Multi-cut-flow soybean combined harvester

A technology for combine harvesters and soybeans, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of difficult field use, large volume and high cost, and achieve obvious effects and reduce volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

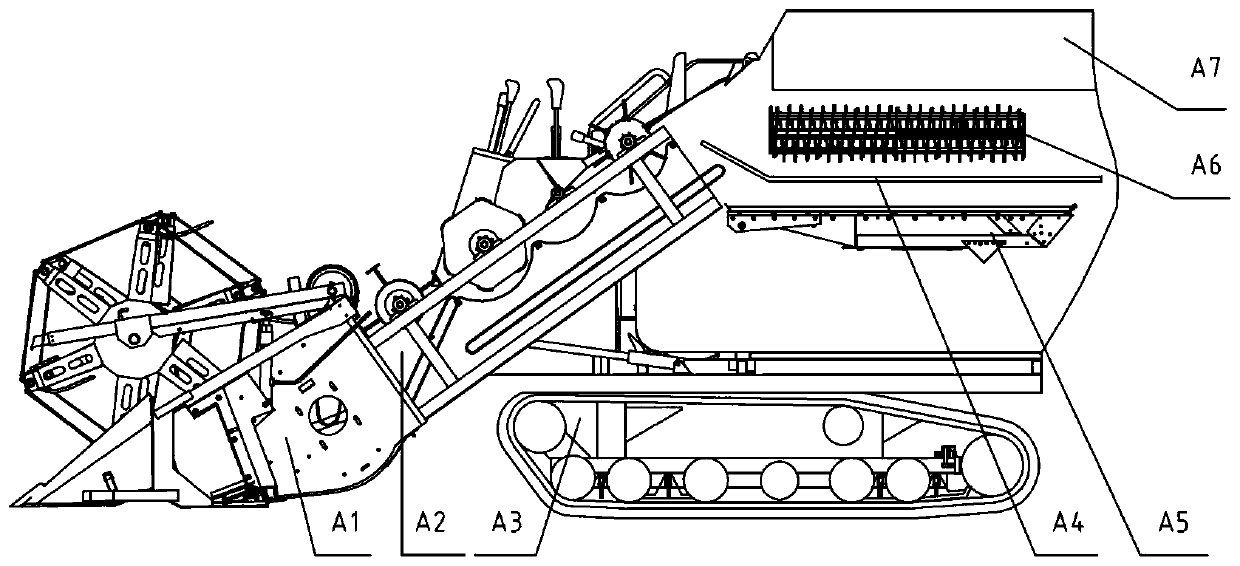

[0034] The multi-cut flow soybean combine harvester of the present embodiment is as figure 1 As shown, the front part of the crawler-type walking chassis A3 supports the bridge crossing device A2 hinged at the upper end through the top support hydraulic cylinder. The selection device consists of a straw conveying roller A6 conveyed along its axial direction, a concave screen A4 located under the straw conveying roller A6, a cleaning vibrating screen A5 located under the concave screen A4, and a grain box A7 is placed on the straw conveying roller A6.

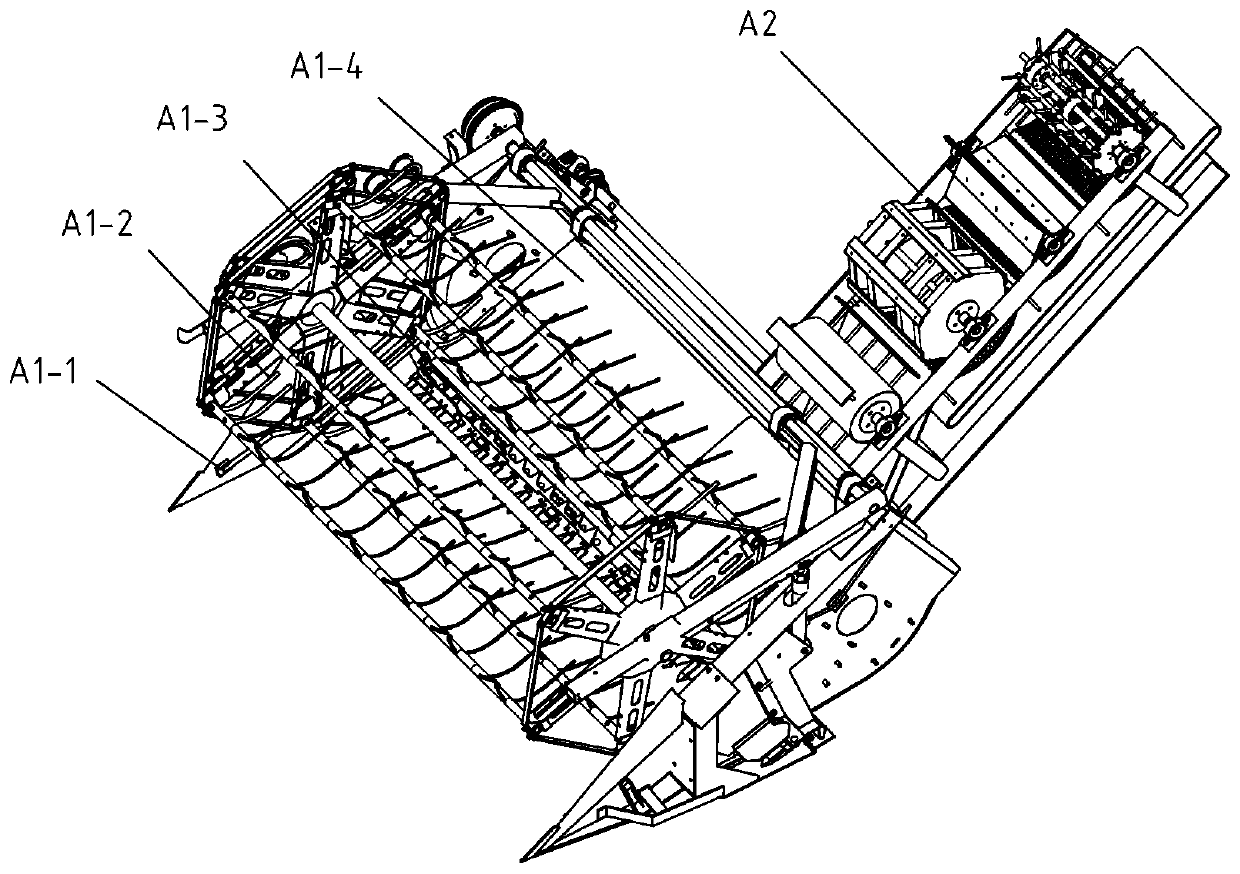

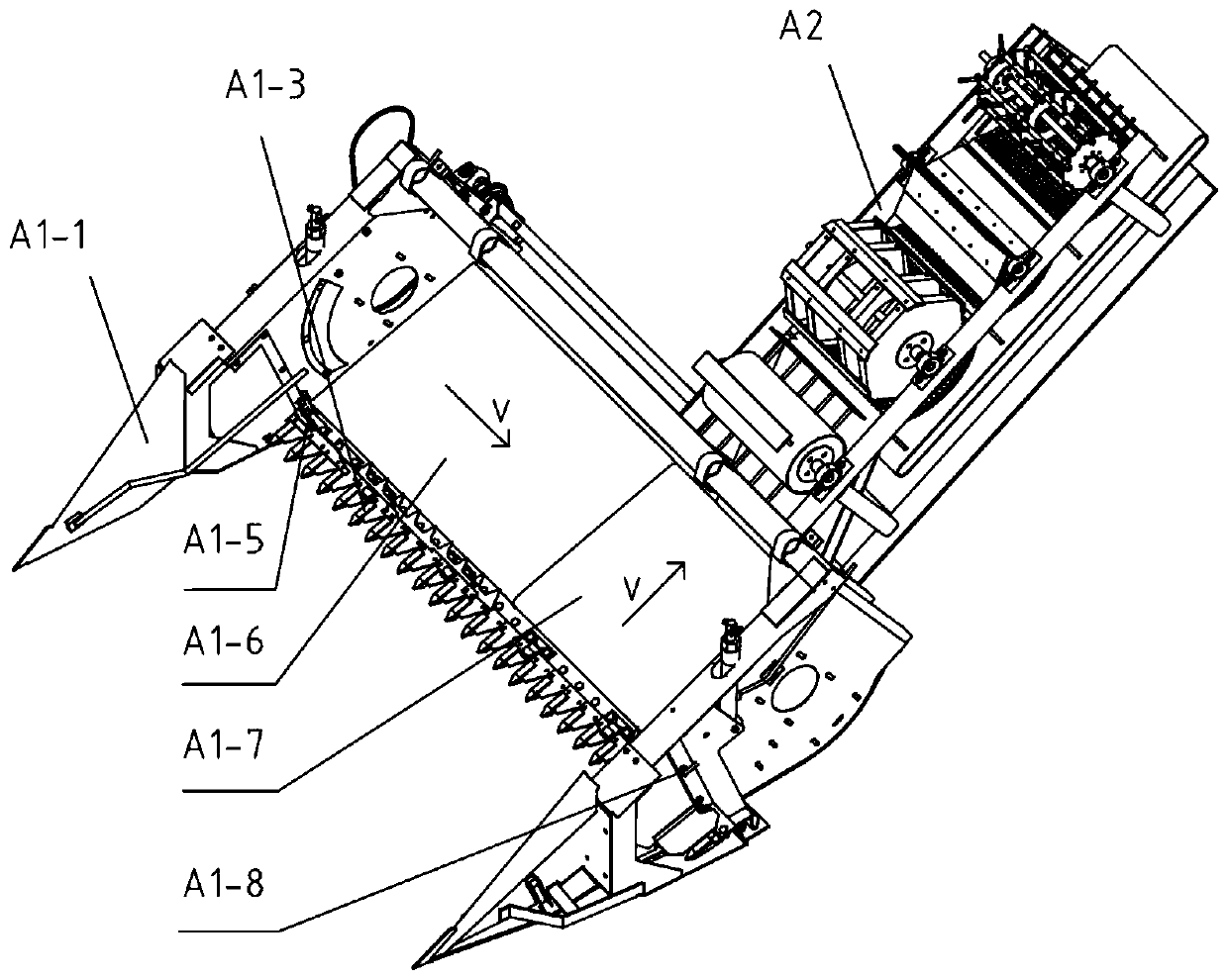

[0035] header A1 as figure 2 As shown, it contains the same two-sided triangular grain divider A1-1 as the prior art, the upper horizontal shaft reel A1-2, the bottom shaving cutter A1-3, and also contains the rear cutter A1-3 Conveying and feeding mechanism A1-4. Different from the traditional harvester header auger feeding mechanism, the conveyor belt feeding mechanism adopted in this embodiment is as follows: image 3 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com