Bridge guardrail template removing device

A technology for removal and formwork, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of high risk of demolition and installation operations, low efficiency of formwork removal and installation, and improve the efficiency of formwork removal and stability and reliability, the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] The present invention will be further explained below in conjunction with the drawings and specific embodiments:

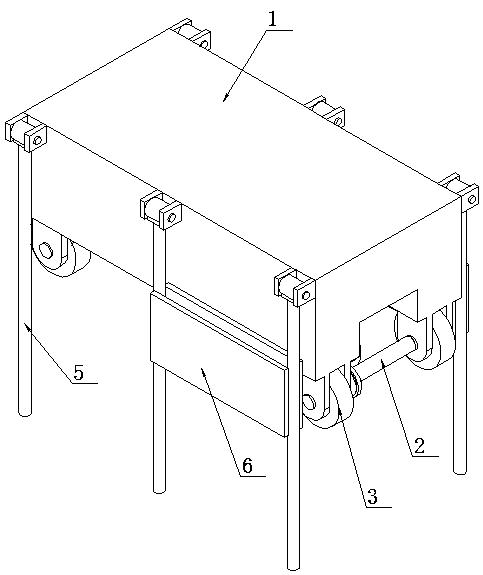

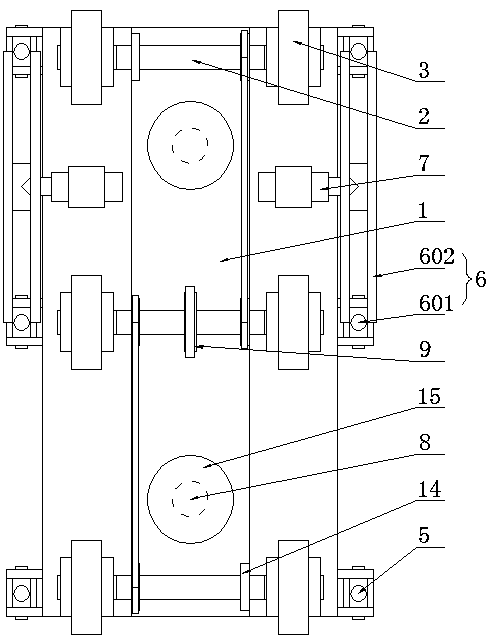

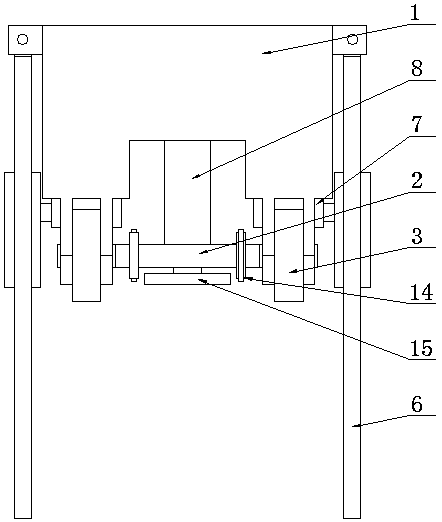

[0029] Such as Figure 1~Figure 7 As shown, a bridge guardrail template removal device includes a frame body 1, a walking component, a template fixing component, and a jacking component, and the walking component and the jacking and jacking component are located at the lower part of the frame 1. The template fixing components are located on both sides of the frame body 1;

[0030] The frame body 1 is a hollow shell;

[0031] The walking assembly is composed of a walking shaft 2, a walking wheel 3 and a walking motor 4. The walking shaft 2 is located under the frame 1 and is rotatably connected with the frame 1. The walking shafts 2 are arranged in a uniform array along the length of the frame 1. There are multiple, the traveling wheels 3 are fixedly arranged at both ends of the traveling shaft 2, the traveling motor 4 is fixedly installed inside the frame 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com