Lamination method for cell manufacturing and cell electrode group manufacturing equipment

A cell and laminate technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, non-aqueous electrolyte batteries, etc., can solve the problems of slow speed and low cell manufacturing efficiency, shorten manufacturing time, improve cell Manufacturing efficiency and the effect of improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

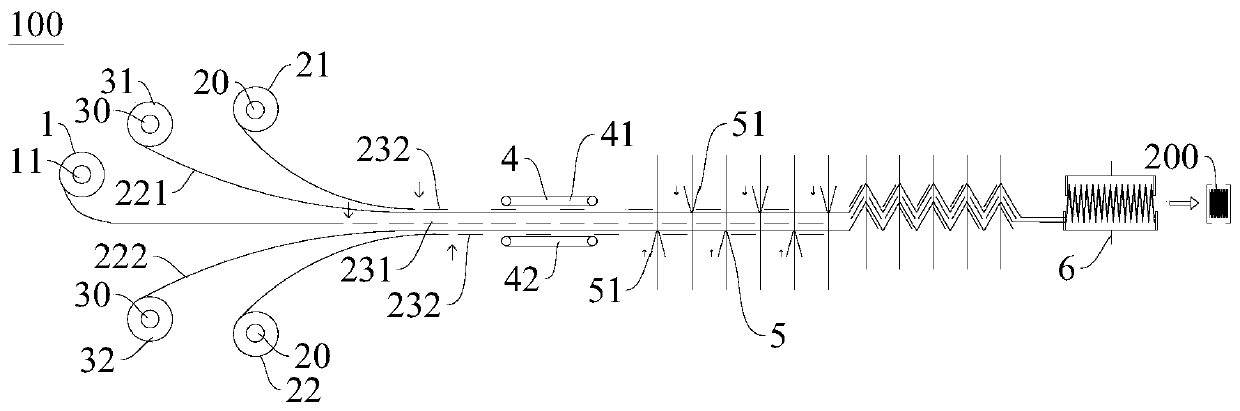

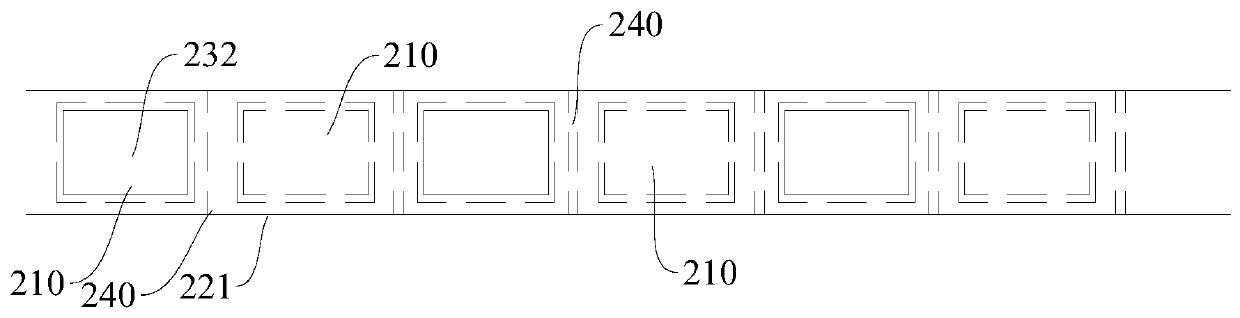

[0026] Refer below Figure 1-Figure 2 The lamination method of the embodiment of the present invention will be described in conjunction with the embodiments.

[0027] like Figure 1-Figure 2 As shown, the stacking method may include installing the positive electrode sheet 231, the negative electrode sheet 232, the first separator 221, and the second separator 222 into a laminated unit 210, and folding a plurality of laminated units 210 to form a set of battery cells. Group 200, wherein the positive electrode sheet 231, the negative electrode sheet 232, the first diaphragm 221 and the second diaphragm 222 are installed into a laminated unit 210, including: the first diaphragm 221 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com