Patents

Literature

34results about How to "Reduce loudness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

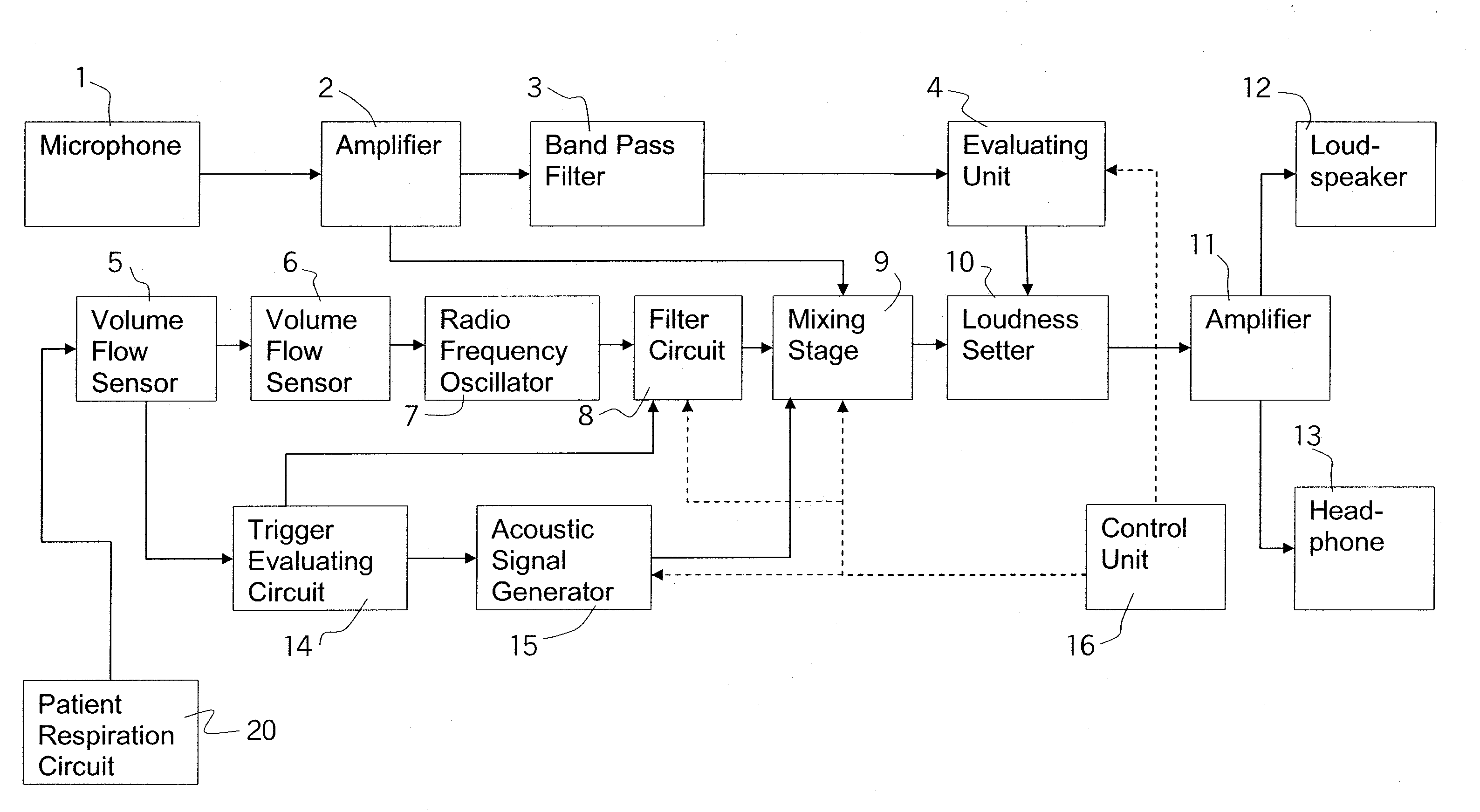

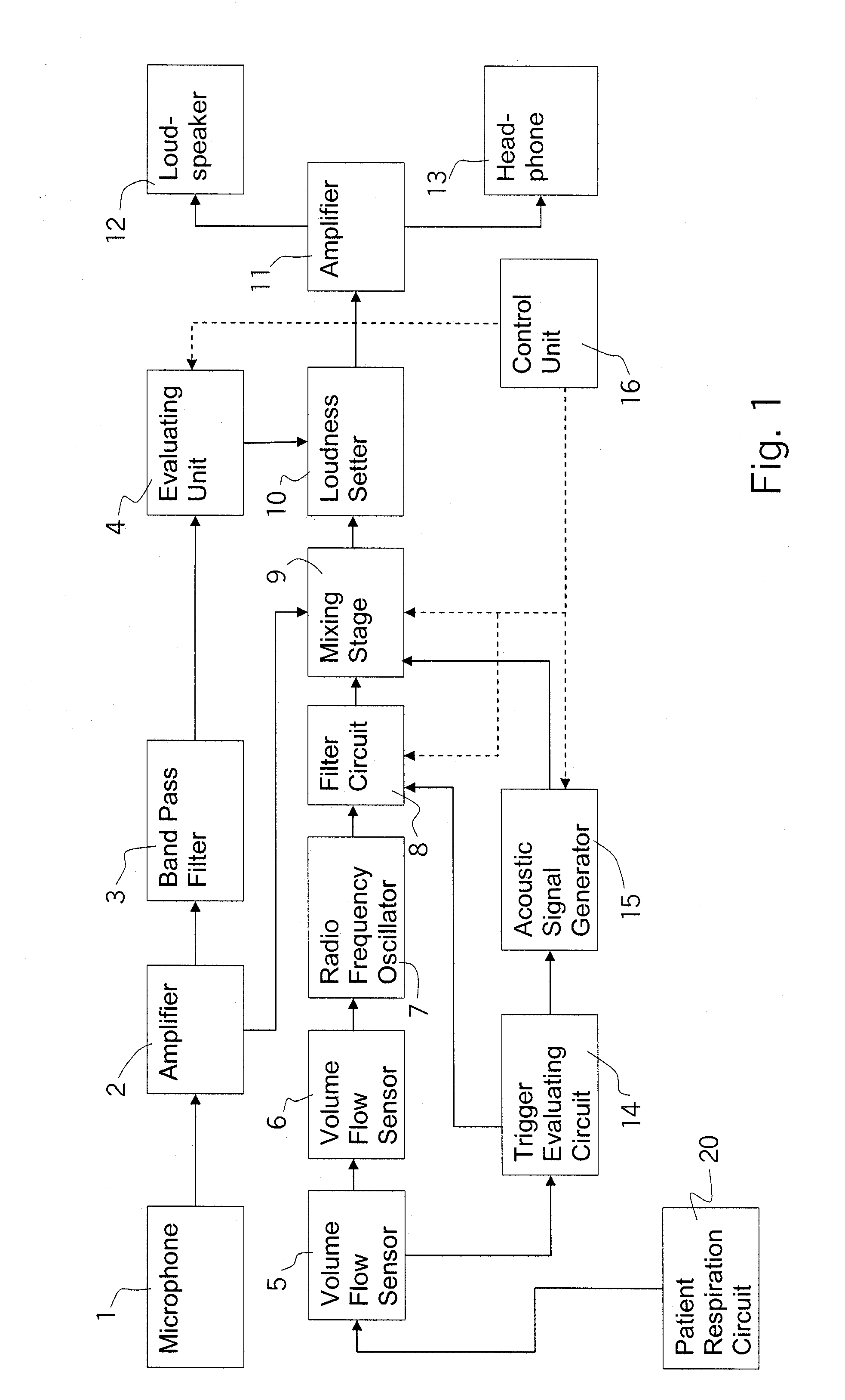

Device for acoustically reproducing the respiratory function for a respirator

InactiveUS20070208267A1Improve respiratory functionEasy detectionRespiratorsRespiratory organ evaluationRespiratorMedicine

A device is provided for acoustically reproducing the respiratory function for a respirator, with a patient respiration circuit. The device has a noise generator, a volume flow sensor device, which determines the volume flow in the patient respiration circuit and generates an electric signal representing the volume flow, and a volume flow evaluating unit, which is set up to pick up the volume flow signal and to generate a control signal for the noise generator as a function of this in such a way that an acoustic signal with a loudness rising (falling) with rising (falling) volume flow is generated. To optimize the loudness of the acoustic signal, a microphone and an evaluating unit connected thereto are provided, which said evaluating unit is set up to generate at least a first measure for the instantaneous ambient noise level on the basis of the microphone signal by averaging over at least one period of time and to increase (reduce) the loudness of the acoustic signal with rising (falling) ambient noise level as a preset monotonic function of the at least one measure.

Owner:DRAGERWERK AG

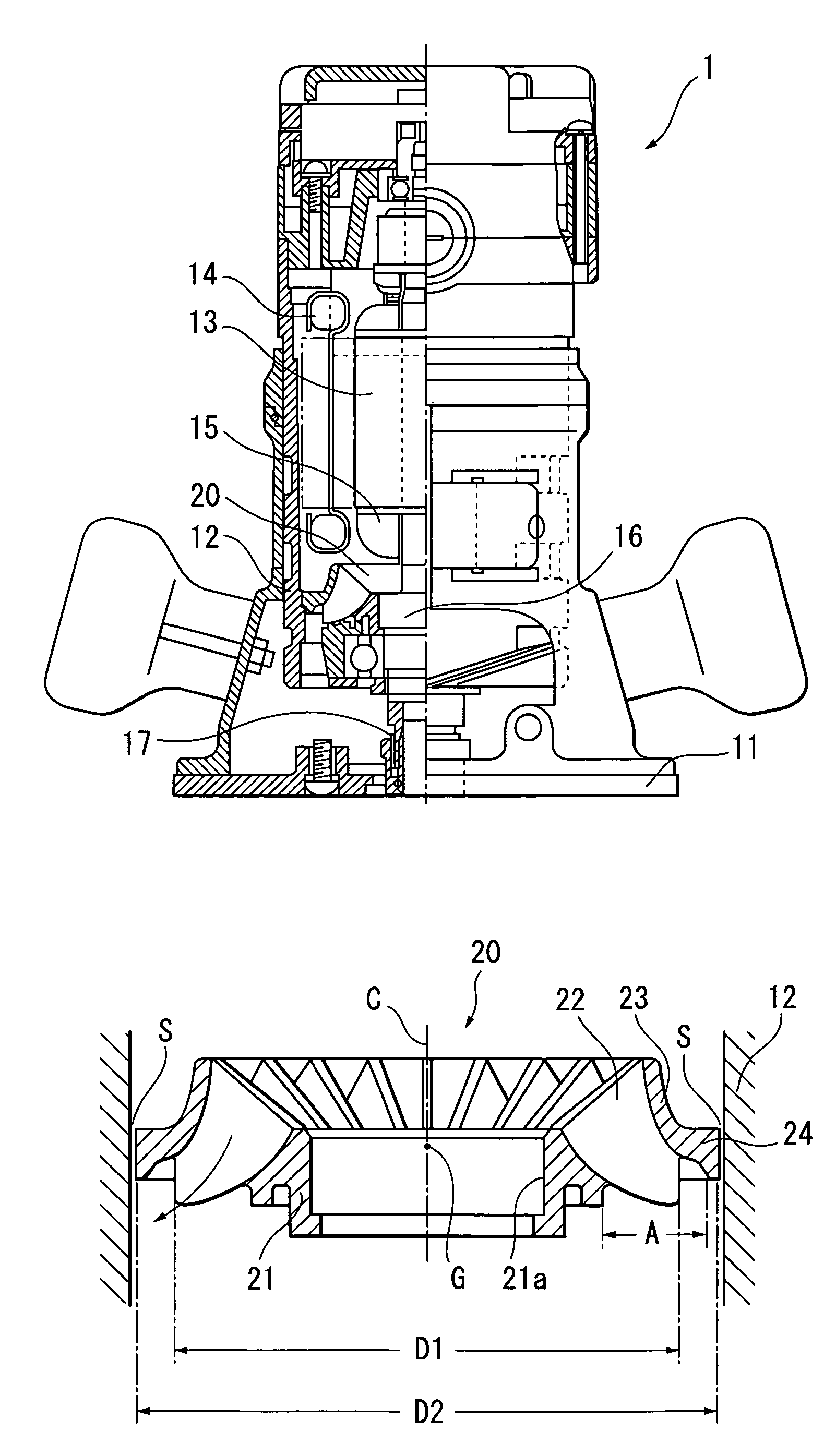

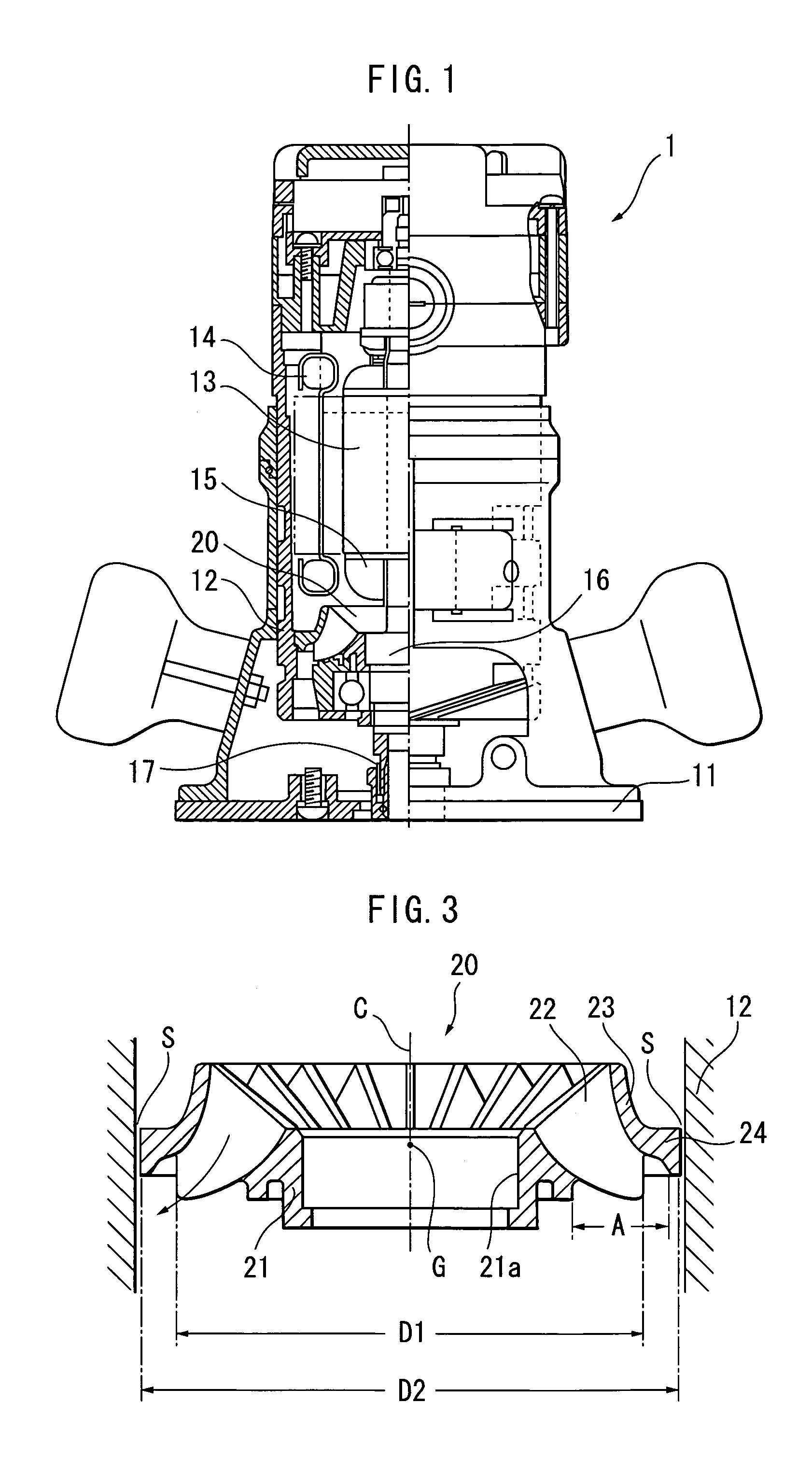

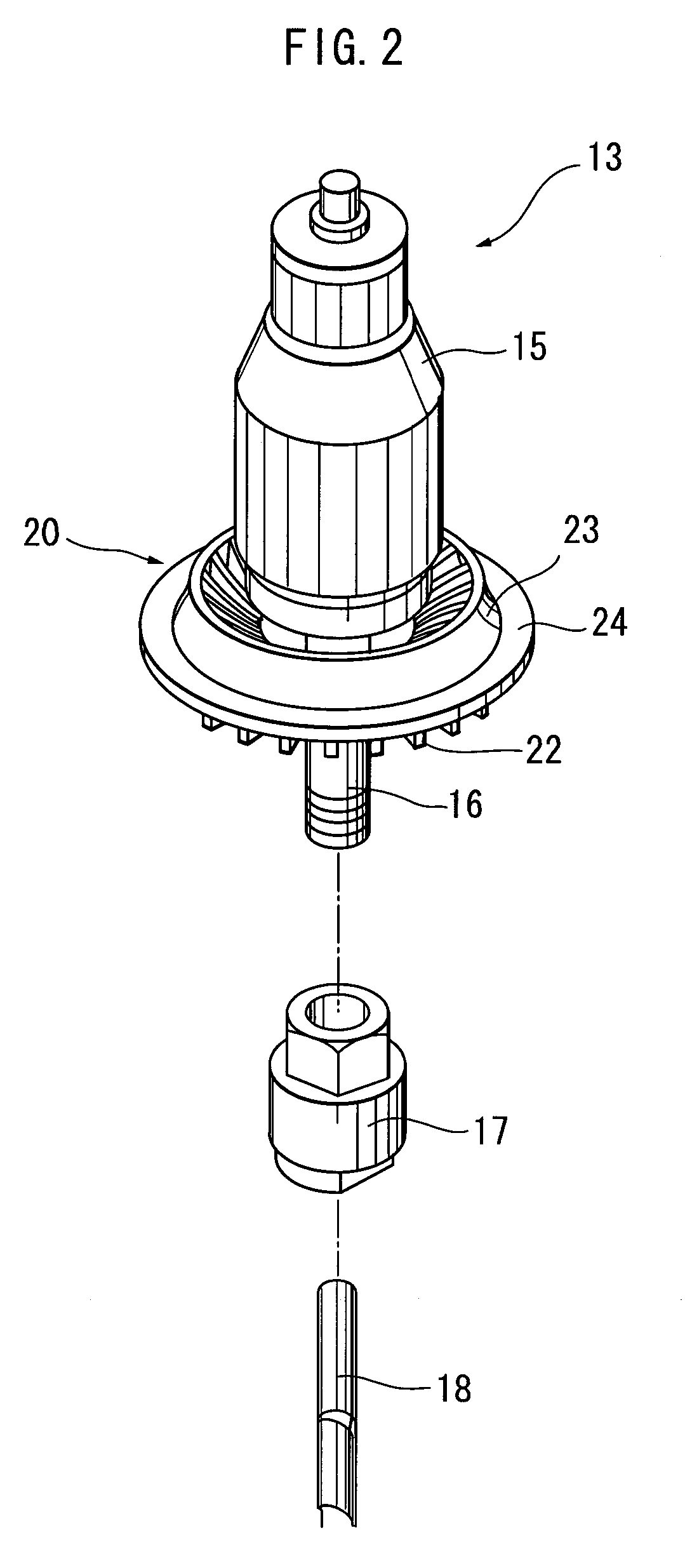

Portable electric router having radial fan

ActiveUS7171997B2Avoid noiseReduce manufacturing costMulti-purpose machinesProfiling/shaping machinesElectricityLow noise

A compact and light-weight portable electric router produced at a low cost and capable of providing high cutting efficiency with low noise. A radial fan includes a cylindrical hub functioning as an attachment portion to a motor shaft, a plurality of fan blades having parts connecting to the hub, and a ring like guide section connected to the hub through the fan blades. An annular weight is connected to the guide section at a radially outer side of the guide section. The weight serves as a restriction section for restricting backflow of air from a discharge side to a motor side.

Owner:KOKI HLDG CO LTD

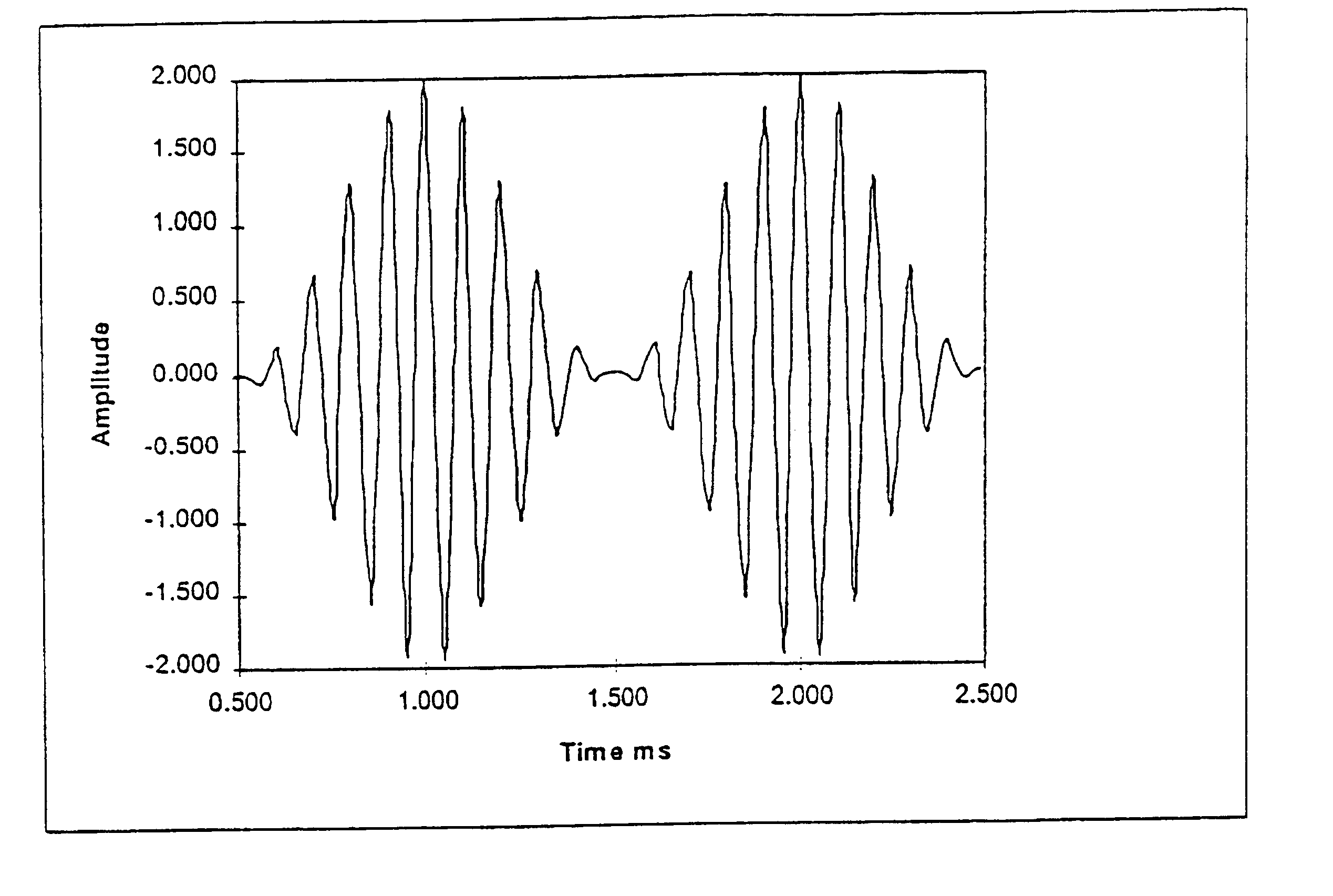

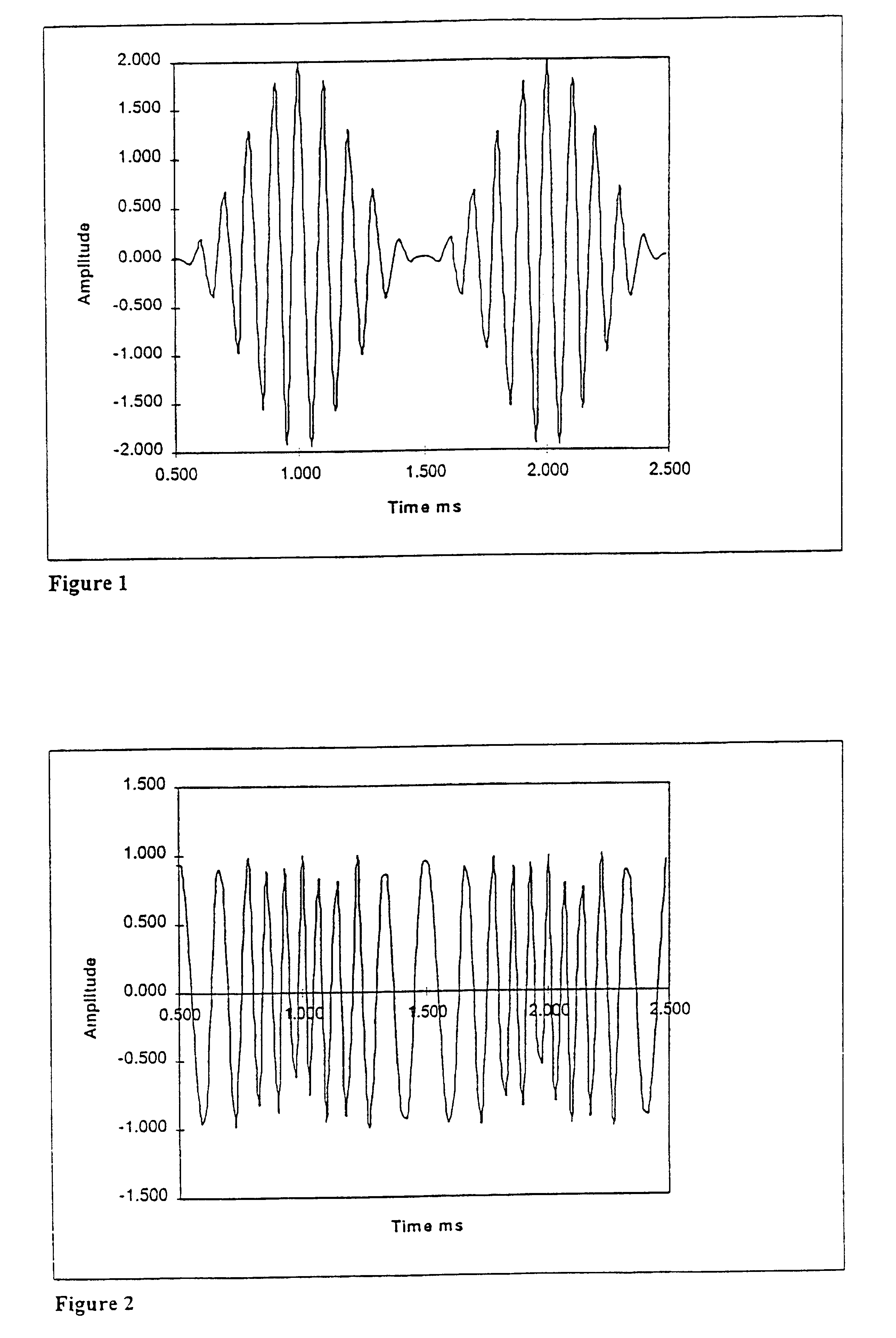

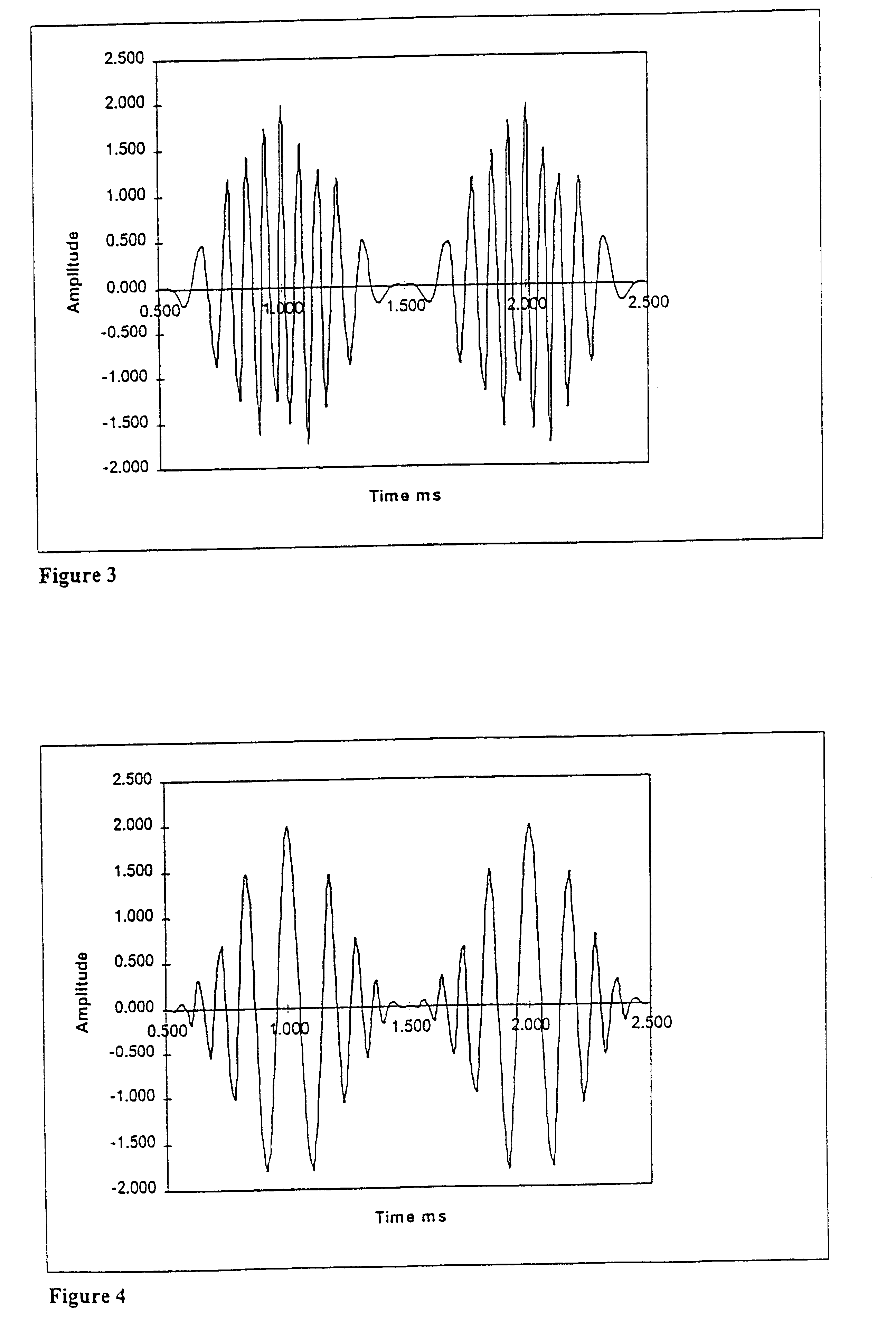

Phase lock evoked response audiometer

InactiveUS6406439B1Strong evoked potentialStronger evoked potentialsElectroencephalographyAudiometeringEngineeringAudiometer

An evoked response audiometer method and apparatus in which a patient receives an auditory stimulus signal comprising a carrier frequency which is periodically amplitude modulated and frequency modulated whereby the stimulus is at least substantially frequency specific, the brain potential signals of the patient evoked by the auditory signal being sampled to determine whether phase locking to the modulated auditory signal has occurred, the auditory signal being selectively controlled to advance or delay one modulation with respect to the other modulation to cause enhancement of the evoked response to the auditory stimulus.

Owner:UNIVERSITY OF MELBOURNE

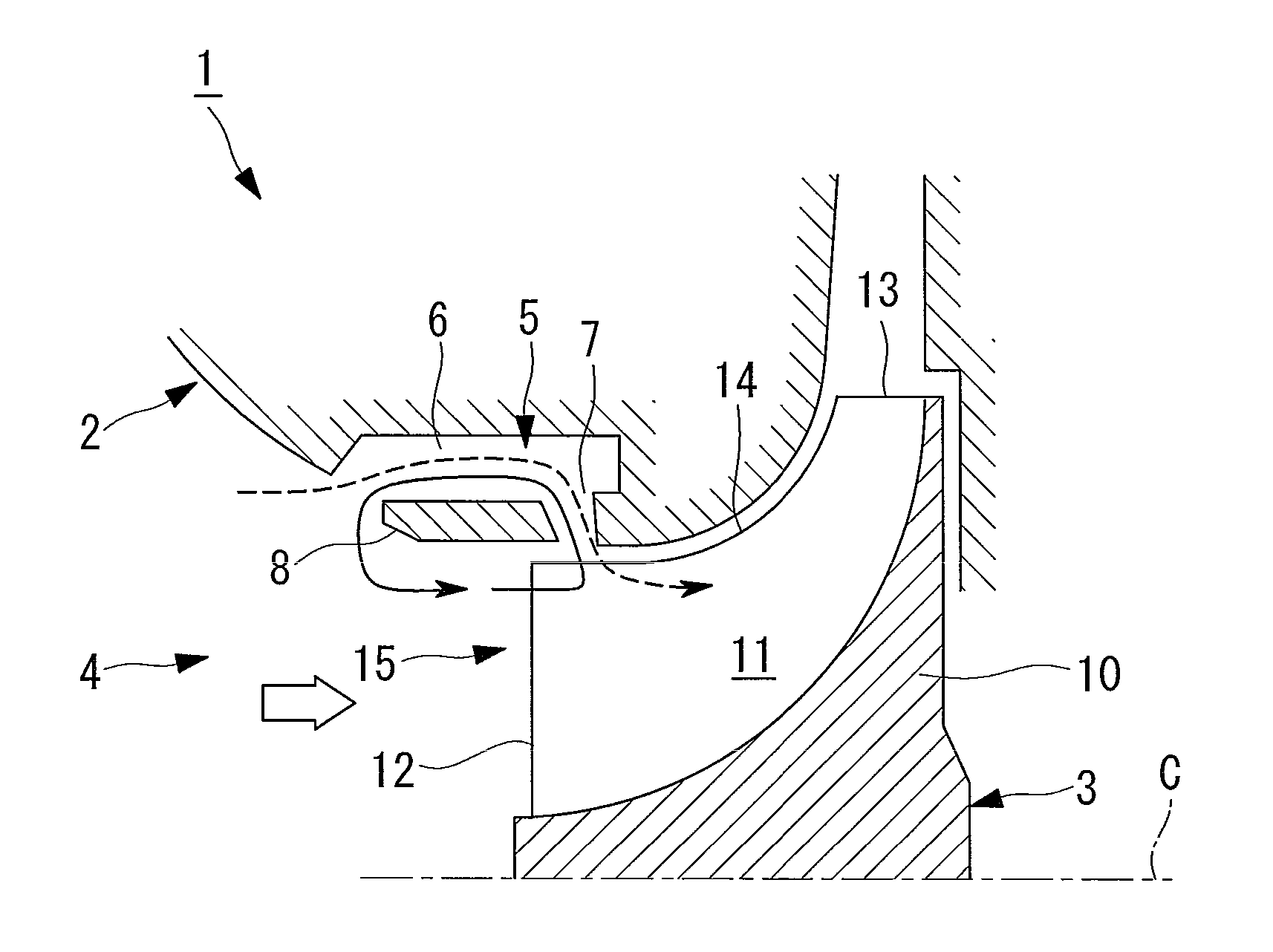

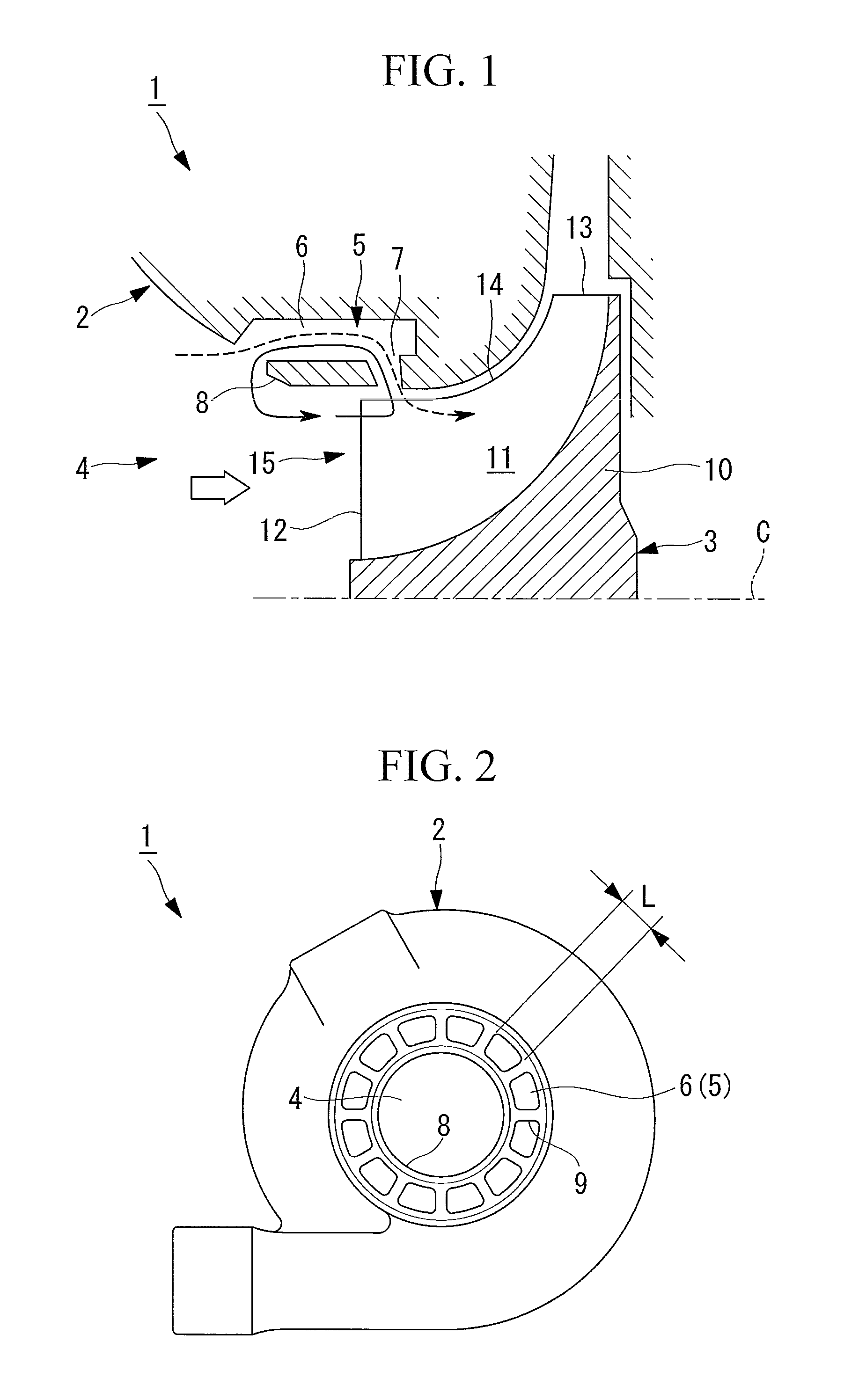

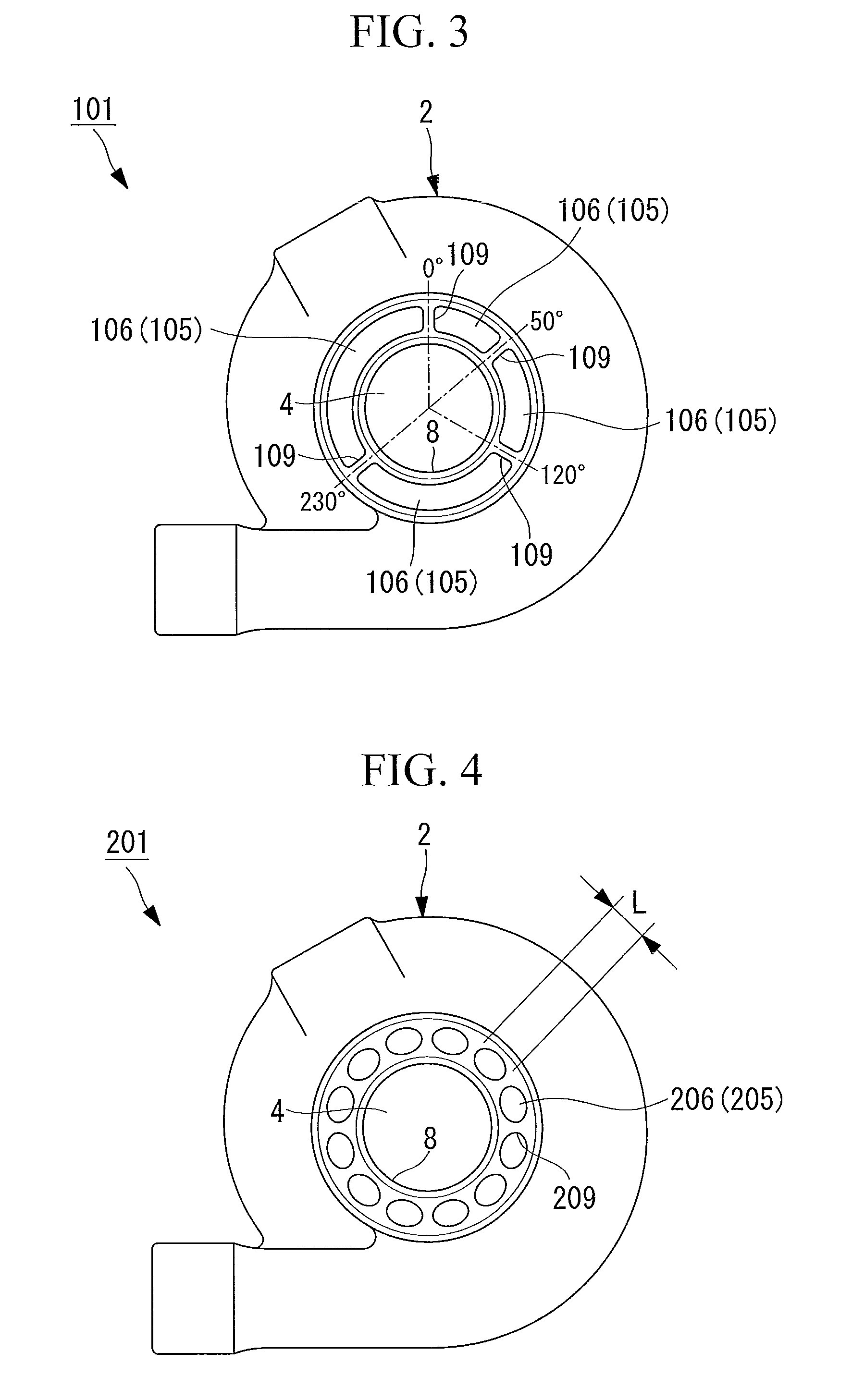

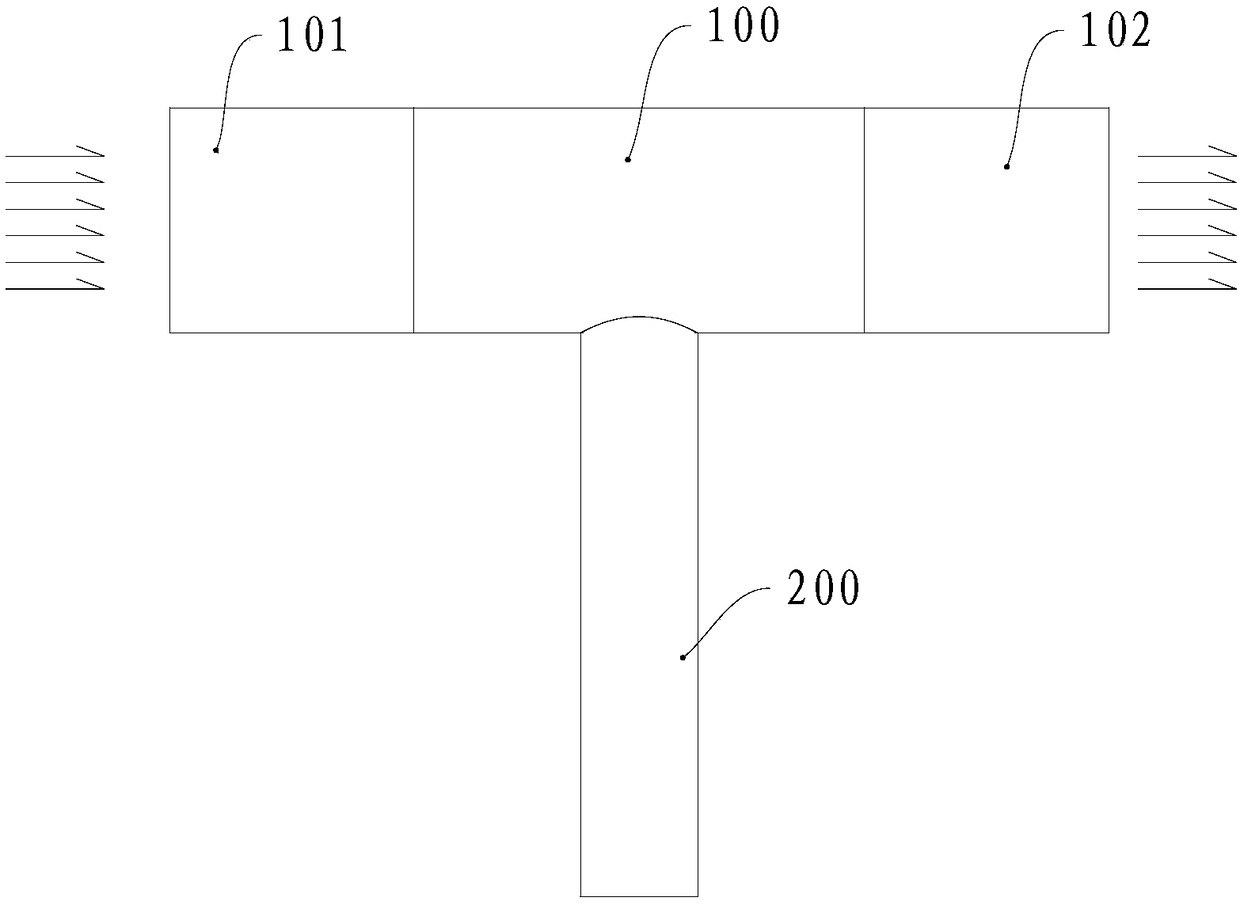

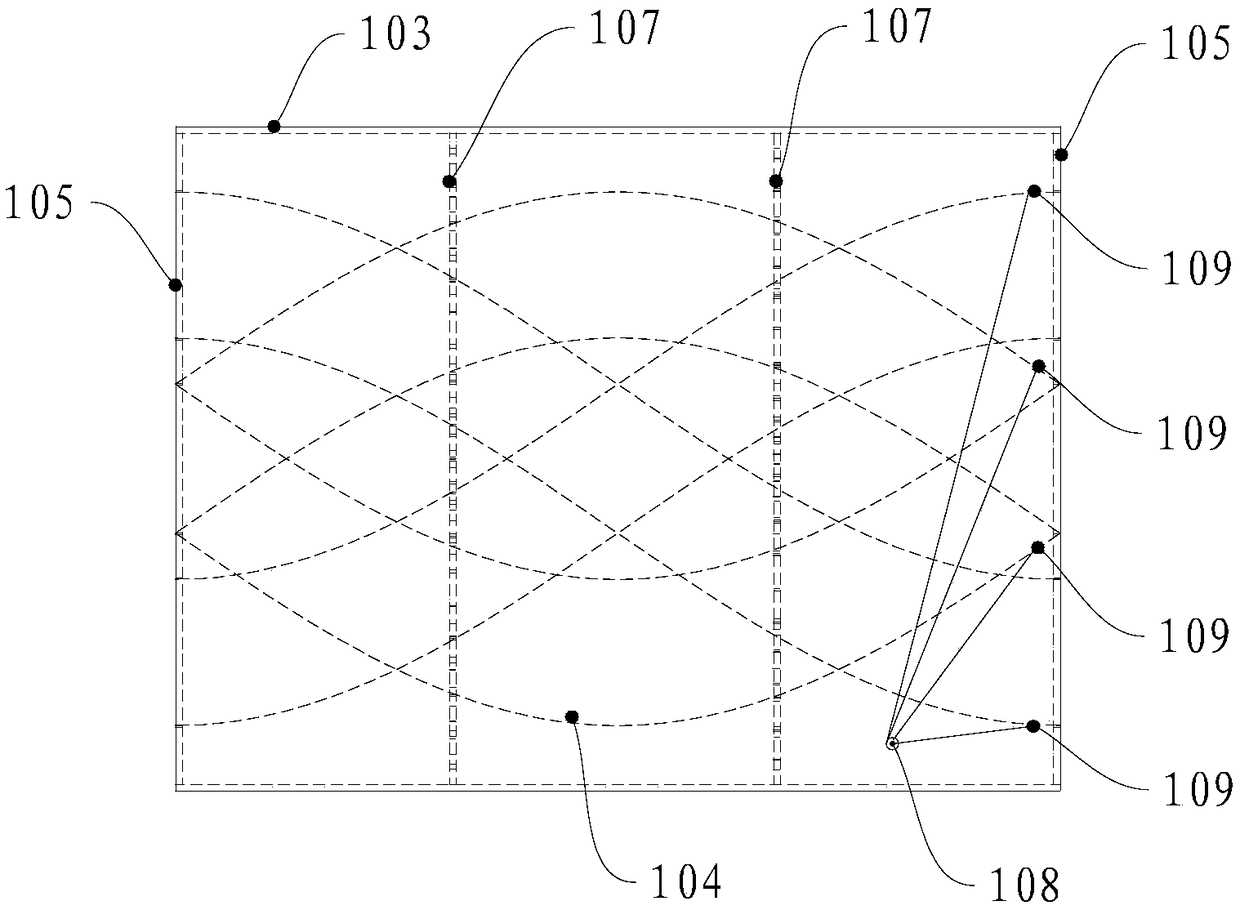

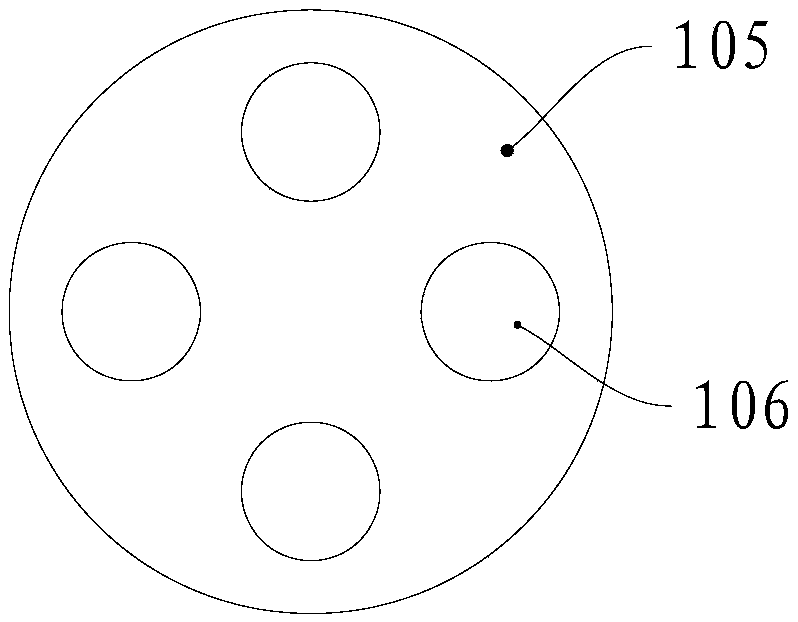

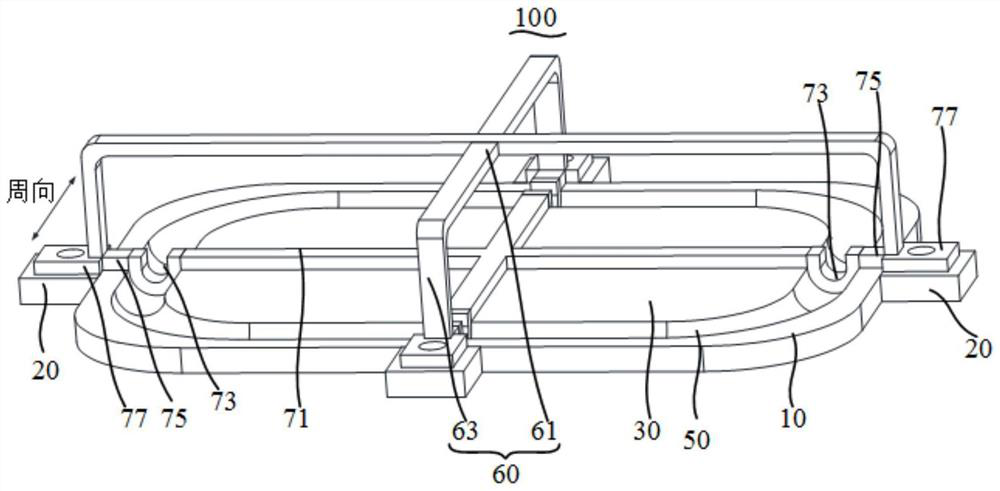

Compressor device

ActiveUS20100172741A1Reduce loudnessReduce areaPump componentsReaction enginesRotation velocityRotational axis

There is provided a compressor device in which resonance in a circulating channel is reduced so that an increase in noise generated from the compressor device is prevented. The compressor device includes: a plurality of blades rotated about a rotation axis; an air inlet extending along the rotation axis and introducing air to the blades; a circulating channel disposed on a circumference centered on the rotation axis and communicating between the air inlet and the shroud of the blades; and a strut extending radially centered on the rotation axis and dividing the circulating channel. Resonance frequencies determined from circumferential lengths in the circulating channels divided by the strut are higher than a noise frequency determined from the rotational speed of the blades and the number of blades.

Owner:MITSUBISHI HEAVY IND LTD

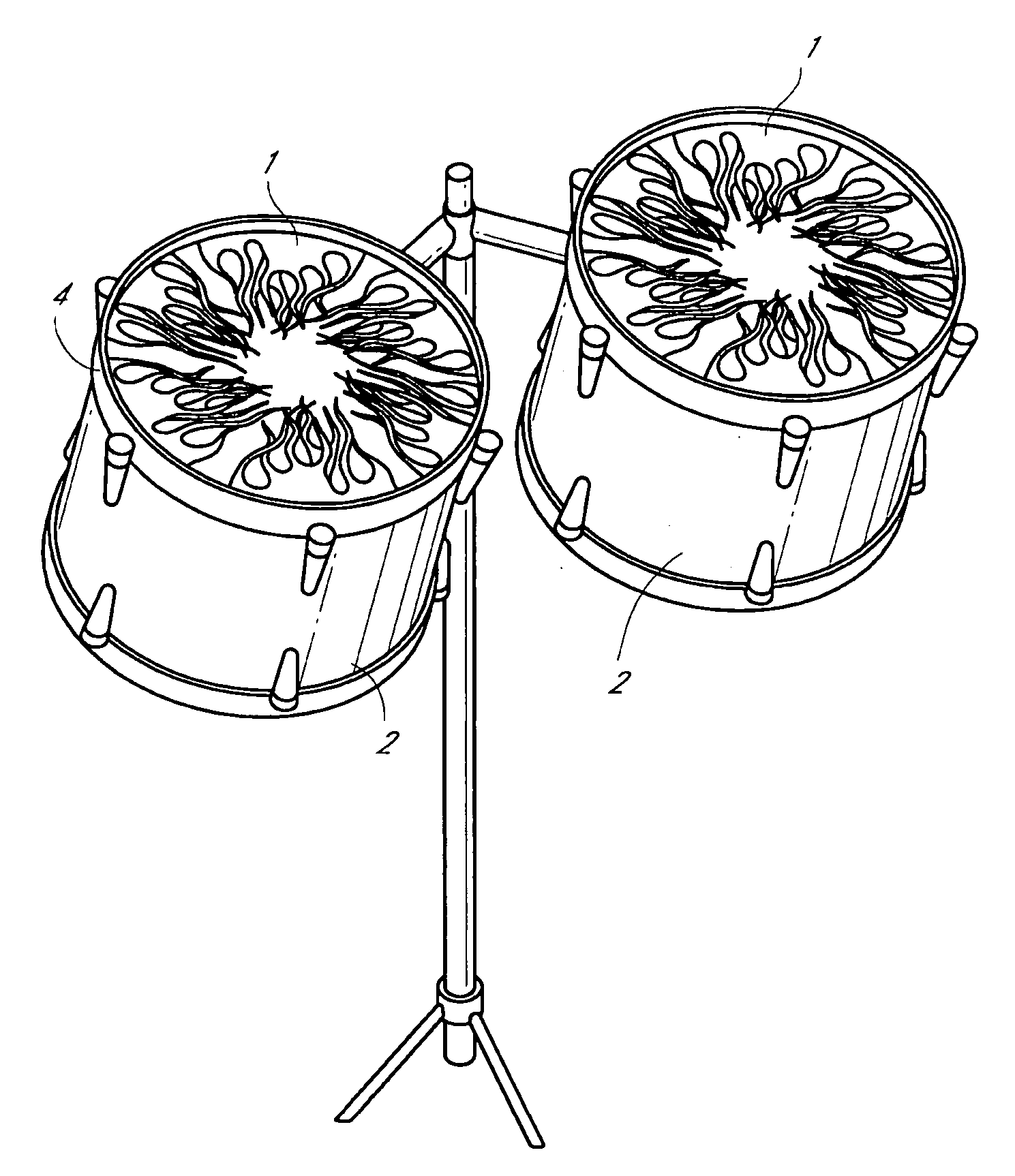

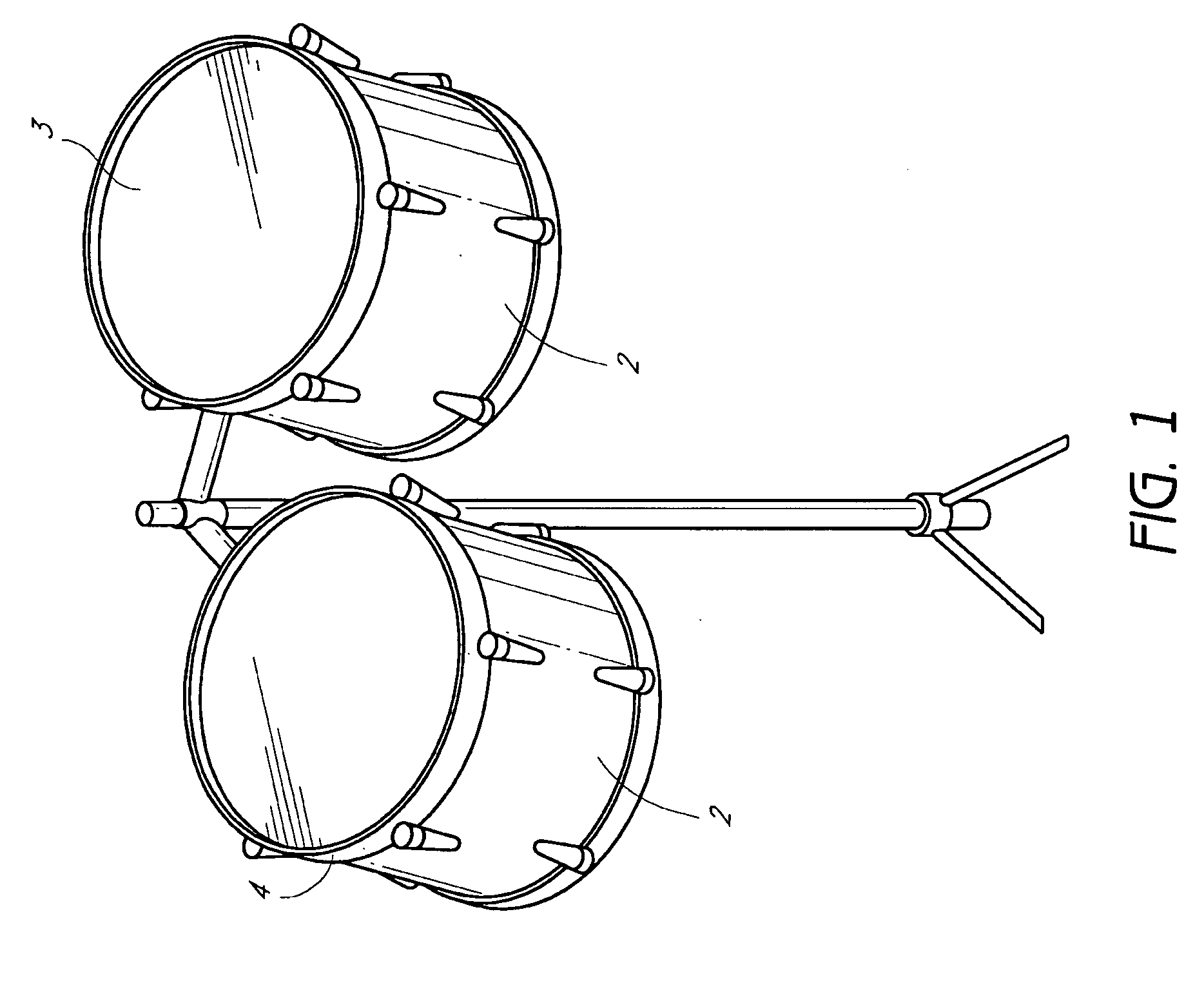

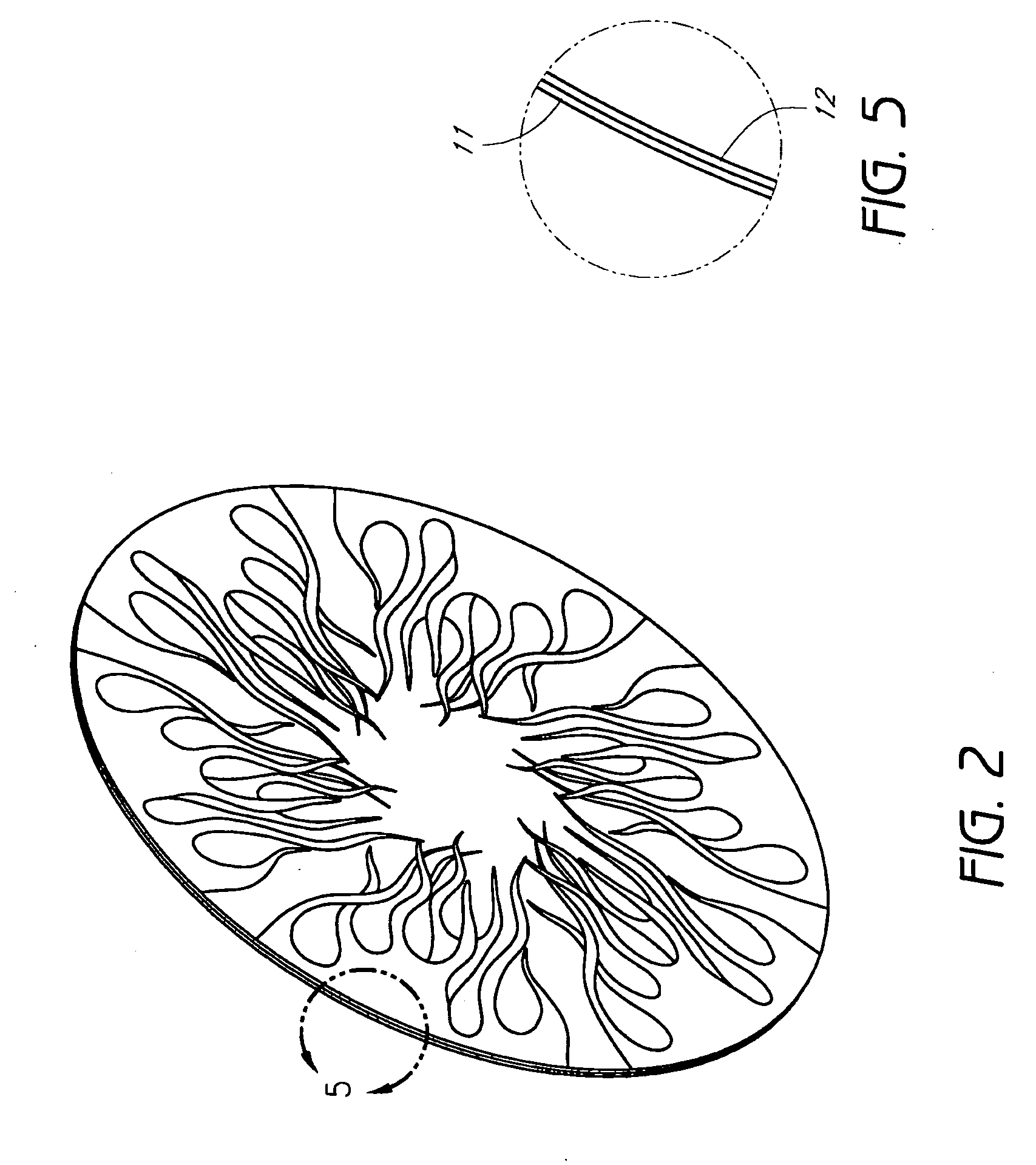

Drum damper systems

InactiveUS20070022863A1Reduce loudnessMaintaining sound clarity and tone qualityPercussion musical instrumentsEngineeringUltimate tensile strength

A drum damper for a musical drum comprises a first portion including material having high impact strength and durability suitable for withstanding the forces generated by striking a musical drum. A second portion includes material having sound damping properties suitable for reducing the sound level generated by striking a musical drum.

Owner:ROSS KEVIN

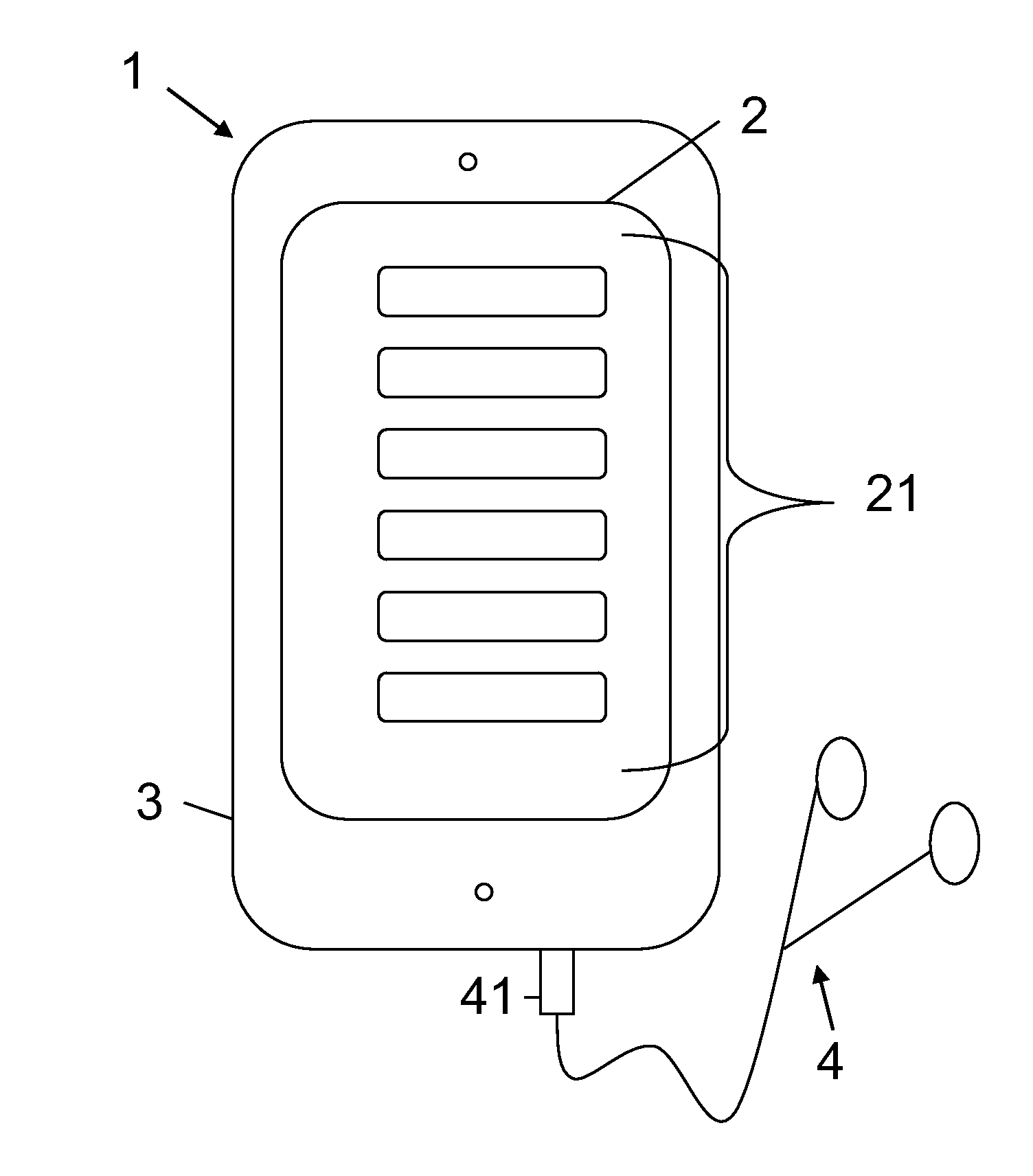

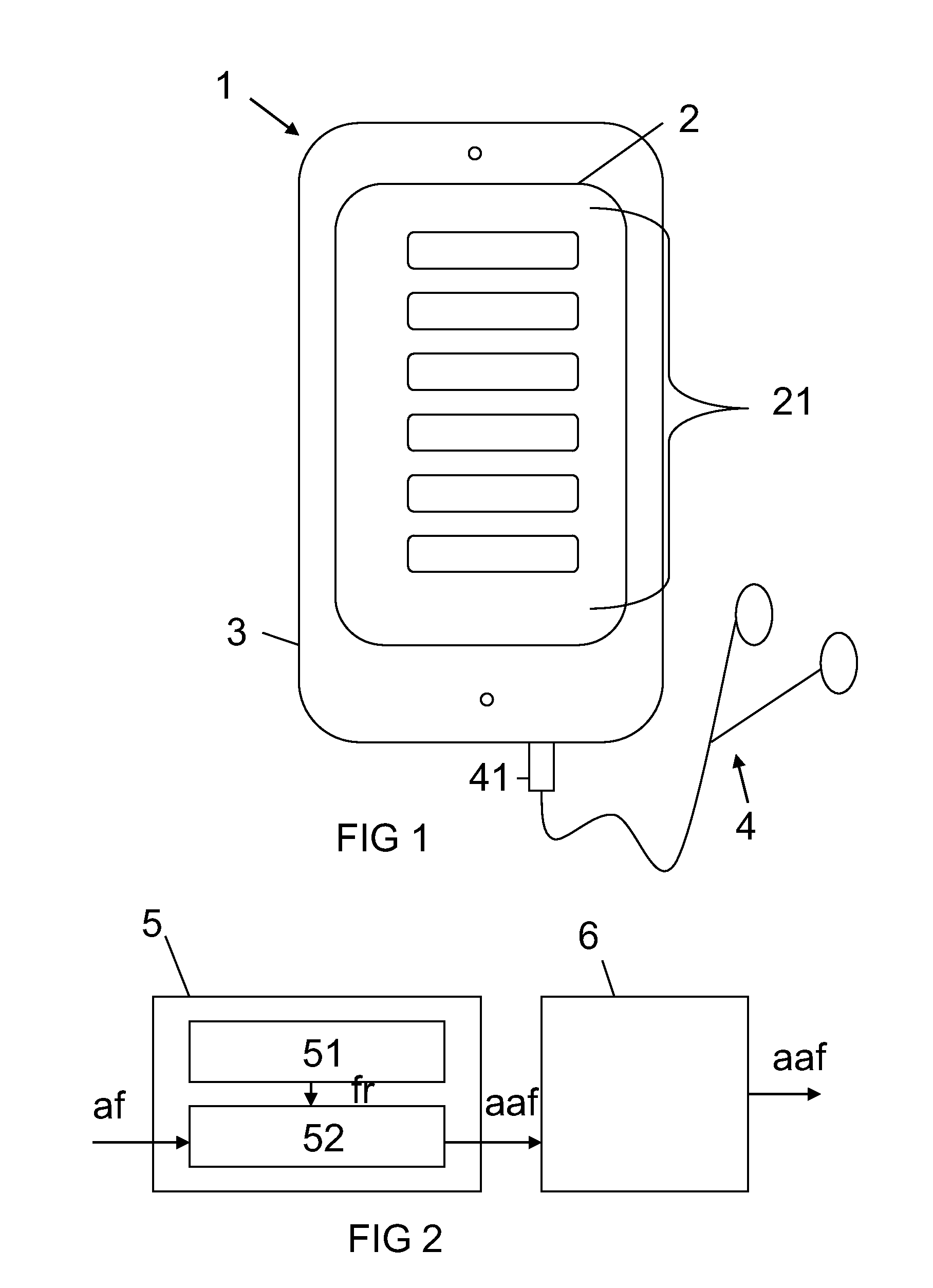

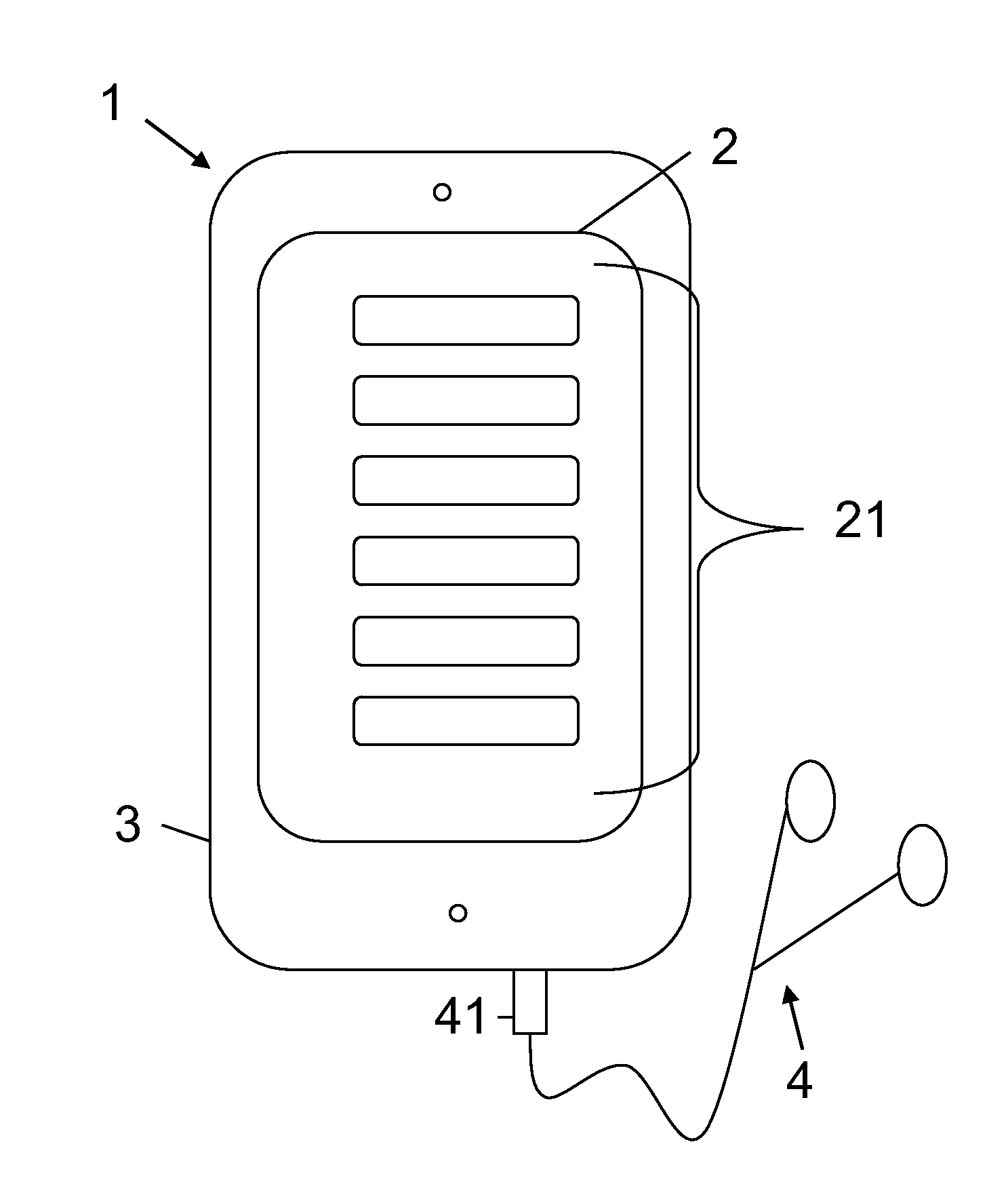

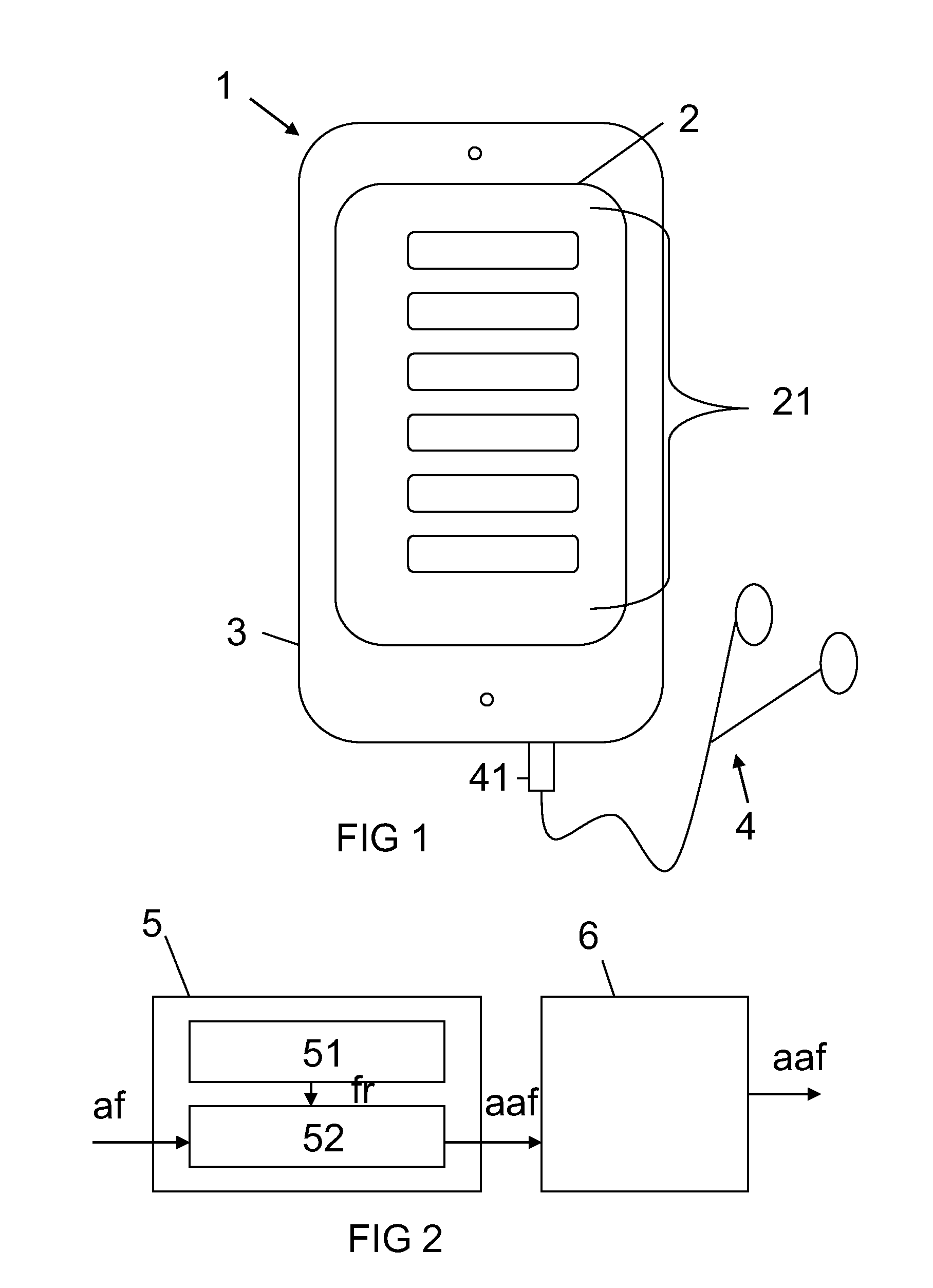

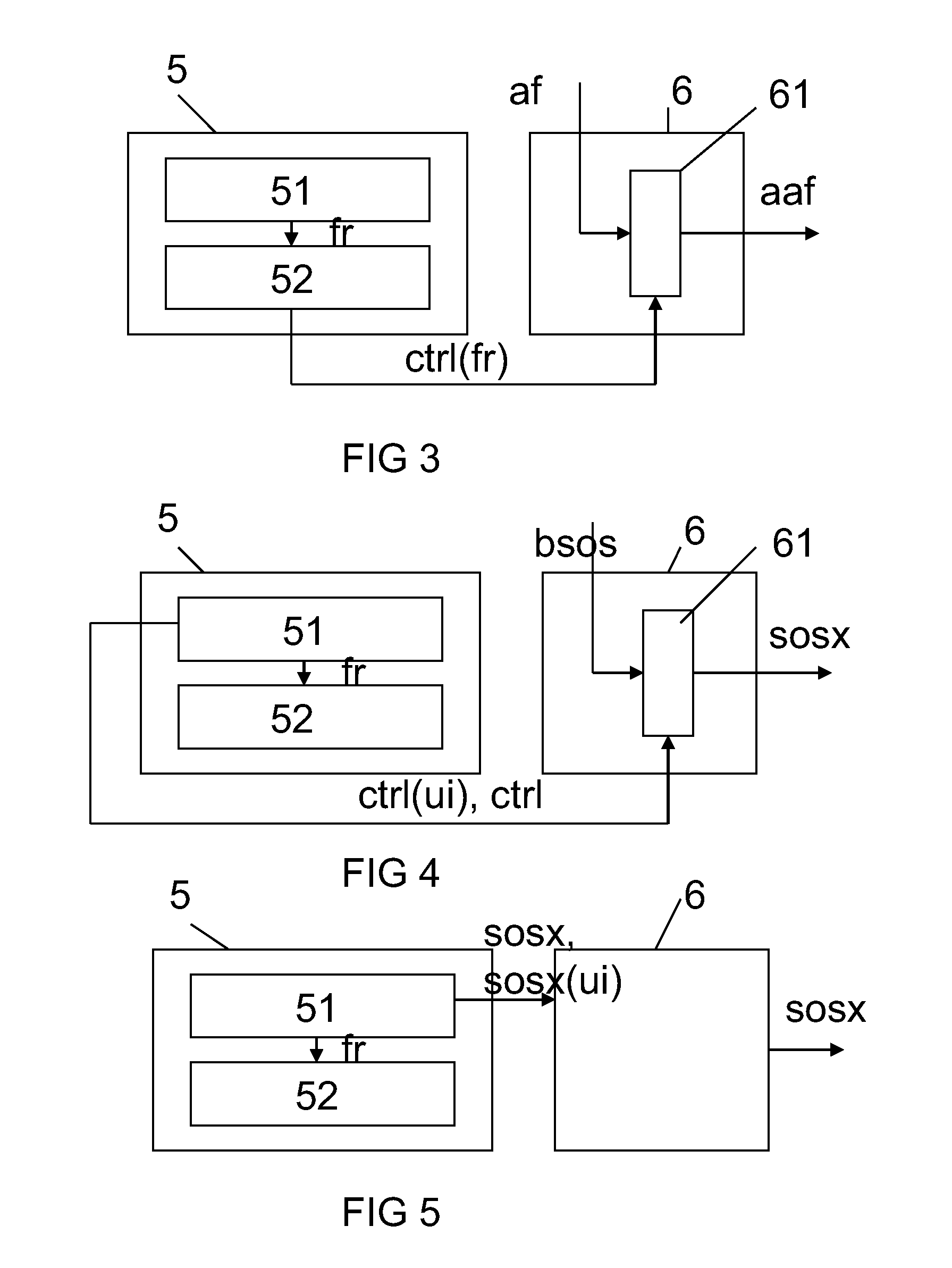

Generating an adapted audio file

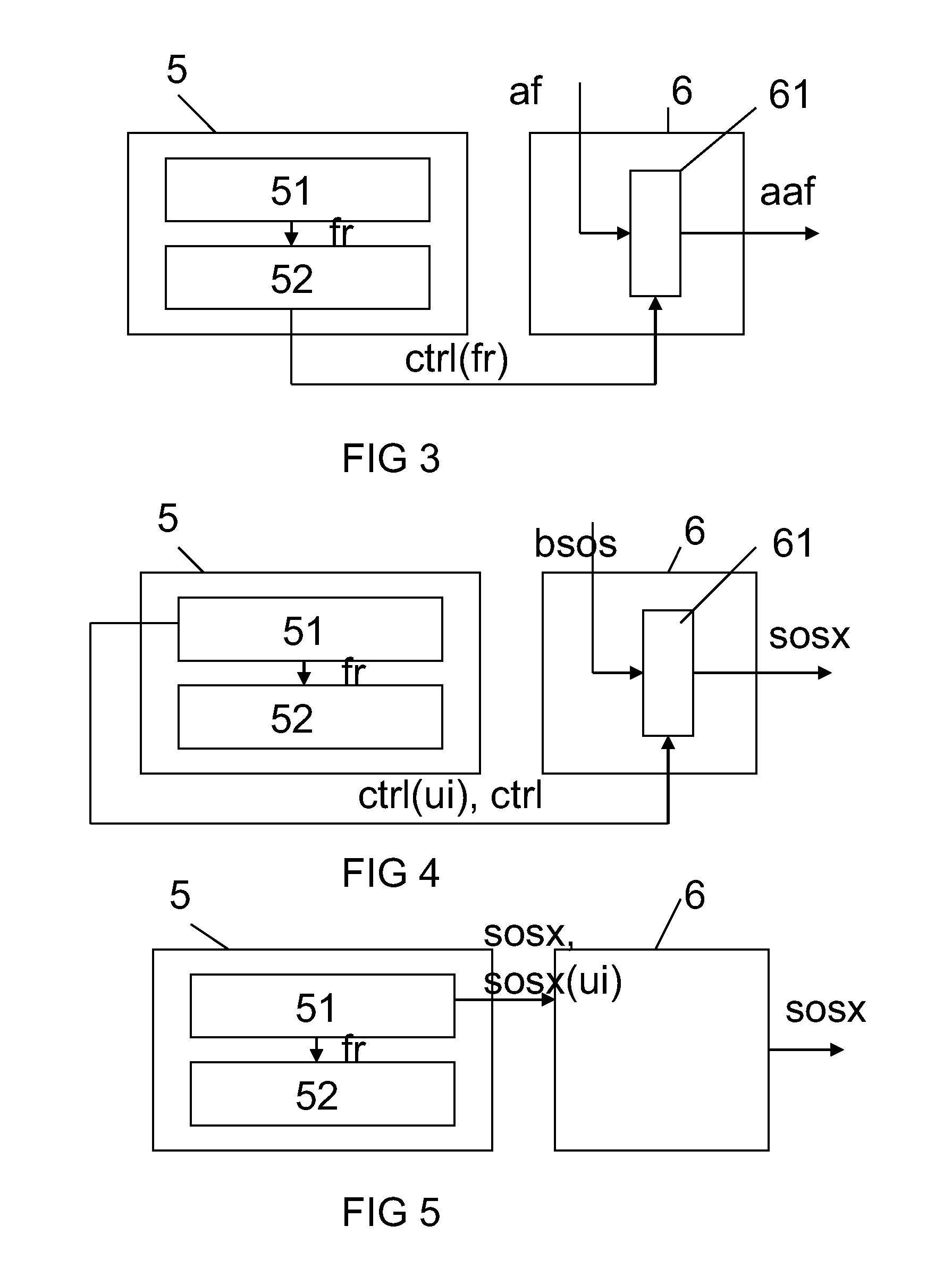

ActiveUS20140288685A1Easy to monitorEnhanced informationElectric tinnitus maskersAudio data retrievalIdentification deviceFrequency characteristic

The present idea refers to an apparatus for generating an adapted audio file. The apparatus comprises an identification unit (51) for supporting identification of a frequency range (fr) associated with an auditory disorder of a user of the apparatus, and an adaptation unit (52) for adapting a frequency characteristic of an audio file (af) representing a track of music which adaptation is subject to the identified frequency range (fr). An audio player (6) is provided for playing the adapted audio file (aaf).

Owner:MY TINNITUS HAS GONE

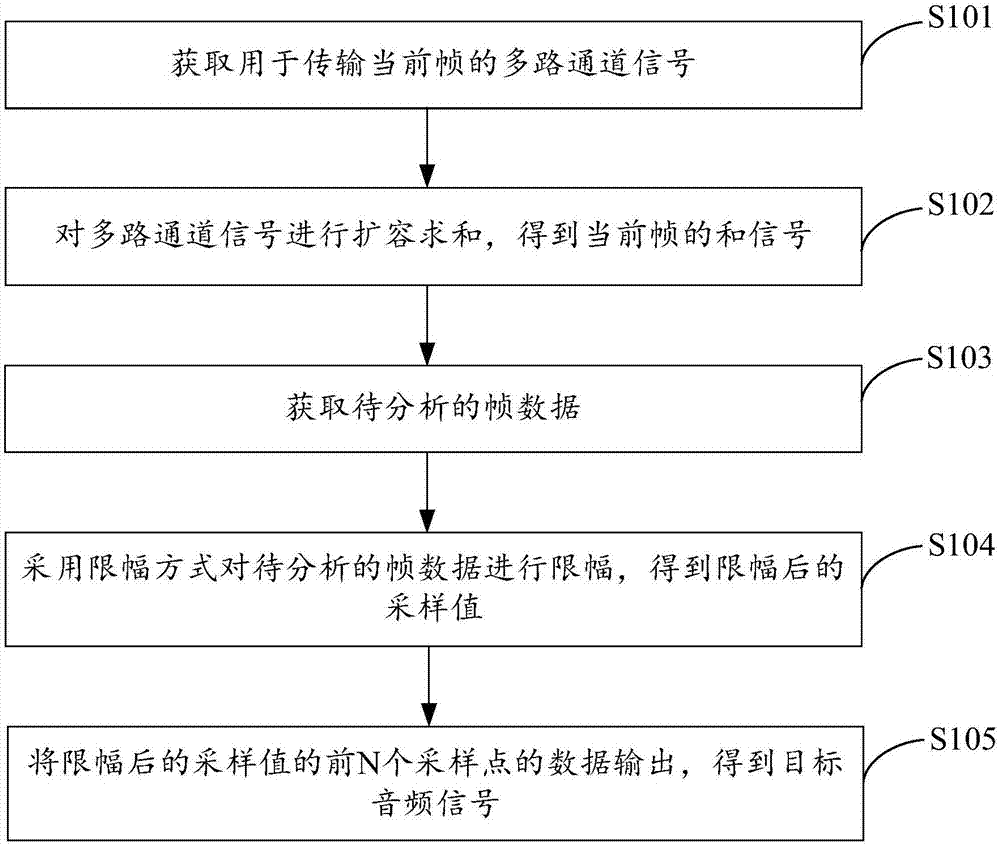

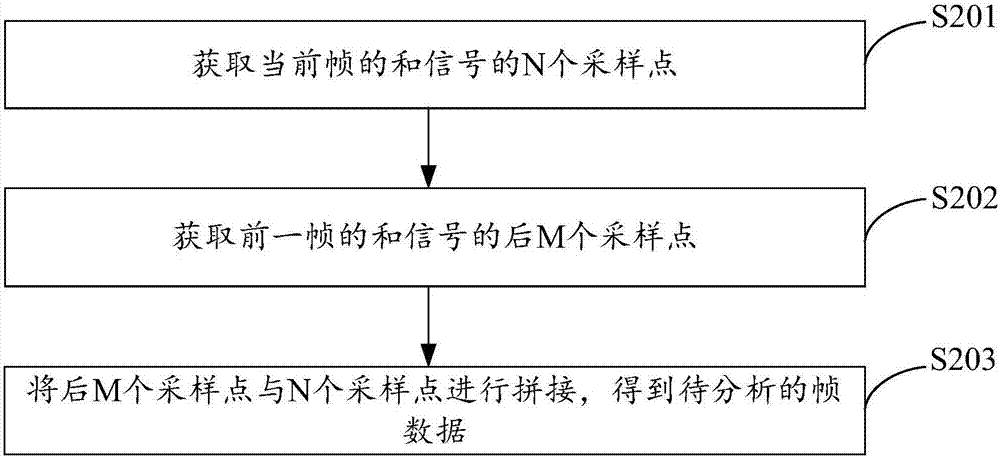

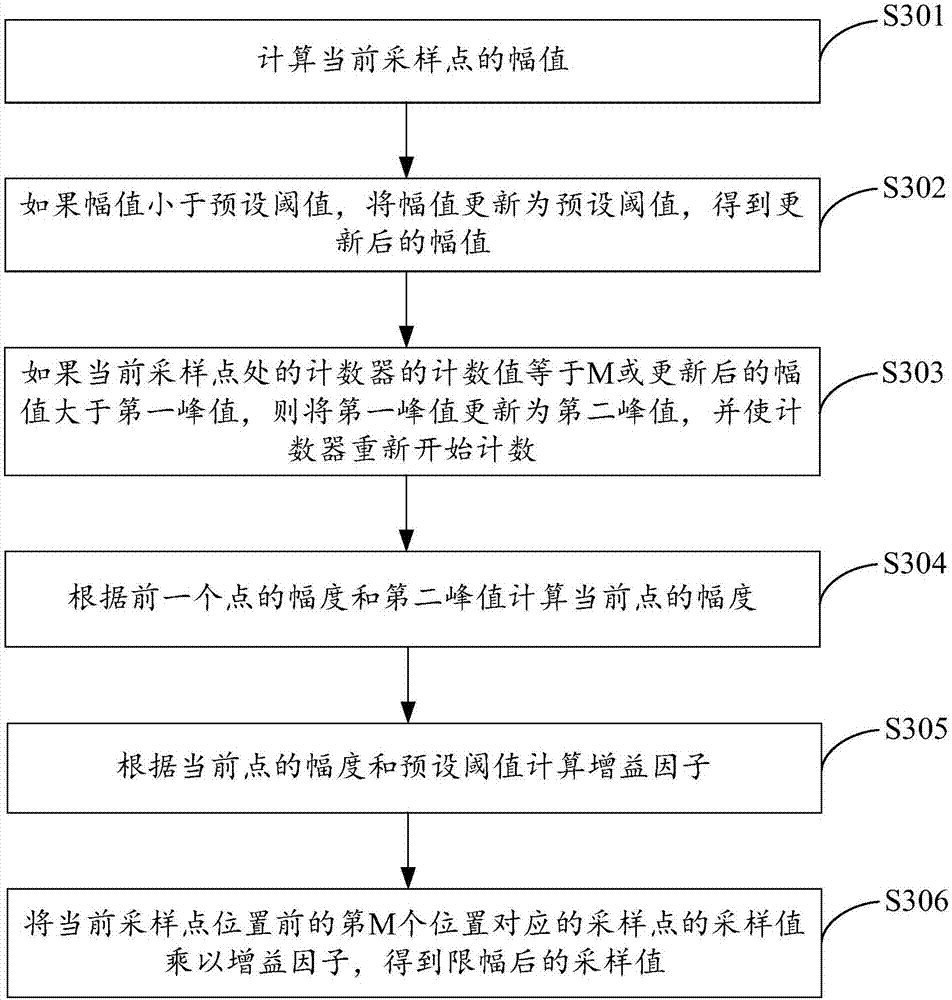

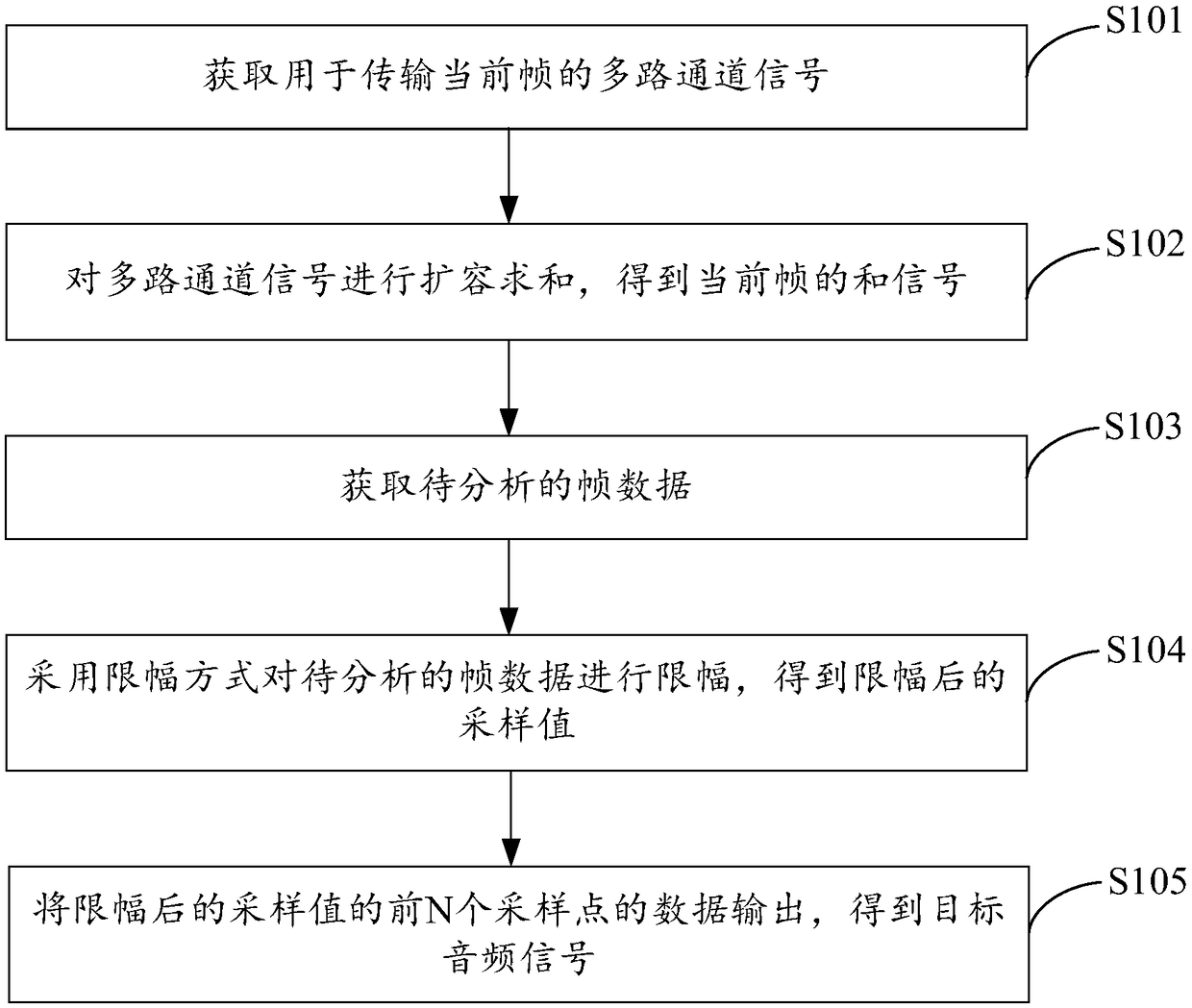

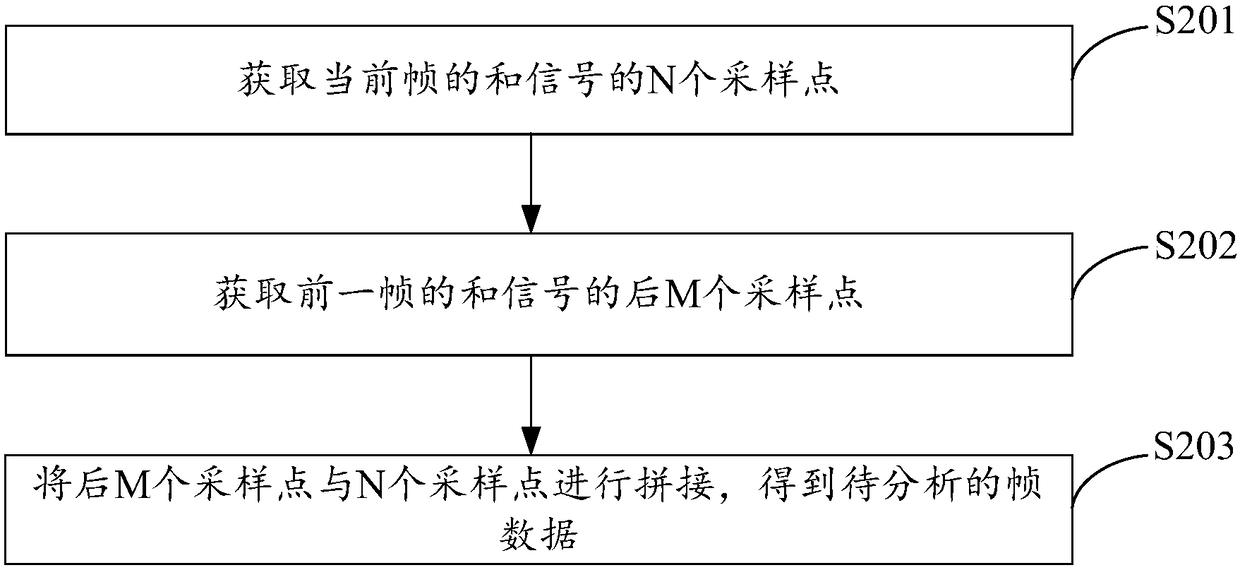

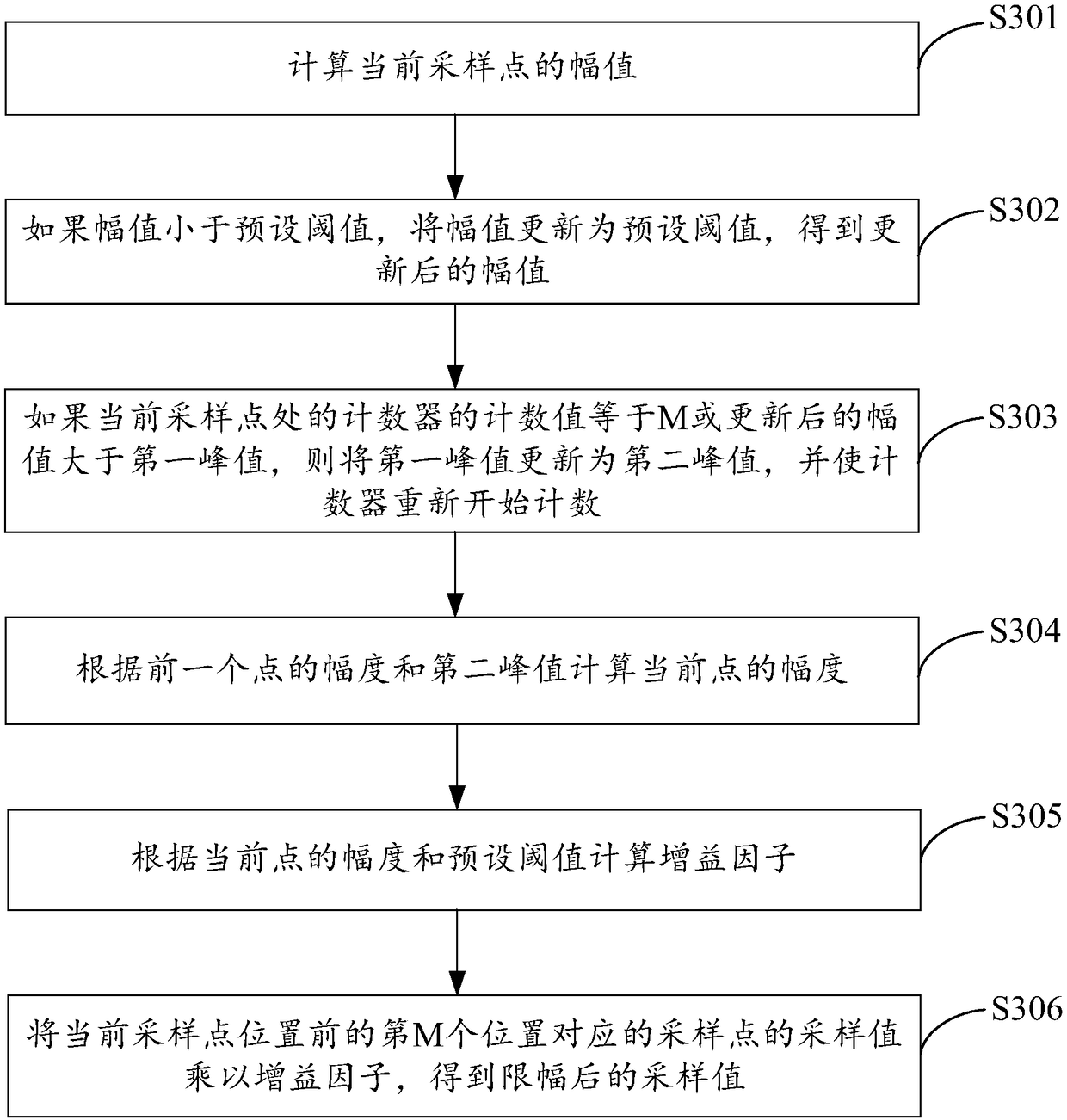

Multichannel sound mixing method and apparatus

ActiveCN107426651AReduce loudnessImprove sound qualitySignal processingLoudspeaker signals distributionSound qualityComputer science

The invention provides a multichannel sound mixing method and apparatus. The method comprises the following steps: obtaining multiple paths of channel signals used for transmitting a current frame; performing volume expansion summation on the multiple paths of channel signals to obtain a sum signal of the current frame; obtaining to-be-analyzed frame data; limiting the amplitude of the to-be-analyzed frame data in an amplitude limiting manner to obtain a sampling value after amplitude limiting; and outputting the data of N sampling points in front of the sampling value after amplitude limiting to obtain a target audio signal. In the multichannel sound mixing method provided by the invention, the sound mixing is performed by combining the volume expansion summation with the amplitude limiting, so that the sound quality of the obtained target audio signal is better and is more real, and the technical problem of serious distortion of sound mixing in the traditional sound mixing method is relieved.

Owner:世邦通信股份有限公司

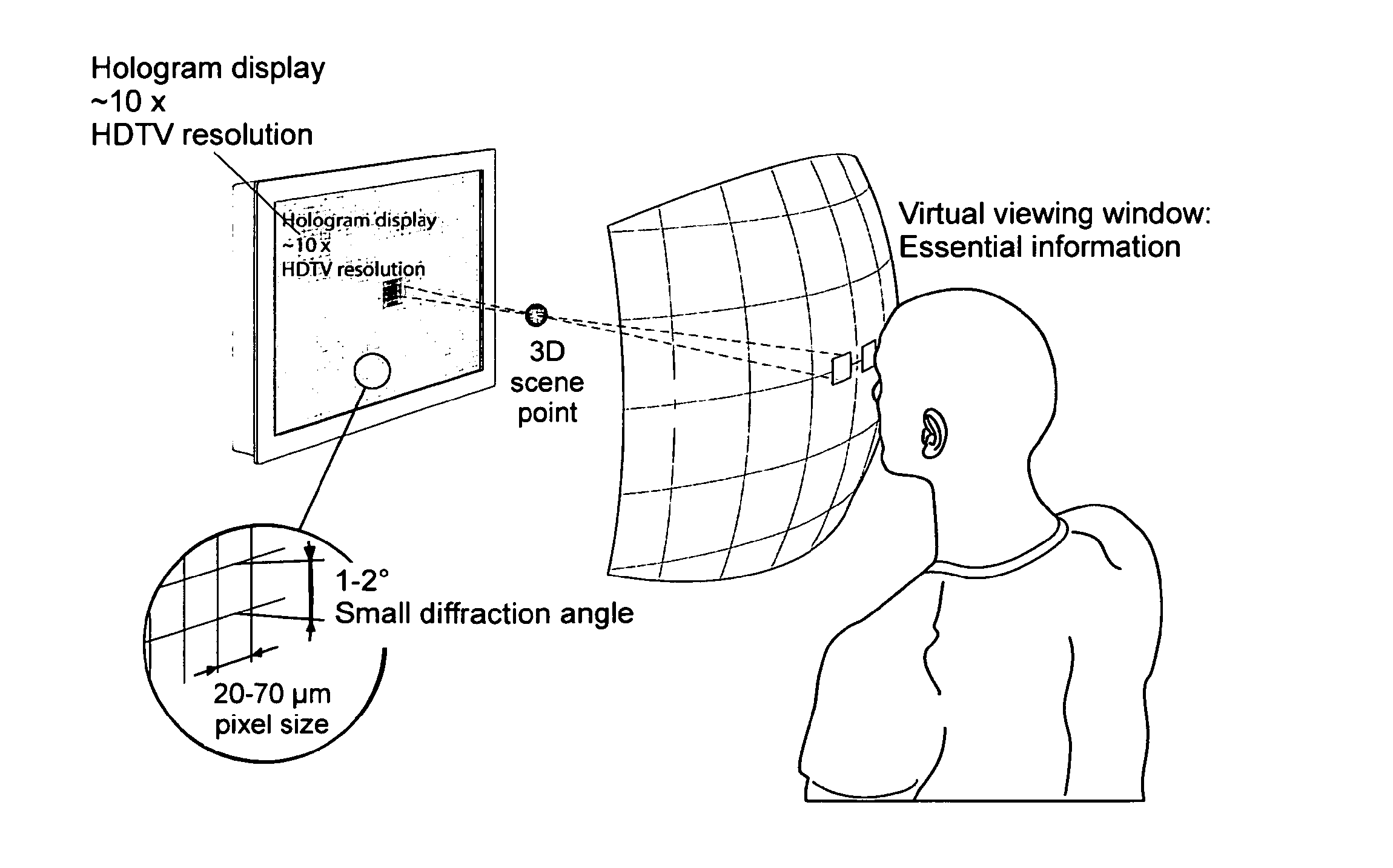

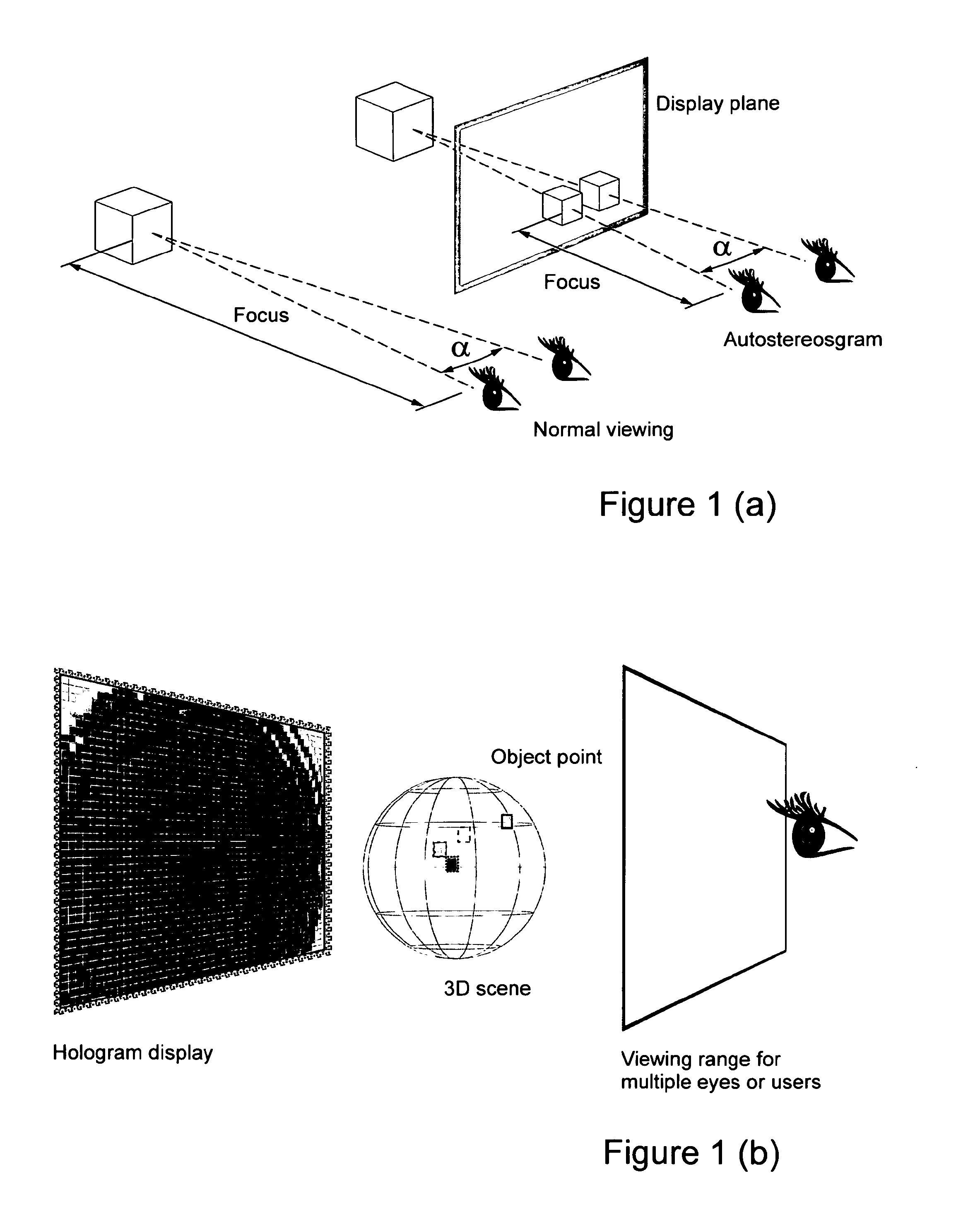

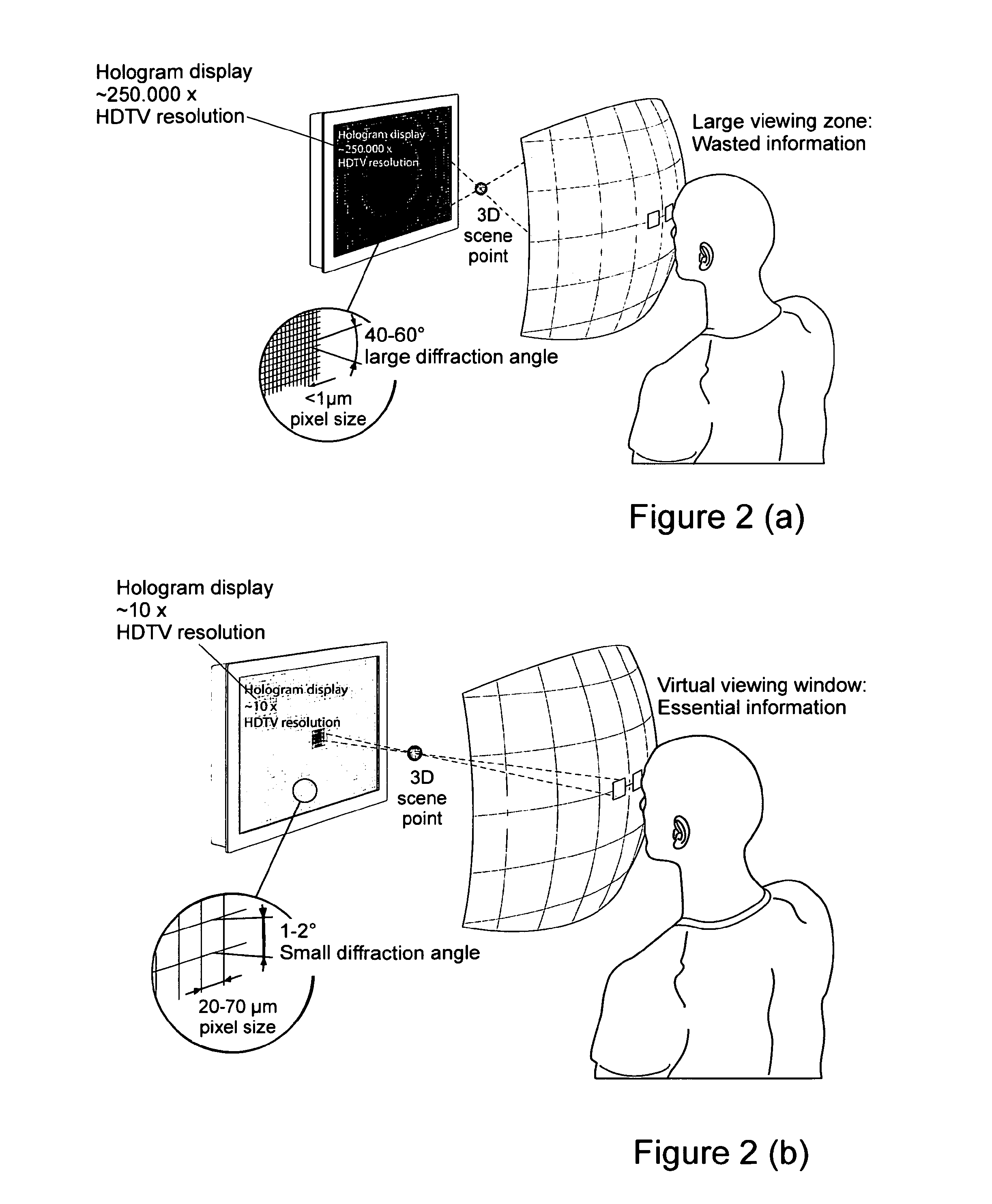

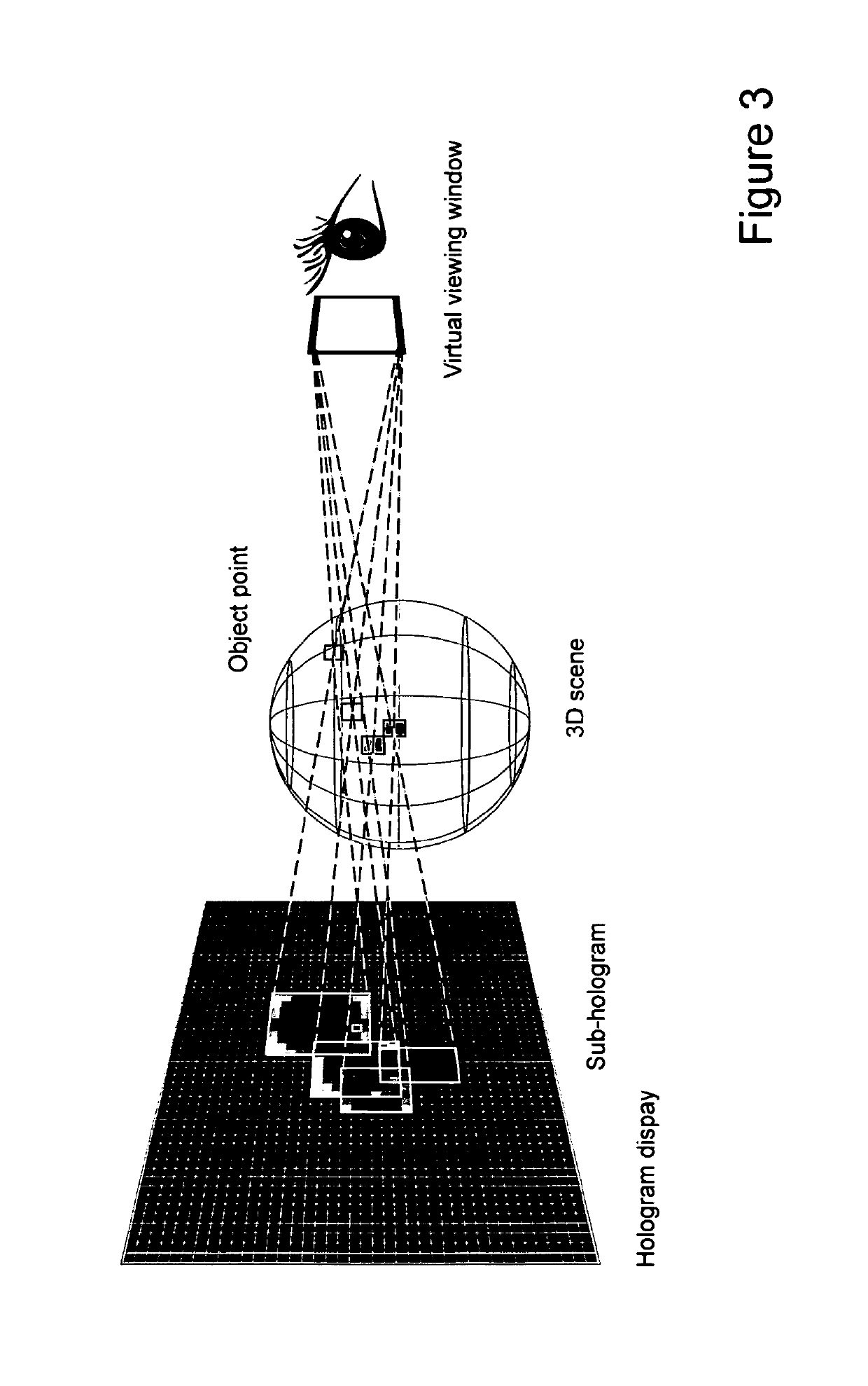

Method and device for encoding three-dimensional scenes which include transparent objects in a holographic system

ActiveUS20170038728A1Improve and reduce visibilityReduce loudnessHolographic object characteristicsDigital holography electronic componentSound sourcesComputer science

Owner:SEEREAL TECHNOLOGIES

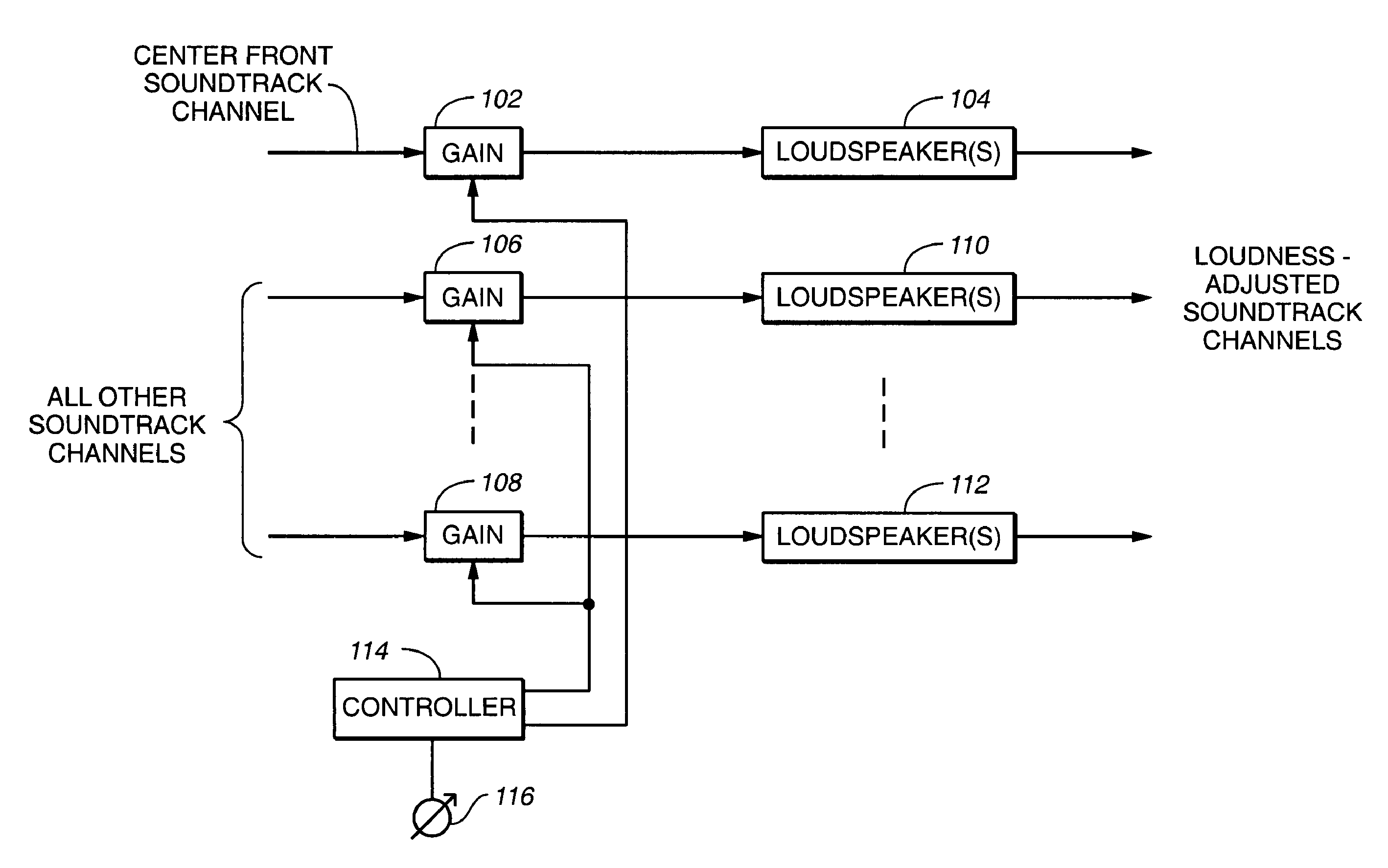

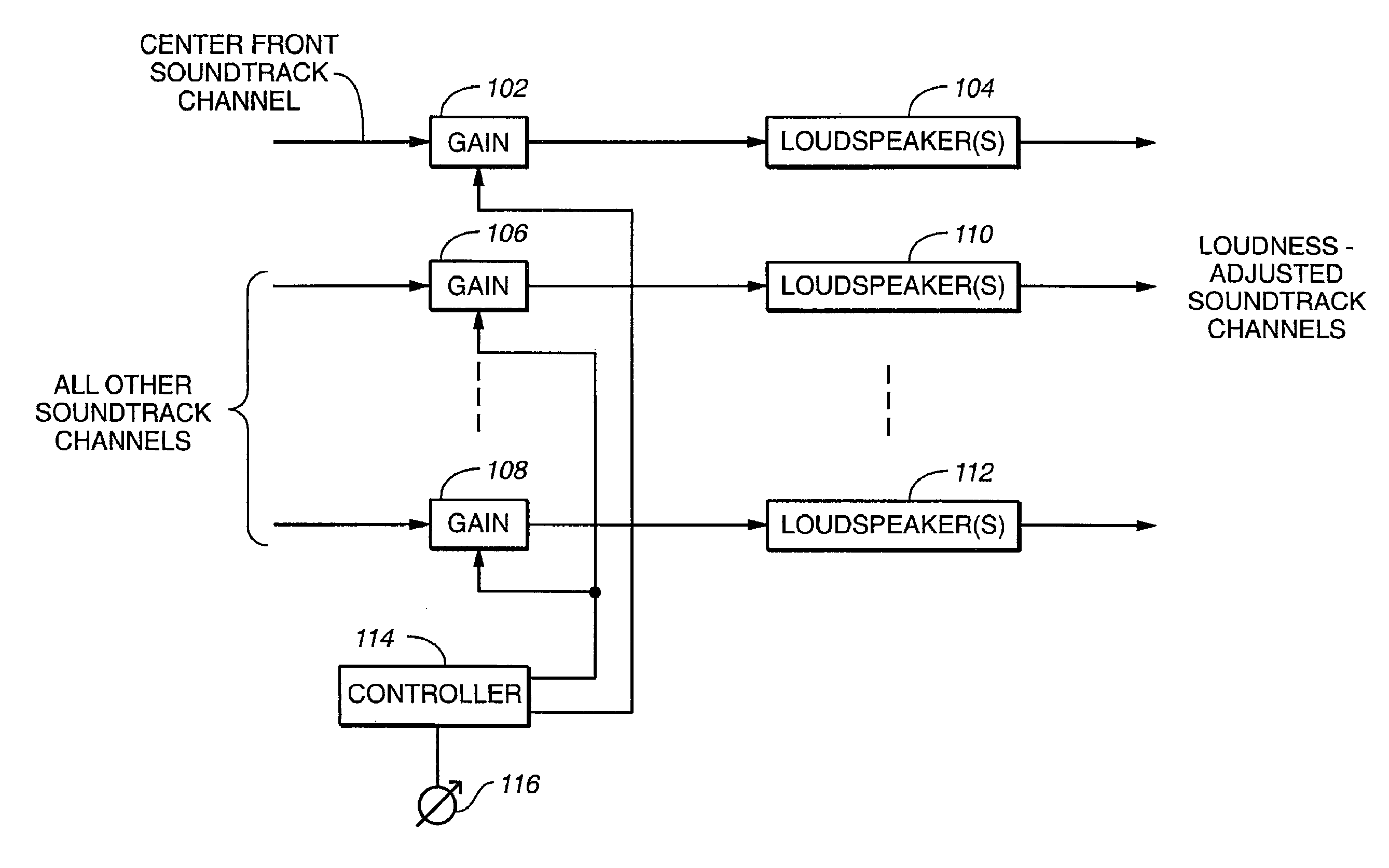

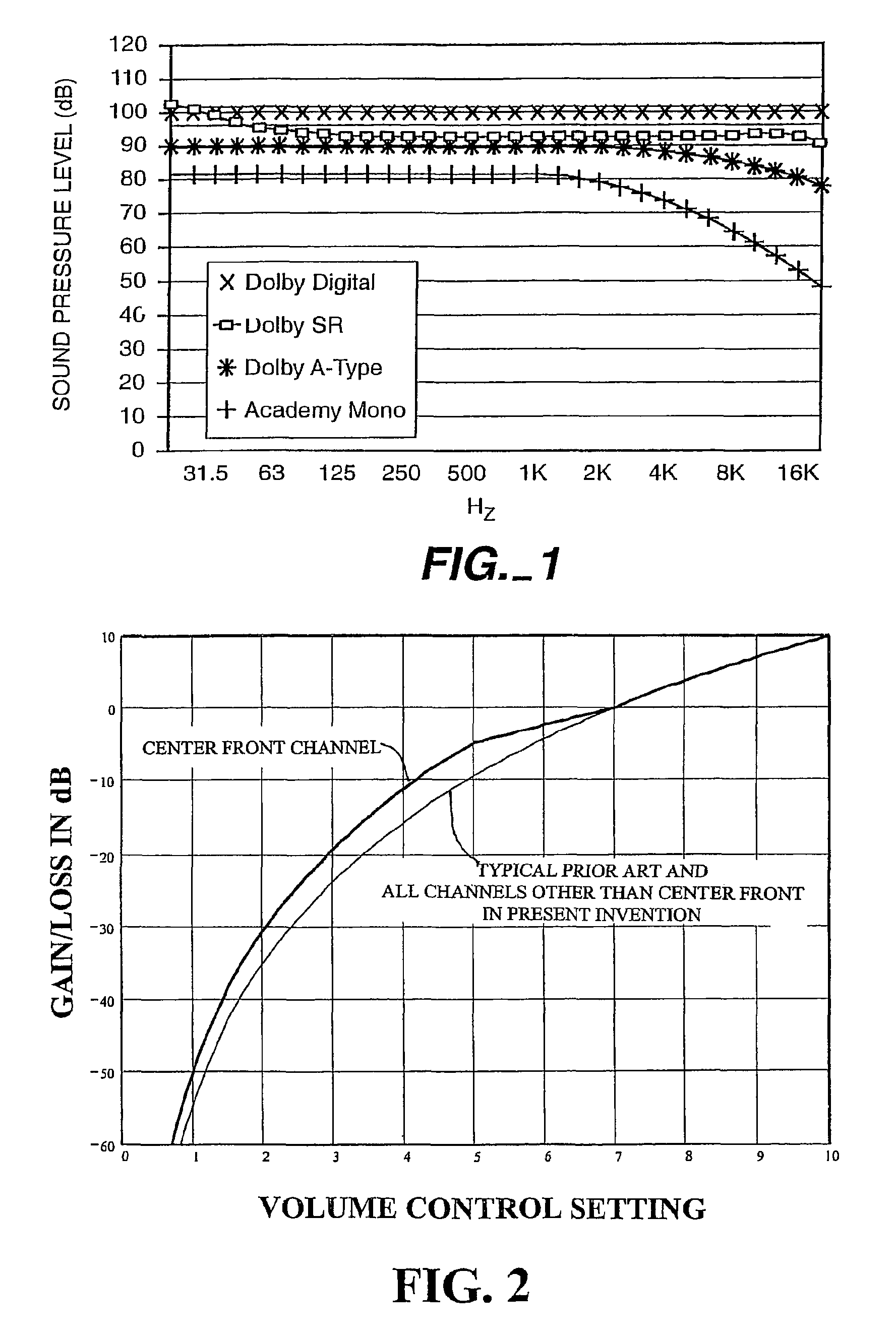

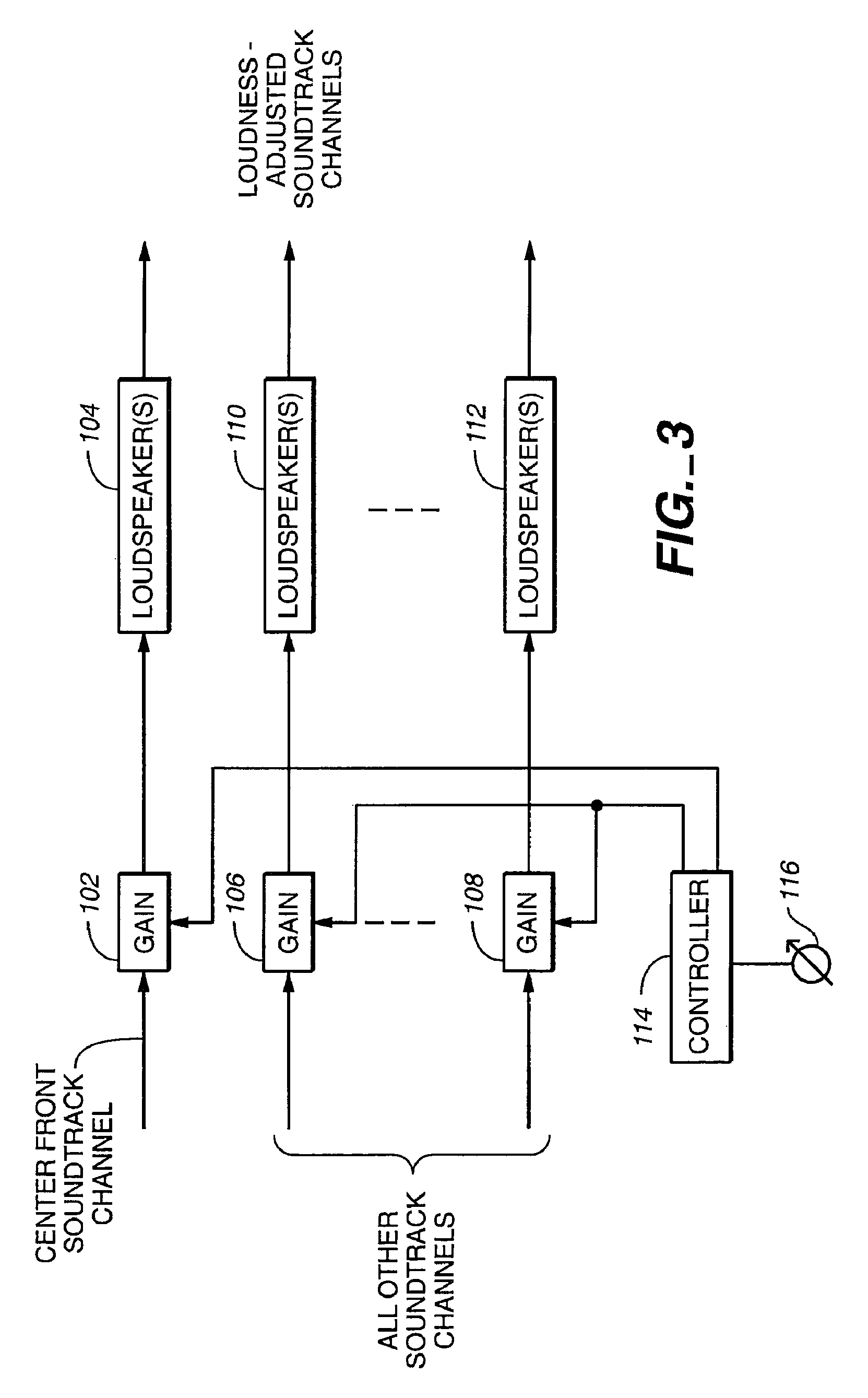

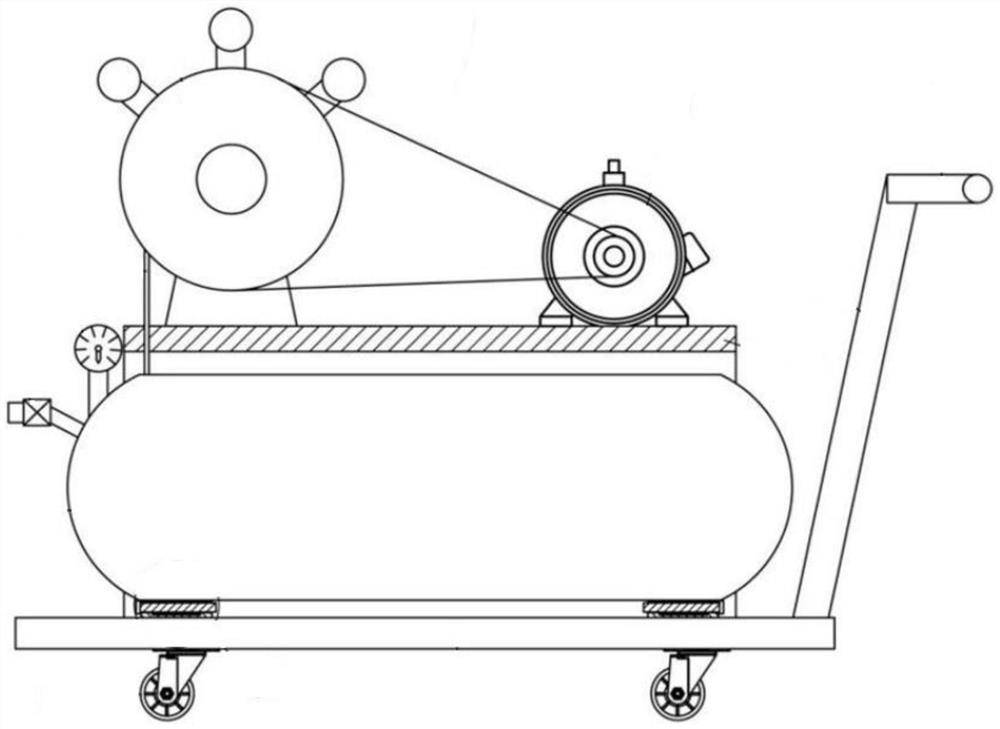

Volume control for audio signals

InactiveUSRE43132E1Maintain levelIncrease in proportionate contributionGain controlStereophonic systemsAudio signal flowAudio frequency

Owner:DOLBY LAB LICENSING CORP

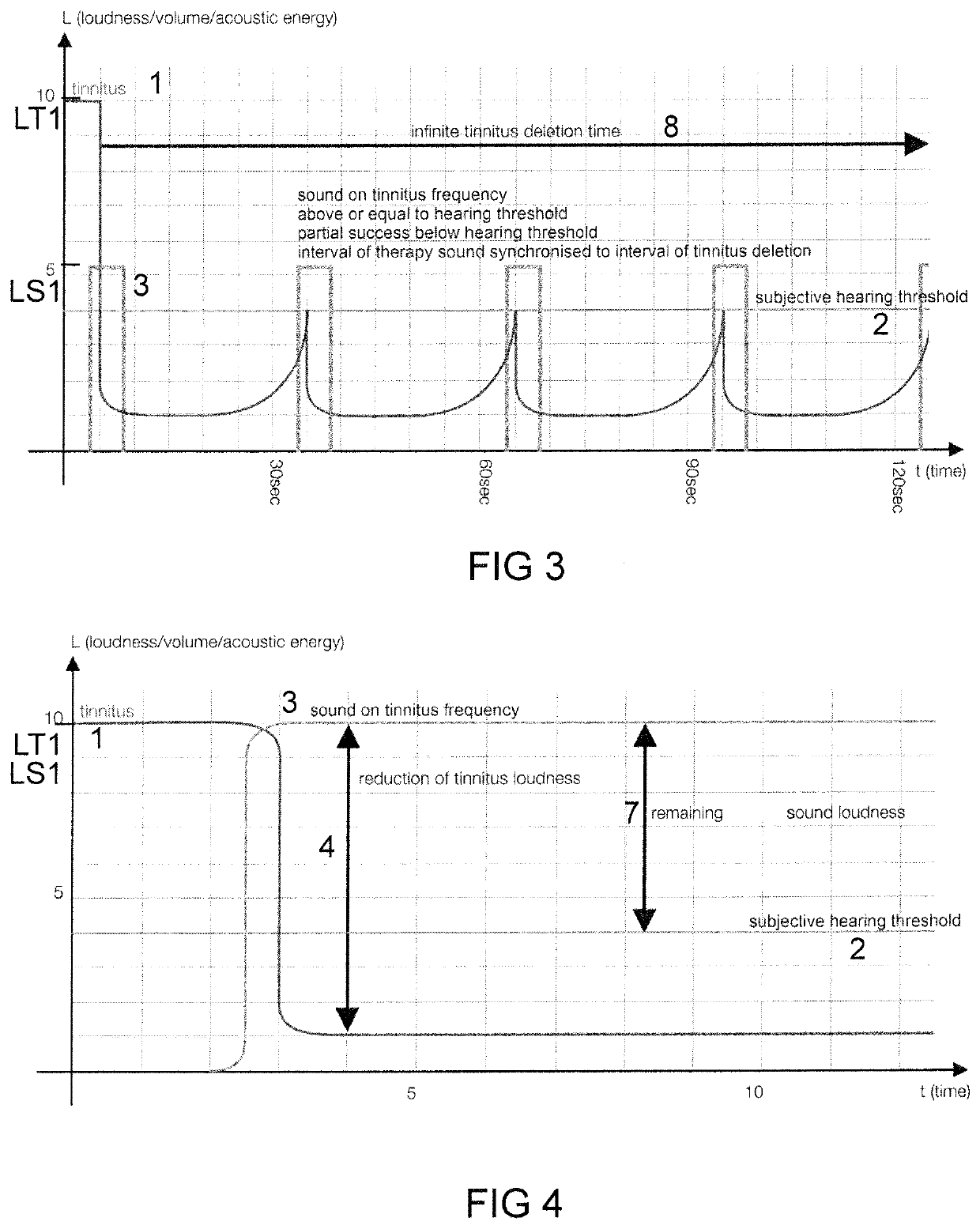

Device for providing an audio signal

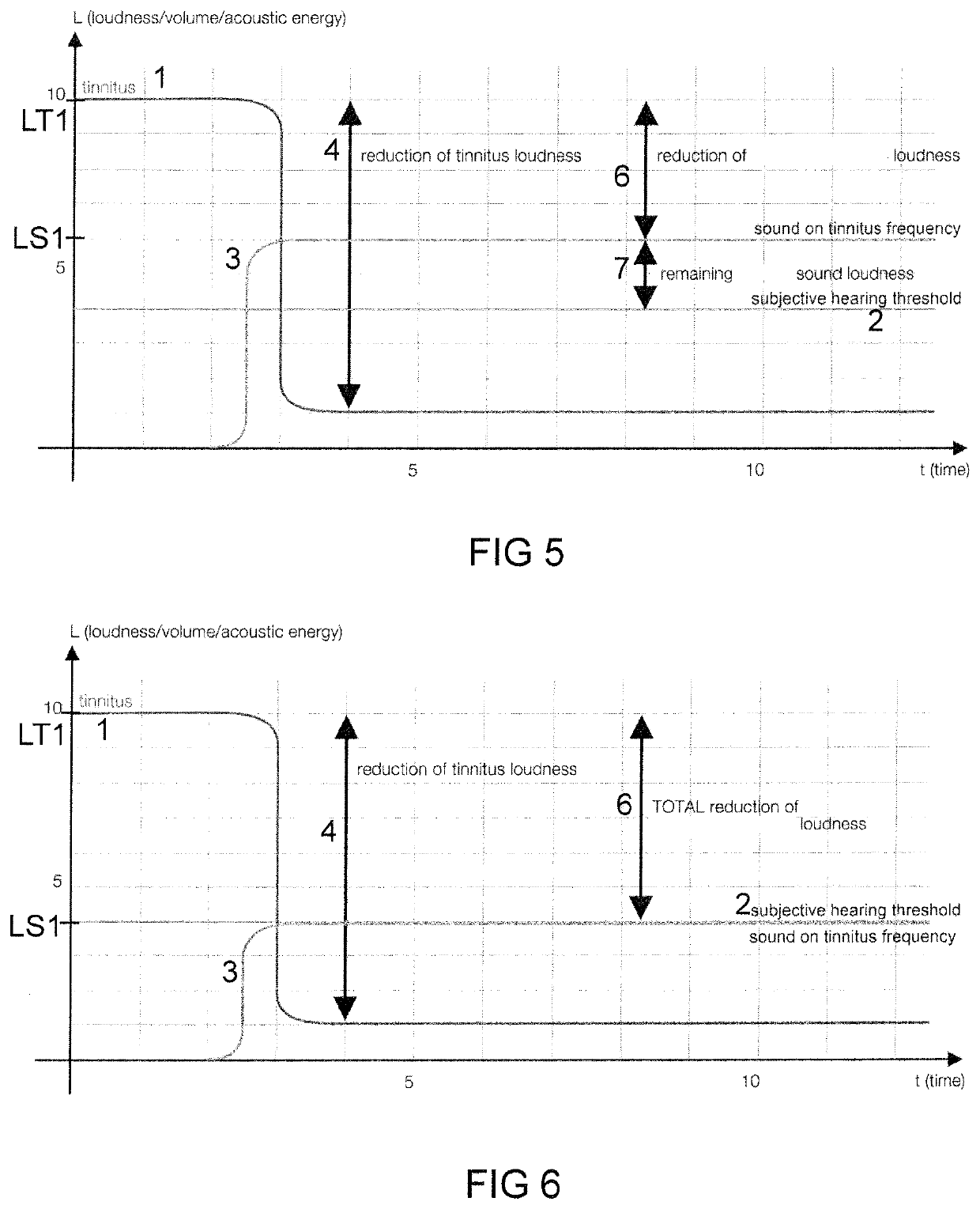

ActiveUS20220078566A1Less effortDecrease and suppresses tinnitusElectric tinnitus maskersDiagnostic recording/measuringFrequency spectrumAudio frequency

The present idea refers to a device for providing an audio signal for suppressing or decreasing a user's tinnitus. The device comprises an identification unit for supporting a determination of at least one parameter regarding the user's tinnitus, an adaptation unit configured to modify a received audio signal based on the at least one parameter, thereby obtaining the audio signal, or to generate the audio signal based on the at least one parameter, wherein a defined frequency spectrum of the audio signal is based on a tinnitus suppression frequency, and an audio output unit configured to play the audio signal to the user.

Owner:MY TINNITUS HAS GONE

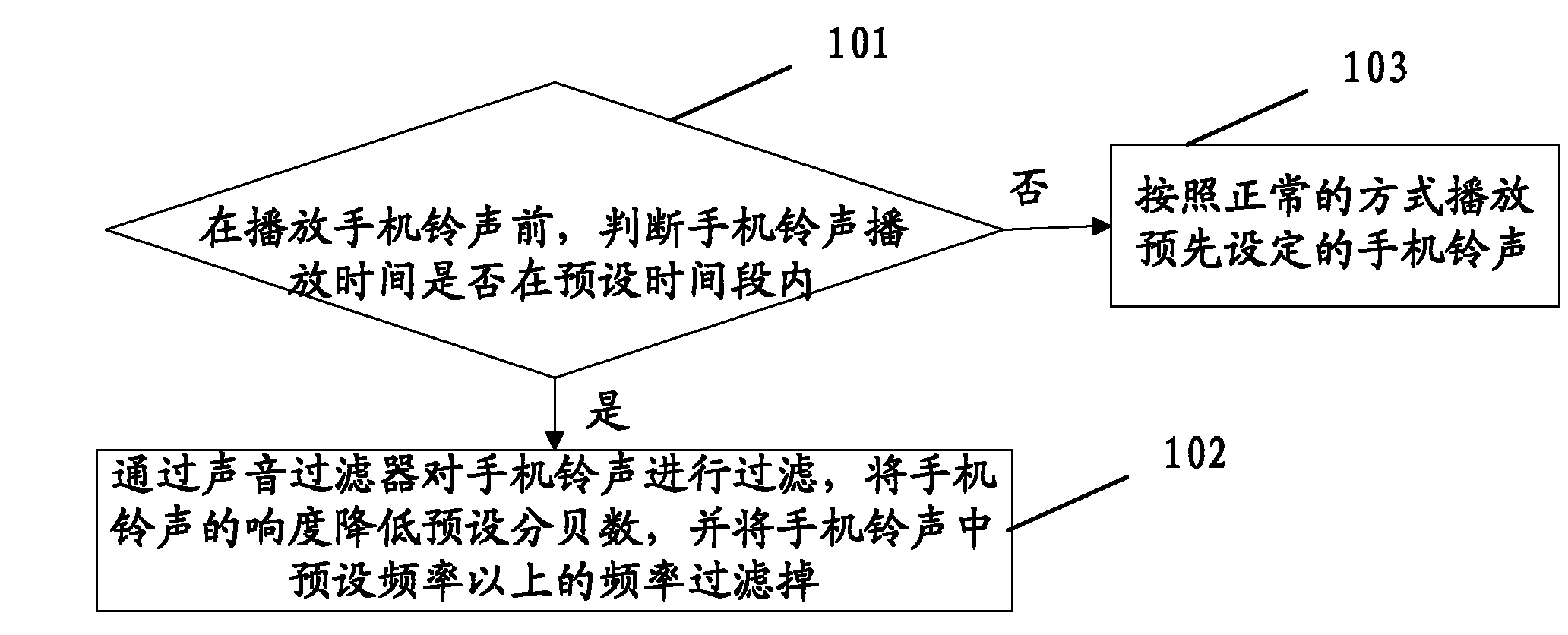

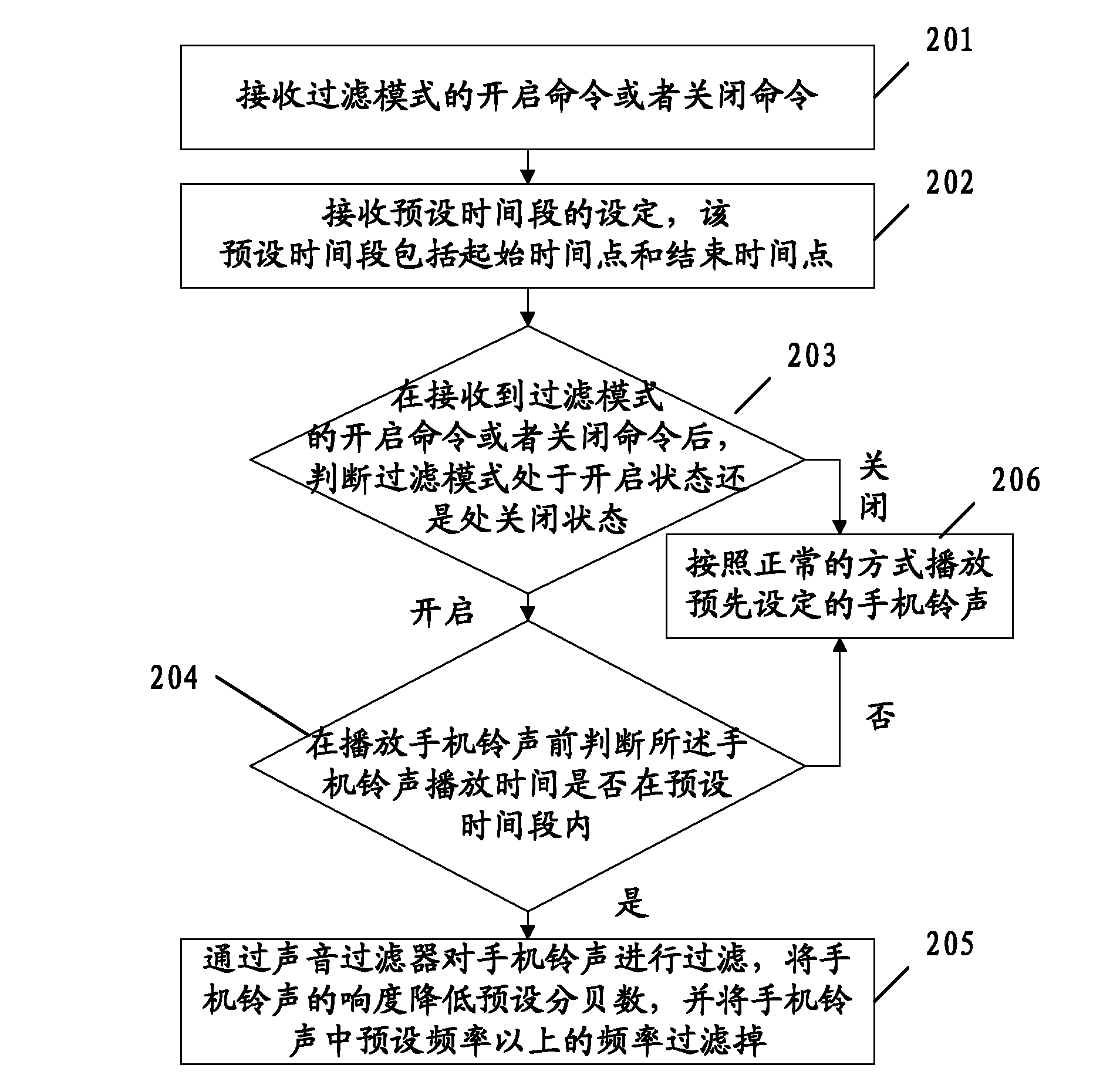

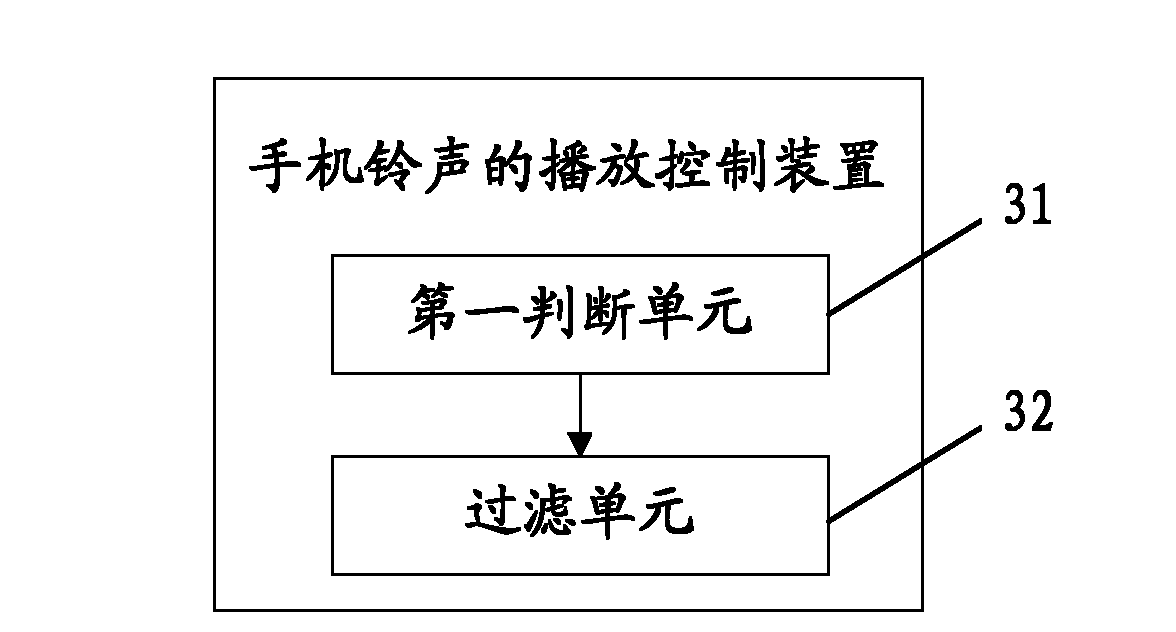

Playing control method and device for mobile phone ring tone and mobile phone

InactiveCN102006369AReduce loudnessReduce frequencyCurrent supply arrangementsSubstation equipmentTime segmentLoudness

The embodiment of the invention discloses a playing control method and a playing control device for mobile phone ring tone and a mobile phone, and relates to the technical field of mobile terminals. The method and the device can automatically filter the mobile phone ring tone in the specified time before the mobile phone ring tone is played so as to reduce the frequency and the loudness of the ring tone. The method comprises the following steps of: before the mobile phone ring tone is played, judging whether the mobile phone ring tone playing time is in the preset time slot, if so, filtering the mobile phone ring tone through a sound filter to reduce the loudness of the mobile phone ring tone to the preset decibels and filter the frequency above the preset frequency in the mobile phone ring tone. The method and the device are mainly applied to the mobile phone.

Owner:HUAWEI DEVICE CO LTD

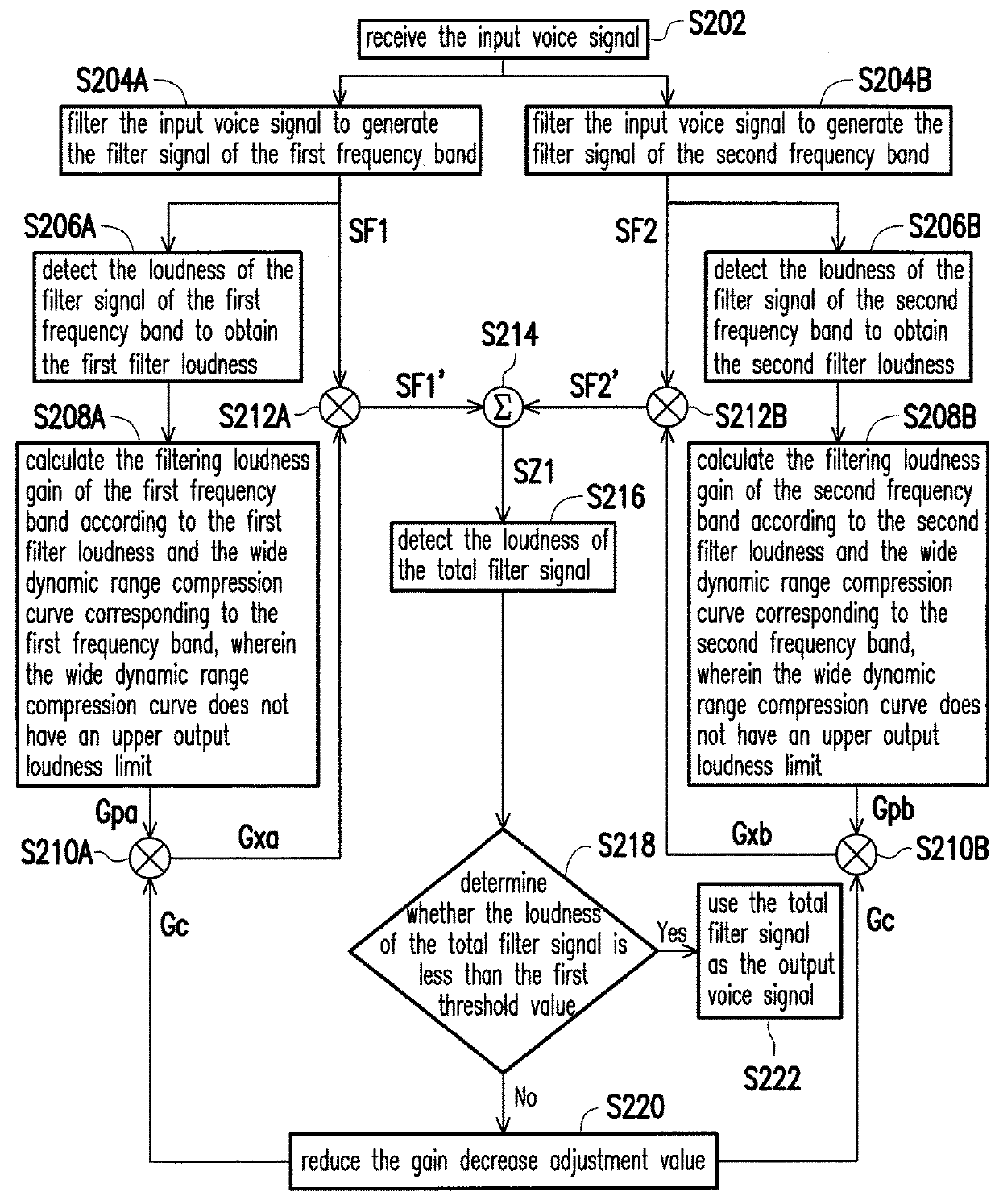

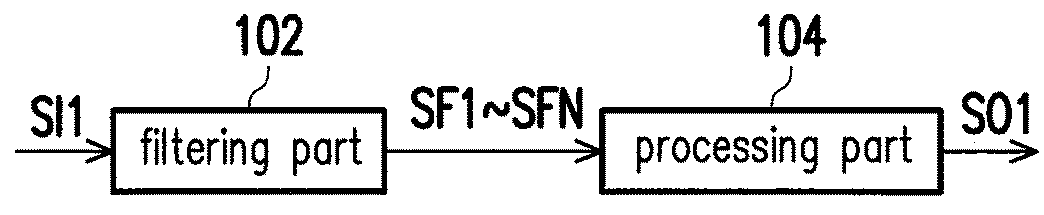

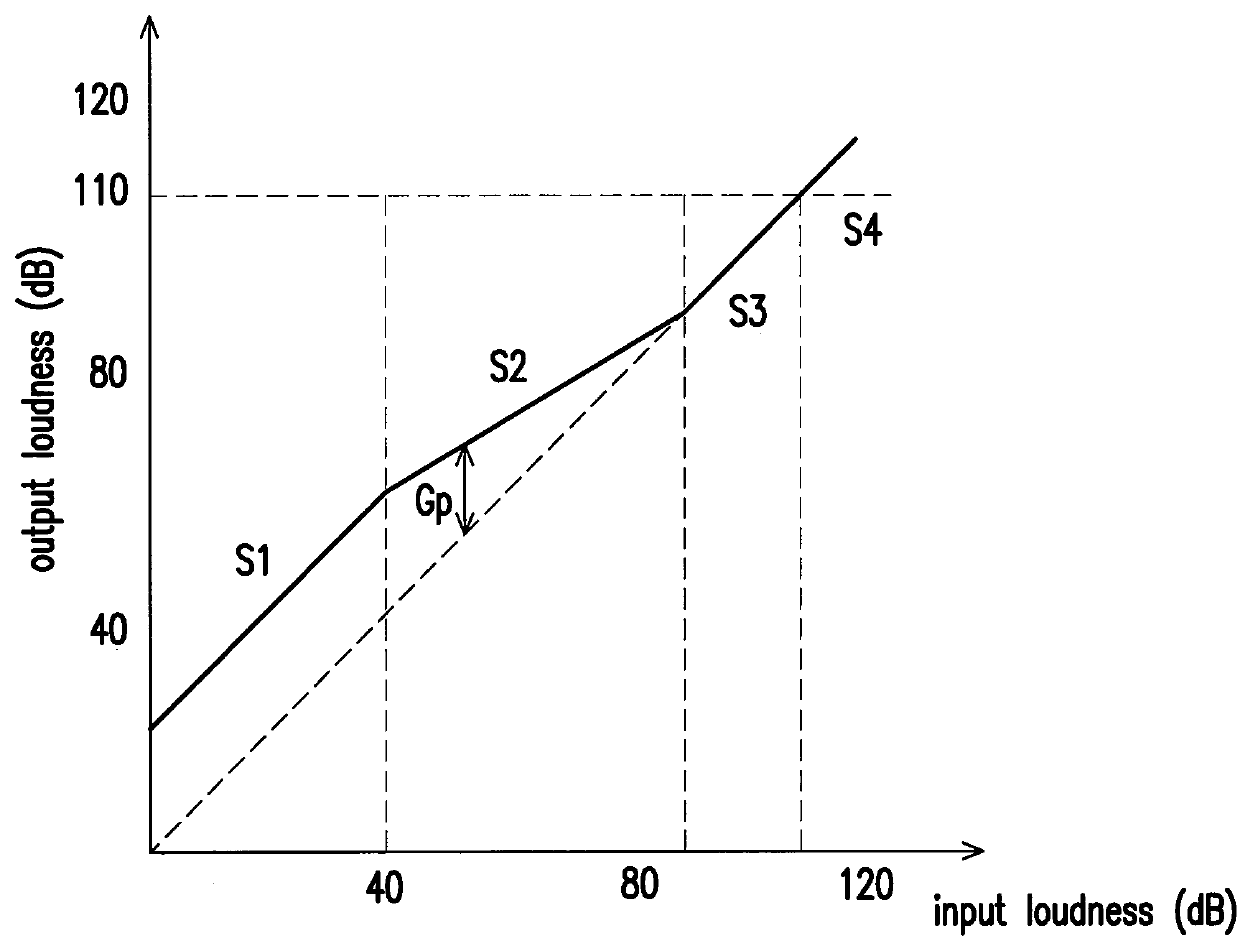

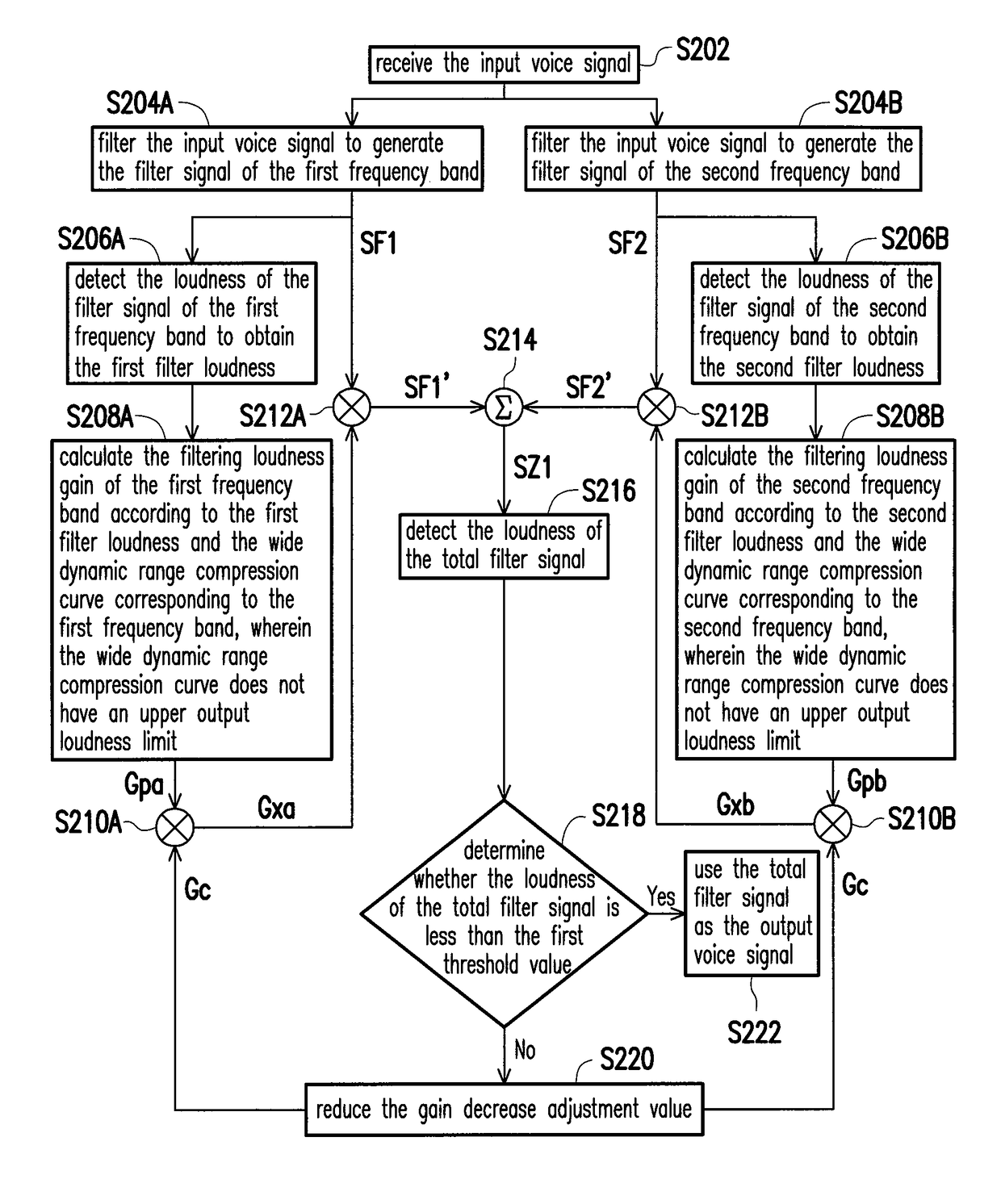

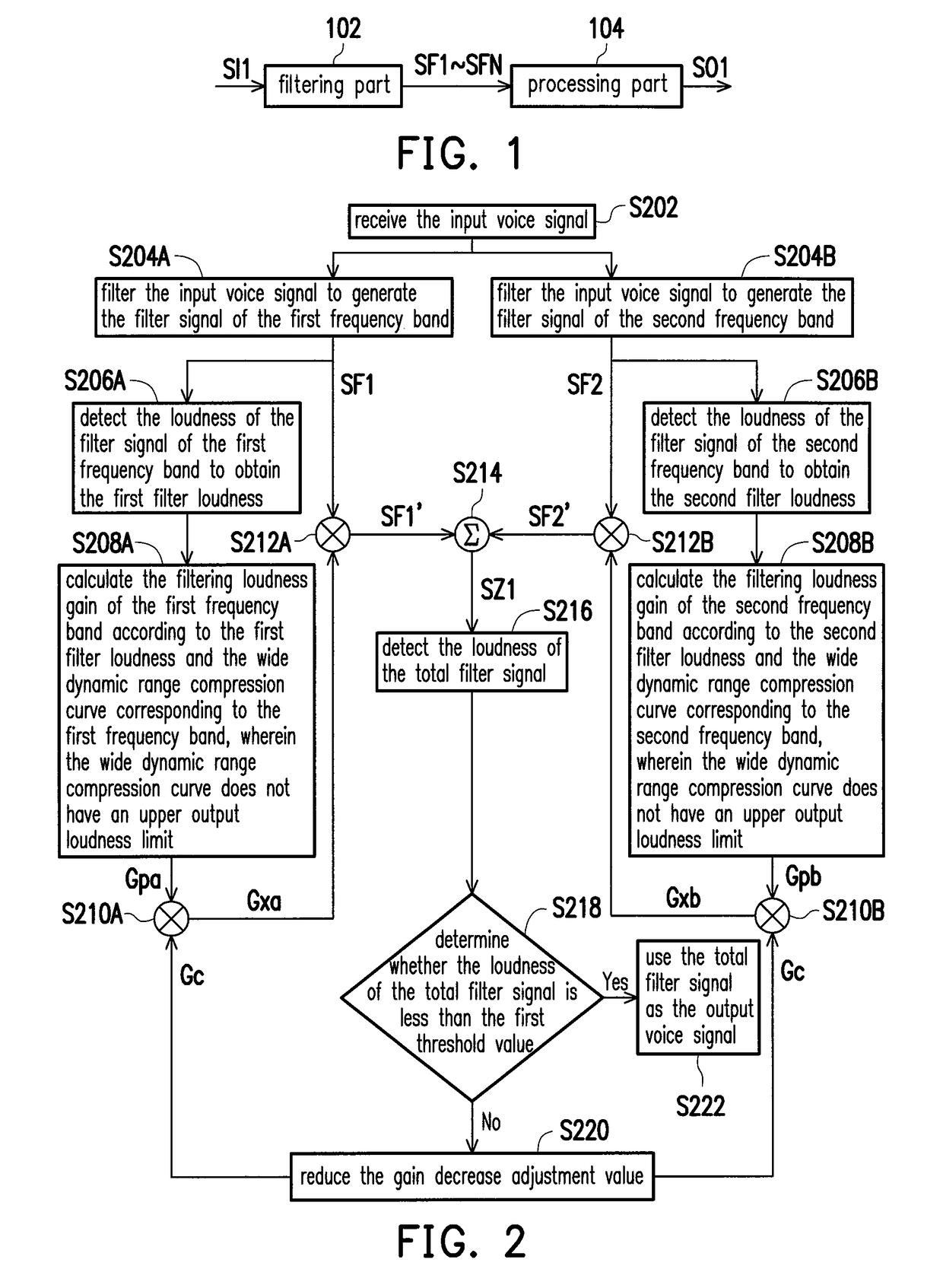

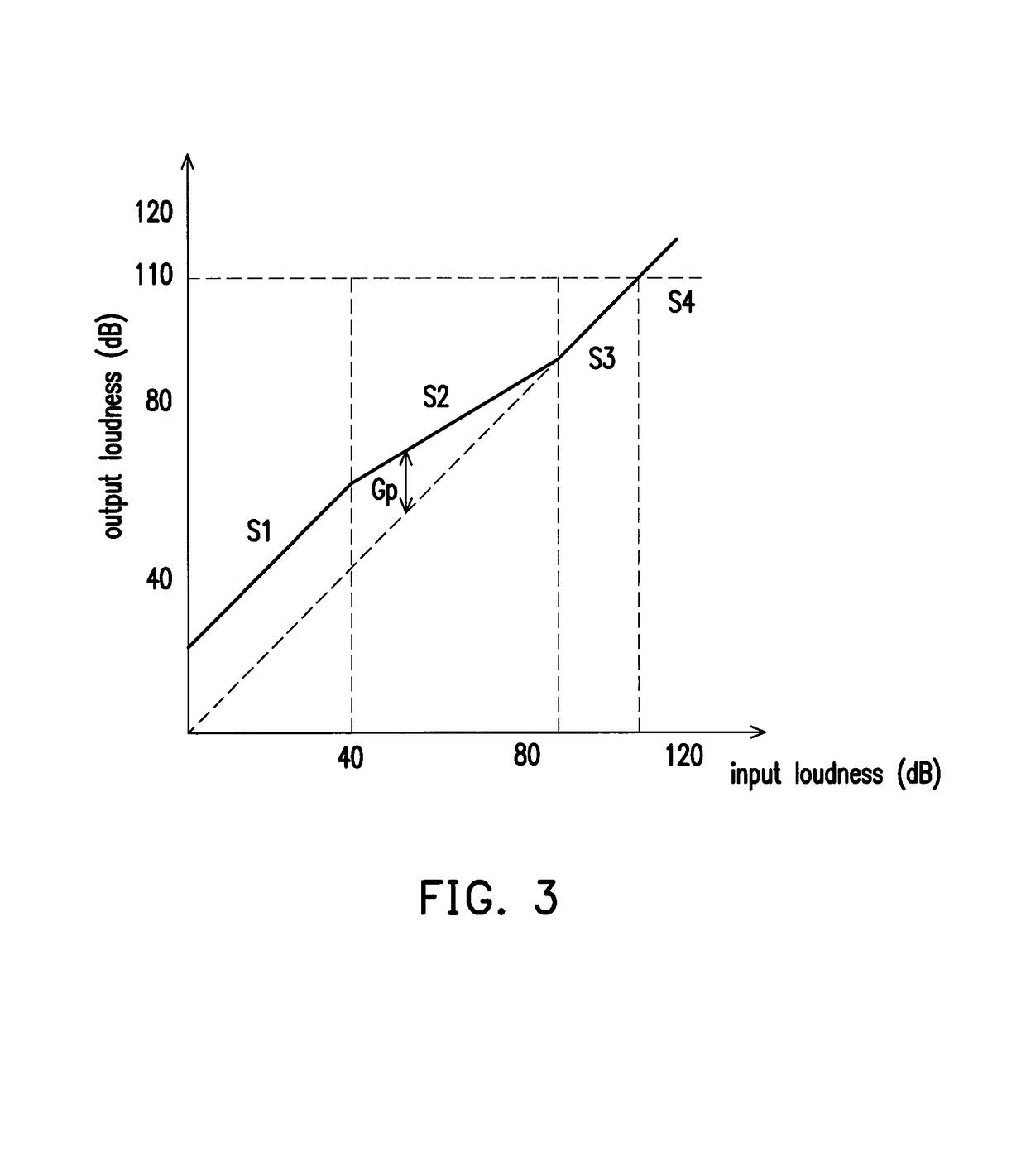

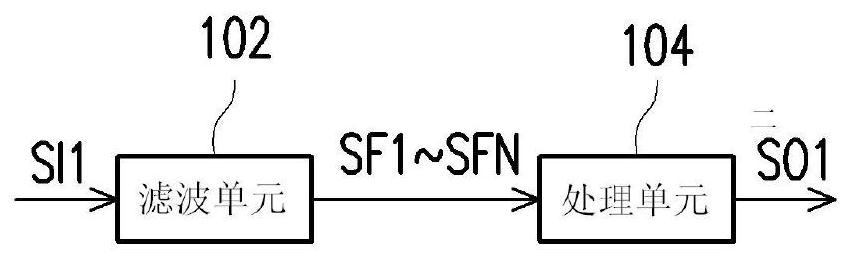

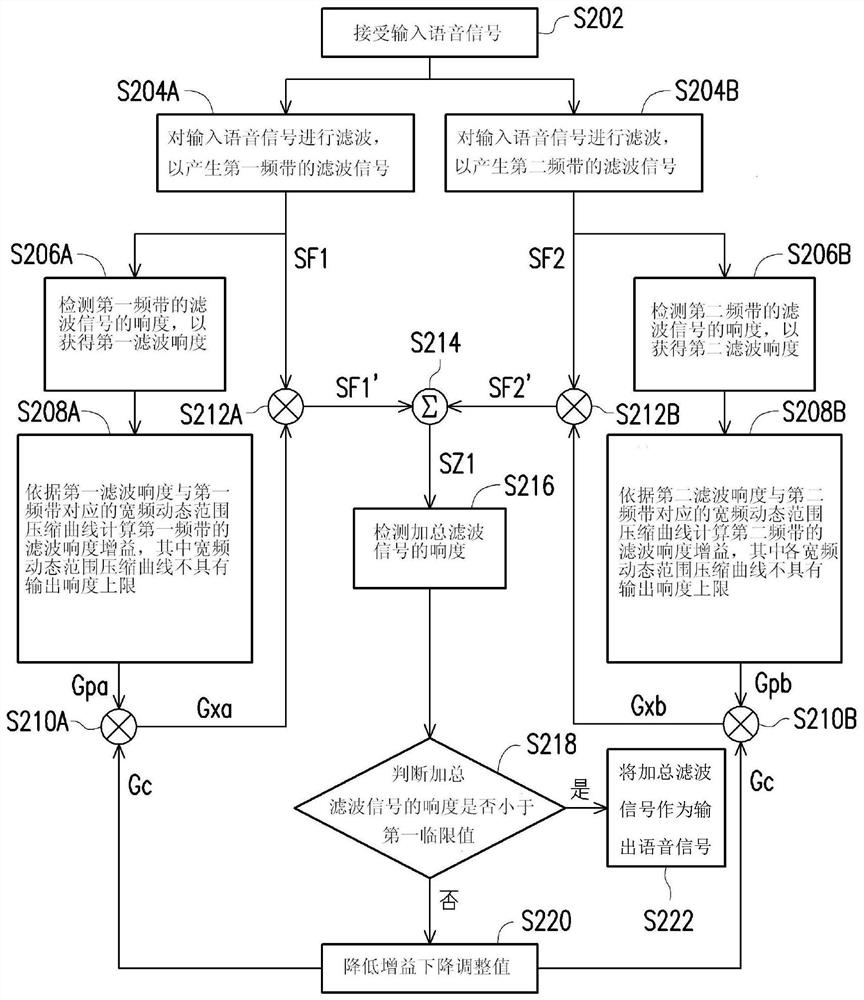

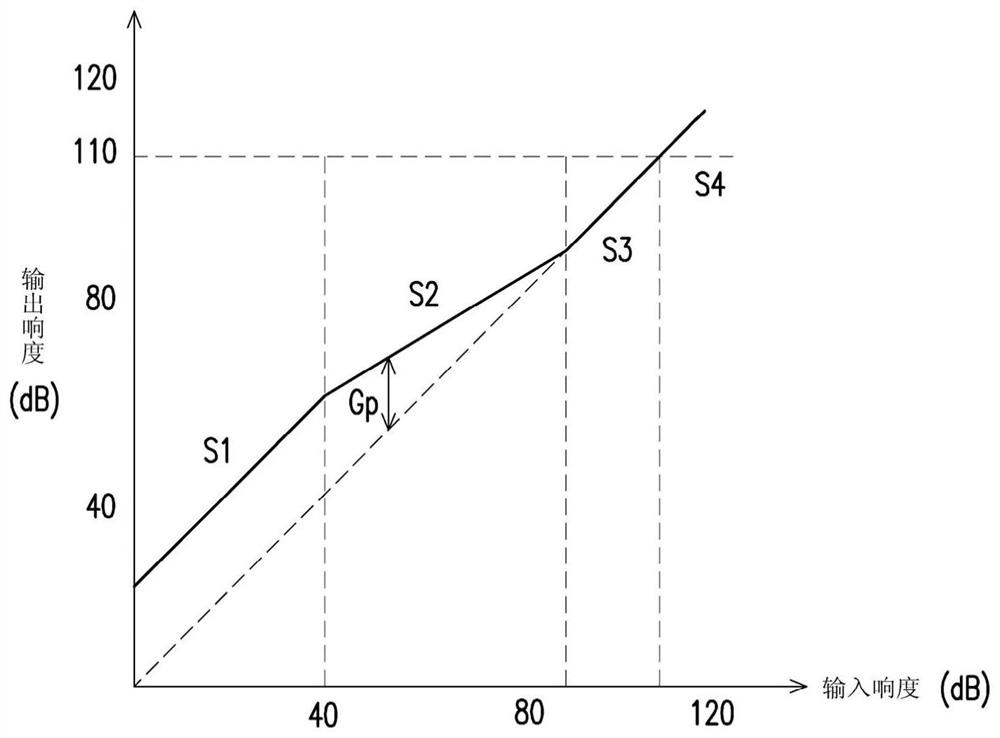

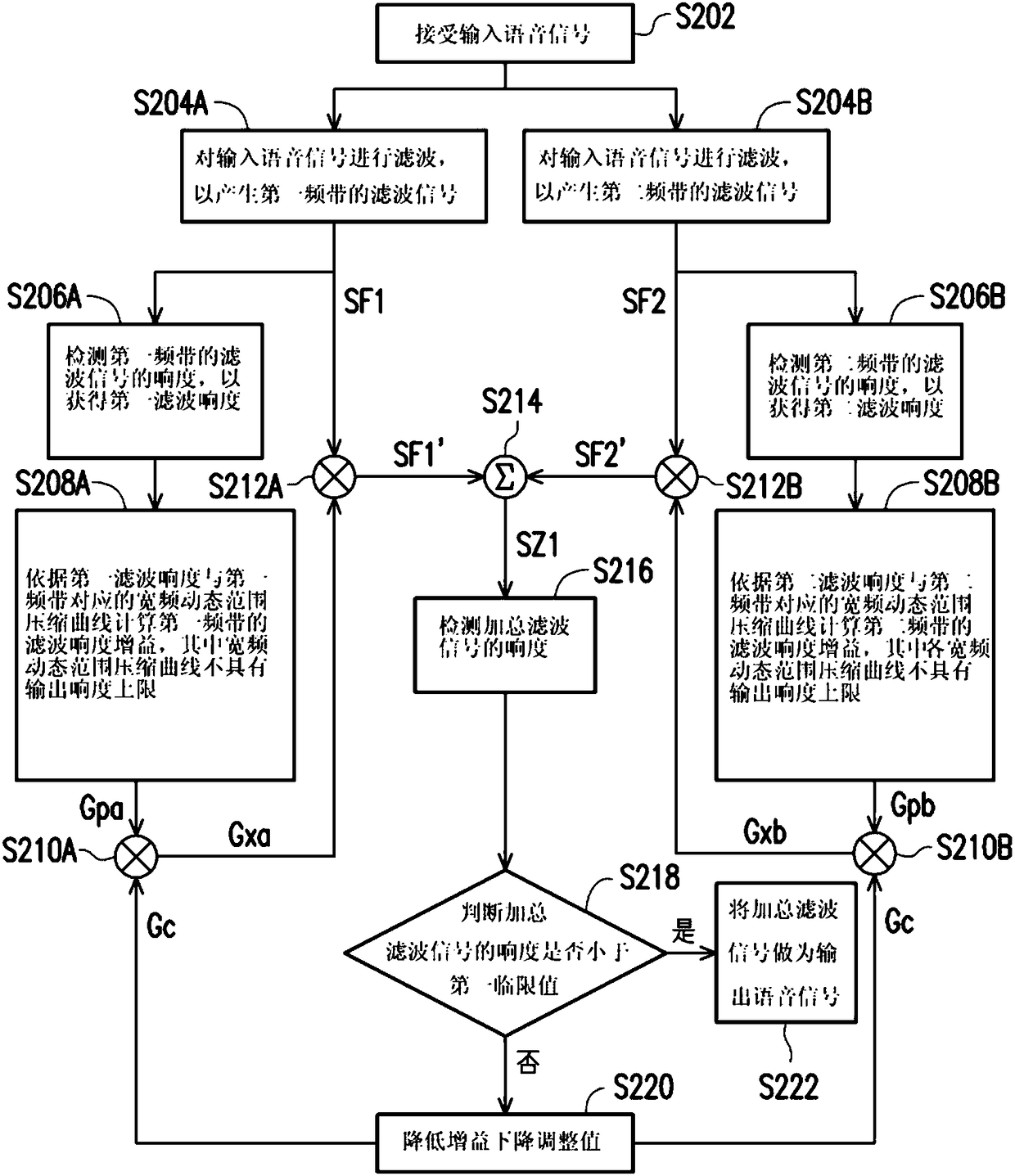

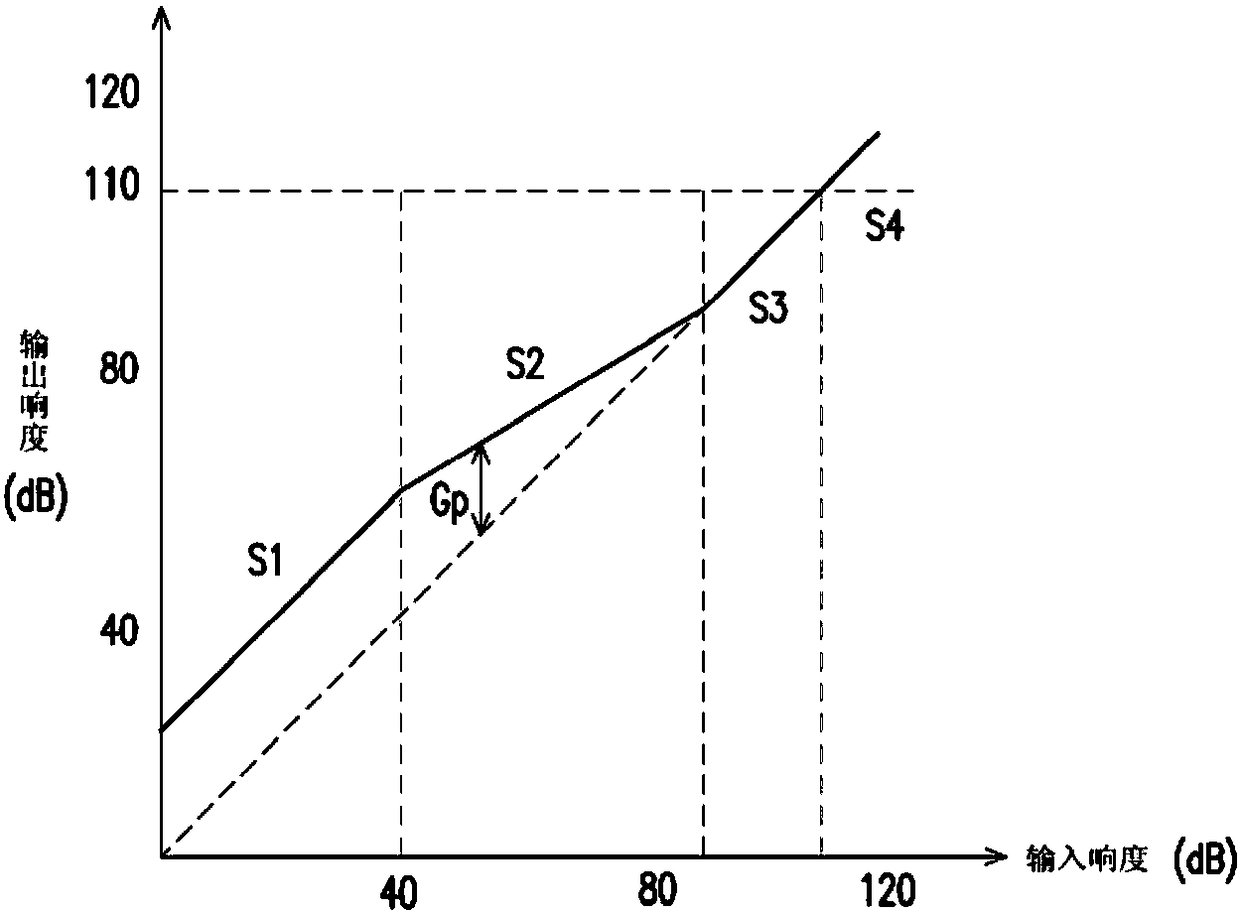

Voice signal processing apparatus and voice signal processing method

ActiveUS20180166092A1Improve output qualityReduce the valueSpeech analysisHearing aids signal processingEngineeringLoudness

A voice signal processing apparatus and a voice signal processing method are provided. A filtering loudness gain of a filter signal of each frequency band is adjusted according to a wide dynamic range compression curve without an upper output loudness limit. The filtering loudness gain of each frequency band is reduced by lowering a gain decrease adjustment value, so as to reduce a loudness of a loudness adjusted filter signal, and thus a loudness of an output voice signal is lower than a first threshold value.

Owner:ACER INC

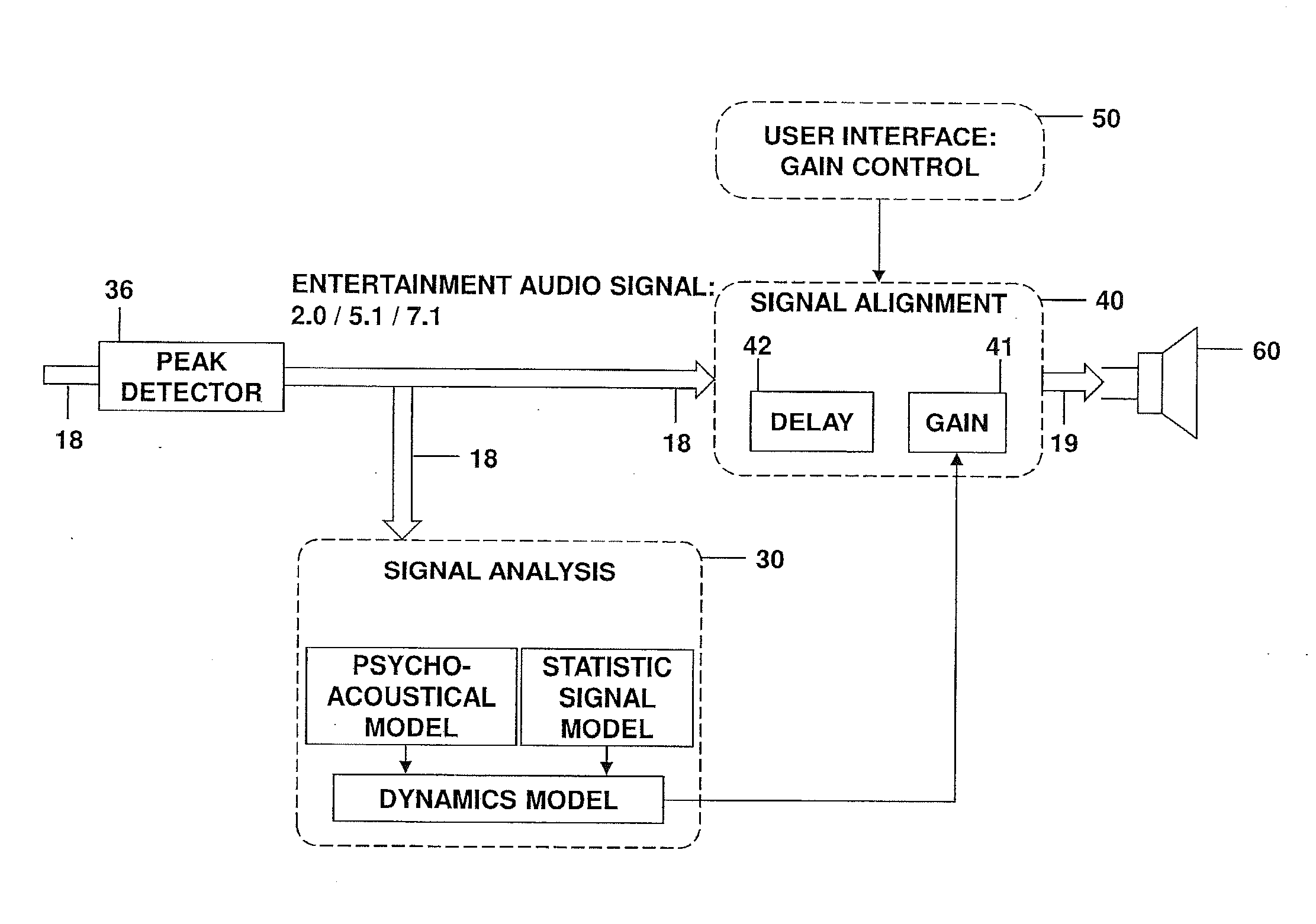

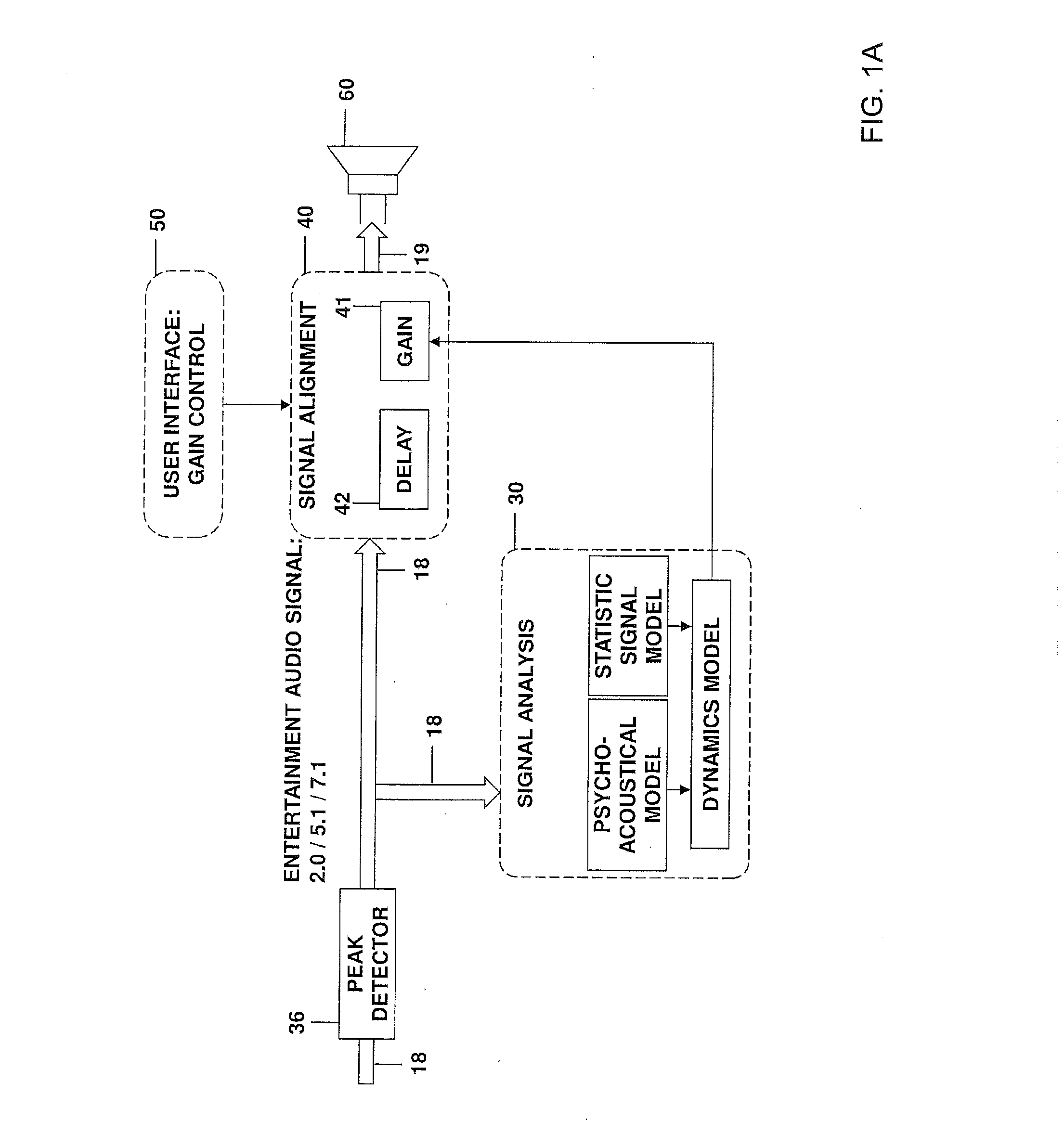

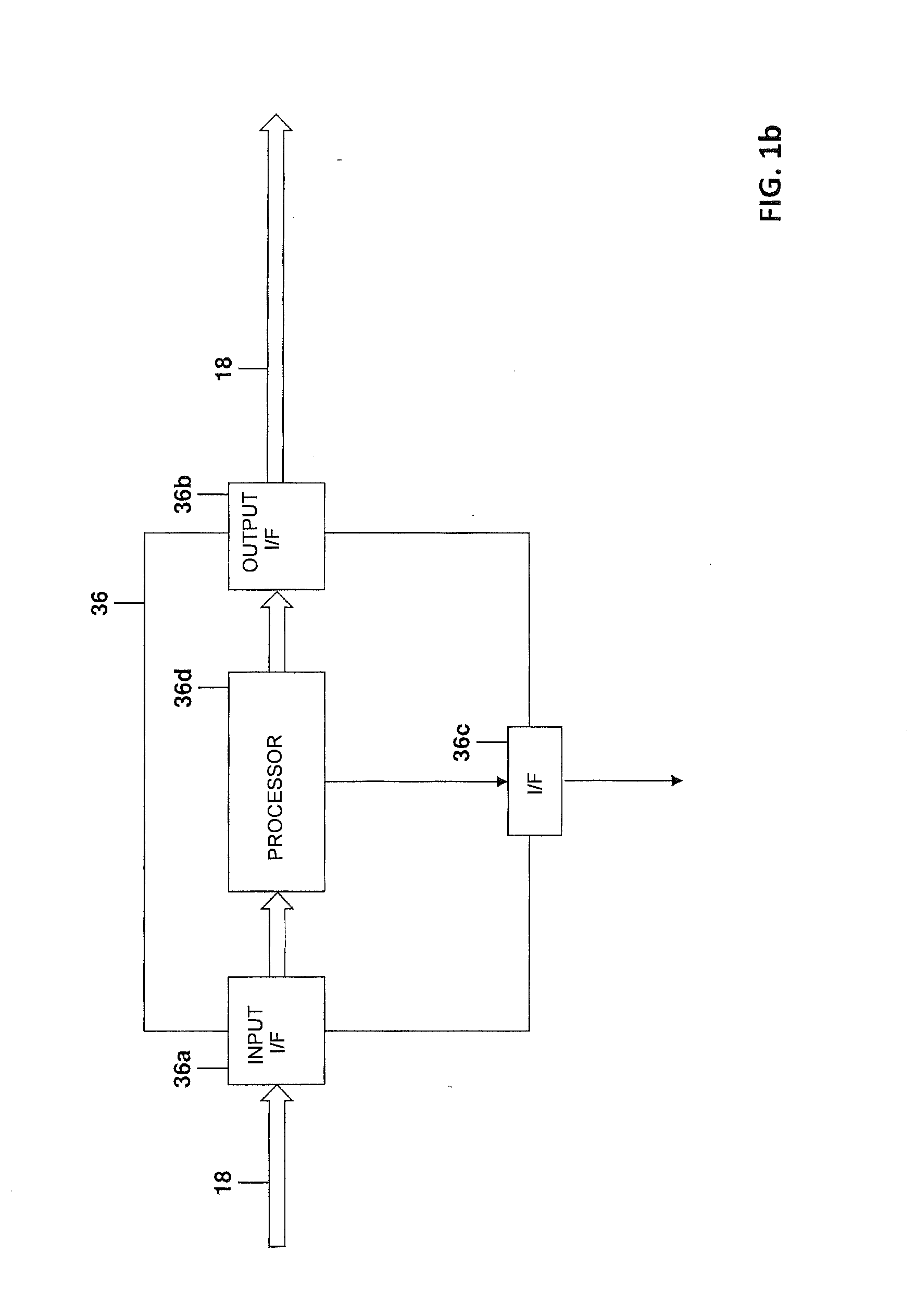

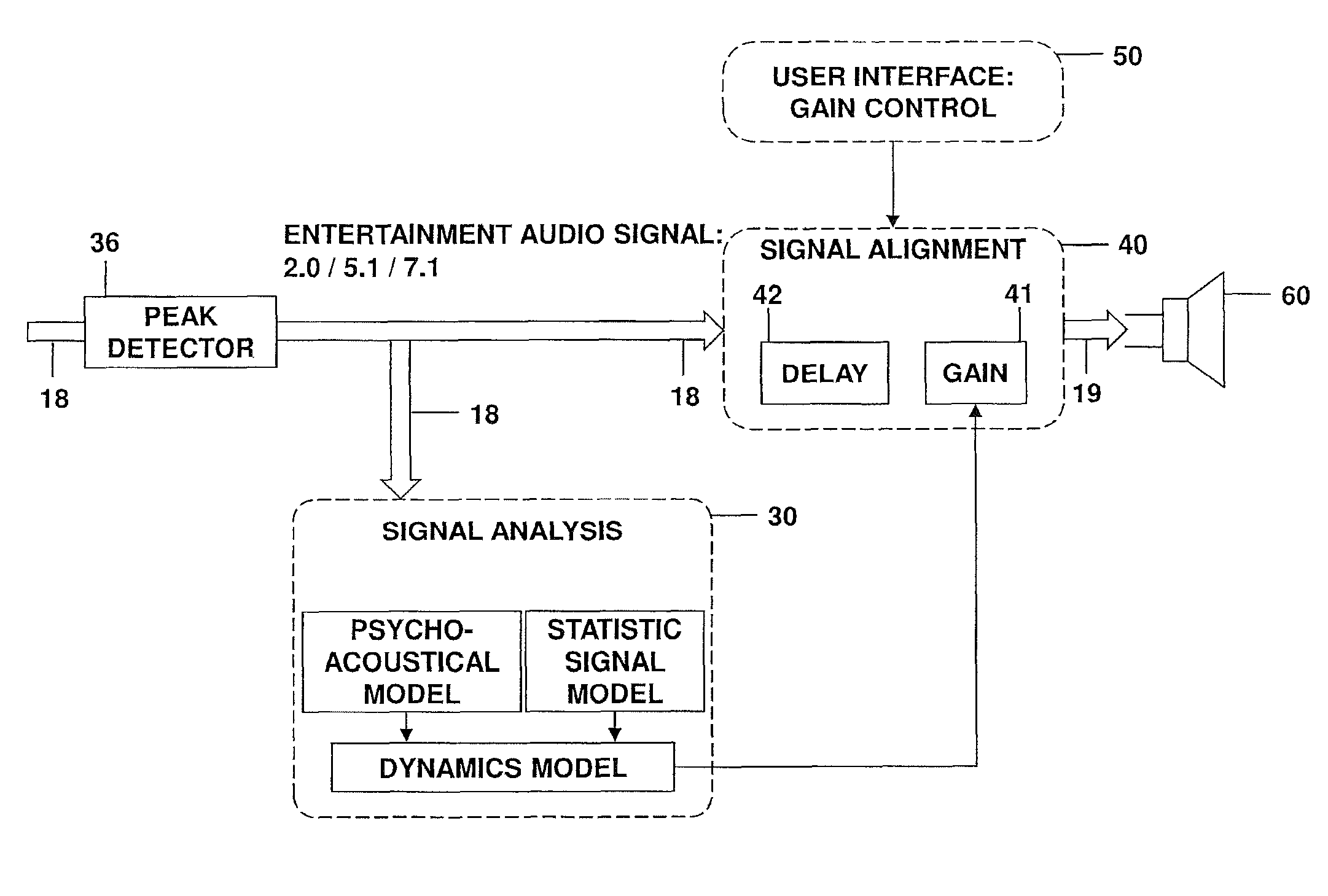

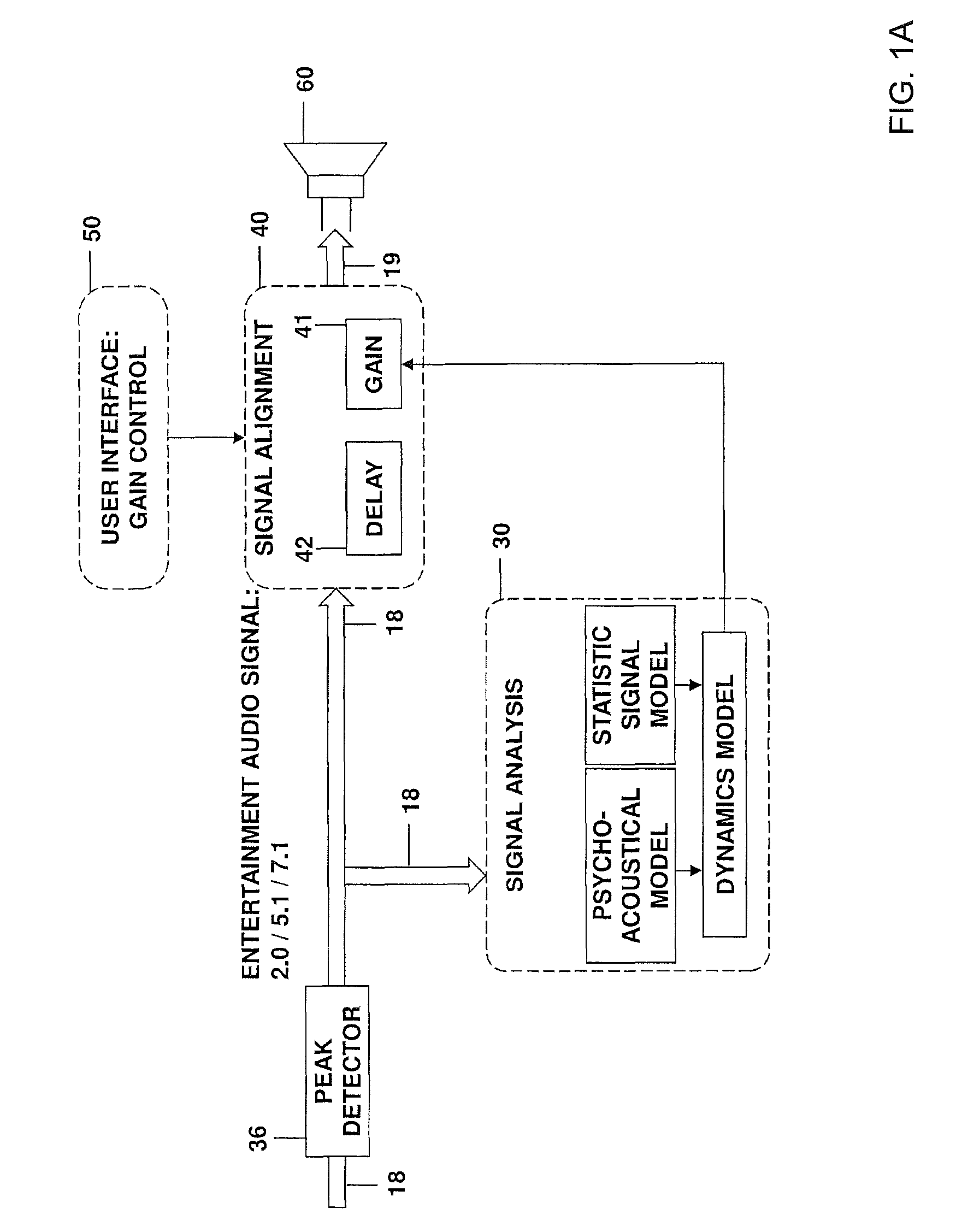

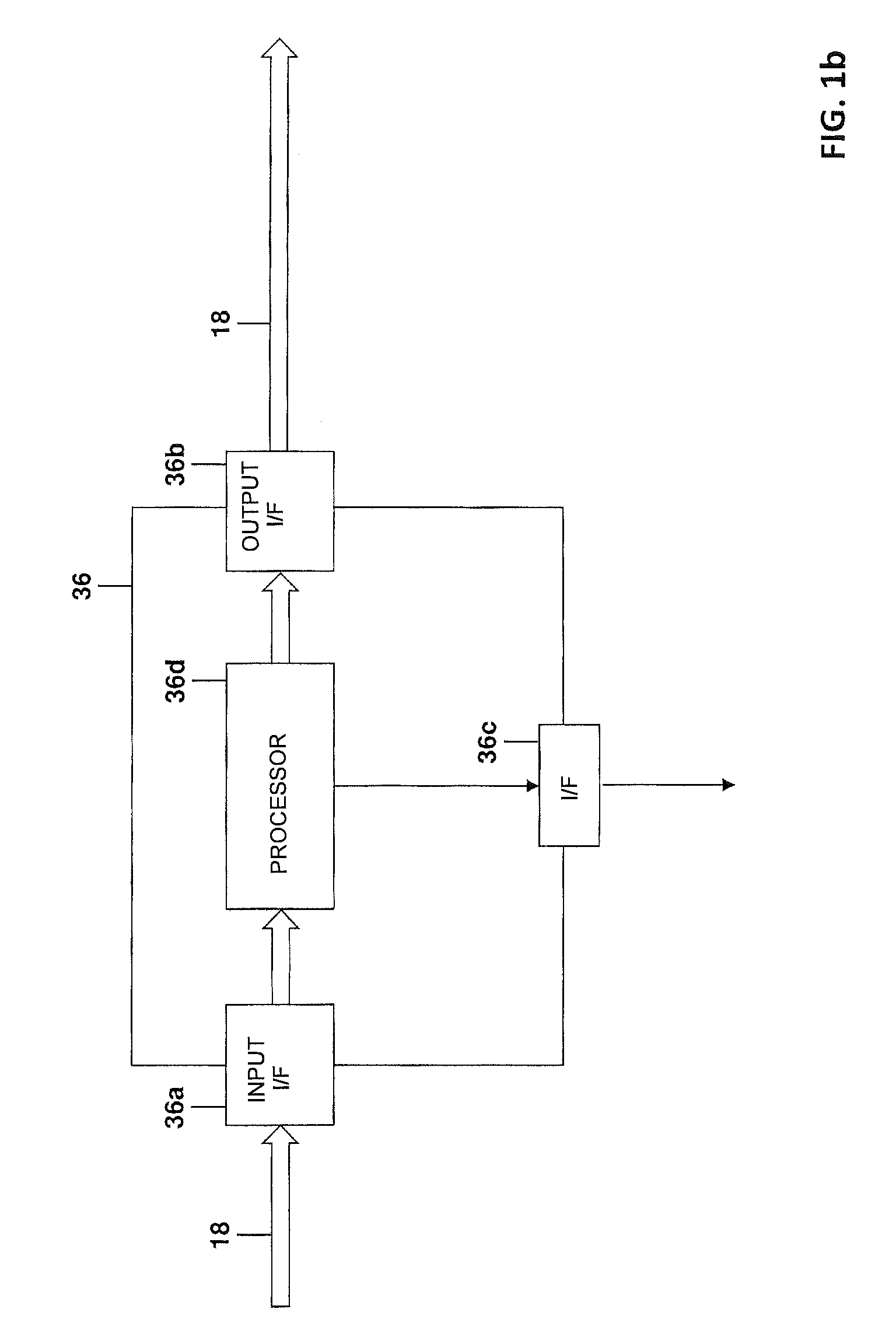

Peak detection when adapting a signal gain based on signal loudness

ActiveUS20130195279A1Increase control flexibilityIncrease flexibilityGain controlDigital signal tone/bandwidth controlContinuous signalTime constant

Various embodiments relate to a system for adapting a signal gain, which comprises a peak detector configured to receive an audio input signal containing consecutive signal blocks and to dynamically establish a current input signal level of the audio input signal, and a loudness determination unit configured to dynamically determine a perceived loudness of a current signal block of the audio input signal based on a psycho-acoustic model of a human hearing. Furthermore the system comprises a time constant generation unit configured to determine a time constant based on the perceived loudness of the current signal block and the perceived loudness of a preceding signal block, wherein the time constant describing a change of the signal gain. A gain determination unit is configured to determine the signal gain for the current signal block based on the time constant and the current input signal level.

Owner:HARMAN BECKER AUTOMOTIVE SYST

Voice signal processing apparatus and voice signal processing method

ActiveUS10109293B2Improve output qualityReduce the valueGain controlSpeech analysisEngineeringLoudness

A voice signal processing apparatus and a voice signal processing method are provided. A filtering loudness gain of a filter signal of each frequency band is adjusted according to a wide dynamic range compression curve without an upper output loudness limit. The filtering loudness gain of each frequency band is reduced by lowering a gain decrease adjustment value, so as to reduce a loudness of a loudness adjusted filter signal, and thus a loudness of an output voice signal is lower than a first threshold value.

Owner:ACER INC

Peak detection when adapting a signal gain based on signal loudness

ActiveUS9219455B2Increase signal gainReduce signalingGain controlCombination control in untuned amplifierPeak detectionSignal gain

Owner:HARMAN BECKER AUTOMOTIVE SYST

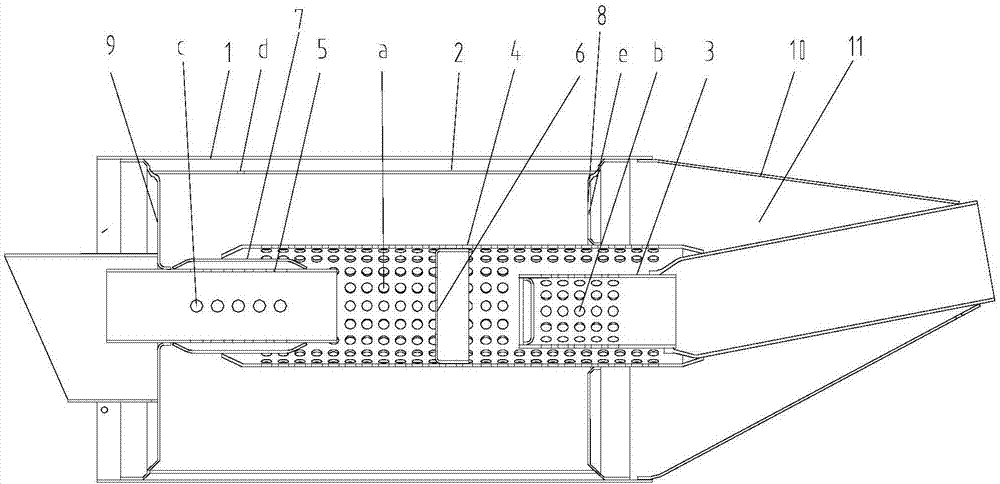

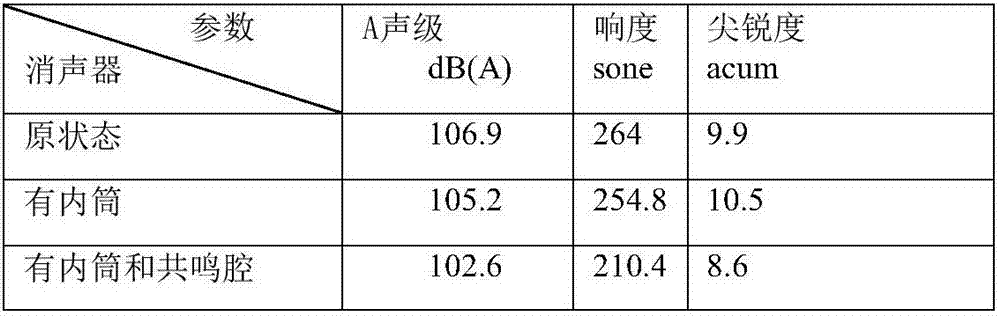

Exhaust resonant silencer and motorcycle with same

ActiveCN107387201ANo reduction in noise reduction performanceLow costInternal combustion piston enginesSilencing apparatusResonant cavityExhaust fumes

The invention discloses an exhaust resonant silencer and a motorcycle with the same. The exhaust resonant silencer comprises a silencer barrel and an internal tube assembly arranged in the silencer barrel for introducing and exhausting waste gas; the internal tube assembly includes a front tube, a middle tube and a tail tube, the tail tube is communicated with the middle tube for introducing waste gas into the tail tube, part of the tail tube is sleeved with a sleeve, a first resonant cavity is formed between the sleeve and the tail tube, and the sidewall of the tail tube corresponding to the sleeve is provided with a radial resonant hole whereby an inner cavity of the tail tube is communicated with the first resonant cavity; the resonant cavity is arranged in the silencer, so that loudness and sharpness of high-frequency noise can be decreased; the tone is greatly improved; through simple adjustments on internal structure of the silencer, the cost of the silencer can be effectively reduced without decreasing the silencing performance of the silencer or affecting dynamic performance of an engine.

Owner:CHONGQING LONCIN MOTOR +1

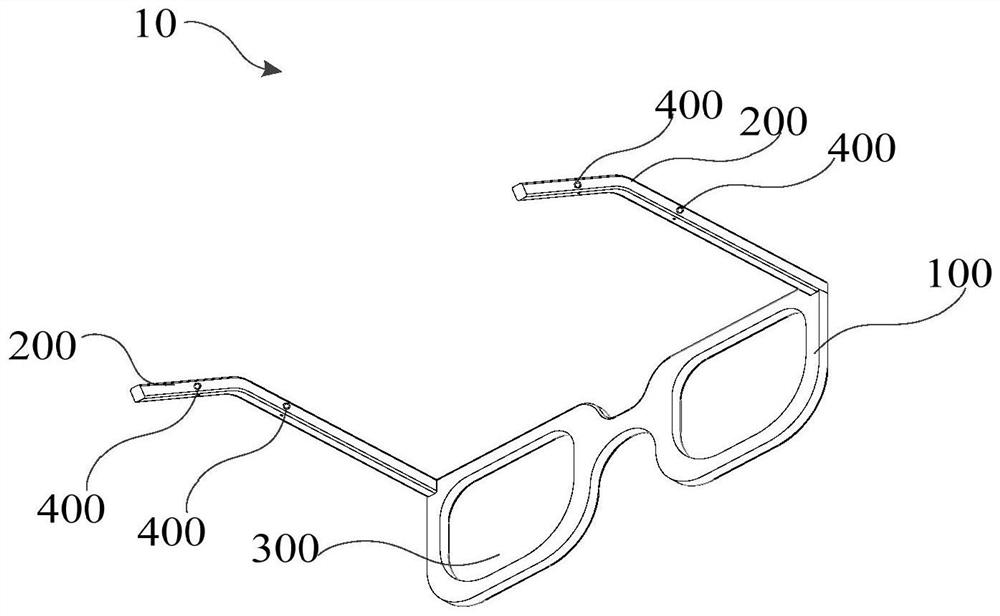

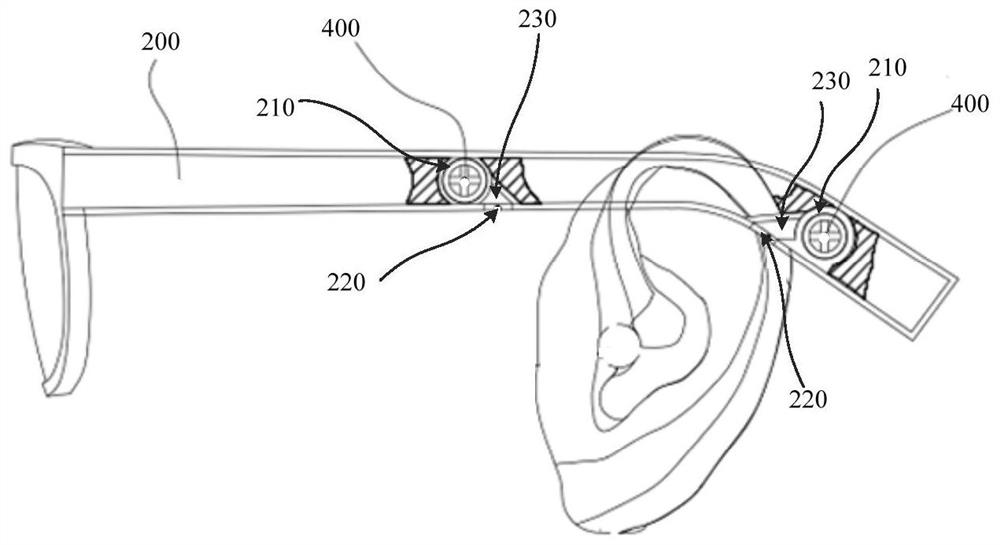

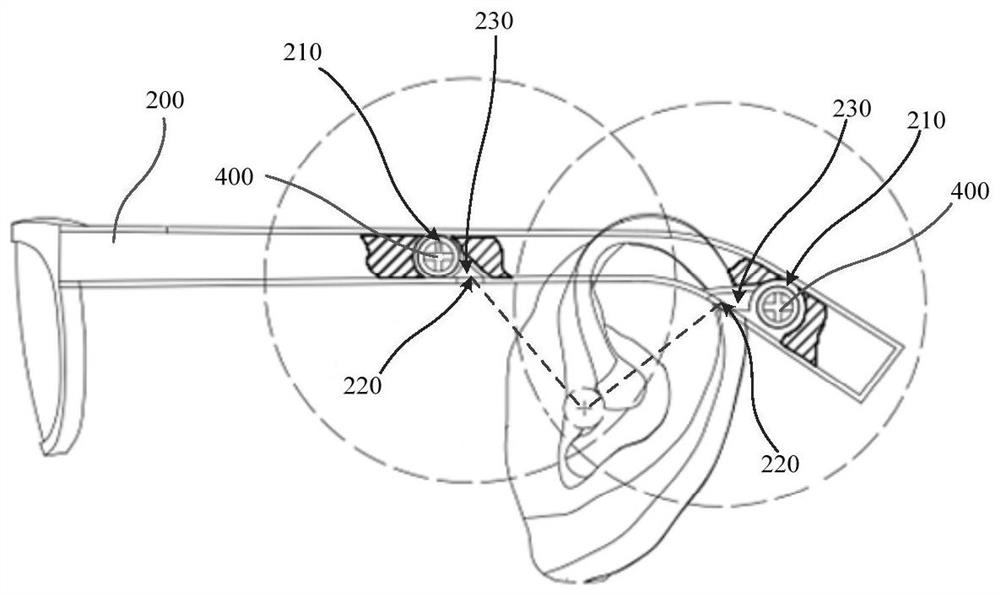

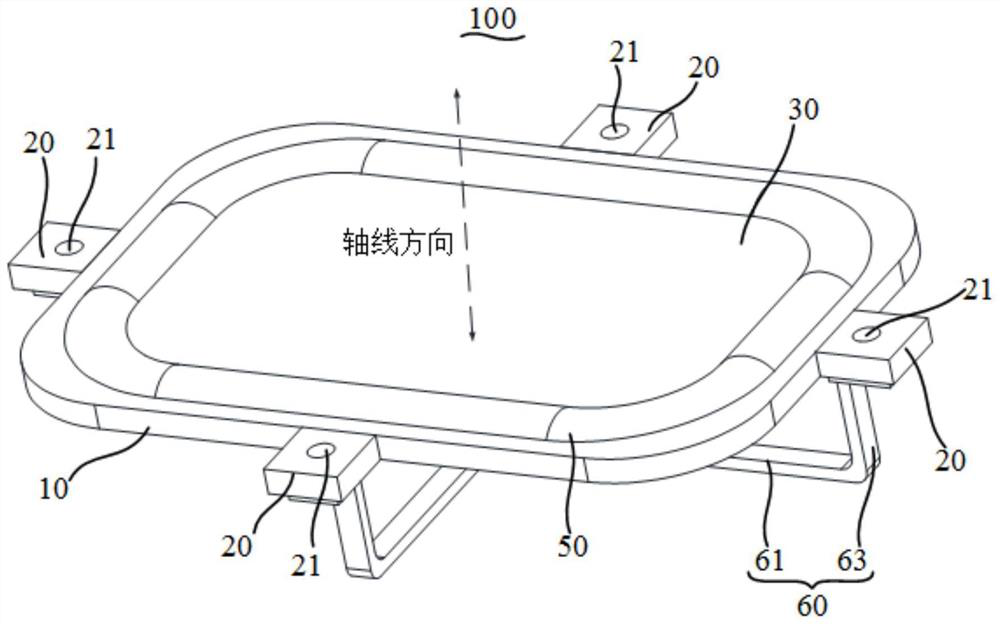

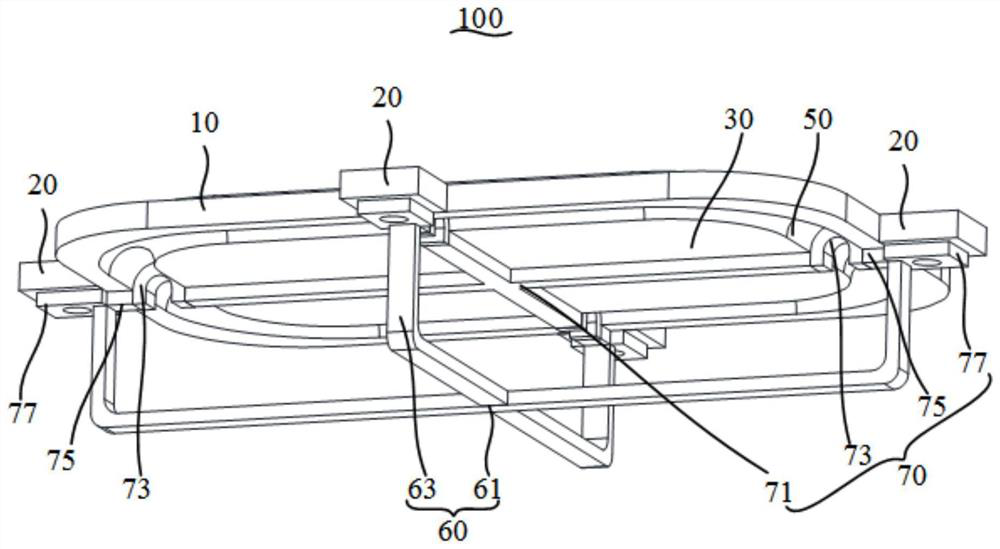

Glasses

PendingCN113805360AReduce the impact of noiseReduce loudnessNon-optical adjunctsEyewearSound production

The invention discloses a pair of glasses, which comprise glasses frames, glasses legs and at least one sound production device. The glasses legs are connected with the glasses frames, and the at least one sound production device is arranged in the at least one glasses leg. The glasses legs are provided with at least two sound outlet holes which are arranged at intervals, and the at least two sound outlet holes are used for transmitting sound emitted by at least one sound production device. In a wearing state, the distances between at least two of the sound outlet holes in the glasses legs and ear canal openings of corresponding ears are the same. In this way, the sound quality effect can be effectively improved.

Owner:ANKER INNOVATIONS TECH CO LTD

Electric hair drier

InactiveCN109330155AHas a sound-absorbing effectImprove qualityHair dryingSound producing devicesMicrocontrollerAir volume

The invention discloses an electric hair drier, and belongs to the field of household appliances. The electric hair drier comprises an electric hair drier body and a handle, wherein the two ends of the electric hair drier body are provided with an air inlet and an air outlet respectively, the air inlet and the air outlet are provided with sound quality regulating devices respectively, and each sound quality regulating device comprises a shell body matched with the shape of the electric hair drier body and a sound production assembly arranged in the corresponding shell body; the two ends of each shell body are provided with sealing plates, the inner portion of each shell body is provided with a spiral airflow channel in the axial direction of the shell body, each sound production assembly comprises a microcontroller comprising a storage module and a micro speaker arranged in an outlet of the corresponding spiral airflow channel, and sound files are pre-stored in the storage modules. Combined with the noise elimination design of the spiral airflow channels, the loudness of the noise of the electric hair drier is reduced, according to the used air volume gear of the electric hair drier, the preset sound files are played automatically through the sound production assemblies, the time-frequency characteristics of the noise of the electric hair drier are regulated, the sound comfortlevel is improved, and the sound quality of the electric hair drier is improved.

Owner:仇俊易 +1

Generating an adapted audio file

ActiveUS9277337B2Reduced activityReduce loudnessElectric tinnitus maskersAudio data retrievalFrequency characteristicAudio frequency

Owner:MY TINNITUS HAS GONE

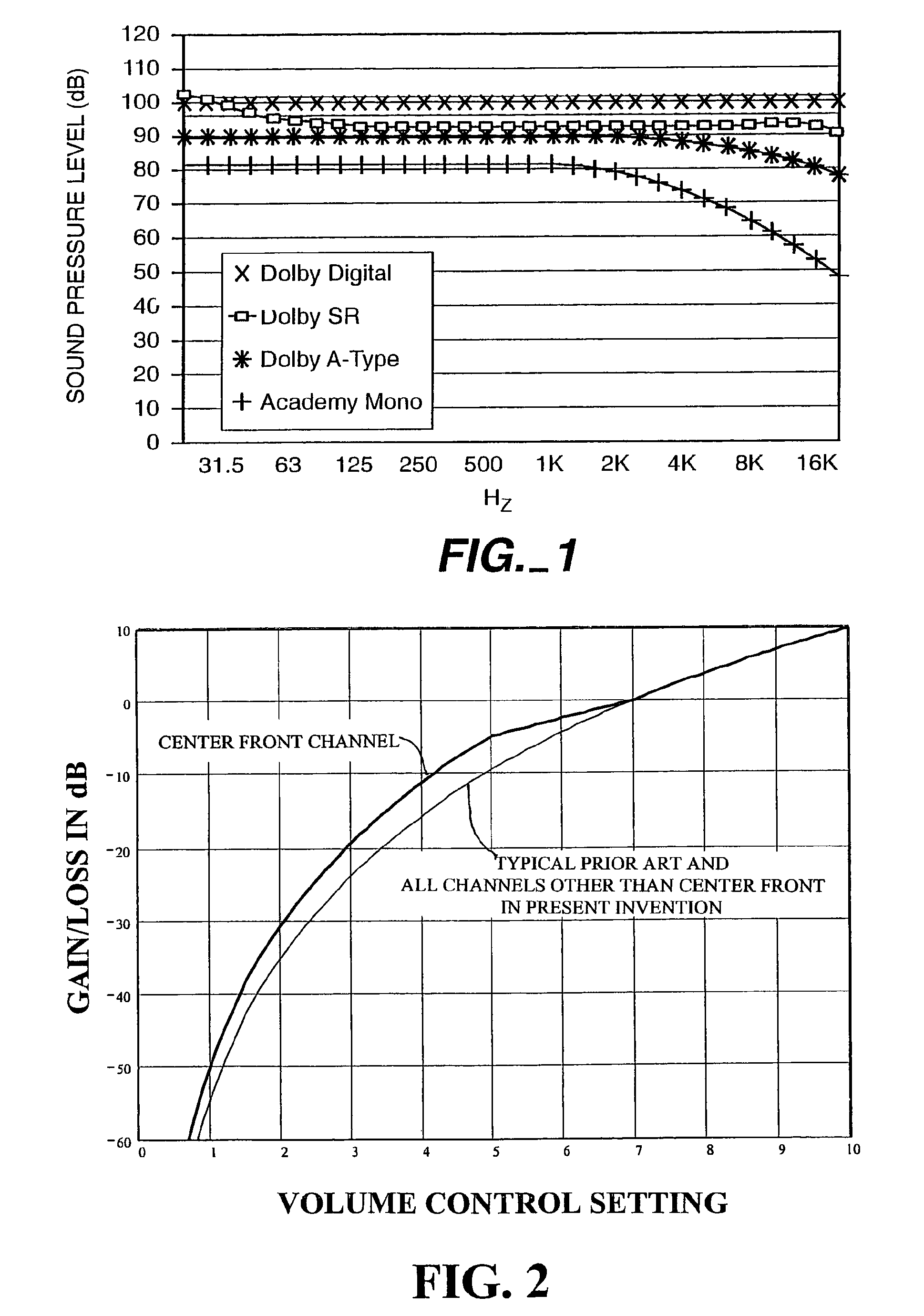

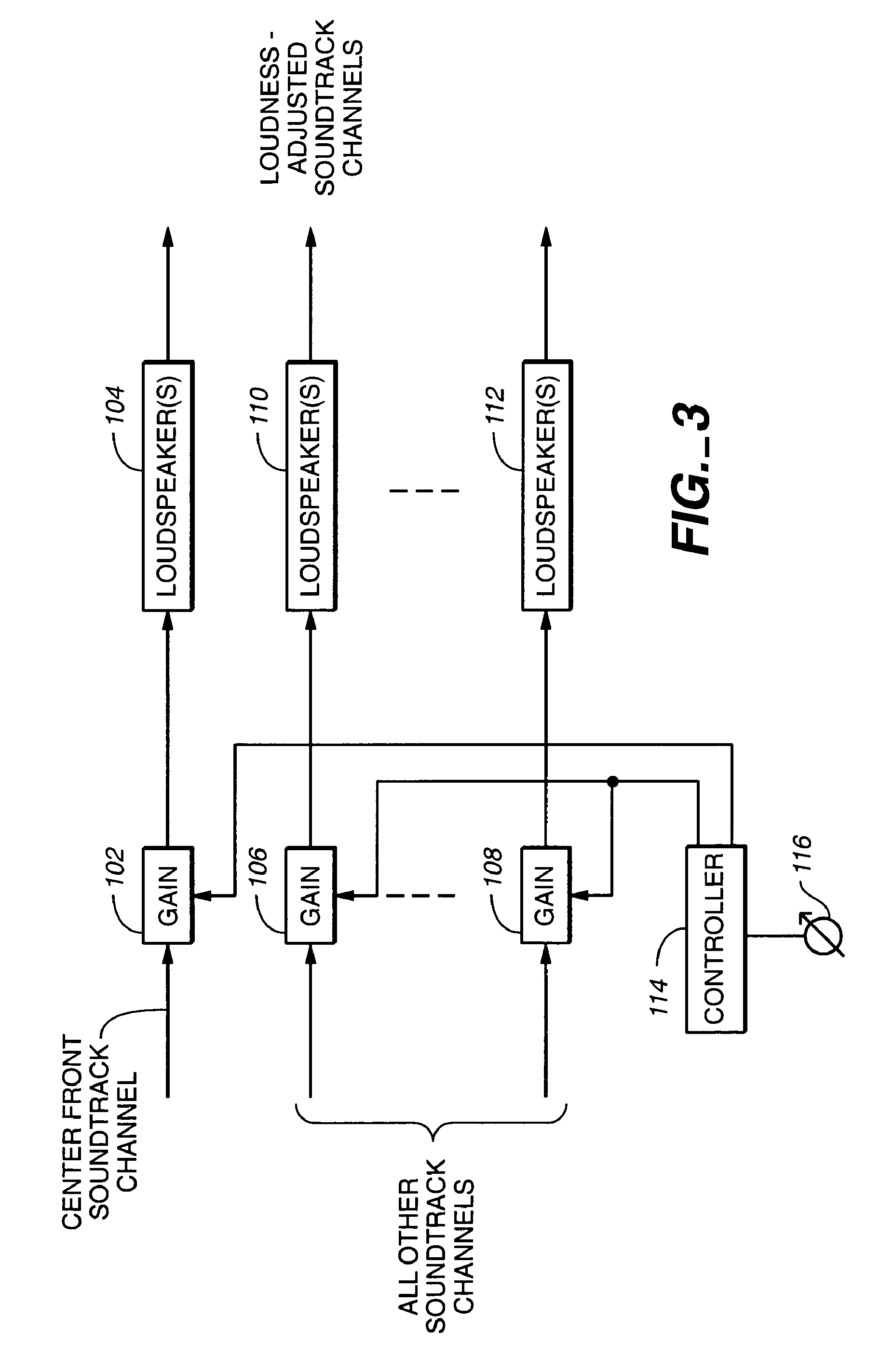

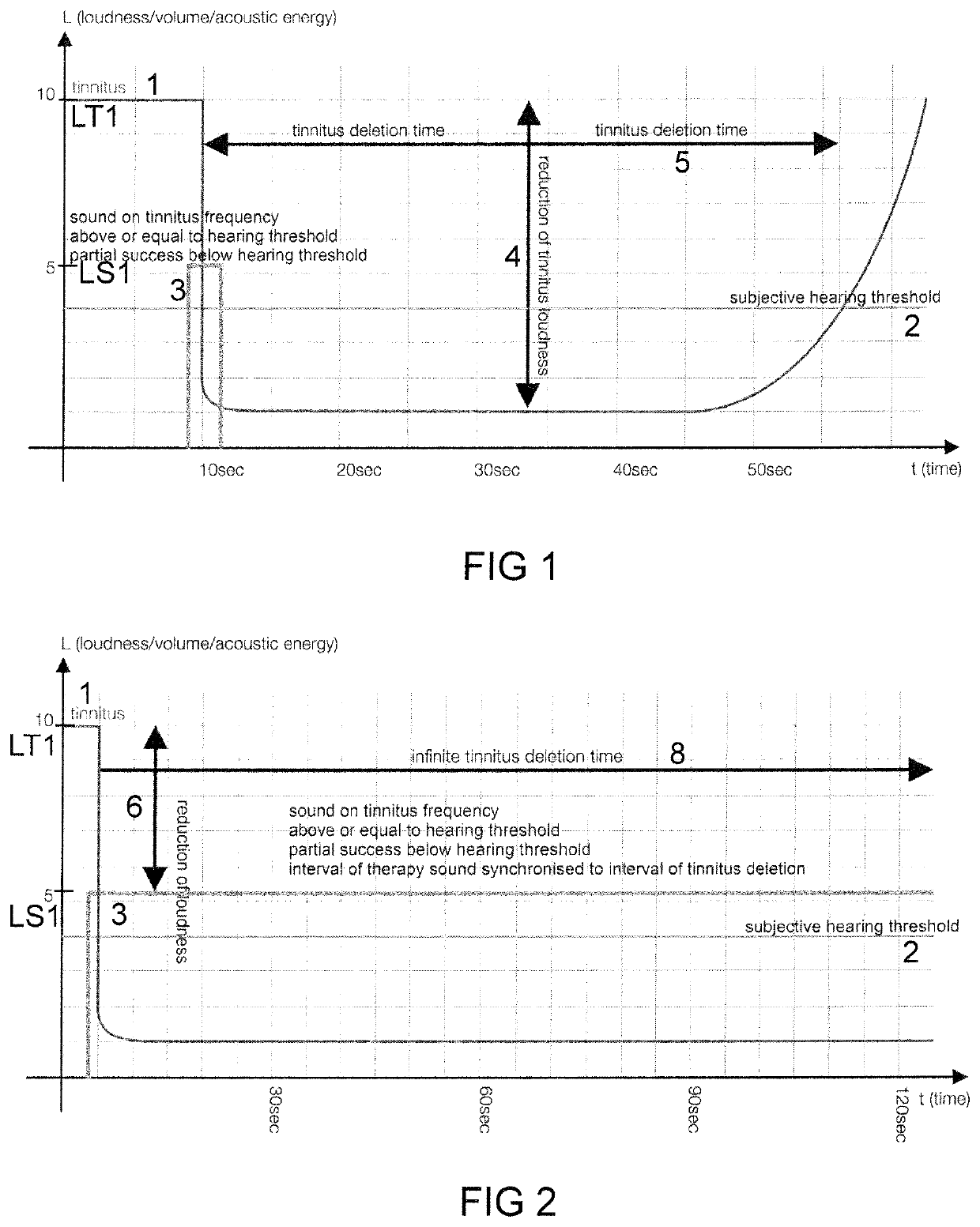

Volume control for audio signals

InactiveUSRE44261E1Maintain levelIncrease in proportionate contributionGain controlStereophonic systemsAudio signal flowAudio frequency

A motion picture soundtrack reproduction system has a center front soundtrack channel and a plurality of other soundtrack channels. A volume control adjusts the gain of all the channels. The volume control has a range of settings from a minimum to a maximum, the gain of the center front channel having substantially a first relationship to the volume control settings and the gain of the other channels having substantially a second relationship to the volume control settings, the relationships being such that for a range of volume control settings less than a first setting the gain of the center front channel remains substantially constant while the gain of the other channels decreases as the setting decreases or decreases more gradually than the gain of the other channels as the setting decreases.

Owner:DOLBY LAB LICENSING CORP

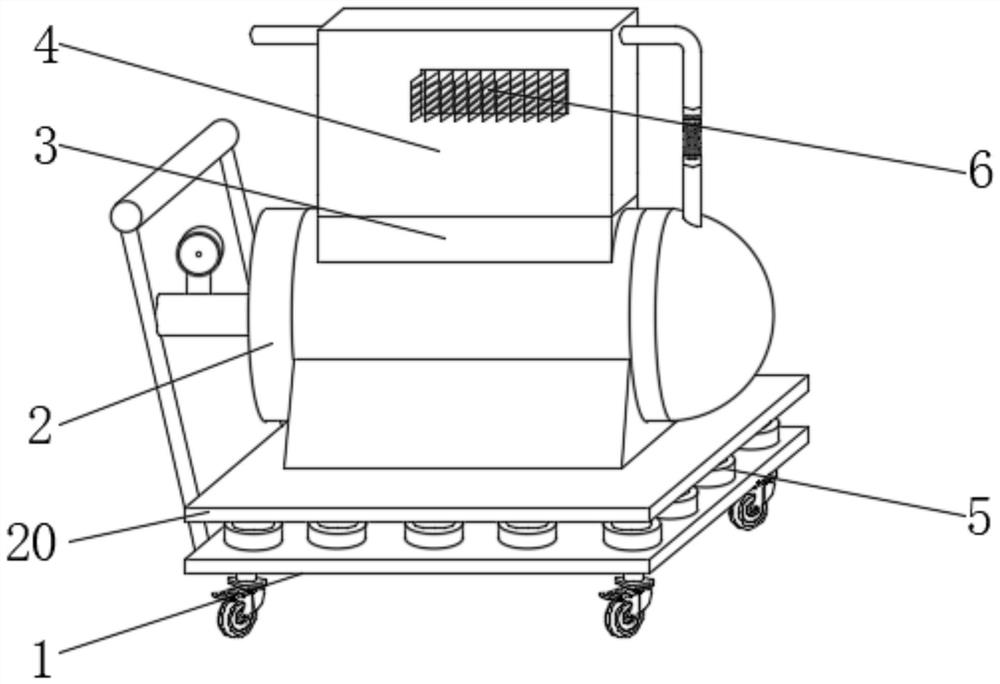

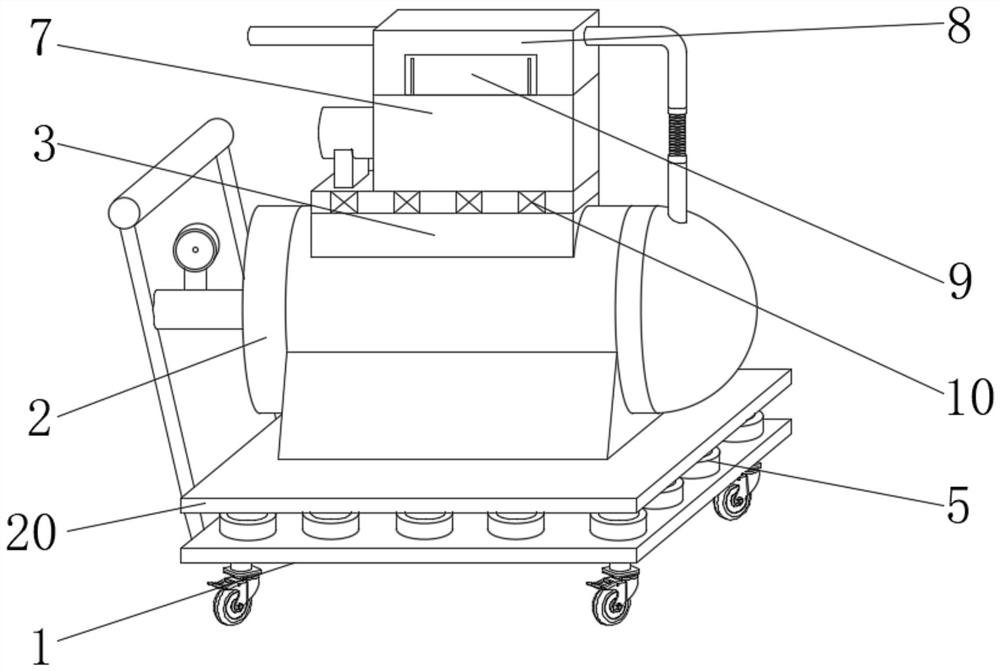

Shock-resistant and noise-reducing reciprocating piston compressor

PendingCN114278537AEnsure tight fitReduce noisePositive displacement pump componentsEnergy storagePhysicsPiston

The invention relates to an anti-vibration and noise-reduction reciprocating piston compressor which comprises a transfer trolley and an air storage tank, a mounting base is arranged on the lower portion of the periphery of the air storage tank, a supporting plate is mounted on the upper surface of the transfer trolley, and a plurality of damping telescopic rods which are evenly distributed in an array mode are mounted between the transfer trolley and the supporting plate; a mounting base of the air storage tank is fixedly connected to the middle of the upper surface of the supporting plate, a supporting base is fixedly connected to the upper portion of the periphery of the air storage tank, a gear box is mounted on the outer surface of the upper end of the supporting base, a plurality of damping springs evenly distributed in an array mode are mounted between the gear box and the supporting base, and a power motor is mounted on one side of the gear box. The upper side of the gearbox is fixedly connected and communicated with a plurality of piston cylinders which are evenly distributed at equal intervals, the outer surface of the upper end of the gearbox is fixedly connected with a heat dissipation box covering the outer sides of the piston cylinders, and a sound insulation box covering the outer sides of the gearbox, the heat dissipation box and the power motor is installed on the outer surface of the upper end of the supporting base.

Owner:BENGBU AUTO COMPRESSOR

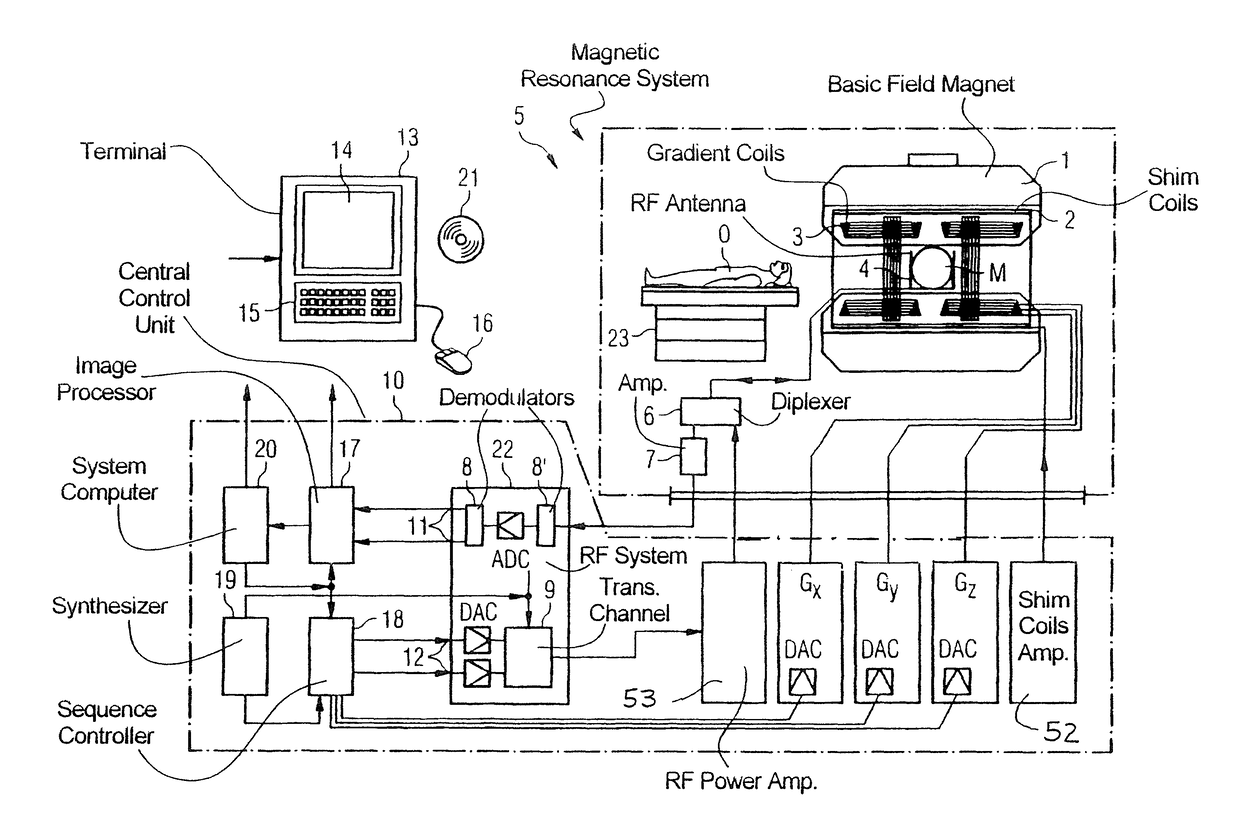

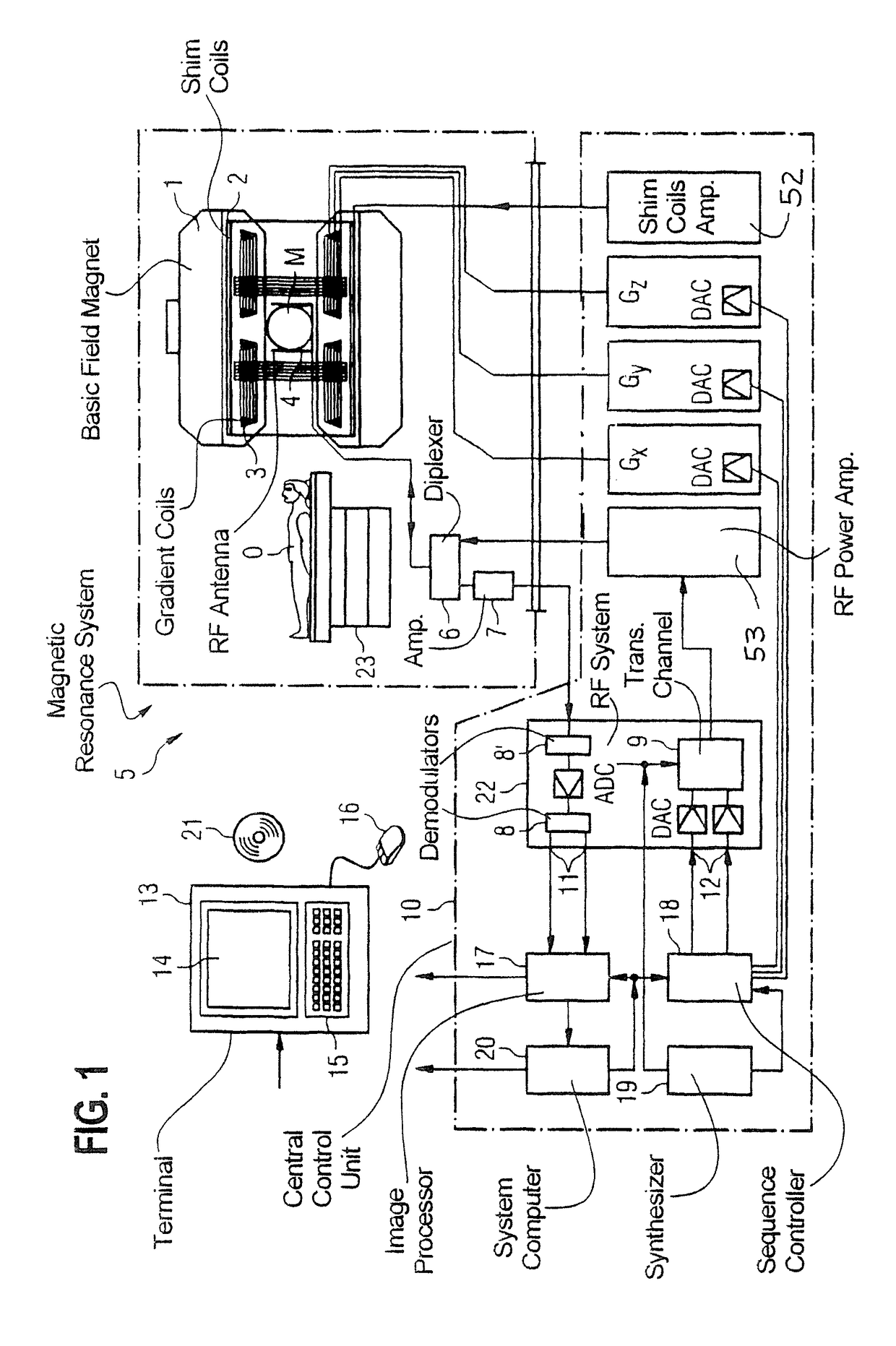

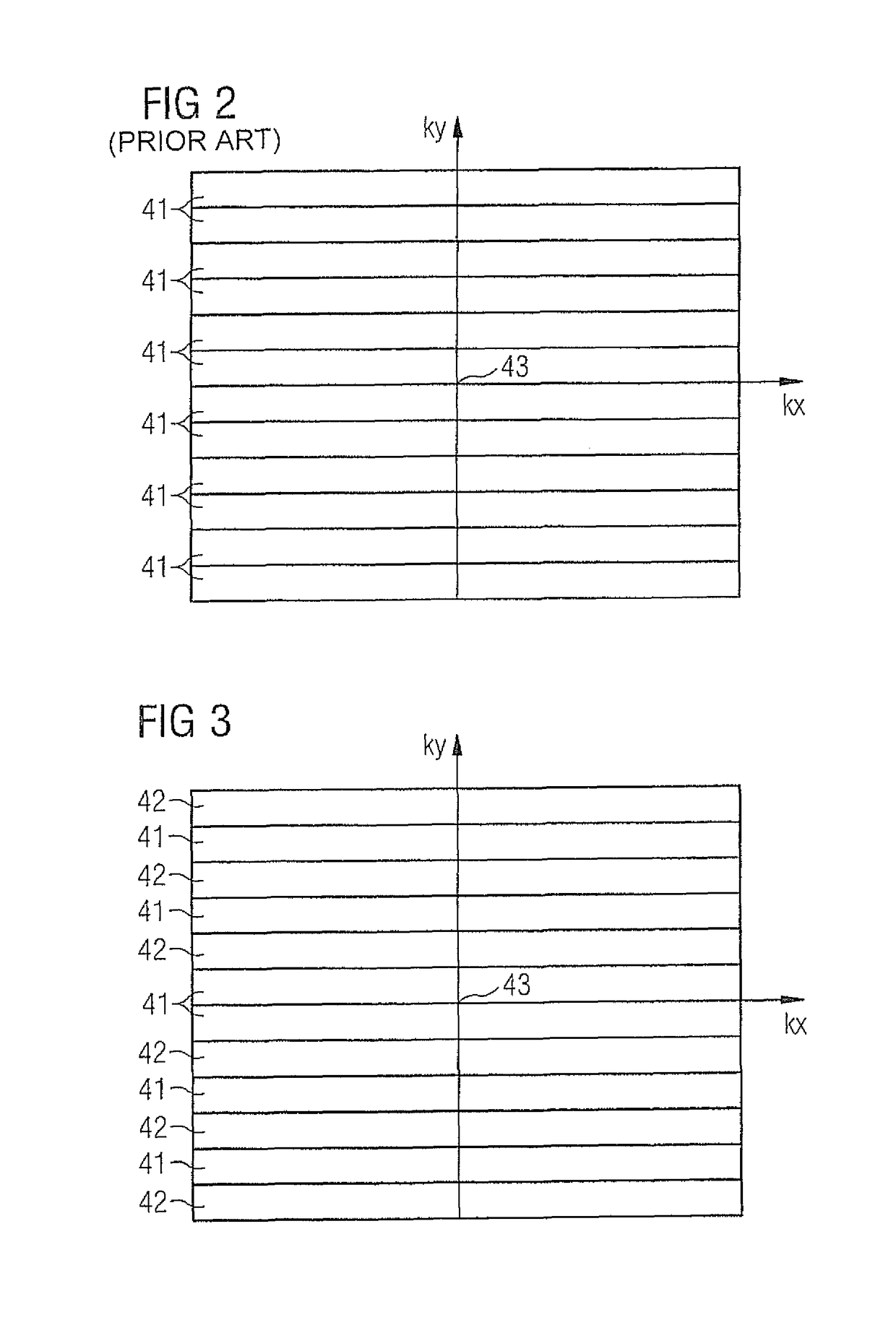

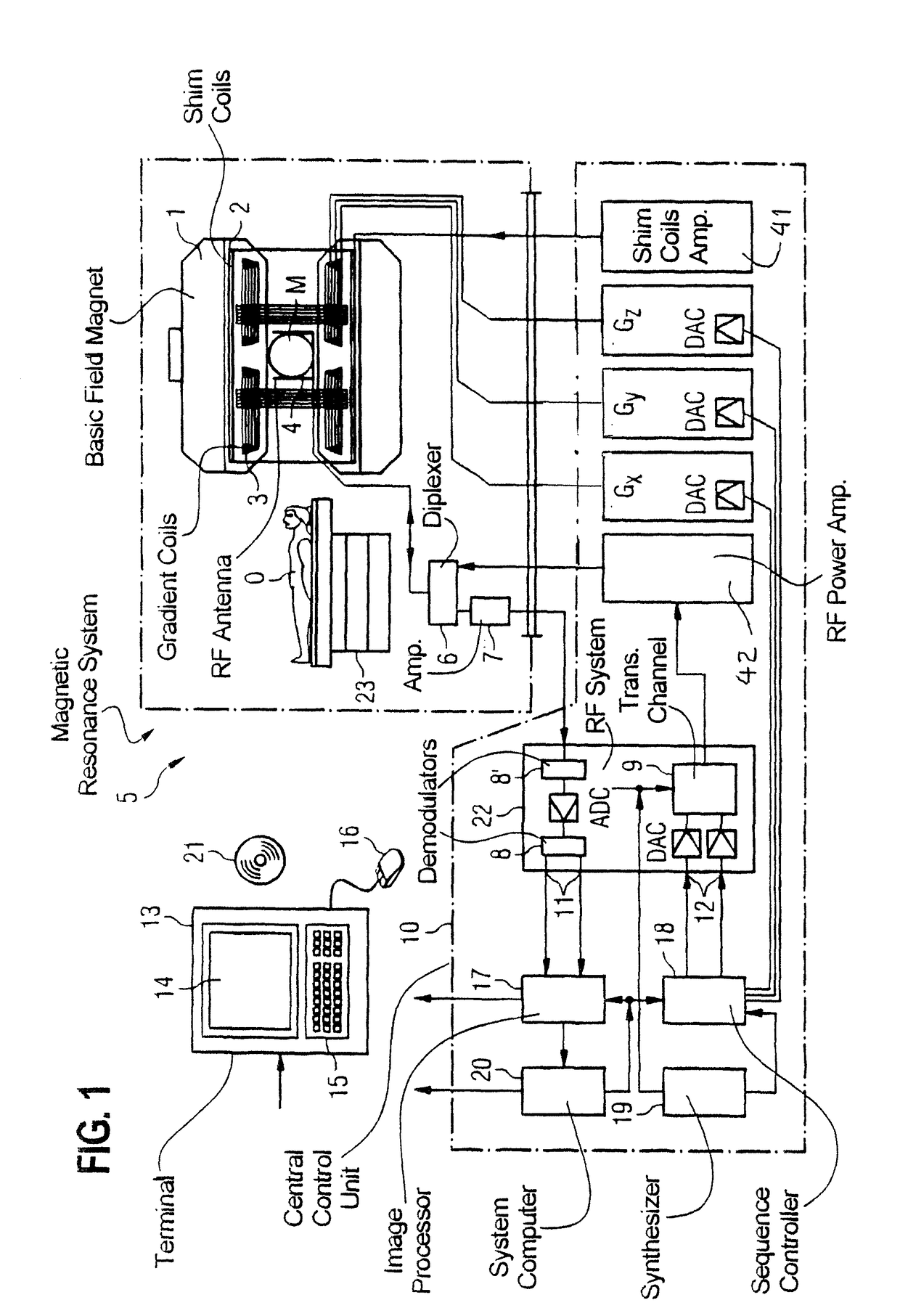

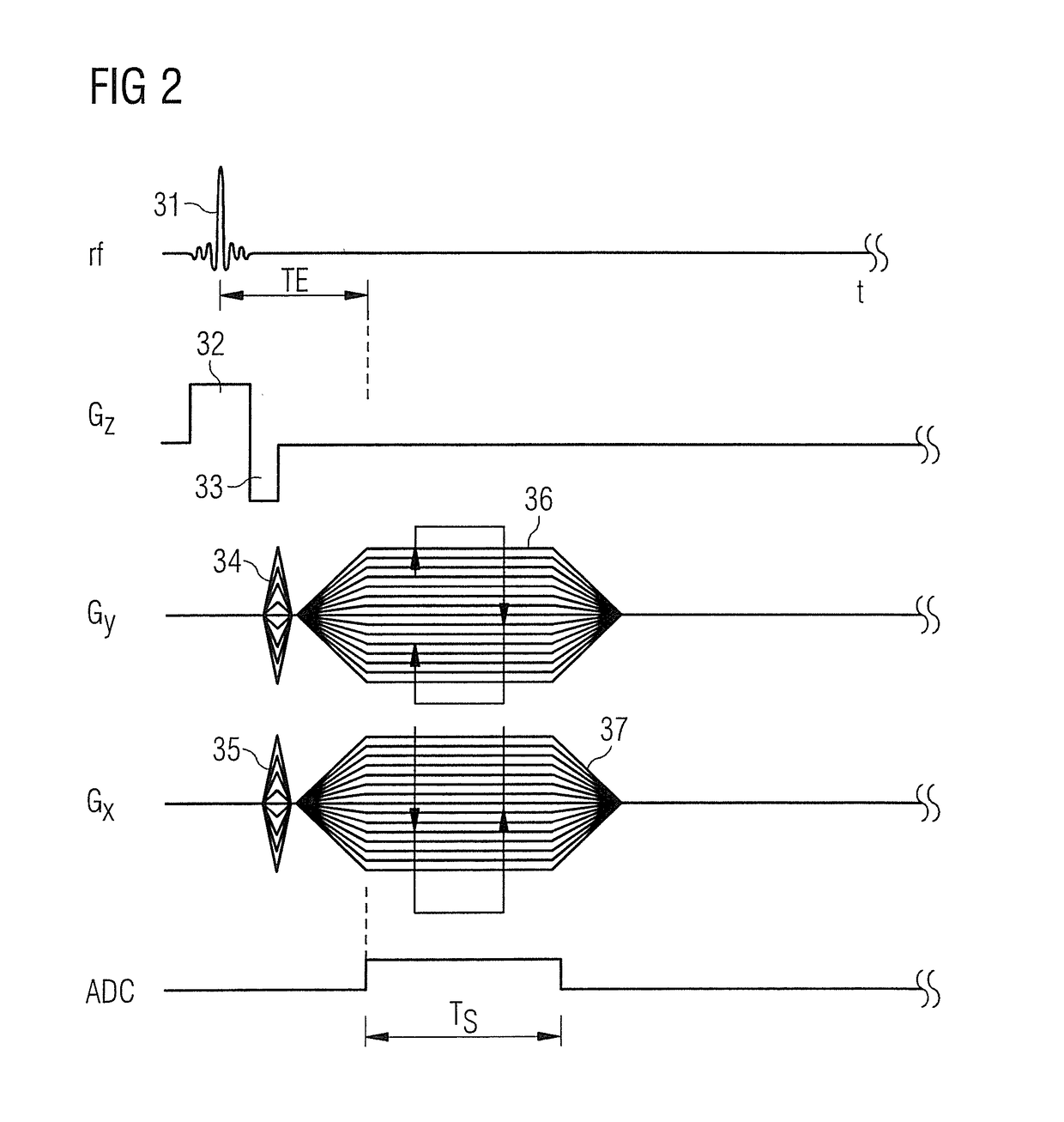

Method and magnetic resonance apparatus with reduction of audible noise by shortening the acquisition time for individual interior k-space lines

ActiveUS10012712B2Reduce loudnessSmall thicknessMeasurements using NMR imaging systemsElectric/magnetic detectionResonanceAcquisition time

For each k-space line, a time period is defined that starts with the application of the RF pulse directly prior to the acquisition of the respective k-space line, and ends at the time point of the echo during the acquisition of the MR data of the respective k-space line. This time period is set shorter for those k-space lines that lie in a central region of k-space than for k-space lines that lie outside of the central region.

Owner:SIEMENS HEALTHCARE GMBH

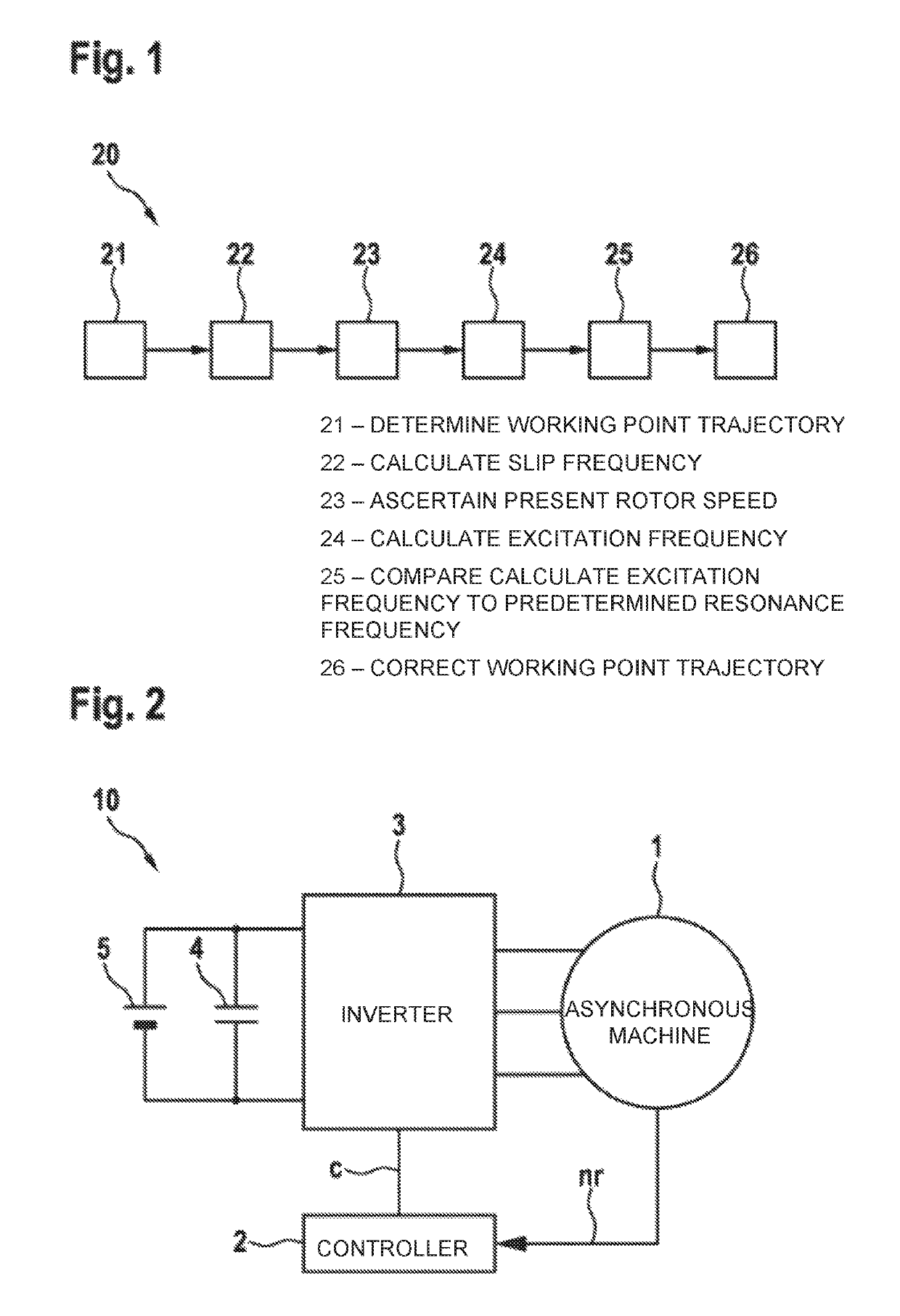

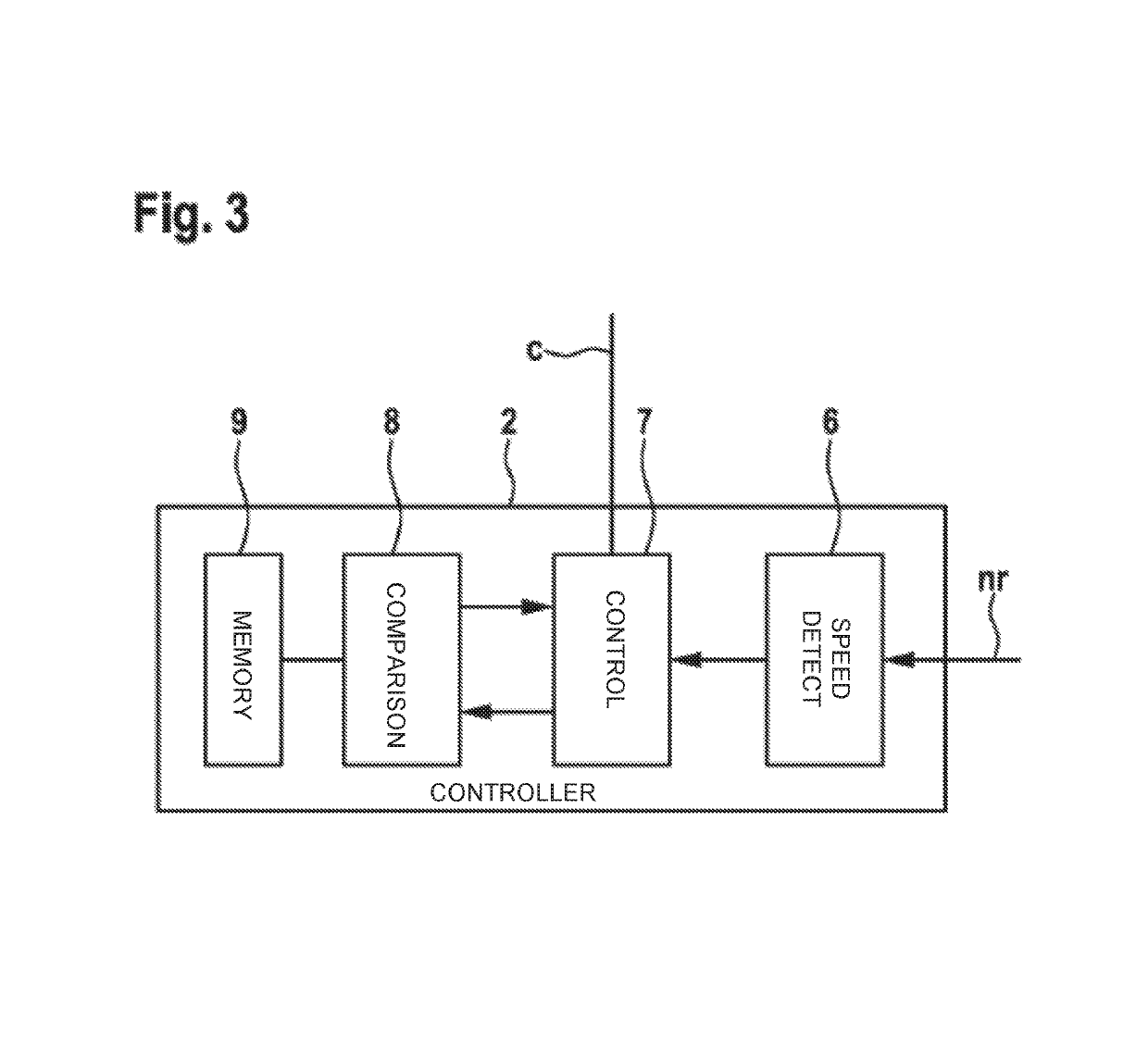

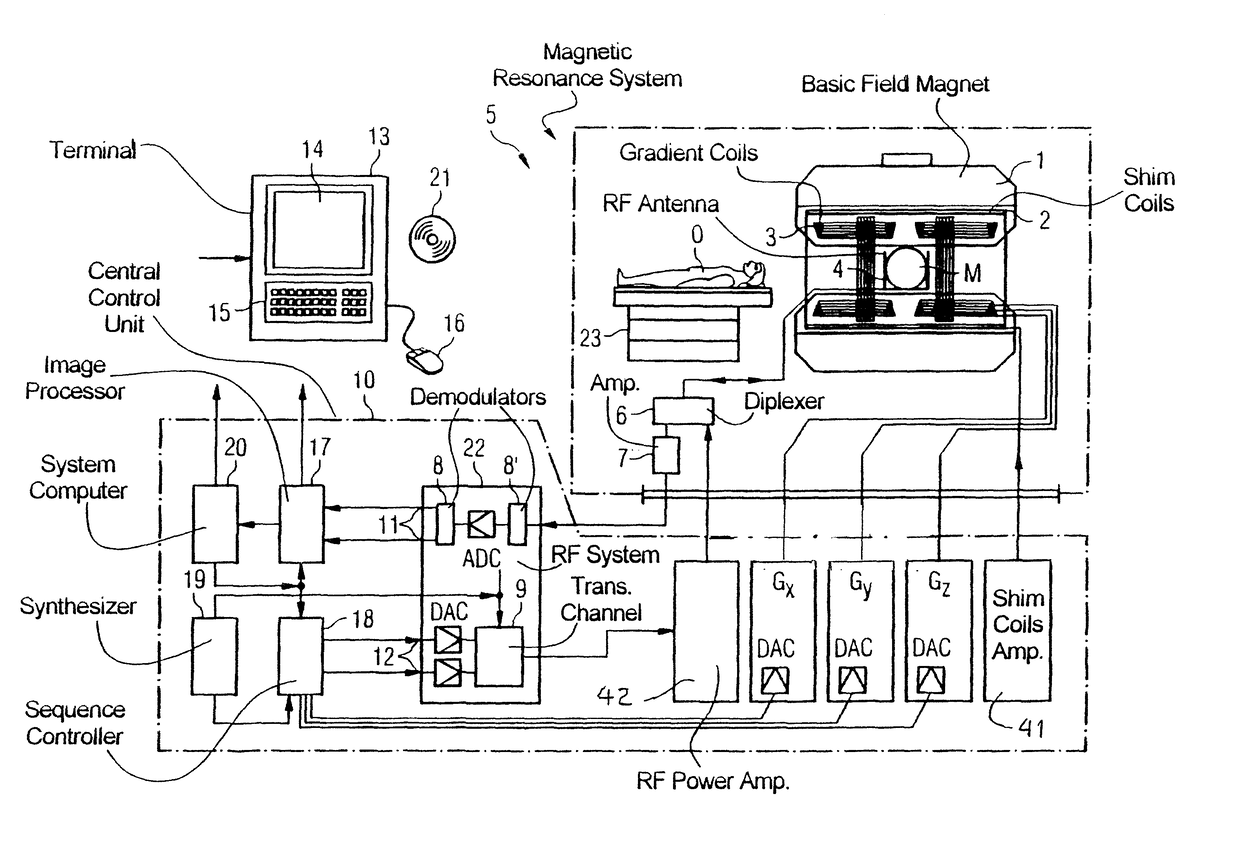

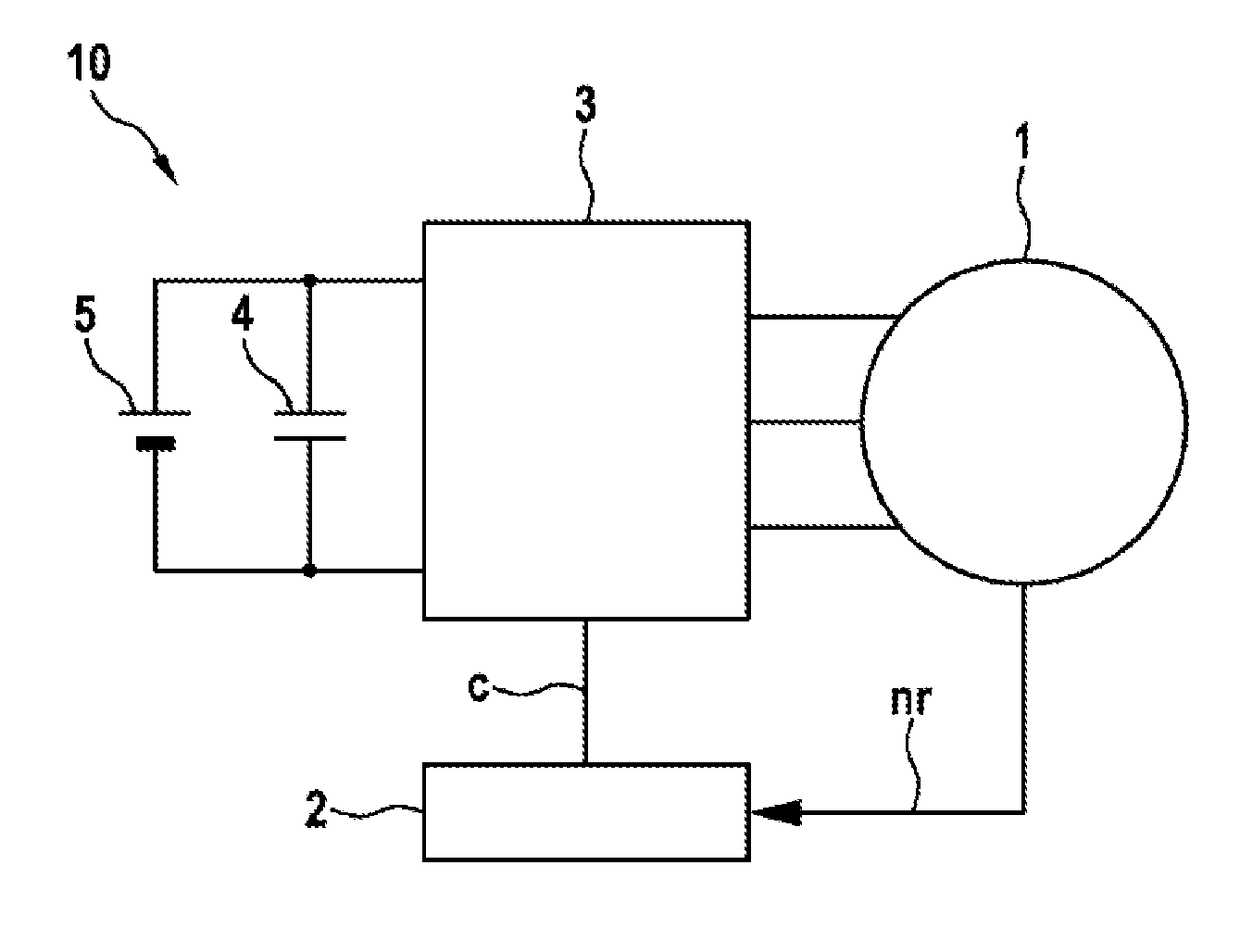

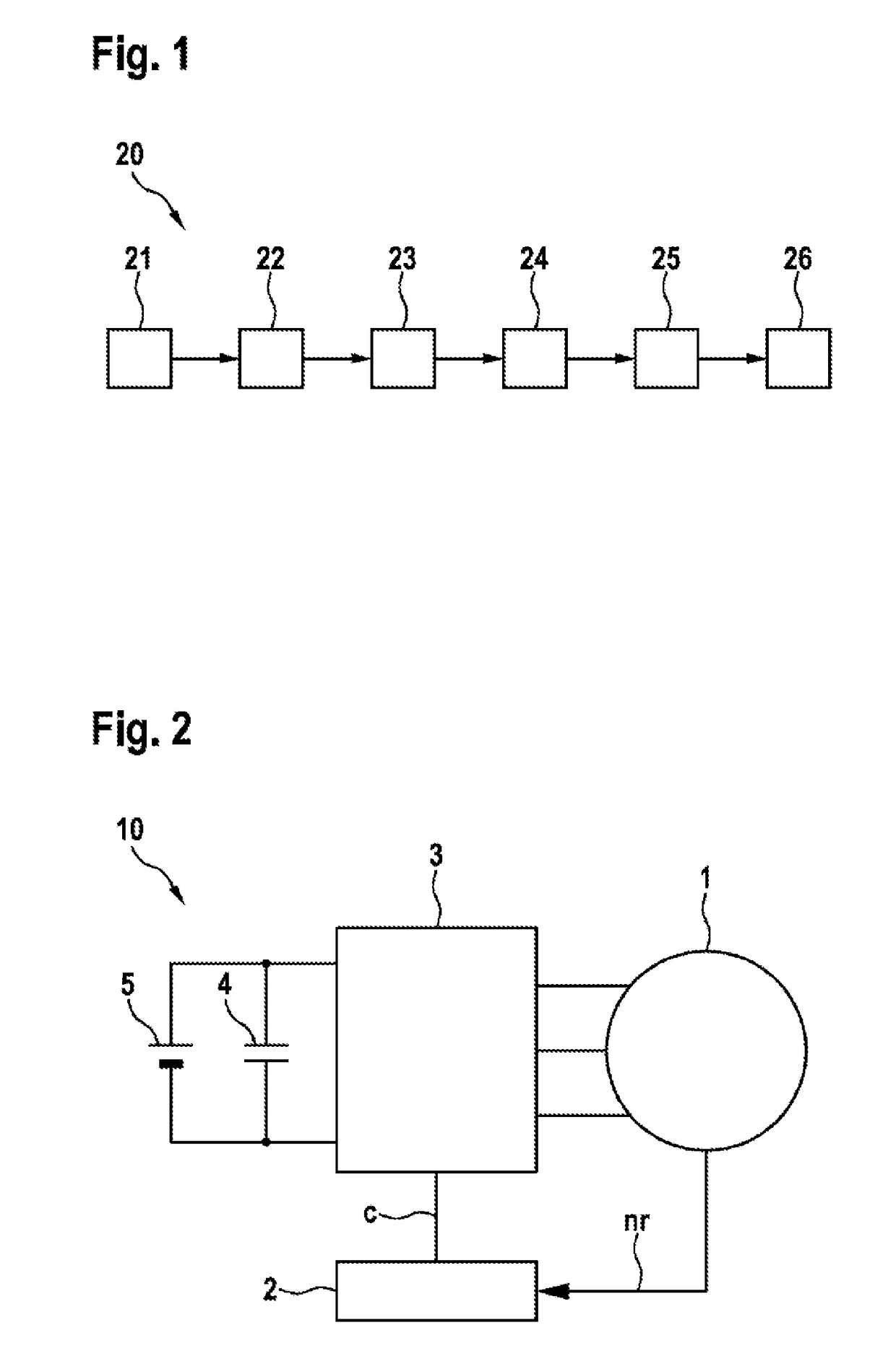

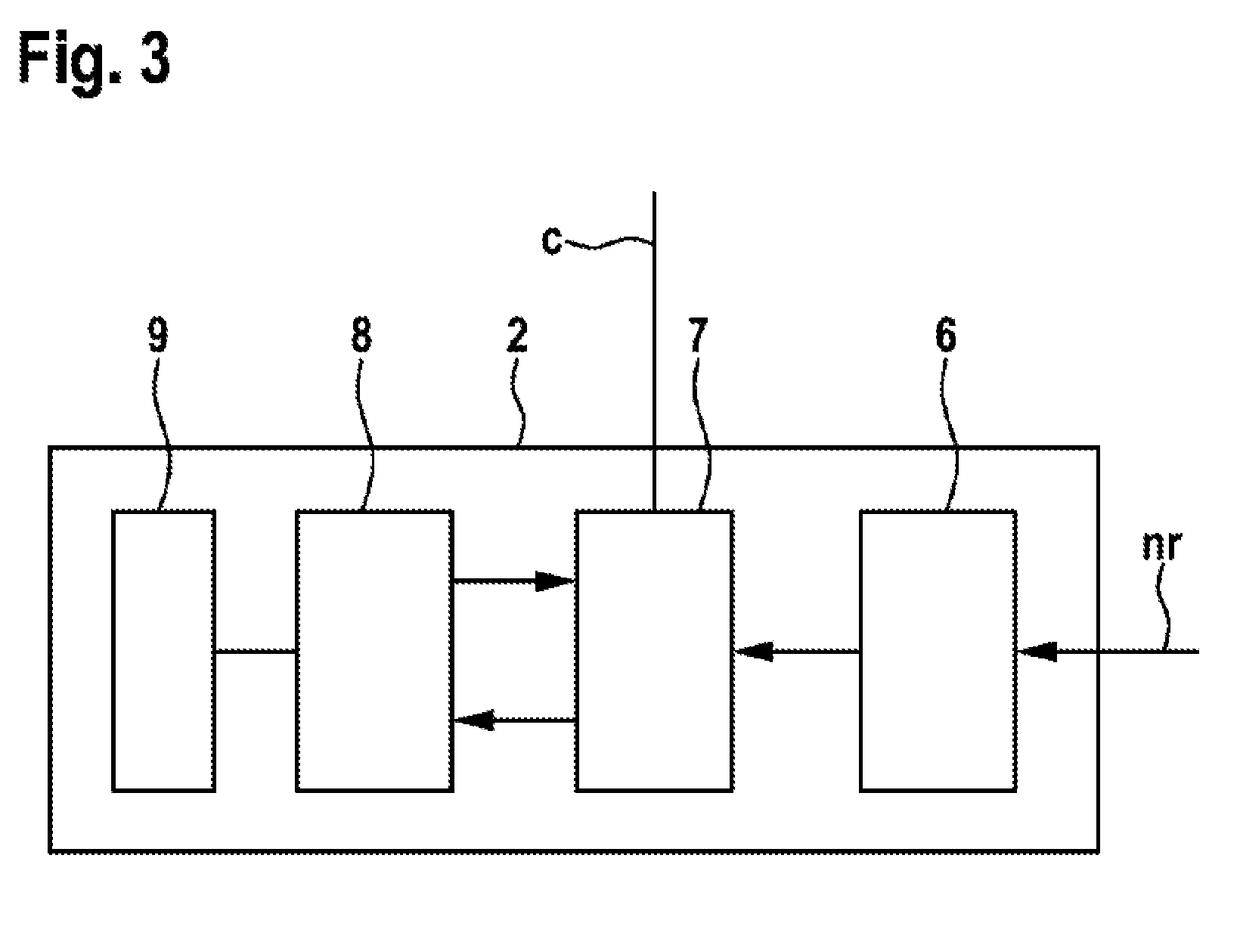

Control device for an asynchronous machine and method for operating an asynchronous machine

ActiveUS10432126B2Reduce loudnessReduce the differenceTorque ripple controlVibration measurement in fluidOperating pointResonance

The invention relates to a method for operating an asynchronous machine comprising the steps: determining an operating point trajectory for the asynchronous machine for a plurality of desired torques of the asynchronous machine by calculating 2-tuples from longitudinal current values and cross current values in a synchronously rotating coordinate system of the asynchronous machine; calculating a slip frequency of the asynchronous machine for each of the 2-tuples calculated from longitudinal current values and cross current values; determining a current rotor speed of the asynchronous machine; calculating an excitation frequency of the asynchronous machine by summation of the calculated slip frequency and the current rotor speed weighted with the number of pole pairs of the asynchronous machine; and comparing the calculated excitation frequency of the asynchronous machine with at least one predetermined resonance frequency value of the asynchronous machine. The determined operating point trajectory is thereby corrected by changing the ratio between longitudinal current value and cross current value at a constant desired torque for each of the 2-tuples for which the calculated excitation frequency corresponds to the at least one resonance frequency value.

Owner:ROBERT BOSCH GMBH

Magnetic resonance method and apparatus in which data are acquired along k-space spokes originating from k-space center

ActiveUS10036791B2Reduce loadLower conversion rateMeasurements using NMR imaging systemsElectric/magnetic detectionResonanceMR - Magnetic resonance

In a method and a magnetic resonance system for acquiring MR data in a predetermined volume segment of an examination subject, an RF excitation pulse is radiated and MR data are acquired along trajectories extending radially through the center of k-space. The MR data of one k-space spoke, which corresponds to one half of a trajectory, are acquired while gradients are switched. Starting from the same RF excitation pulse, only MR data of one k-space spoke are acquired by starting in the k-space center, acquiring the MR data continuously up to the k-space periphery. The echo time is greater than 1 ms.

Owner:SIEMENS HEALTHCARE GMBH

Multi-channel sound mixing method and device

ActiveCN107426651BReduce loudnessImprove sound qualitySignal processingLoudspeaker signals distributionSound qualityComputer science

The invention provides a multichannel sound mixing method and apparatus. The method comprises the following steps: obtaining multiple paths of channel signals used for transmitting a current frame; performing volume expansion summation on the multiple paths of channel signals to obtain a sum signal of the current frame; obtaining to-be-analyzed frame data; limiting the amplitude of the to-be-analyzed frame data in an amplitude limiting manner to obtain a sampling value after amplitude limiting; and outputting the data of N sampling points in front of the sampling value after amplitude limiting to obtain a target audio signal. In the multichannel sound mixing method provided by the invention, the sound mixing is performed by combining the volume expansion summation with the amplitude limiting, so that the sound quality of the obtained target audio signal is better and is more real, and the technical problem of serious distortion of sound mixing in the traditional sound mixing method is relieved.

Owner:世邦通信股份有限公司

Speech signal processing device and speech signal processing method

The invention provides a voice signal processing device and a voice signal processing method. According to the invention, the filtering loudness gain of a filtering signal of each frequency band is adjusted according to a wide dynamic range compression curve without an output loudness upper limit. Therefore, the filtering loudness gain of each frequency band is reduced through reducing a gain decrease adjustment value, so that the loudness of a loudness adjustment filtering signal is reduced. As a result, the loudness of an outputted voice signal is lower than a first threshold value. By meansof the voice signal processing device and the voice signal processing method, the sound quality of outputted voice signals can be greatly improved.

Owner:ACER INC

Voice signal processing device and voice signal processing method

ActiveCN108281148AFilter Loudness Gain ReductionReduce loudnessSpeech analysisFrequency bandVIT signals

The invention provides a voice signal processing device and a voice signal processing method. According to the invention, the filtering loudness gain of a filtering signal of each frequency band is adjusted according to a wide dynamic range compression curve without an output loudness upper limit. Therefore, the filtering loudness gain of each frequency band is reduced through reducing a gain decrease adjustment value, so that the loudness of a loudness adjustment filtering signal is reduced. As a result, the loudness of an outputted voice signal is lower than a first threshold value. By meansof the voice signal processing device and the voice signal processing method, the sound quality of outputted voice signals can be greatly improved.

Owner:ACER INC

Passive radiator and sound production device

PendingCN113852891AReduce low frequency resonant frequencyImprove stabilityFrequency/directions obtaining arrangementsPassive radiatorEngineering

The invention discloses a passive radiator and a sound production device, the passive radiator comprises a frame, a vibrating diaphragm, a folding ring and a damping assembly, and the frame is provided with an opening; the vibrating diaphragm is arranged in the opening; the inner side of the folding ring is connected with the vibrating diaphragm, and the outer side of the folding ring is connected with the edge of the opening; the damping assembly comprises first damping pieces and second damping pieces which are connected, the first damping pieces are arranged on the surface of the vibrating diaphragm, the second damping pieces are arranged on the surface of the folding ring, the first damping pieces are arranged on the surface of the vibrating diaphragm in a central symmetry mode, the first damping pieces are made of elastic materials, and the second damping pieces are made of flexible materials. According to the passive radiator, the low-frequency vibration frequency can be improved, and the distortion phenomenon is avoided while the radiation quantity is increased.

Owner:GEER TECH CO LTD

Control device for an asynchronous machine and method for operating an asynchronous machine

ActiveUS20180026564A1Reduce loudnessReduce the differenceElectric motor controlVector control systemsOperating pointResonance

Owner:ROBERT BOSCH GMBH

Method and device for encoding three-dimensional scenes which include transparent objects in a holographic system

ActiveUS10520889B2Improve and reduce visibilityReduce loudnessHolographic object characteristicsDigital holography electronic componentSound sourcesComputer graphics (images)

Owner:SEEREAL TECHNOLOGIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com