Nut screw type automobile transporting device

A car carrier and screw-type technology, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems of poor chain transmission reliability and maintainability, which is not conducive to the normal operation of the car carrier, and increases the overall thickness of the carrier. Achieve the effects of wide application range, convenient maintenance and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

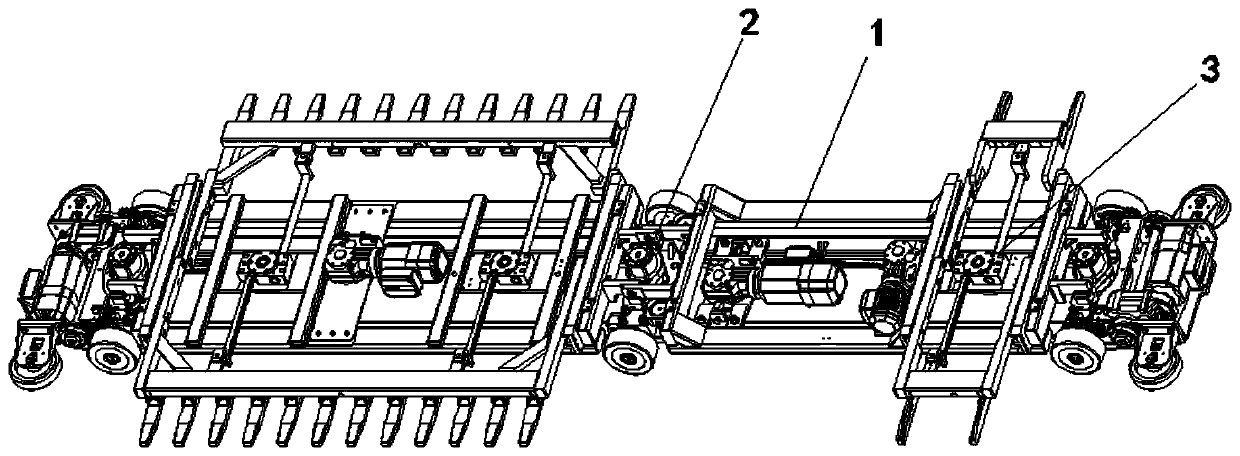

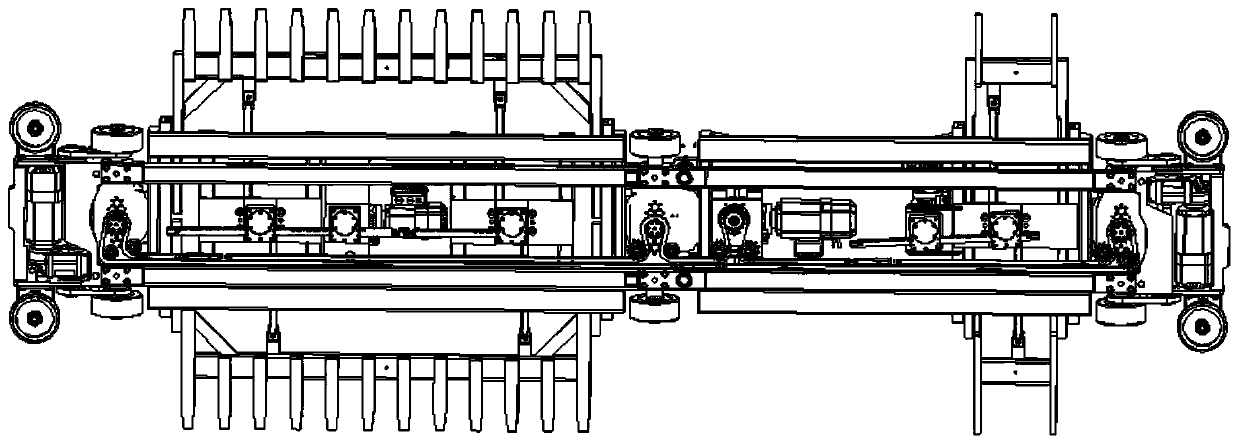

[0039] see Figure 1-2 , a nut screw type vehicle carrier, comprising a carrier, a lifting bracket arranged on the upper side of the carrier and a deployment mechanism 3 arranged on the upper side of the lifting bracket 1; the lifting bracket 1 includes a front upper frame and a rear upper frame, and the front The upper shelf and the rear upper shelf are correspondingly equipped with a jacking mechanism 2 for jacking;

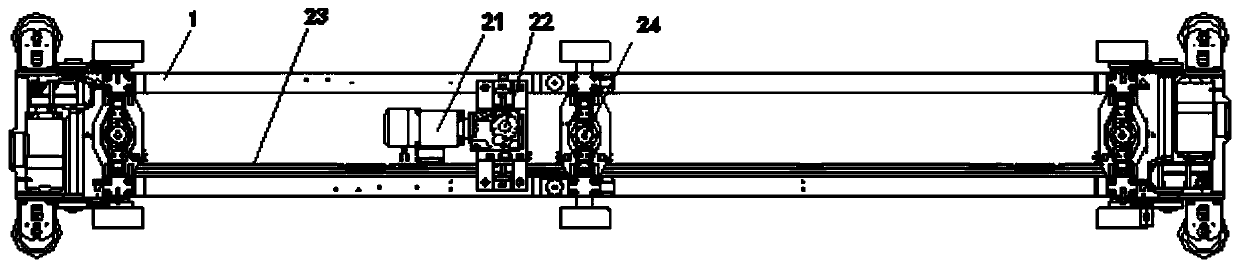

[0040] see Figure 1-4 , the jacking mechanism 2 includes a jacking motor 21, a jacking drive gear assembly 22, a chain 23, a nut screw 24 and a jacking driven sprocket 241, and the output end of the jacking motor 21 is connected to the jacking drive gear assembly 22 transmission connection, the jacking drive gear assembly 22 is transmission connected with the jacking driven sprocket 241 through the chain 23, and the jacking driven sprocket 241 is transmission connected with the input end of the nut screw 24; the nut screw There are three groups of rods 24 an...

Embodiment 2

[0053] The same as the first embodiment, the difference is that the lower end of the nut screw is located on both sides of the jacking driven sprocket and auxiliary sprockets are symmetrically arranged, and the auxiliary sprockets are matched with the chain, so that the setting can play a role of guiding tension , to prevent the chain from falling off, thereby improving its reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com