Circulating ink path system for ink-jet printer and ink path circulating method

An inkjet printer and ink path technology, applied in printing and other directions, can solve problems such as pipeline blockage and printer ink failure, and achieve the effect of improving use efficiency, saving cleaning costs, and avoiding pipeline blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

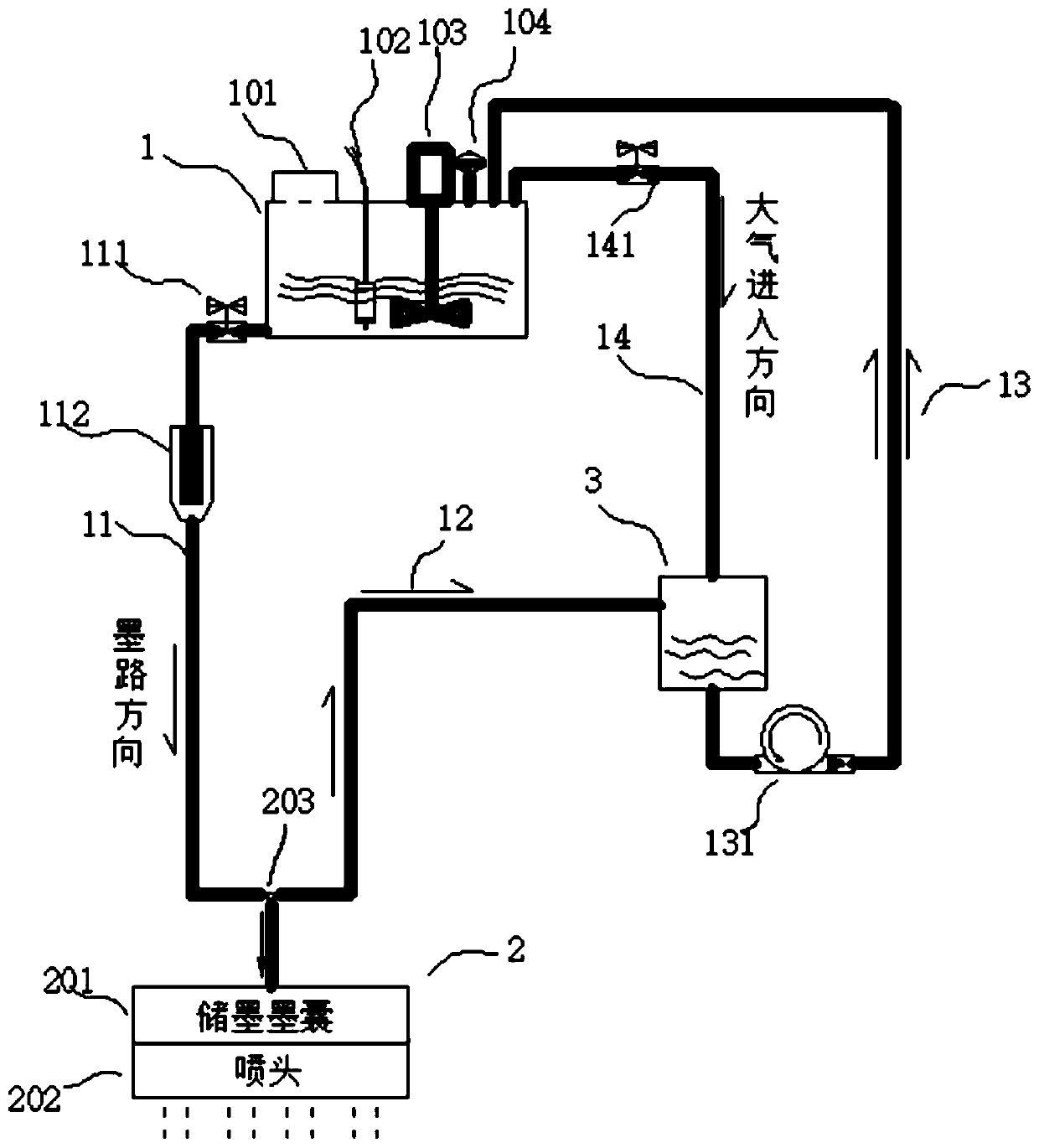

[0037] An ink circulation system and an ink circulation method for an inkjet printer according to the present invention will be described with reference to the accompanying drawings.

[0038] Such as figure 1 Shown, as preferred embodiment of the present invention:

[0039] from figure 1 It can be seen that a circulating ink system for an inkjet printer may include an ink storage bottle 1, an inkjet assembly 2, a return ink bottle 3, a first feeding pipeline 11, a second feeding pipe Road 12, the third feeding pipeline 13, the fourth feeding pipeline 14;

[0040] The ink storage bottle 1 is provided with an ink filling port 101, and is arranged at a corner above the ink storage bottle 1 to facilitate the injection of ink;

[0041] The inkjet assembly 2 includes an ink bag 201 temporarily storing ink and a nozzle 202, and the ink bag 201 has a T-shaped pipe member 203 communicating with the pipeline;

[0042] The return ink bottle 3 is used to store the remaining ink consum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com