Noise reduction dual-cylinder synchronous air compressor

An air compressor and noise reduction technology, applied in mechanical equipment, machines/engines, liquid variable volume machinery, etc., can solve problems such as insufficient compression efficiency and high noise, and achieve reduced loudness, high speed, and large air supply. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

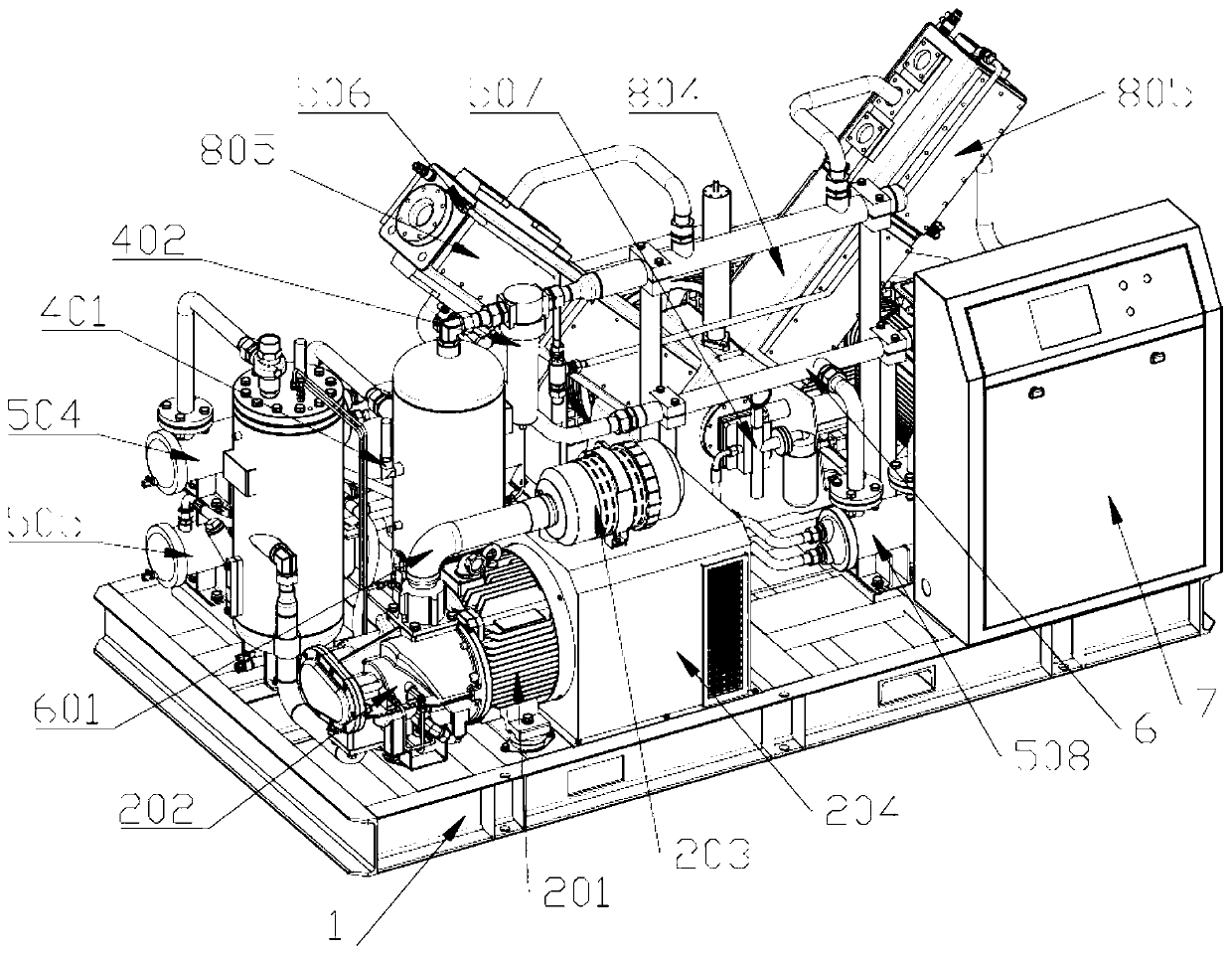

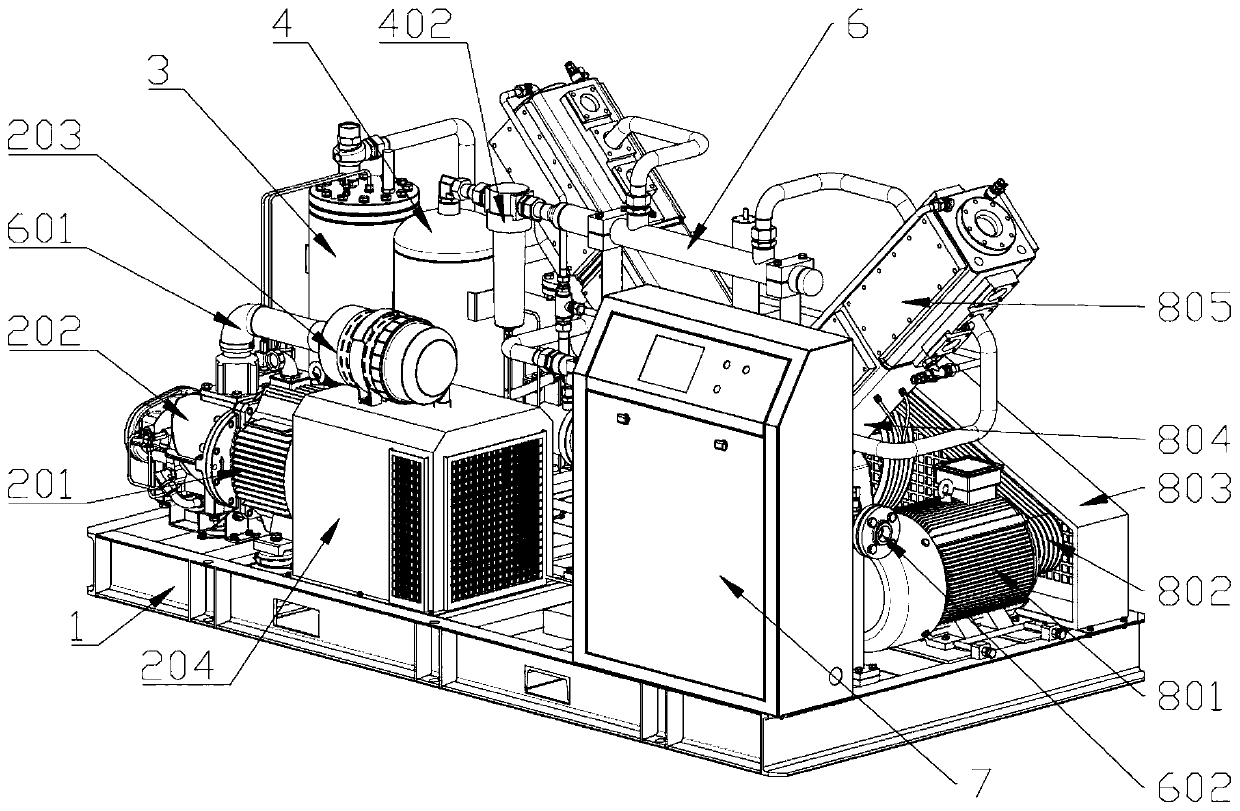

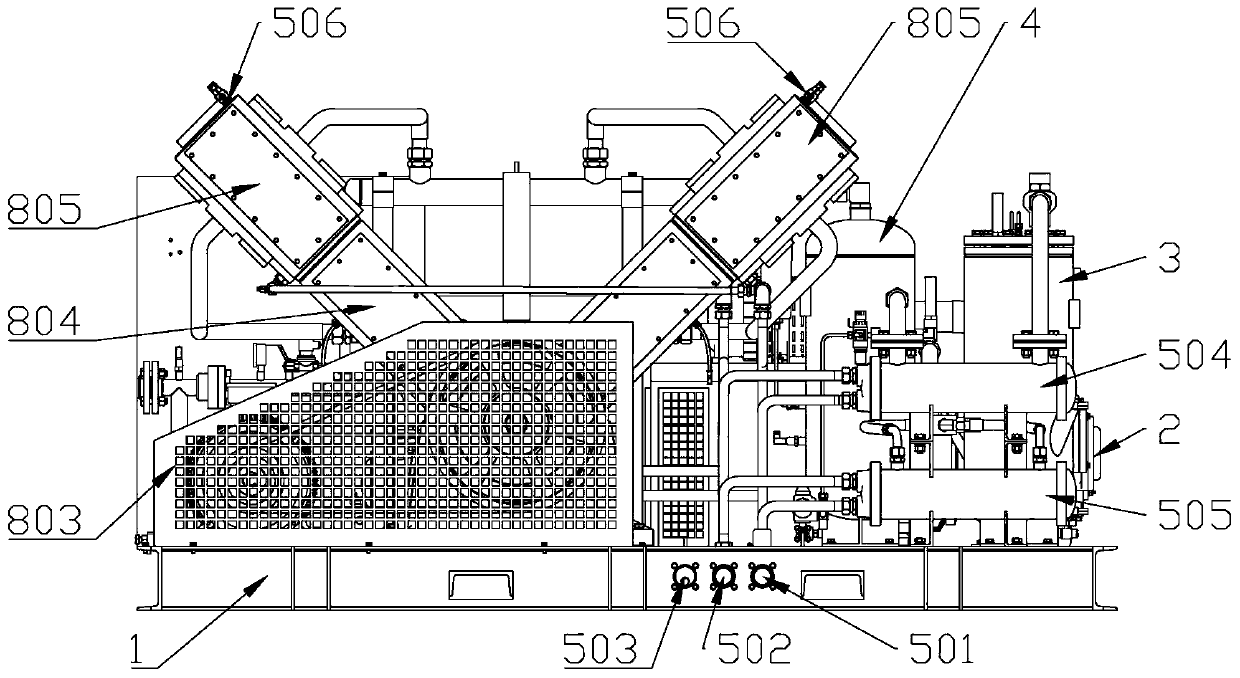

[0026] see Figure 1 to Figure 5 , the present invention is a noise-reducing double-cylinder synchronous air compressor, including a first-stage supercharging assembly 2, a second-stage supercharging assembly 8, and an integrated cooling assembly 5. The following is one embodiment of the present invention.

[0027] The two-stage supercharging assembly 8 includes a second electric motor 801, a crank transmission unit 804 and two two-stage compression pumps 805. The crank transmission unit 804 includes two synchronous crank transmission rods whose lower ends intersect in a V shape. The power part of the two-stage compression pump 805 is connected, and a belt transmission unit 802 is provided between the second motor 801 and the crank transmission unit 804. The crankshaft at the intersection of the crank transmission rod and the rotating shaft of the second motor 801 are respectively provided with pulleys, and the two pulleys Connected by belt rotation. The outer side of the bel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap