Inside-to-outside air supply system assembled in industrial culture chamber

An air supply system, from the inside to the outside, is applied in the direction of control/regulation systems, instruments, non-electric variable control, etc., which can solve the problems of unfavorable factory farming, etc., and achieve the goal of promoting air circulation, speeding up air circulation, and improving survival rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

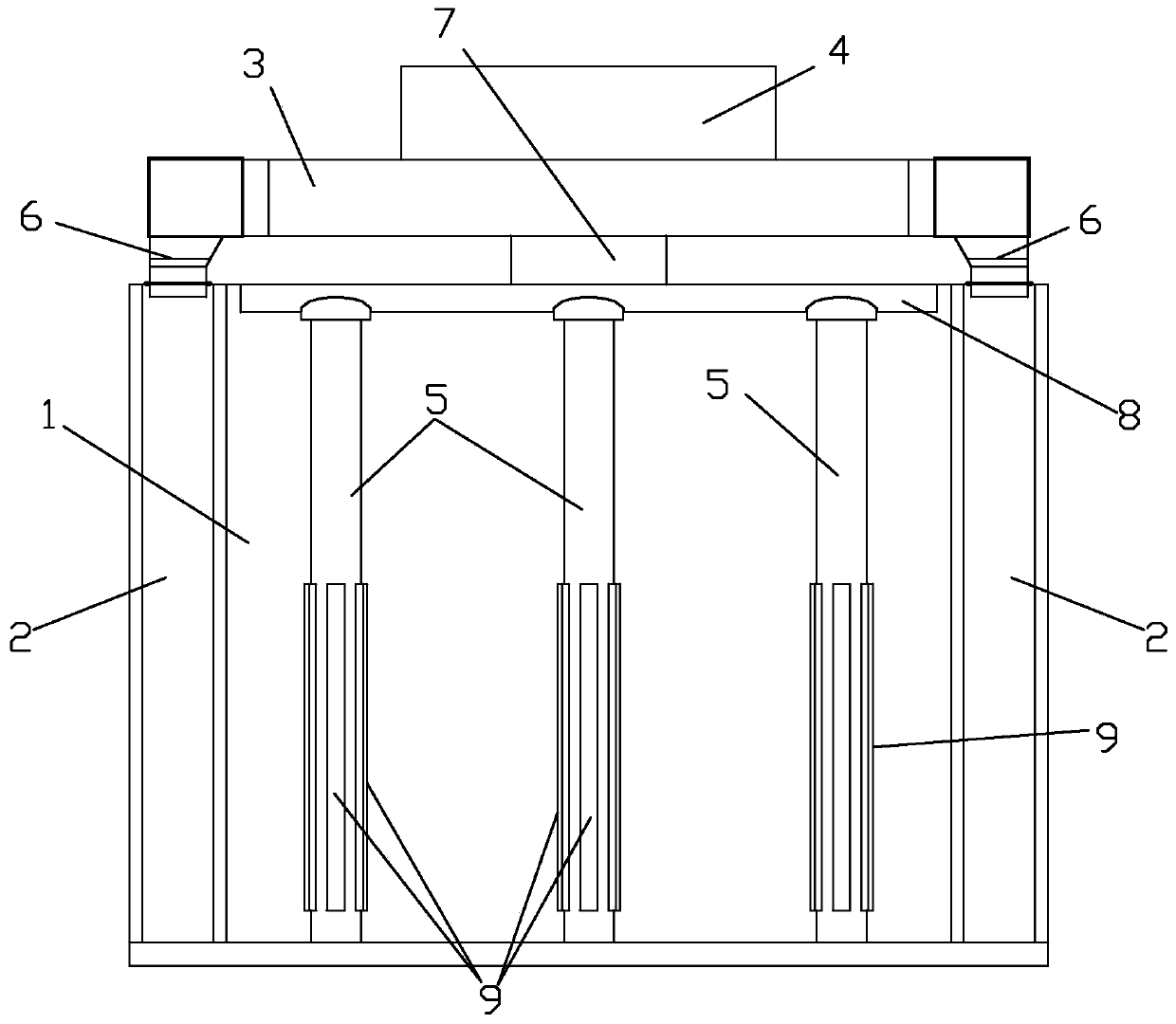

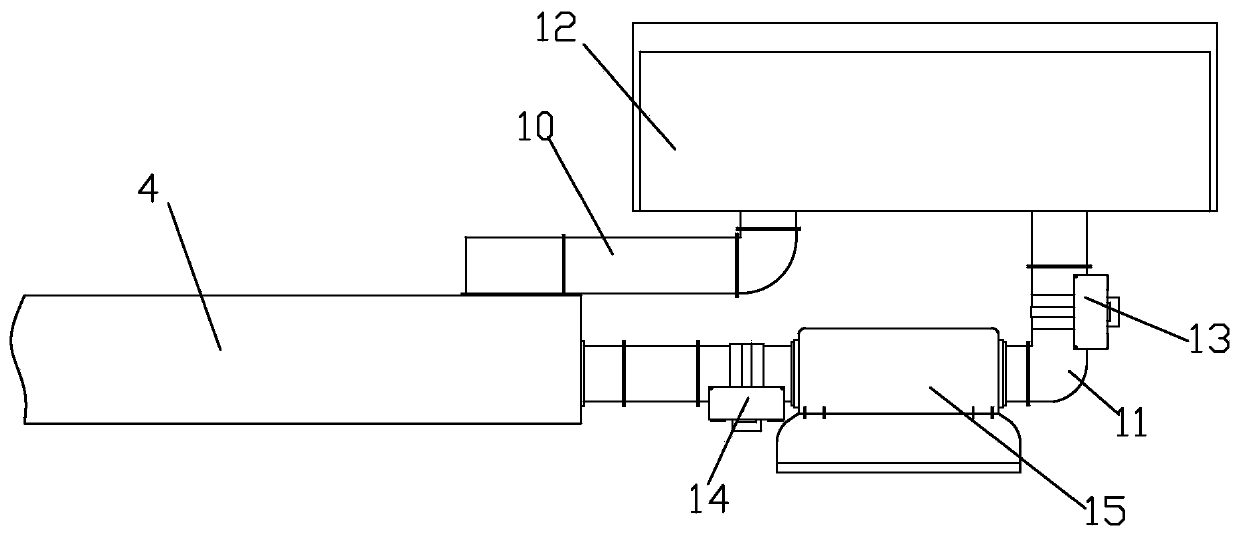

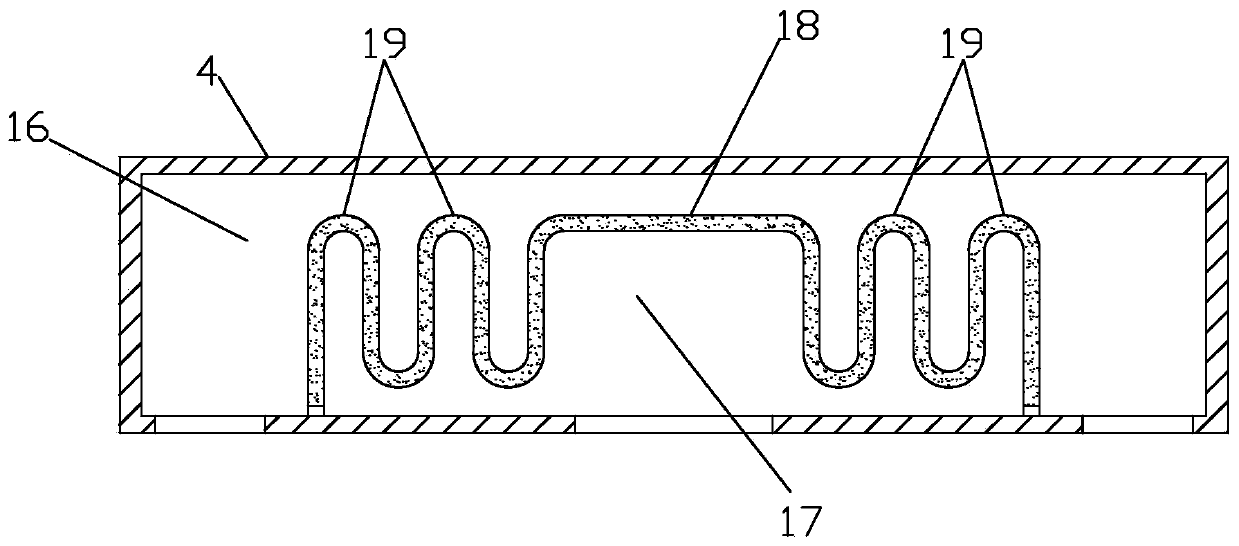

[0041] Such as Figure 1 to Figure 8 As shown, an inside-to-out air supply system assembled in a factory breeding room includes a fan box 12, an air inlet pipe 10, an air outlet pipe 11, an integrated air box 4 for sending back, a multi-pass air sending and returning pipe 3 and a sending and returning air duct 3. Wind column 5, fan box 12 are installed on one end of breeding chamber 1 top;

[0042] The front temperature and humidity sensor 13, the rear temperature and humidity sensor 14 and the temperature and humidity adjustment device 15 are installed on the air outlet pipe 11, the front temperature and humidity sensor 13 is installed close to the fan box 12, and the rear temperature and humidity sensor 14 is installed away from the fan box 12 , both the front temperature and humidity sensor 13 and the rear temperature and humidity sensor 14 can detect the air temperature and humidity in the air duct 11 . The temperature and humidity adjustment device 15 is installed betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com