Military wall camouflage inkjet printing robot

A robot and inkjet technology, applied in the field of inkjet robots, can solve problems such as high labor intensity, emotional impact on workers, inhalation of a large amount of harmful gas, etc., and achieve the effects of high automation, high spraying efficiency, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

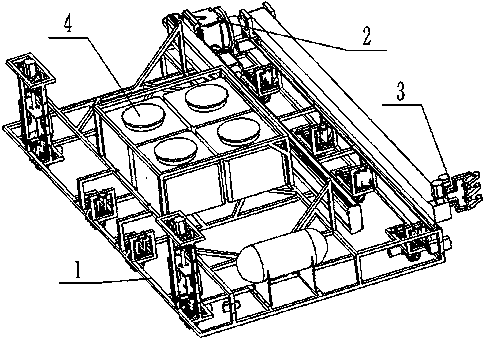

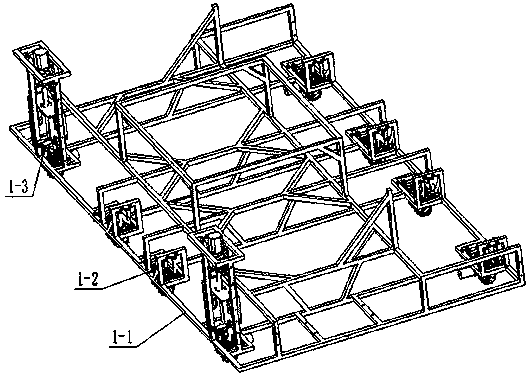

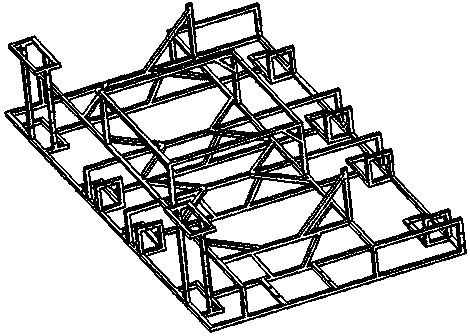

[0034] combined with Figure 1-12 Describe the content and operation of the present invention.

[0035] The military wall camouflage spray painting robot of the present invention comprises: a car body 1 , a foldable planar movement device 2 , a spray painting device 3 and a paint supply system 4 . The car body 1 is the moving part of the robot, and also the supporting and connecting part of other parts. The foldable planar motion device 2 is fixed on the car body 1 by bolt connection, and the spray painting device 3 is fixed on the end of the foldable planar motion device 2 by bolt connection. A paint supply system 4 is arranged on the vehicle body 1 .

[0036] The vehicle body 1 includes: a vehicle frame 1-1, a mecanum wheel set 1-2 and a chassis level adjustment mechanism 1-3. The vehicle frame 1-1 is the supporting and connecting part of the vehicle body 1. The Mecanum wheel set 1-2 and multiple chassis level adjustment mechanisms 1-3 are all fixed on the vehicle frame ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap