Multi-functional support device for middle bench body processing of high-speed precision punching machine

A support device and precision punching technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems affecting the machining accuracy of parts and the decrease in accuracy assurance, so as to reduce the probability of damage, ensure machining accuracy, and use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

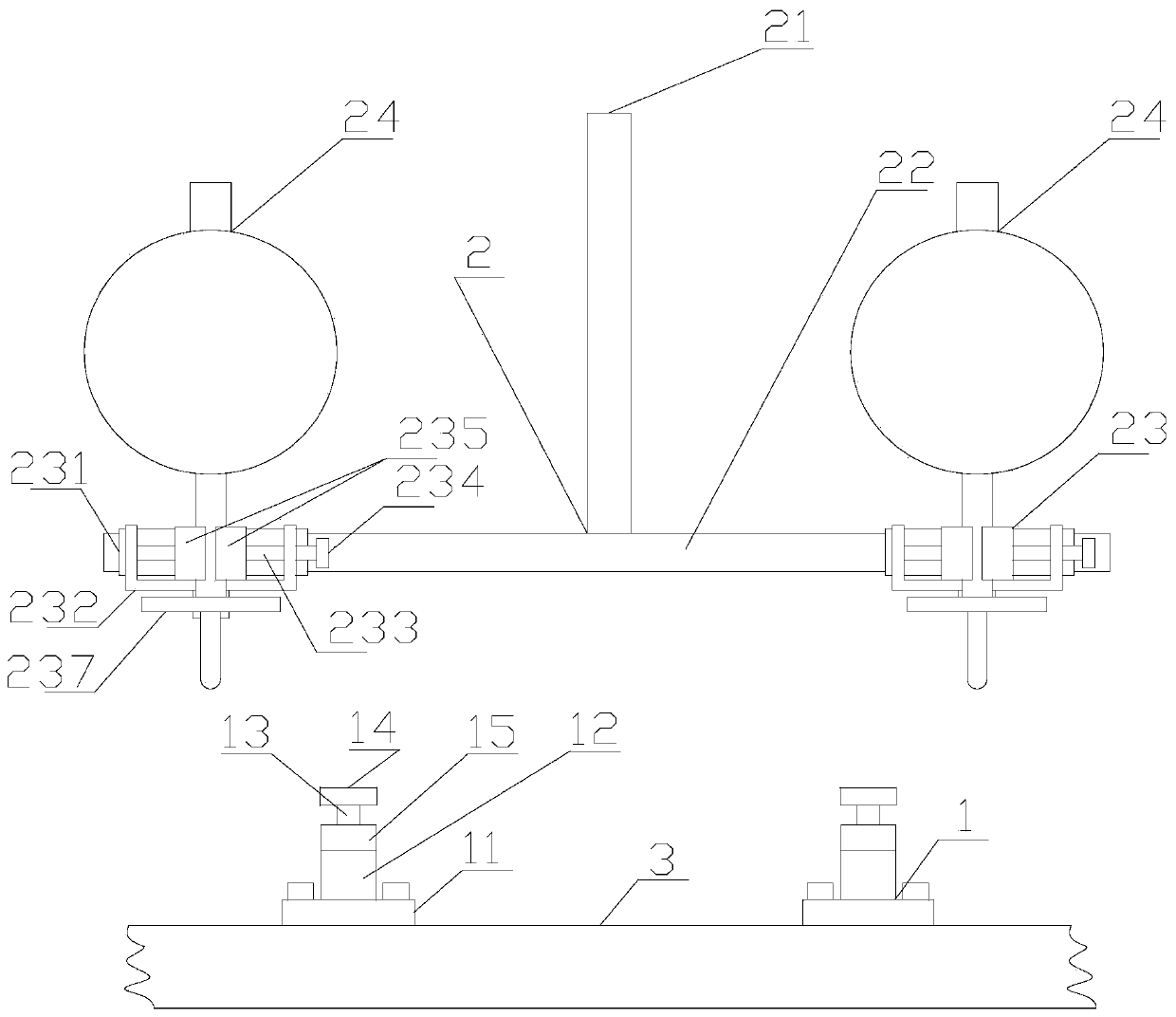

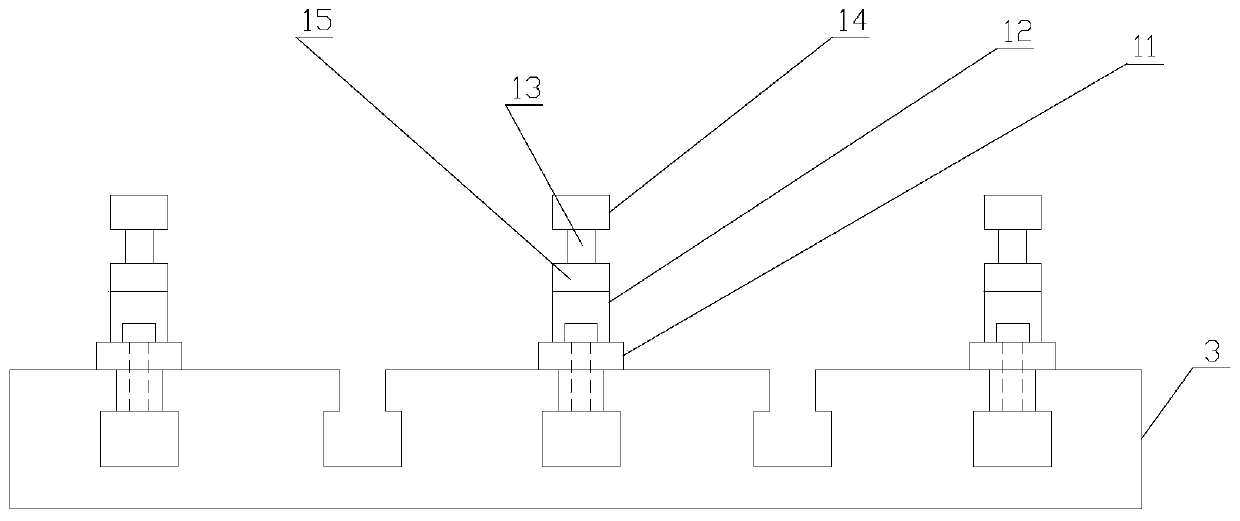

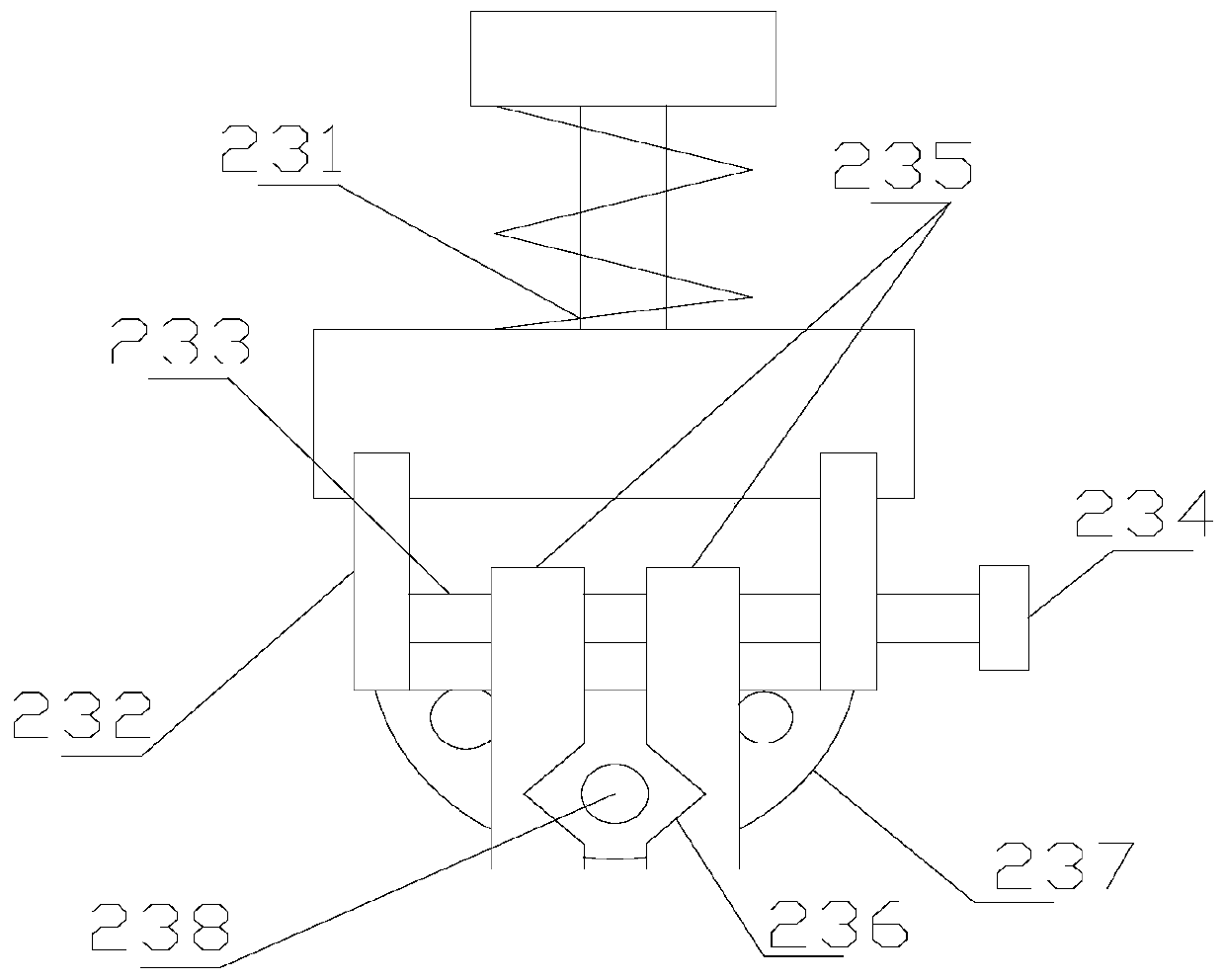

[0016] refer to figure 1 , figure 2 , image 3 with Figure 4 , the present invention is a kind of multi-functional support device for the processing of the middle body of a high-speed precision punching machine, which includes several support mechanisms 1 and leveling mechanisms 2, and all the support mechanisms 1 are fixedly installed on the workbench 3 of the machining center. The leveling mechanism 2 is used to adjust the ends of all the support mechanisms 1 away from the workbench 3 to the same plane, and the support mechanism 1 includes a lower base 11, a sleeve body 12, a screw body 13, an upper base 14 and a fastening nut 15 , the lower base 11 is fixedly connected with the workbench 3 by fastening bolts, the upper end of the lower base 11 is provided with a sleeve body 12, and the sleeve body 12 is provided with a threaded screw body 13, and the screw body 13 There is a fastening nut 15 pressed on the upper end of the sleeve body 12, the upper end of the screw bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com