Double-station automatic assembling mechanism for comb tooth bead heads and using method of double-station automatic assembling mechanism

An automatic assembly and double-station technology, which is applied in the field of mechanical processing, can solve the problems of reducing manual operation costs, increasing the repair rate, and the bead head is not round enough, so as to save cycle time, stabilize the operation cycle, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

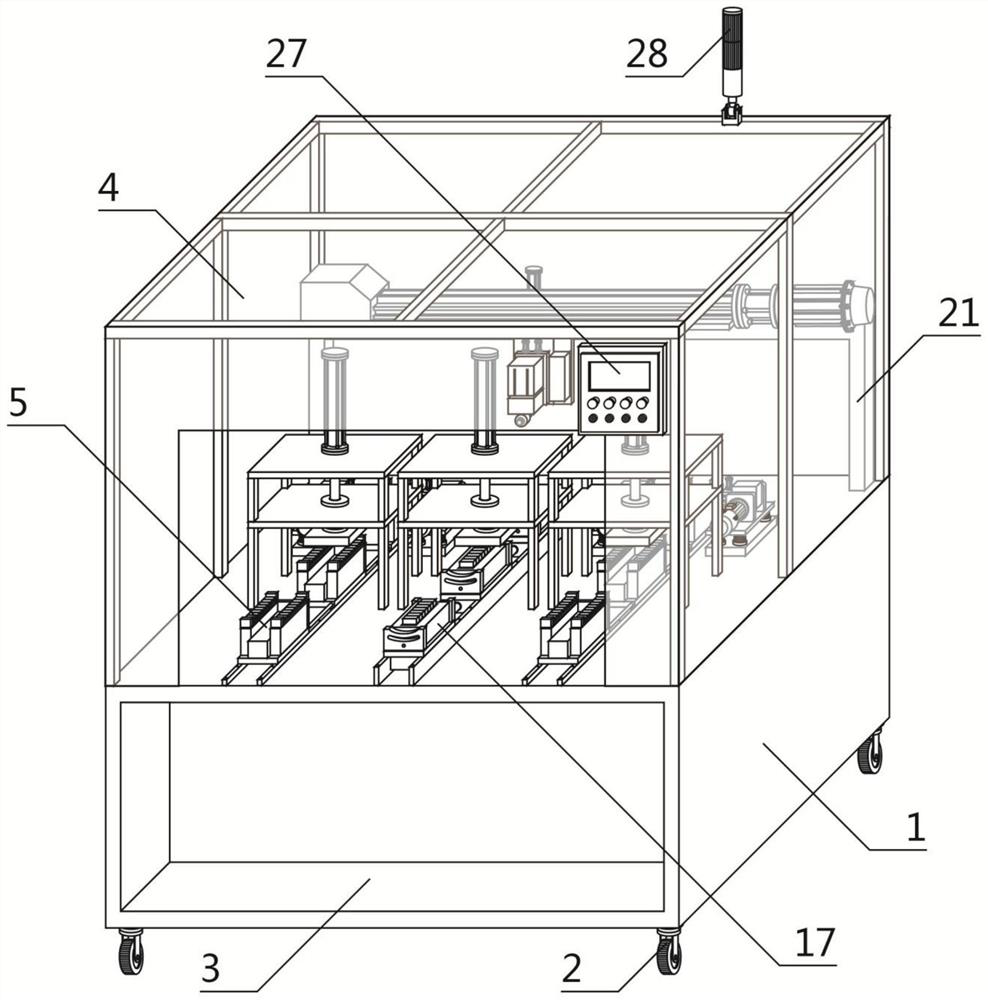

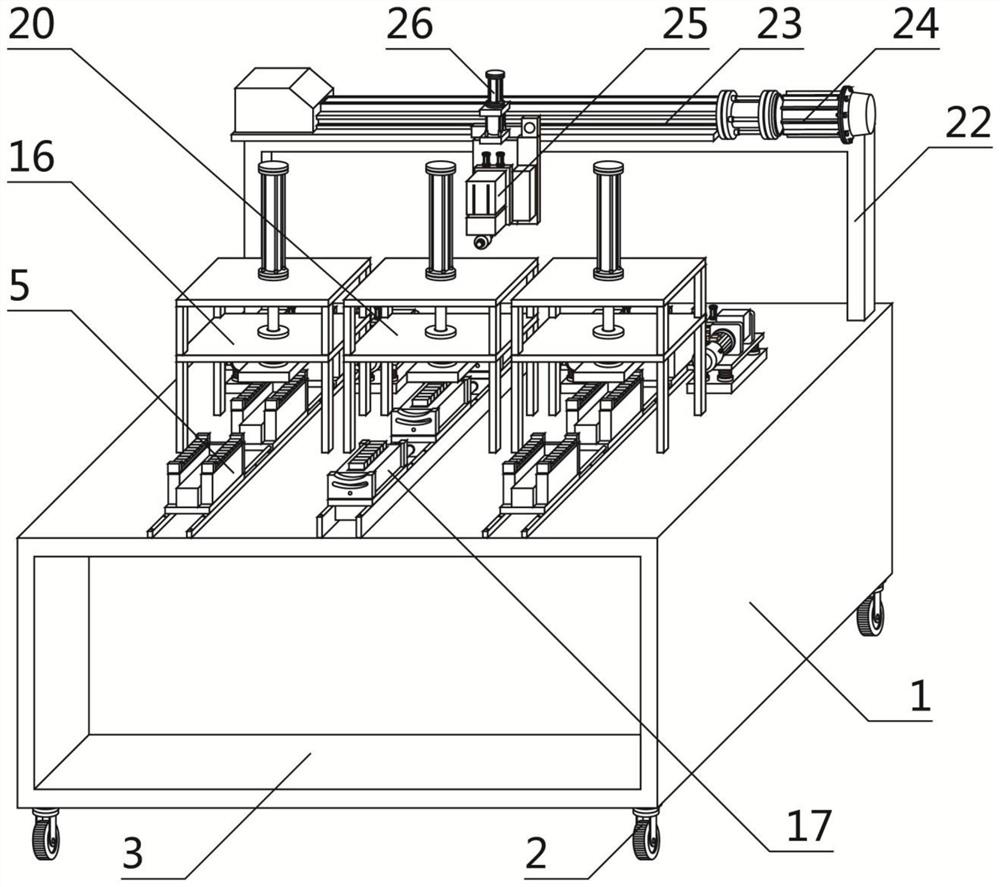

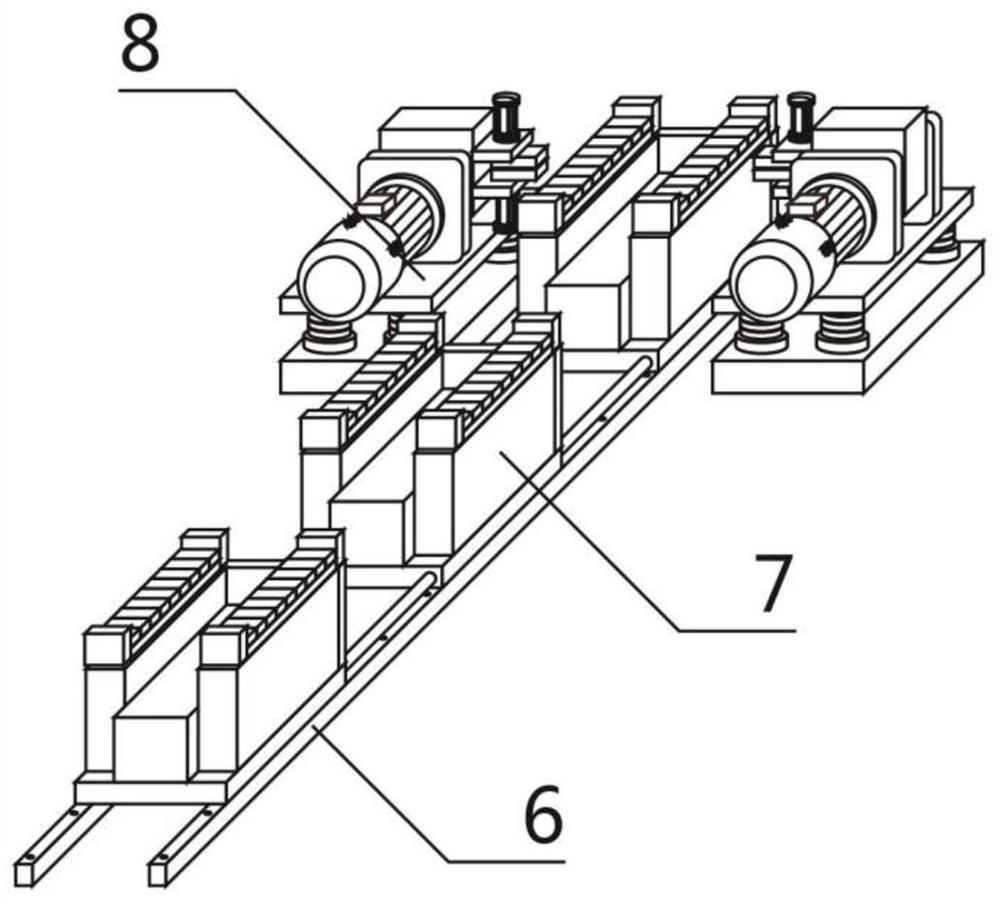

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6Shown is a double-station automatic assembly mechanism for comb teeth, which is characterized in that it consists of an electric control cabinet 1, a protective cover 4, two eager cutting modules 5, a pre-insertion pressing module 17, and a handling and clamping module. It consists of a pre-inserted module 21, a touch screen 27 and an indicator light 28. The electric control cabinet 1 is also provided with four rollers 2 and an operation groove structure 3. The four rollers 2 are respectively located at the four corners of the bottom of the electric control cabinet 1. position, the four rollers 2 are fixedly connected with the electric control cabinet 1, the operation groove structure 3 is located on one side of the electric control cabinet 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com