MVR (mechanical vapor recompression) concentration and rectification system and recovery method for DMAC (dimethylacetamide) waste liquid

A rectification system and waste liquid technology, applied in separation methods, chemical instruments and methods, fractional distillation, etc., can solve the problems of long residence time of DMAC, no good, toxic odor of dimethylamine, etc., and solve the problems of air pollution and water pollution. Pollution, reduced operating costs, good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

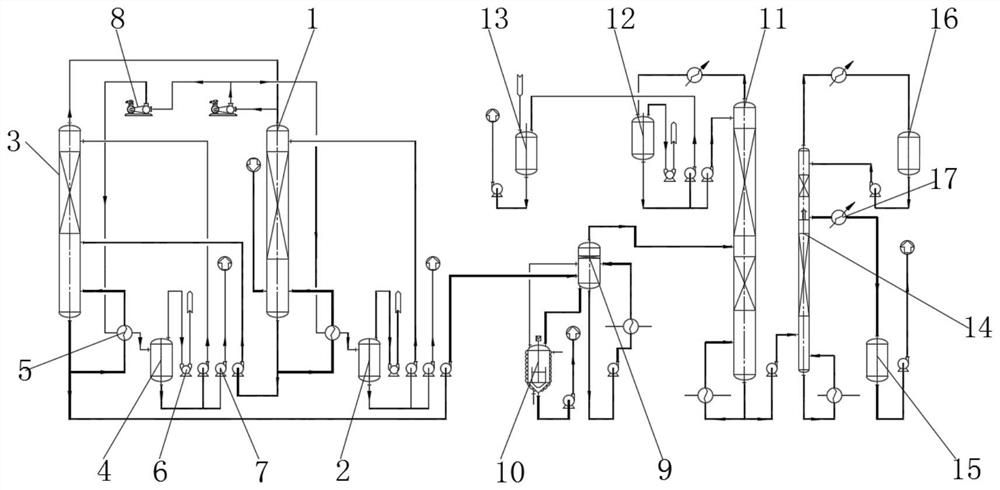

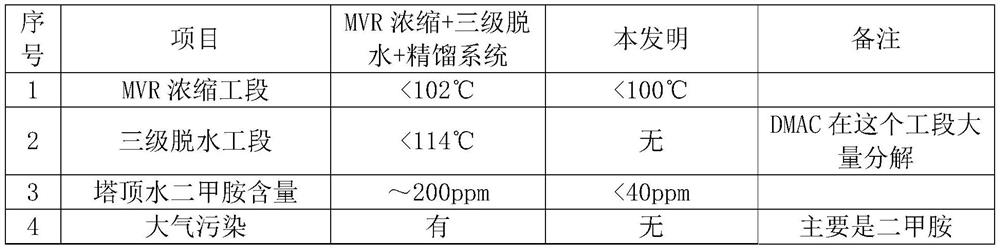

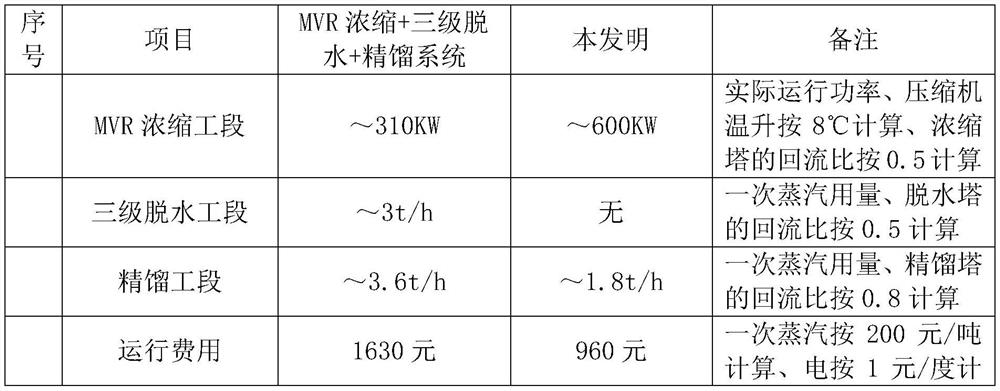

[0054] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0055] refer to figure 1 , the present invention solves the air pollution and water pollution of the prior art. The adopted technical scheme is: DMAC is concentrated within 100°C, rectified and deacidified within 100°C, and the whole process is all carried out at low temperature. DMAC Basically no decomposition, DMAC processing includes the following steps:

[0056] Step 1: The waste liquid containing DMAC is sent to the first concentration tower 1 through the waste liquid pump (centrifugal pump 7) for dehydration and concentration for the first time. The temperature at the top of the first concentration tower 1 is 90°C, and the corresponding temperature at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com