Novel test loading device based on lever principle

A technology of loading device and lever principle, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as failure to obtain test reinforcement effects, and achieve the effects of simple structure, convenient experimental operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

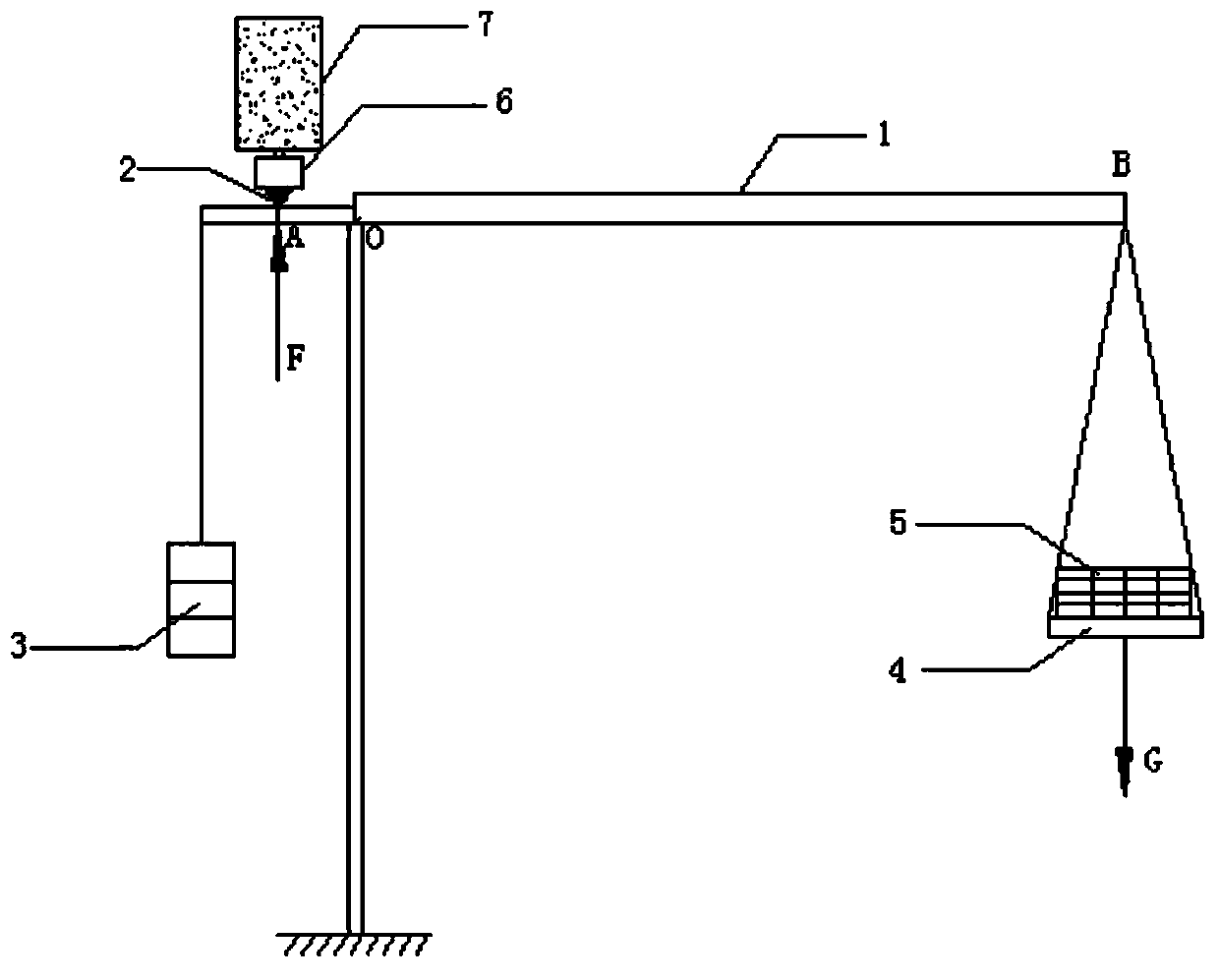

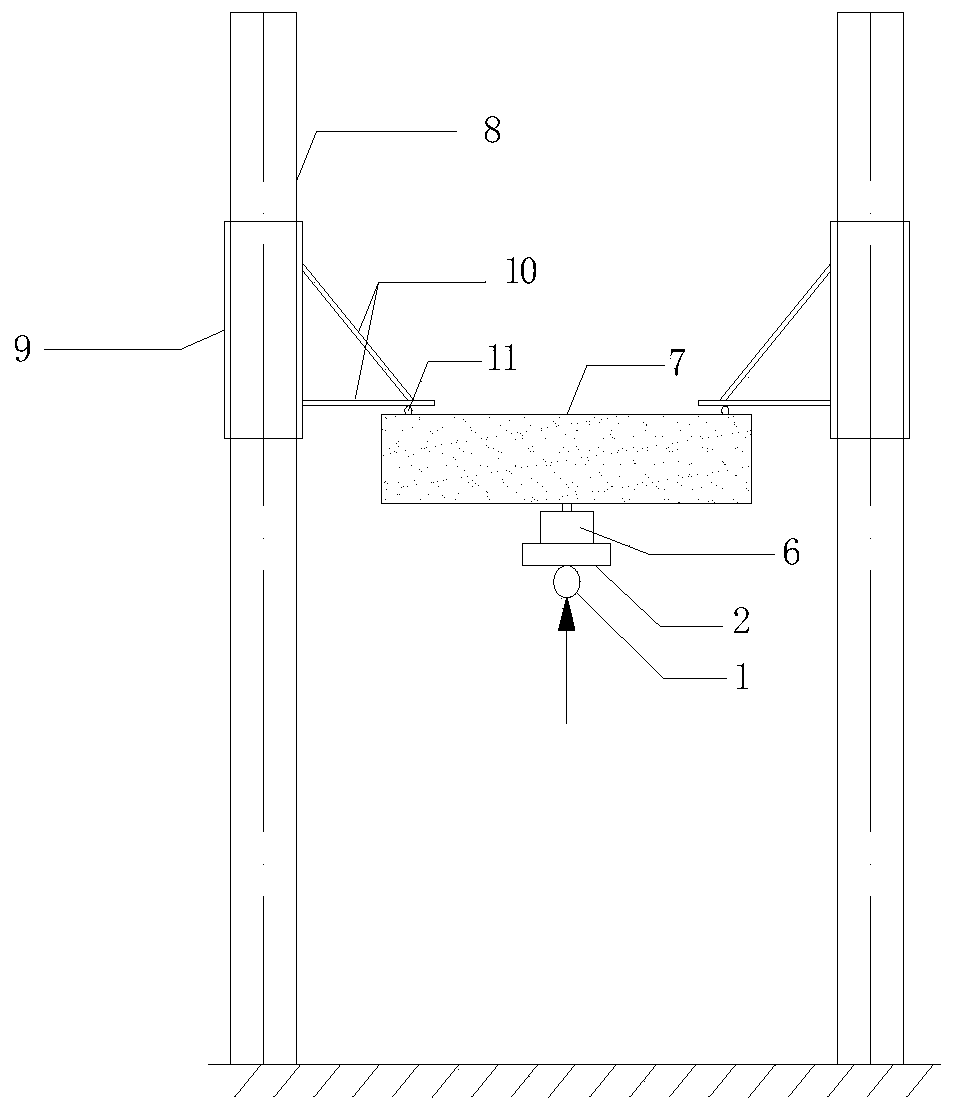

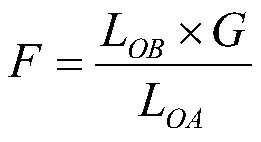

Embodiment 1

[0020] Such as Figure 1-2 As shown, this embodiment provides a new type of test loading device based on the principle of leverage, including a threaded rod 8 directly anchored in the ground, and a steel casing 9 anchored to the threaded rod 8 through a nut. The steel bracket 10 is two thin steel plates welded to the steel casing 9 . A force sensor 6 is arranged under the test beam 7, and a rotating shaft 2 is arranged under the force sensor to be connected with the lever 1, and the rotating shaft can rotate freely. A balance object 3 is suspended from one end of the lever, and a bearing plate 4 is suspended from the other end, on which a loading object 5 is placed. exist figure 1 A heavy object G is applied to the bearing plate at the position of point B, because the fulcrum O can rotate, then there will be an upward force F applied to the test beam at point A. According to the calculation of the principle of leverage, the force F can be obtained. The mid-span load borne ...

Embodiment 2

[0028] This embodiment provides a method for embedding a shape memory alloy wire at the upper end of a test beam, and the specific steps are:

[0029] 100 Grooving: first loosen the surface of the local cracks of the test beam or clean up the defective parts, and then chisel off a certain thickness of the original concrete protective layer in the local cracked area of the test beam to realize slotting within the depth of the concrete protective layer , the shape of the groove is a dog bone shape, and finally clean up the sundries that have been opened in the groove, and wipe the inner wall of the groove with alcohol;

[0030] 200 tensile alloys: first, install the shape memory alloy on the stretching system, which includes tensioning equipment and sensor data acquisition equipment; adjust the position of the shape memory alloy to ensure that the jack rod of the tensioning equipment and the shape memory alloy The center of the wire is on the same horizontal line, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com