A kind of anti-swelling two-dimensional layered film with controllable interlayer channel size, preparation and application

A two-dimensional layered, interlayer channel technology, applied in the direction of membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of resin encapsulation method process, complexity, etc., achieve low cost, improve swelling problem, repeat sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing a swelling-resistant two-dimensional layered film with controllable interlayer channel size of the present invention mainly includes:

[0026] Step 1, depositing two-dimensional nanosheets on the surface of the substrate to obtain an undisturbed layered film;

[0027] Preferably, the two-dimensional nanosheet suspension is deposited on the surface of the substrate by suction filtration, spin coating or spray coating; the substrate is preferably a polyvinylidene fluoride film, a mixed cellulose ester film, a polypropylene film or an anodized aluminum filter membrane, The pore size of the substrate is 50-450nm.

[0028] Wherein, the preparation of the suspension of two-dimensional nanosheets is an existing traditional preparation method, and the preparation method in the following examples is preferred. The two-dimensional nanosheets of the present invention can be selected from graphene oxide nanosheets, MXene nanosheets, clay material nanosheets ...

Embodiment 1

[0035] Step 1, add 1g lithium fluoride to 20mL6M hydrochloric acid, stir and dissolve to obtain etchant solution, then add 1gTi 3 AlC 2 After reacting for 36 hours, the reaction product was repeatedly washed with deionized water until the pH of the solution was greater than 5; the suspended liquid with a pH greater than 5 was centrifuged at 3500 rpm for 1 h to obtain a stable Ti 3 C 2 nanosheet suspension; adopt vacuum filtration to make Ti 3 C 2 T x The nanosheets were regularly deposited on the polyvinylidene fluoride film with a pore size of 220 nm, and dried at room temperature to obtain the original Ti 3 C 2 T x film.

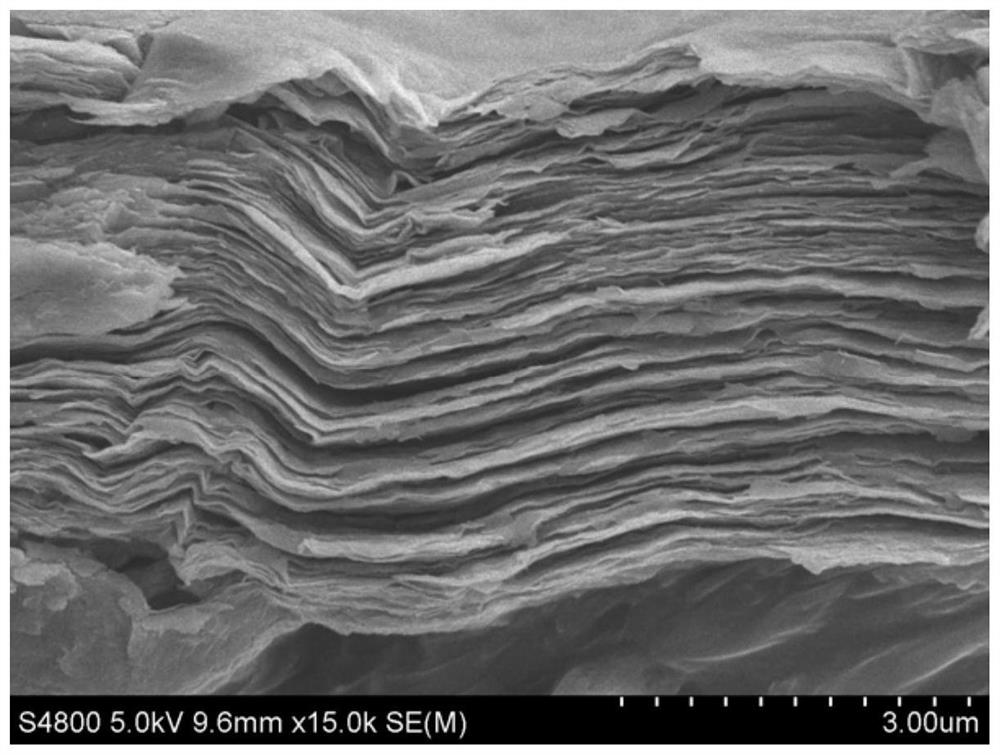

[0036] The cross-sectional view of the undisturbed film prepared in this embodiment is as follows figure 1 As shown, it can be seen that the nanosheets are stacked on the surface of the substrate by layer-by-layer parallel contact.

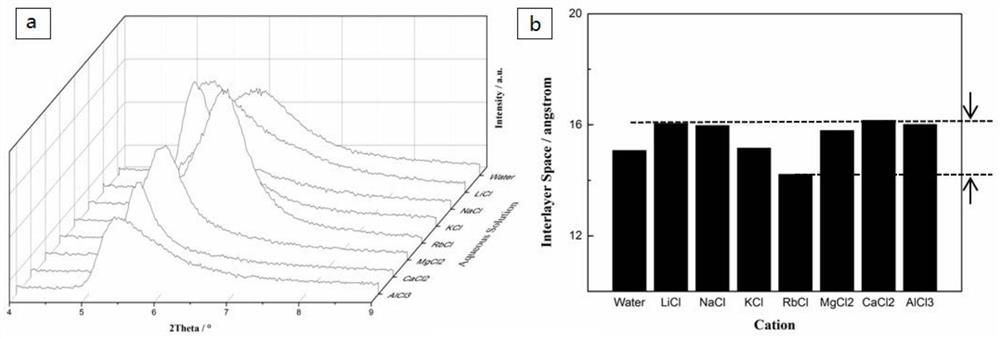

[0037] Step 2, the original state Ti 3 C 2 T x The film is soaked in sodium chloride solution for 2 hours, taken...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is that the solvent used in step 2 of this embodiment is aluminum chloride.

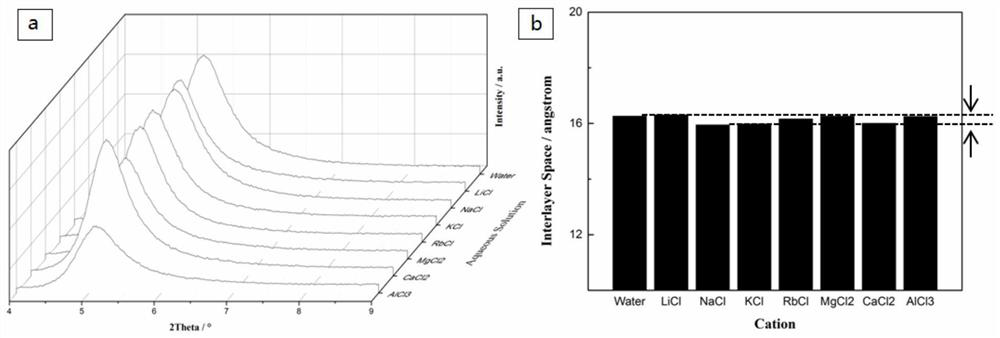

[0049] The two-dimensional layered film prepared in this example maintains good swelling resistance, the interlayer spacing is stable at 1.95nm, and the Na + The speed of the permeable film increases by about 3% relative to Example 1, and the Mg 2+ The permeation rate increased by about 7% relative to Example 1, which is more conducive to the realization of Na + , Mg 2+ separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com