Domestic waste pyrolysis treatment system

A treatment system and technology for domestic waste, applied in the field of domestic waste pyrolysis treatment system, can solve the problems of full, easy to be blown away by wind, blockage, etc., and achieve the effect of avoiding transmission blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

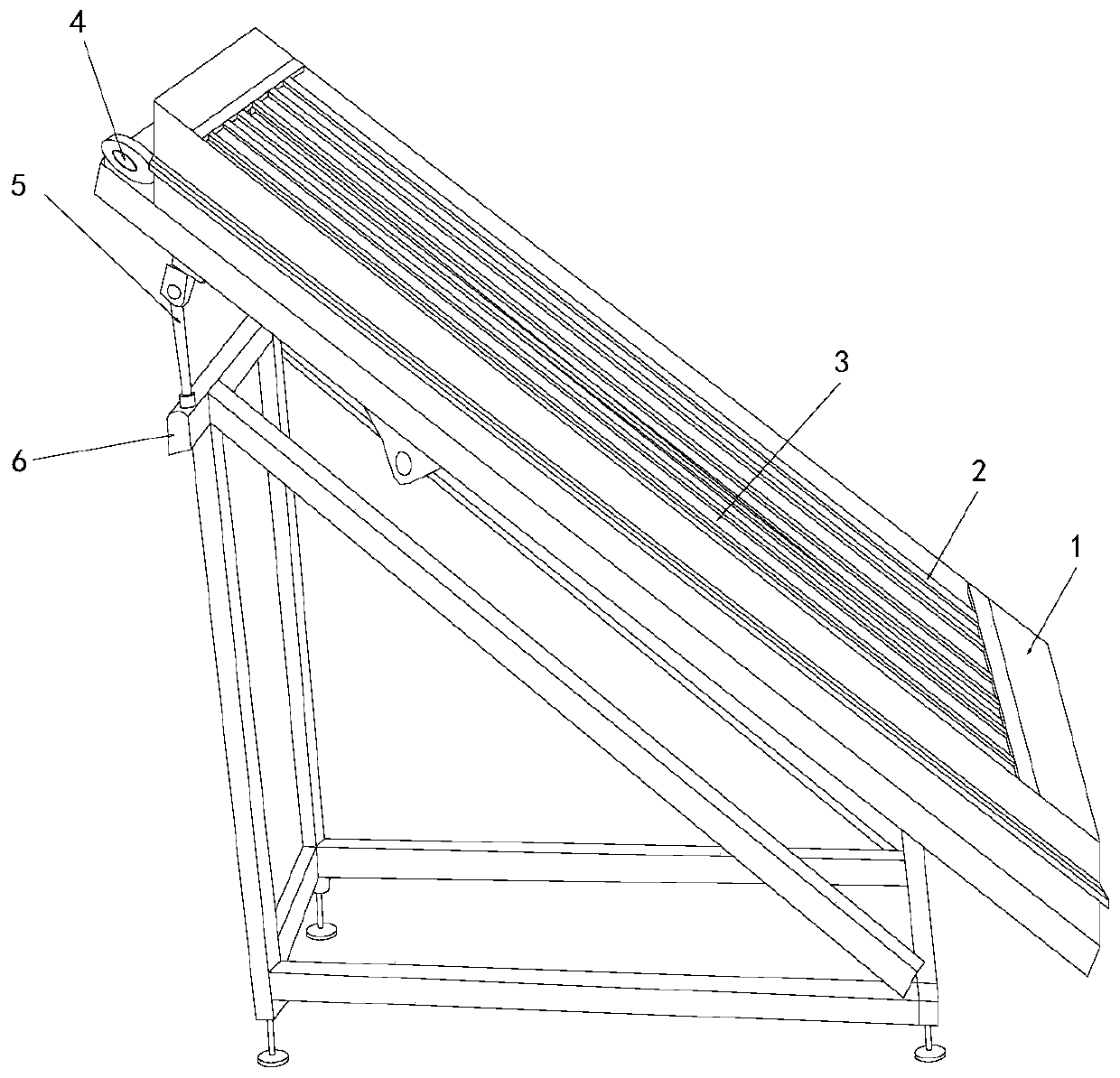

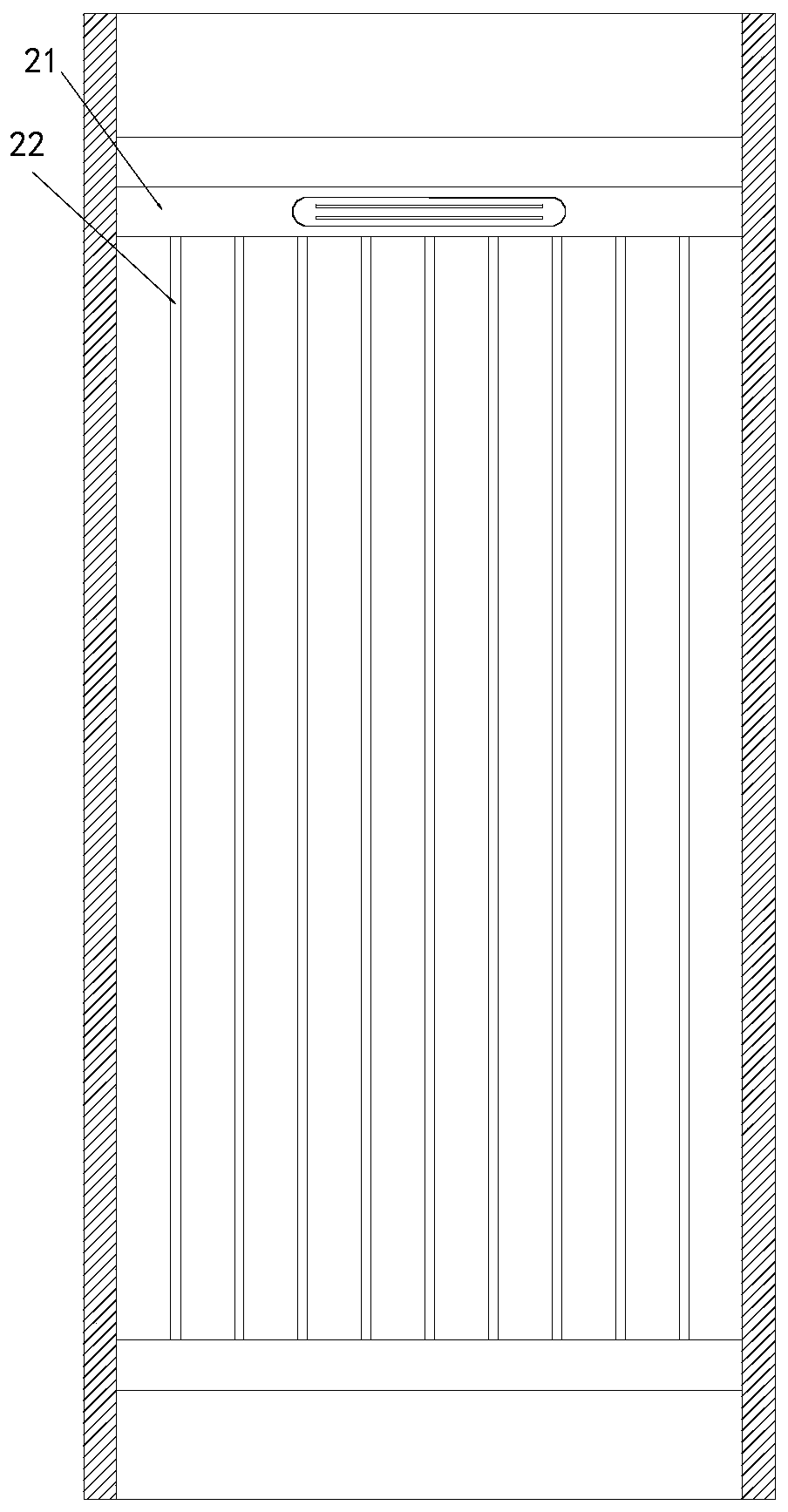

[0031] see Figure 1-Figure 8 , the present invention provides a domestic waste pyrolysis treatment system, including a feeding system, an incinerator, and a waste gas recovery system. The structure of the feeding system includes a first support 1, a windproof structure 2, a conveyor belt 3, a turning and turning structure 4, Telescopic rod 5, bottom bracket 6, one end of the bottom bracket 6 is mechanically connected to the first bracket 1 through the telescopic rod 5, the conveyor belt 3 is installed in the middle of the first bracket 1 horizontally, and the conveyor belt 3 is installed directly above There is a windproof structure 2, and a turning and turning structure 4 is installed at one end of the conveyor belt 3, and the turning and turning structure 4 and the telescopic rod 5 are on the same side.

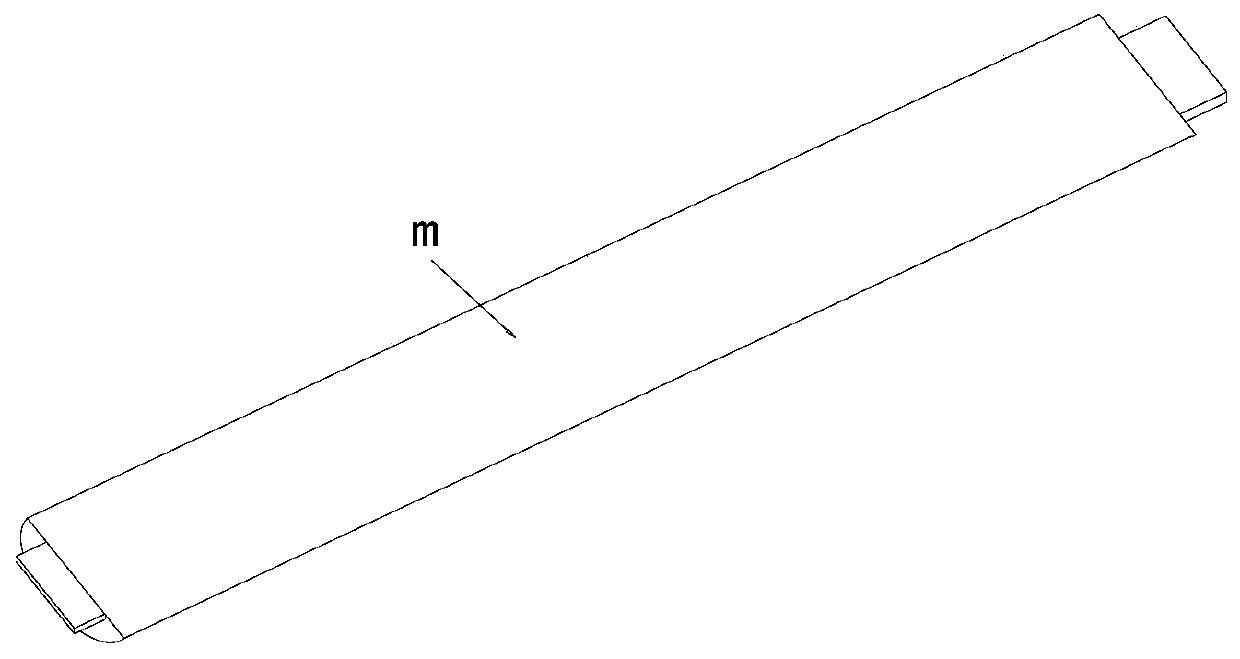

[0032] The turning and turning structure 4 is composed of a pocket block 41, a turning fork lever 42, a rotating shaft 43, and an installation opening 44. An installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com