Novel bag cage connection assembly and use method thereof

A technology for connecting components and bag cages, applied in the field of bag-cage connecting components, can solve the problems of poor connection stability, cumbersome operation, poor versatility of bag cages, etc., and achieve the effects of stable structure, simple operation and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

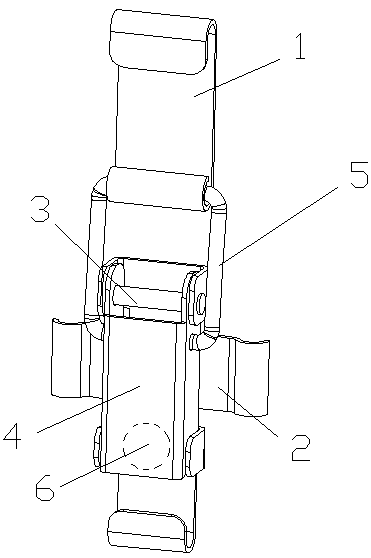

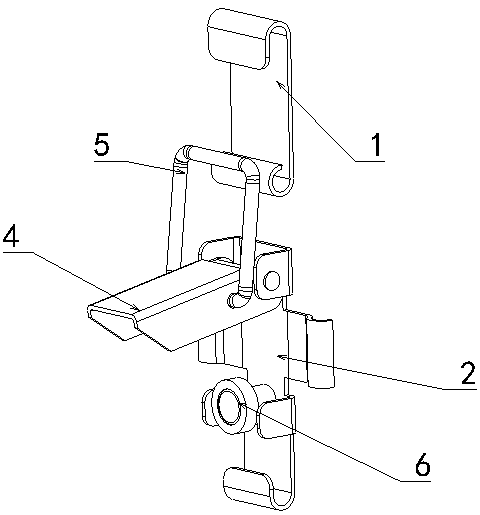

[0023] Embodiment 1: as Figure 1~9 As shown, in this embodiment, a new type of bag-cage connection assembly is provided, which includes a locking device for connecting adjacent bag cages. The locking device includes an upper hook 1, and the upper hook 1 is hooked On the bag cage, the lower hook 1 below is provided with the lower hasp hook 2 which is arranged on the bag cage, and the upper part of the lower hasp hook 2 is hinged with a hasp lock cover 4 via a rivet shaft 3. A square connecting rod 5 is arranged between the top of the hasp lock cover 4 and the bottom of the upper hook 1, the upper hook of the square connecting rod 5 is fixed below the upper hook 1, the bottom of the square connecting rod 5 runs through the hasp lock cover 4 and Swivel fit with hasp lock cover.

[0024] In this embodiment, the lower hasp hook 2 is welded with a magnetic element 6 that is in contact with the inner surface of the hasp lock cover, and the top of the magnetic element is connected t...

Embodiment 2

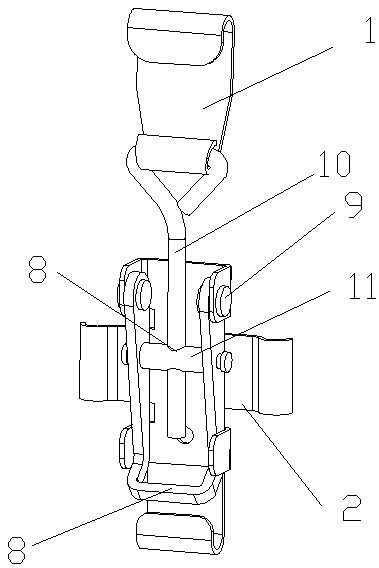

[0029] Embodiment 2: In this embodiment, the inside of the lower hasp hook 2 can also be provided with a hasp lock handle 8, and the upper and lower sides of the hasp lock handle 8 are connected to the upper two sides of the lower hasp hook 2 via rivets 9 respectively. The side is movable and hinged, and the lower hook of the upper hook is provided with a spacing fine-tuning screw 10, and the middle part of the hasp lock is fixedly connected with an eccentric shaft 11 horizontally, and the spacing fine-tuning screw is threadedly connected with the middle part of the eccentric shaft.

[0030] In this embodiment, the middle part of the eccentric shaft 11 has a threaded hole, the threaded hole has an internal thread, and the outer side of the end of the pitch fine-adjustment screw has an external thread that matches the internal thread, and the pitch fine-adjustment screw passes through the threaded hole and the eccentric shaft. connect.

[0031] In this embodiment, the setting o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com