Engineering machinery, engine and piston cooling mechanism thereof

A piston cooling and engine technology, which is applied in the direction of engine cooling, machine/engine, engine components, etc., can solve problems such as cylinder knocking, knocking, and tile phenomenon, and achieve the goal of reducing gaps, reducing noise and knocking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

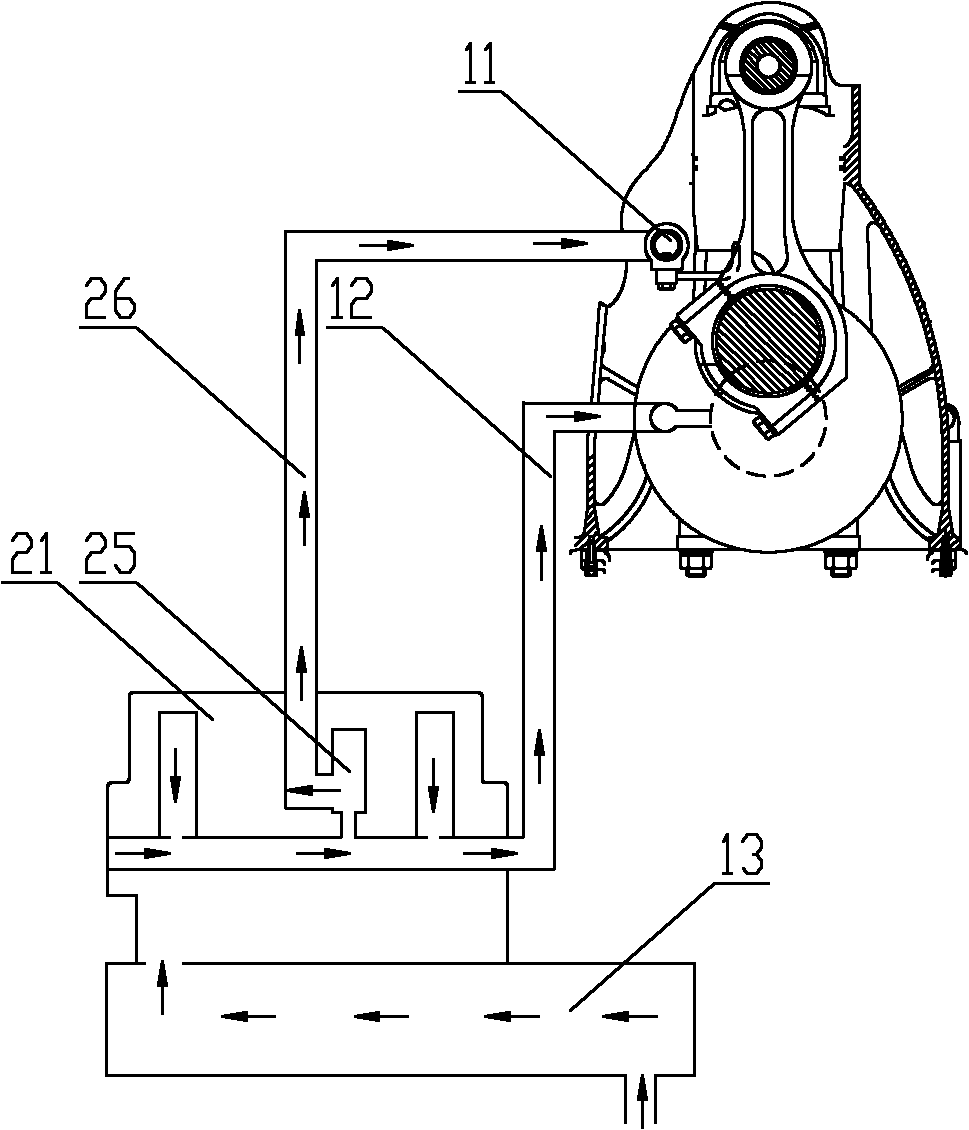

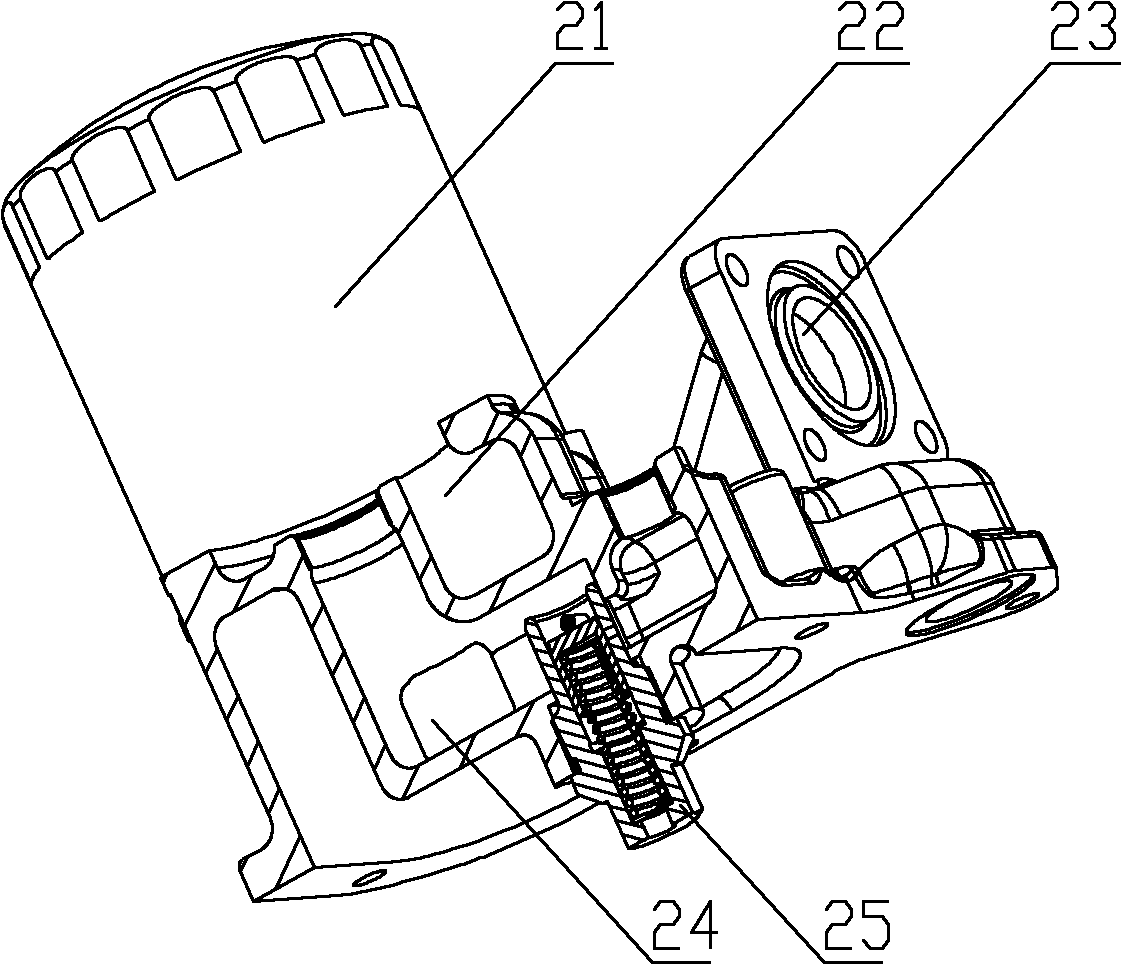

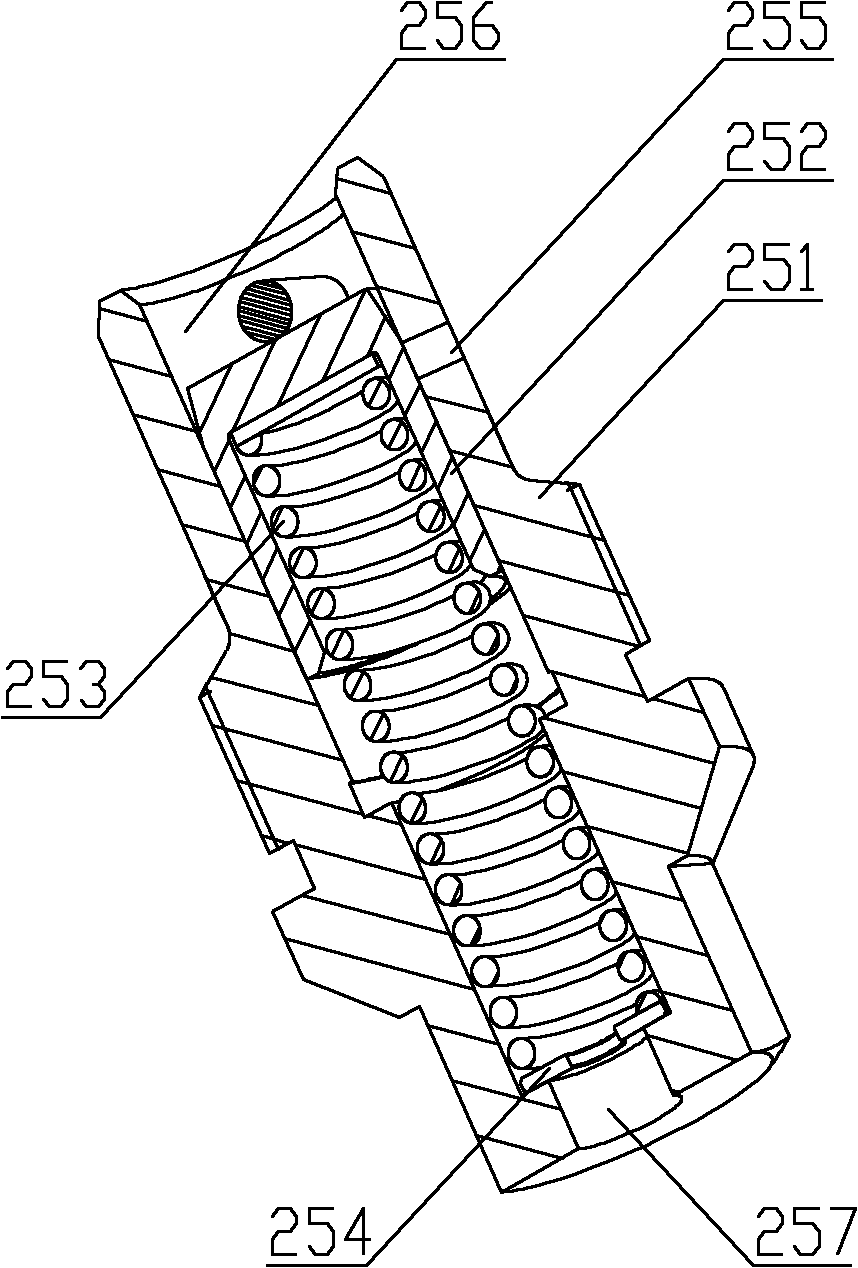

[0028] The core of the present invention is to provide a piston cooling mechanism of the engine, which can control the cooling nozzle to spray engine oil according to the needs, and avoid affecting the expansion of the piston and piston ring under the condition of meeting the cooling requirements, and the cooling oil does not Complete combustion forms carbon deposits. Another core of the present invention is to provide an engine including the piston cooling mechanism of the above-mentioned engine and a construction machine including the above-mentioned engine.

[0029] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Please refer to figure 1 , figure 1 It is a schematic structural diagram of a piston cooling mechanism of an engine provided by a specific embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com