Steel rope anchor bolt

A technology of steel cables and anchor bolts, which is applied in the direction of transmission elements or pulley ropes or cables, pins, connecting components, etc., which can solve the problems of high cost, bending of rod-shaped objects, cumbersome operation, etc., so as to improve the anti-loosening effect and increase The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

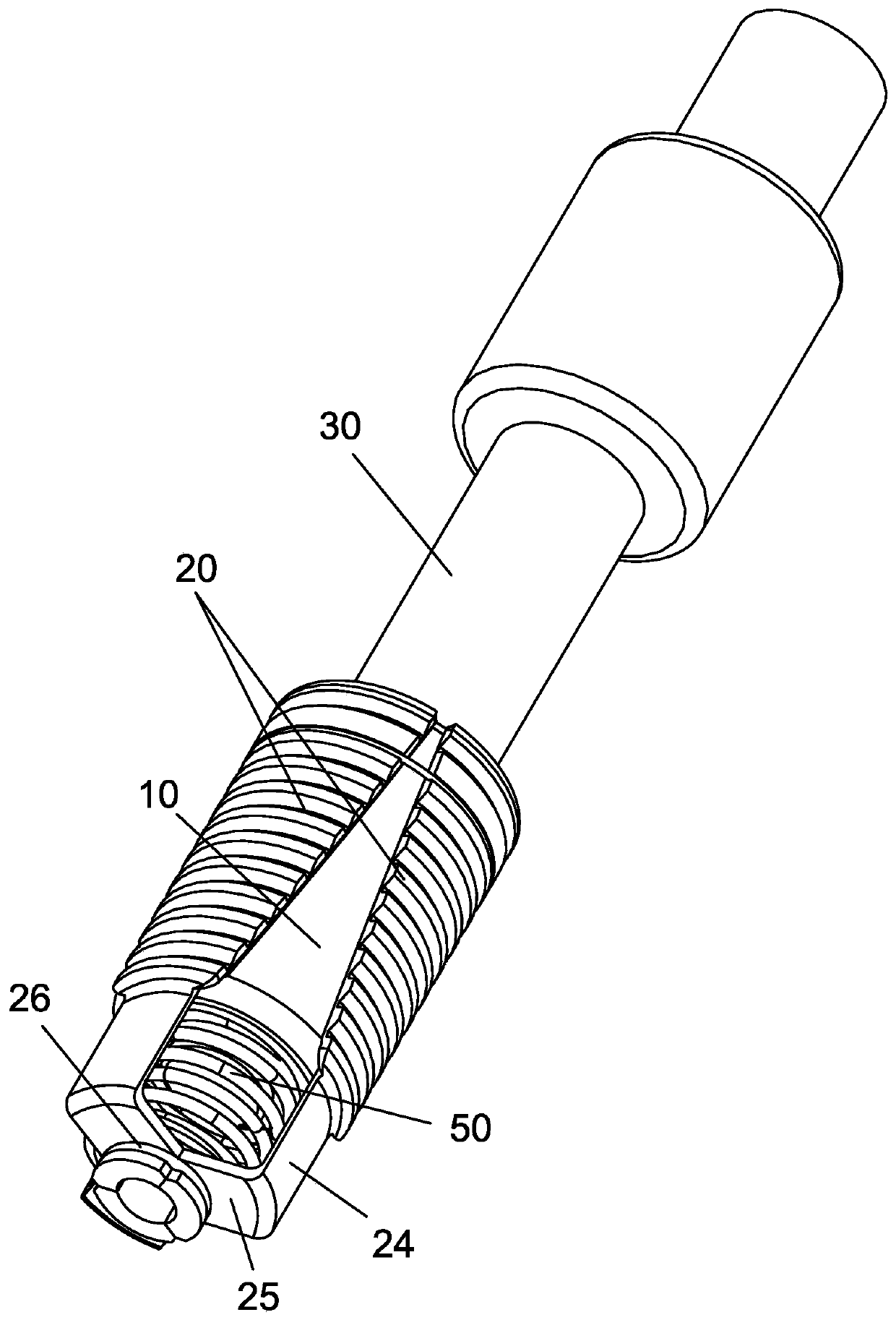

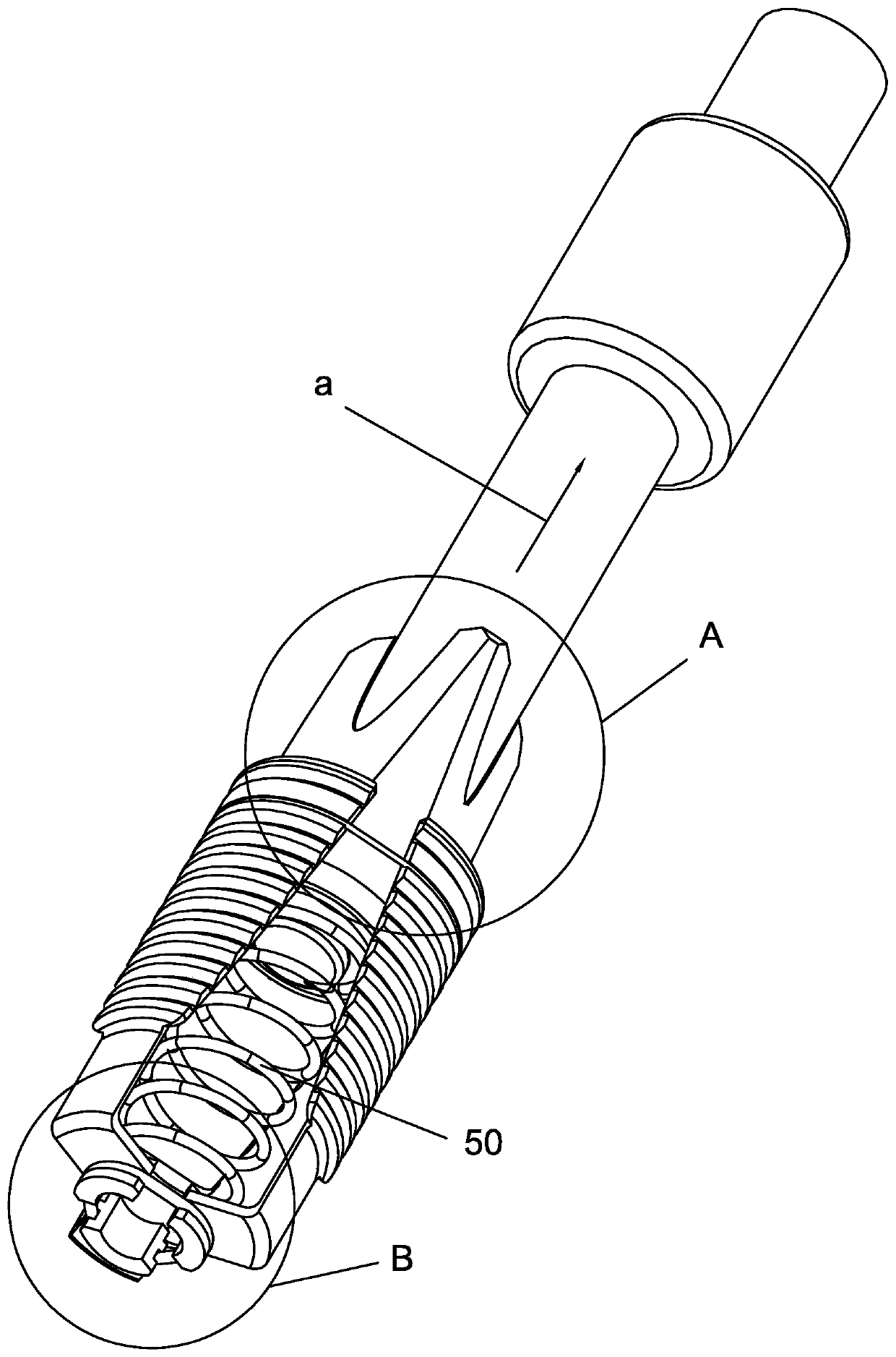

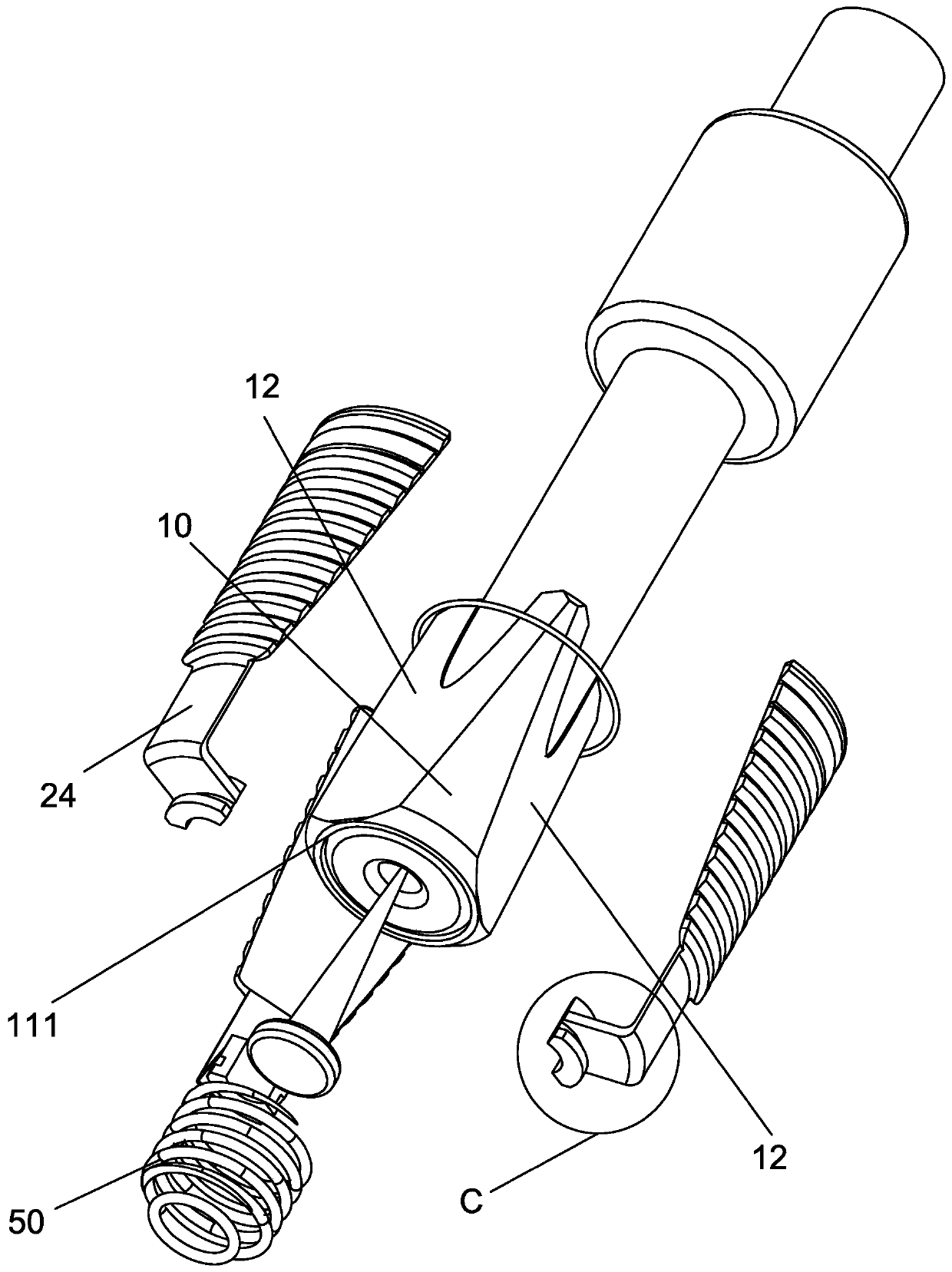

[0035] refer to Figure 1 to Figure 8 ,Such as Figure 1 to Figure 8 The shown cable anchor bolt includes a cylindrical expansion head 10, and the center of the expansion head 10 is provided with a through hole 11, and its outer cylindrical wall is provided with three wedge-shaped surfaces uniformly distributed along its circumferential direction. 12. The tapered tip formed by the virtual extension end of the wedge-shaped surface 12 toward the axial direction of the expansion head 10 faces the tension direction; 12 close to the wedge-shaped block 20, the side of the wedge-shaped block 20 facing away from the wedge-shaped surface 12 fits the outer cylindrical wall contour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com