An organic electroluminescence display panel and display device

An electroluminescent display and display panel technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problem of high power consumption of display panels, reduce external ambient light reflection, increase pixel aperture ratio, and improve light extraction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

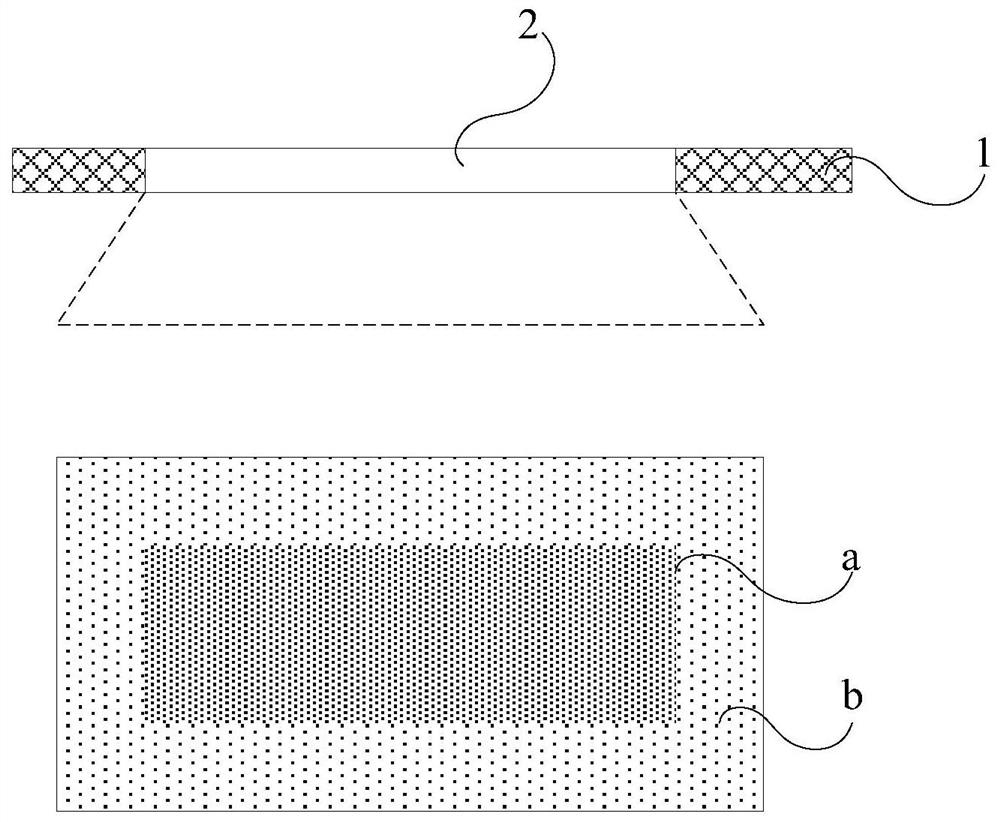

[0037] At present, in organic electroluminescent display panels, the evaporation process is mainly used to produce monochrome organic film layers, such as figure 1 As shown, after the high-precision metal mask 1 (FMM) with an opening 2 is used to cover the substrate, the required pattern is evaporated through the opening. Since the evaporation shadow (Shadow) will inevitably appear during the evaporation process, that is, the dotted line As shown in the box, there is an uneven thickness at the edge of the opening 2, that is, in the finally formed monochromatic organic film layer, the thickness is uniform in the central area A corresponding to the opening 2, and the edge area B surrounding the central area A will appear. A case where the thickness gradually decreases. Because the monochromatic organic film layer emits light in the edge area B with uneven film thickness, color shift will occur, so the edge area B cannot be used as an effective light-emitting area in the prior ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com