A municipal pipe network layout structure and its construction method

A technology of layout structure and municipal pipe network, applied in cleaning methods and utensils, chemical instruments and methods, pipes, etc., can solve problems such as inconvenience in the dredging process, and achieve easy and convenient dredging process, convenient and fast locking and unlocking process. , The effect of simple and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

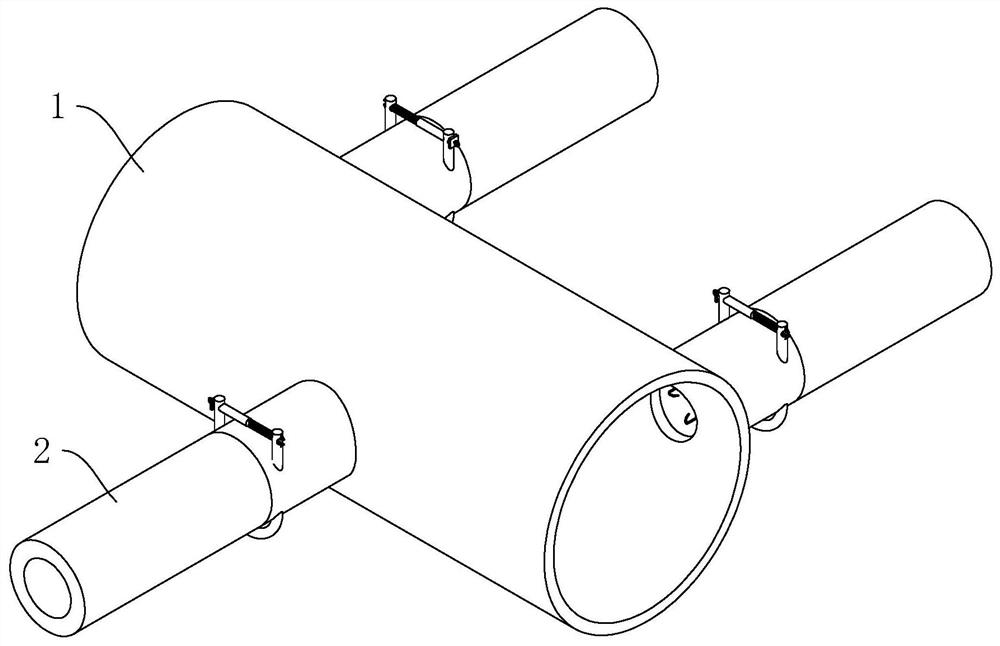

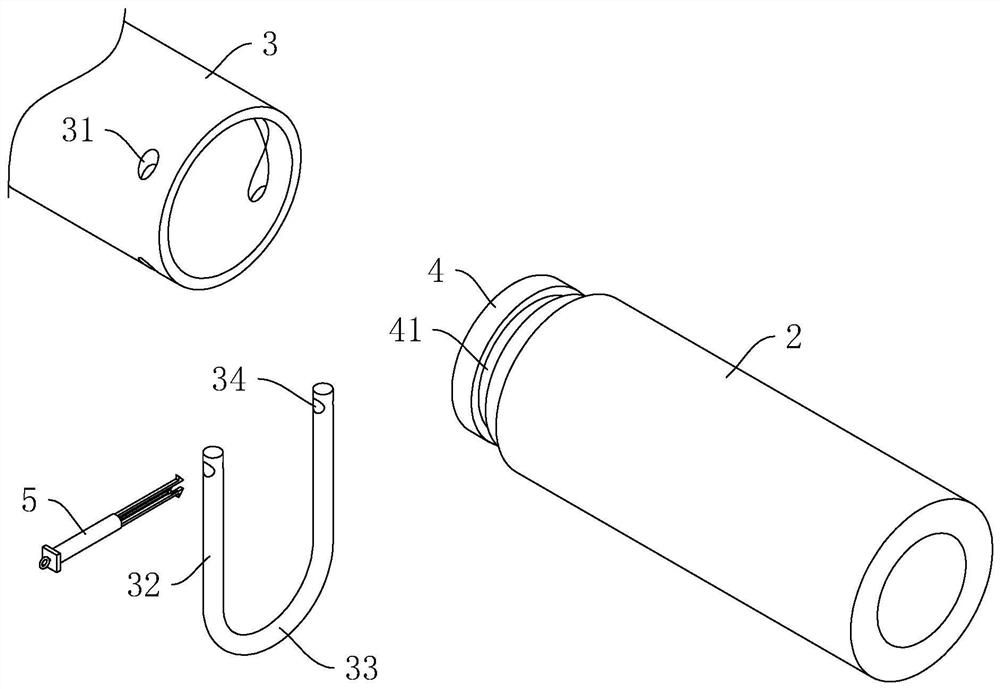

[0040] Embodiment 1: as figure 1 , figure 2 As shown, a municipal pipe network layout structure includes a main pipe 1 and a branch pipe 2 arranged on the side wall of the main pipe 1 . The side wall of the main pipe 1 is provided with a support pipe 3 , and the end of the branch pipe 2 close to the main pipe 1 is provided with a mounting pipe 4 for inserting the support pipe 3 . And in this embodiment, when the installation pipe 4 is inserted into the support pipe 3 , the inner wall of the installation pipe 4 is flush with the inner wall and the outer wall of the support pipe 3 .

[0041] When installing the above-mentioned pipe network, first align the installation pipe 4 at the end of the branch pipe 2 with the support pipe 3 on the side wall of the main pipe 1, and then drive the branch pipe 2 close to the main pipe 1. At this time, the installation pipe 4 slides along the inner wall of the support pipe 3 shift. After the installation pipe 4 is completely inserted into...

Embodiment 2

[0058] Embodiment 2: as Figure 5 As shown, a municipal pipe network layout structure differs from Embodiment 1 in that a sliding sleeve 6 is horizontally slidably connected in the support pipe 3 , and the inner wall of the installation pipe 4 near the end of the support pipe 3 is provided with a barrier against the outer wall of the sliding sleeve 6 . Raised ring 42 .

[0059] Such as Figure 5 As shown, the outer wall of the sliding sleeve 6 is provided with a plurality of elastic ribs 61 , and the end of the elastic ribs 61 away from the sliding sleeve 6 is fixed to the inner wall of the support tube 3 , and the plurality of elastic ribs 61 are evenly distributed along the circumferential direction of the sliding sleeve 6 .

[0060] Such as Figure 5 As shown, the sliding sleeve 6 is close to the main pipe 1 (see figure 1 ) is provided with a plurality of iron hooks 62, and the plurality of iron hooks 62 are evenly distributed along the circumferential direction of the s...

Embodiment 3

[0066] Embodiment 3: a kind of construction method that is used for above-mentioned municipal pipe network layout structure comprises the following steps:

[0067] S1: Take out the branch pipe 2, and make the end with the installation pipe 4 facing the main pipe 1;

[0068] S2: drive the branch pipe 2 to drive the installation pipe 4 to insert the support pipe 3 on the side wall of the main pipe 1;

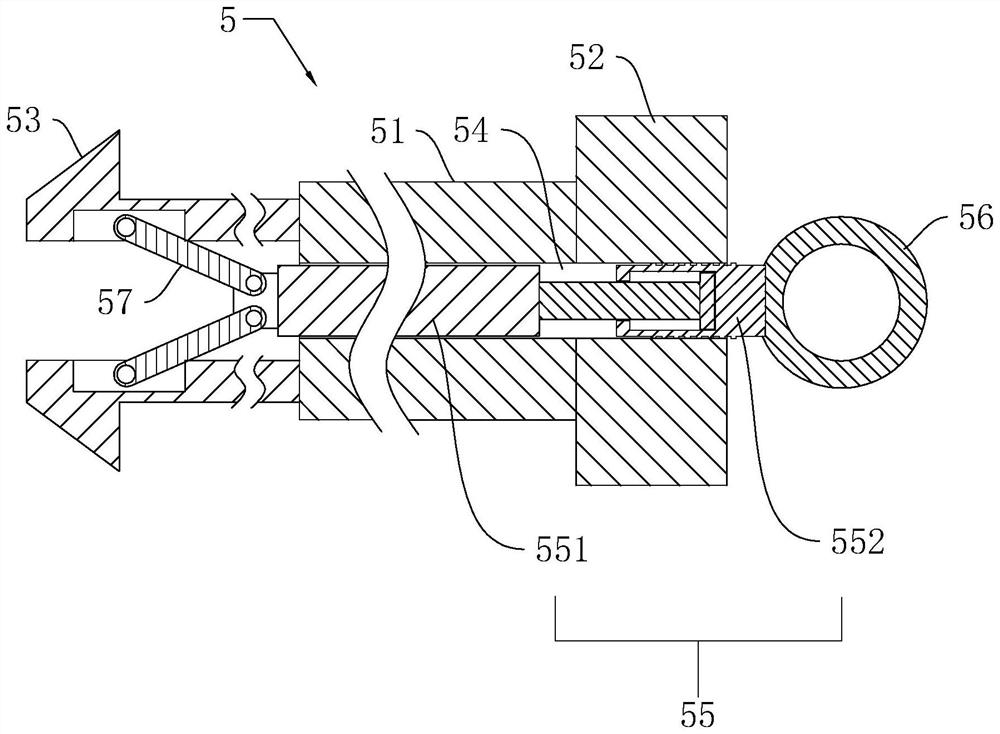

[0069] S3: After the installation tube 4 is fully inserted into the support tube 3, insert the fixing rod 32 into the fixing hole 31 on one side of the support tube 3, and drive the fixing rod 32 to slide along the fixing hole 31 and the inner wall of the fixing groove 41;

[0070] S4: After the end of the fixing rod 32 passes through the fixing hole 31 on the other side of the support tube 3 , the fixing rod 32 is fixed by the locking part 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com