Residual sand collection and treatment system of 3D printer

A 3D printer and processing system technology, used in foundry molding equipment, molds, cores, etc., can solve the problem that residual sand and loose sand cannot be cleaned in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The 3D printer residual sand collection and processing system of the present invention will be described in detail below with specific embodiments in conjunction with the accompanying drawings.

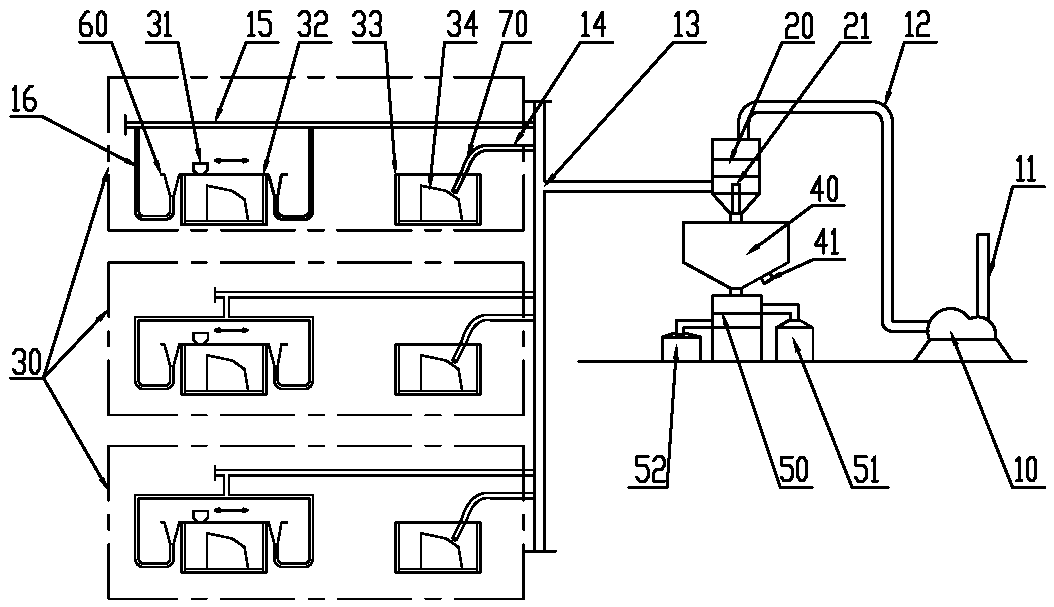

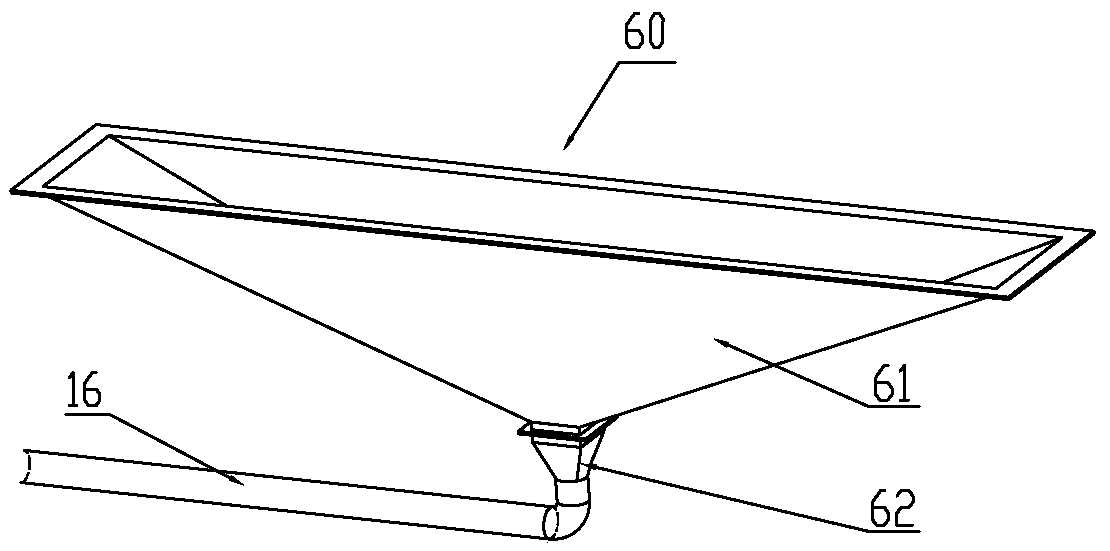

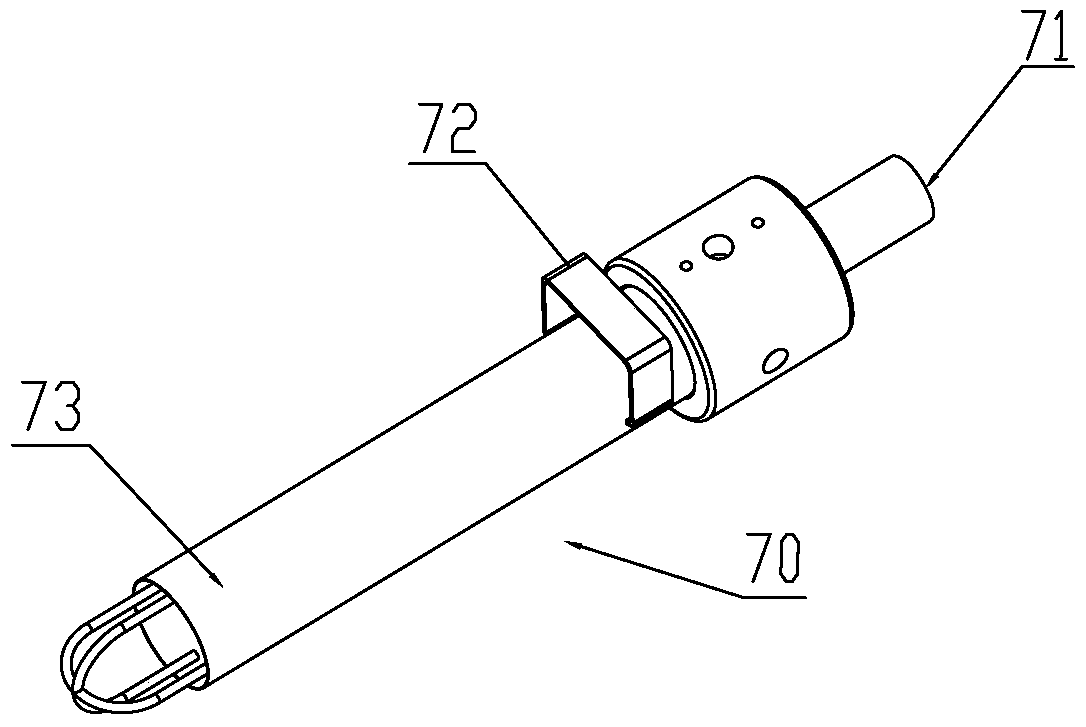

[0021] like figure 1 — Image 6 Shown is the 3D printer residual sand collection and processing system of the present invention, including a number of 3D printers 30 arranged on the sanding printing station, each 3D printer 30 is provided with a working box 32 under the sanding device 31, each working Both sides of the box 32 along the sand laying direction are respectively provided with receiving troughs 60, and the sand cleaning stations corresponding to each 3D printer 30 are respectively equipped with several hand-held sand suction guns for sucking loose sand in each full box working box 33 70; the discharge port 62 and the sand suction gun 70 at the bottom of the receiving tank 60 are connected to the sand suction main pipeline 13 through the suction branch pipe 15 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com