 is rotatably connected to the swivel seat b31. The other end of the telescopic arm b32 is connected with the floating antenna box device 4 . The rotation axis of the telescopic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com