Metal-plastic composite tube provided with enhanced sealing mechanisms on end parts and manufacturing method thereof

A metal-plastic, end-strengthening technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of slow delamination of the inner wall of the metal pipe and the plastic layer, slow delamination of metal and plastic, and easy loss of bonding properties, etc. Achieve the effect of uncomplicated equipment, improved hygienic performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

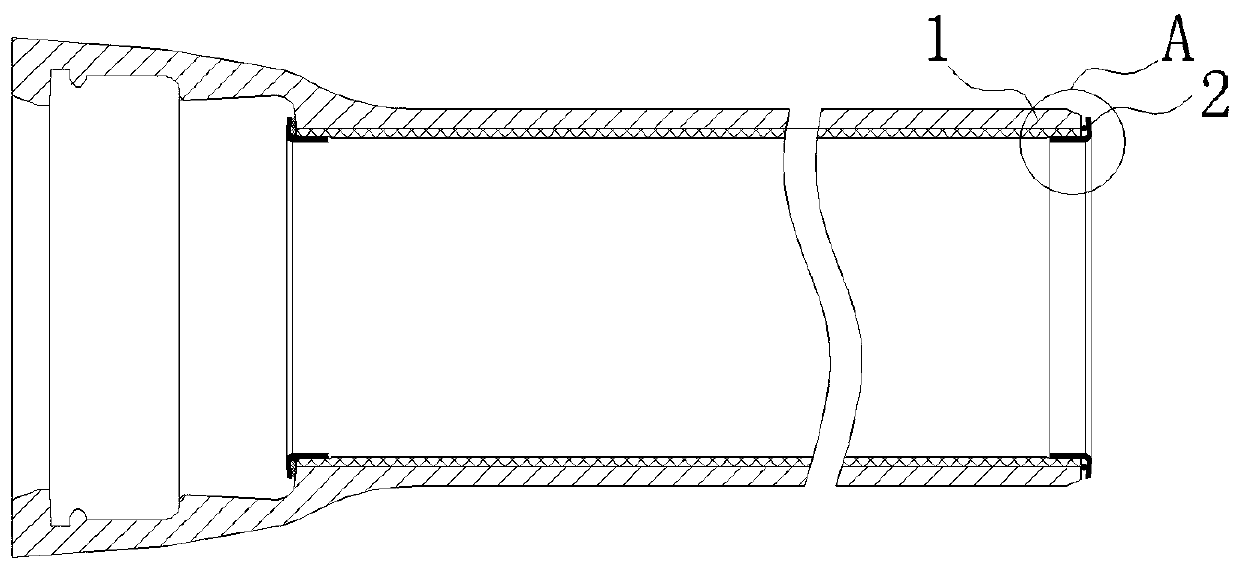

[0044] Refer to attached Figure 1-4 , the metal-plastic composite pipe is a socket-type ductile iron pipe lined with plastic pipe in this embodiment, and this embodiment includes a socket-type ductile iron pipe body 1 lined with plastic pipe and a reinforced sealing mechanism 2, and the reinforced sealing mechanism 2 It is arranged at both ends of the plastic-lined pipe socket type ductile iron pipe body 1 .

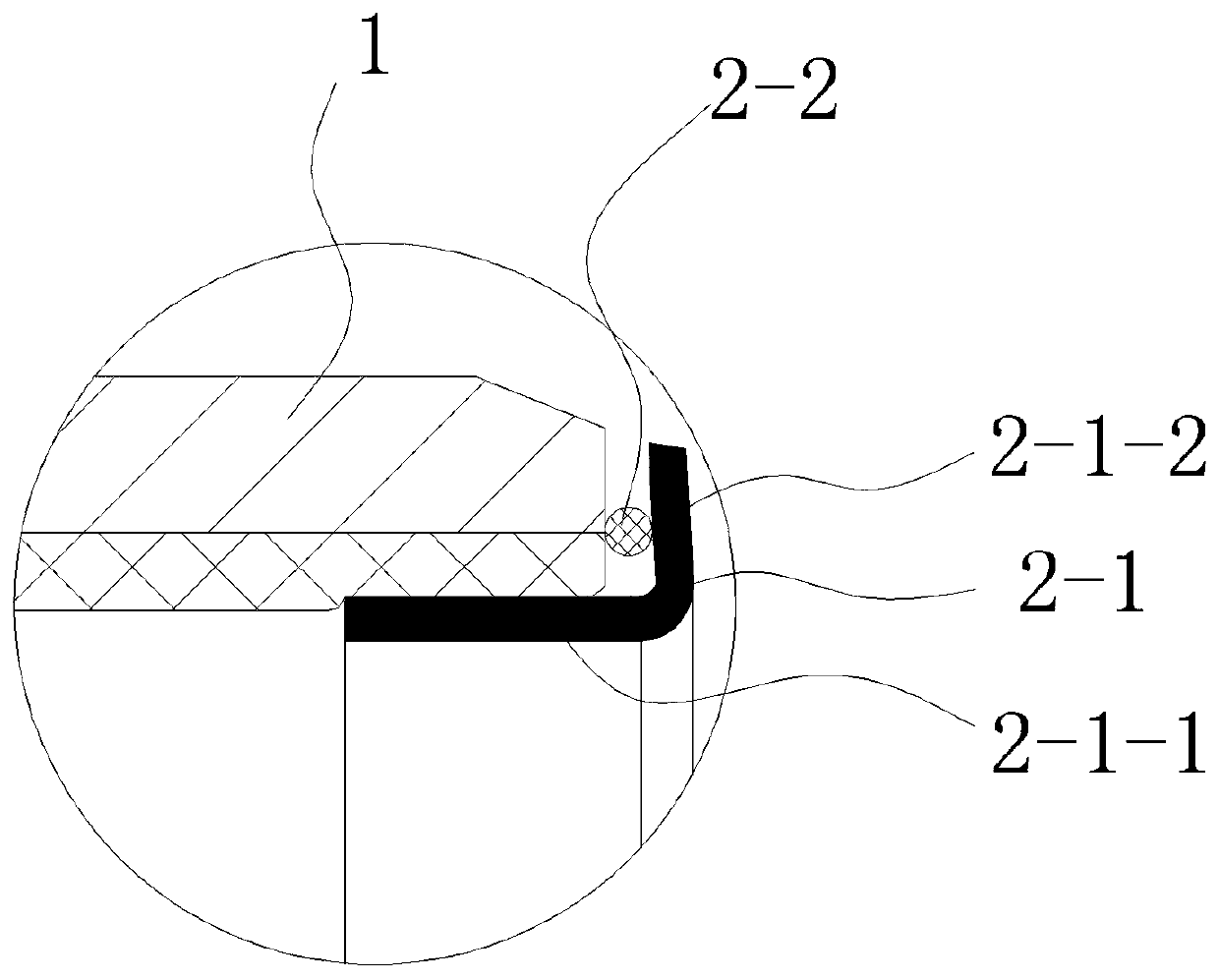

[0045] In this embodiment, the end reinforced sealing mechanism 2 includes a stainless steel reinforcing ring 2-1 and a rubber sealing ring 2-2 with a circular cross section.

[0046] In this embodiment, the stainless steel reinforcing ring 2-1 includes a stainless steel reinforcing ring main body 2-1-1 and a flange 2-1-2, and the outer wall of the stainless steel reinforcing ring main body 2-1-1 is provided with embossing , embossing can increase the friction between the metal reinforcement ring and the inner wall of the metal-plastic composite pipe, so that the insta...

Embodiment 2

[0061] Refer to attached Figure 5-8 , the metal-plastic composite pipe is a straight plastic-lined steel pipe in this embodiment, and this embodiment includes a plastic-lined steel pipe body 1 and an end reinforced sealing mechanism 2, and the end reinforced sealing mechanism 2 is arranged on the plastic-lined steel pipe Both ends of body 1.

[0062] In this embodiment, the end reinforced sealing mechanism 2 includes a stainless steel reinforcing ring 2-1 and a rubber sealing ring 2-2 with a circular cross section.

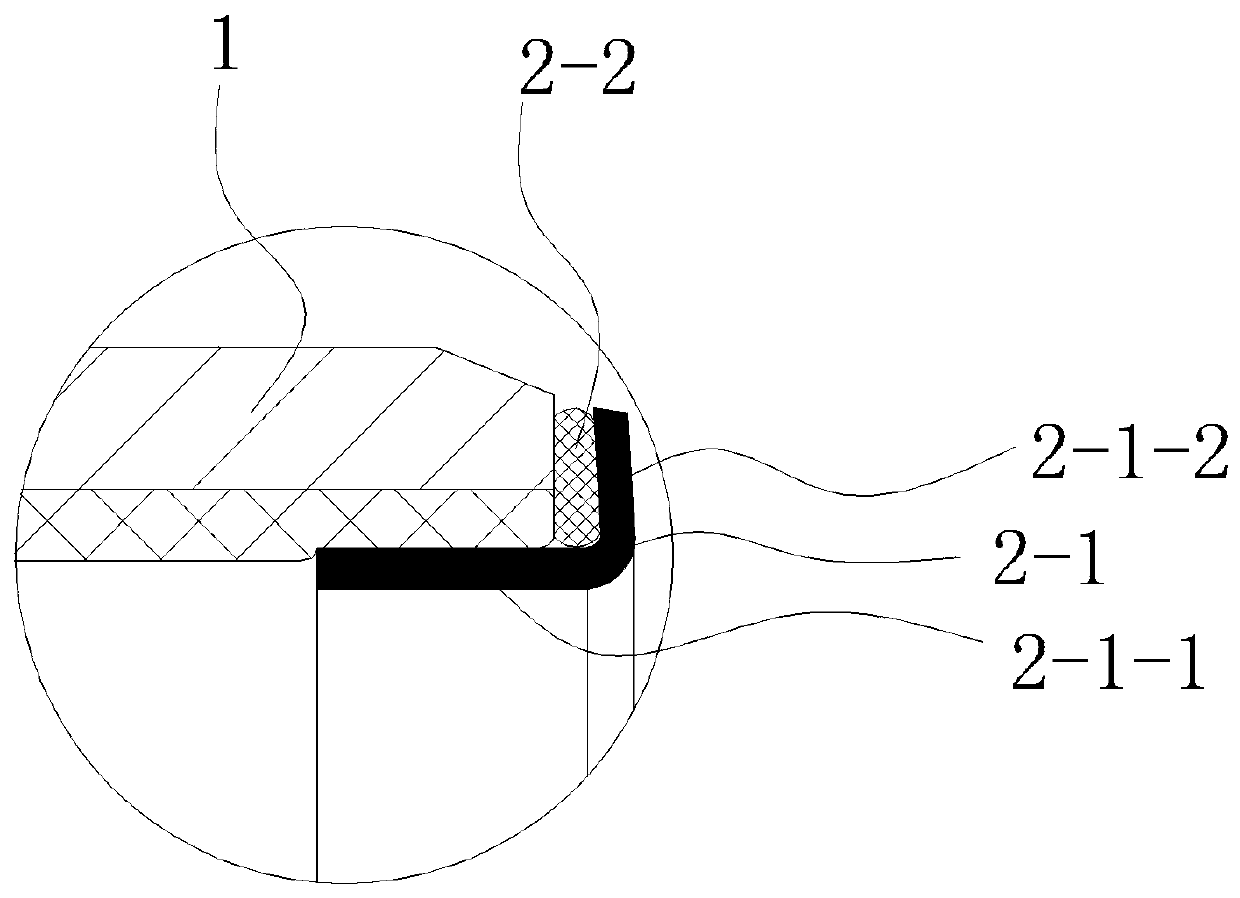

[0063] In this embodiment, the stainless steel reinforcing ring 2-1 includes a stainless steel reinforcing ring main body 2-1-1 and a flange 2-1-2, the outer wall of the main body 2-1-1 is provided with embossing, and the flange 2 -1-2 is located at the outer end of the main body 2-1-1. The rubber sealing ring 2-2 is sleeved on the outer wall of the main body 2-1-1 of the stainless steel reinforcement ring and clings to the flange 2-1-2 at the outer end of the ...

Embodiment 3

[0078] Such as Figure 9 As shown, in this embodiment, the outer wall of the flanging of the metal reinforcement ring 2 - 1 is flush with the outer wall of the plastic-lined steel pipe body 1 .

[0079] Remaining with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com