Exhaust resonant silencer and motorcycle with same

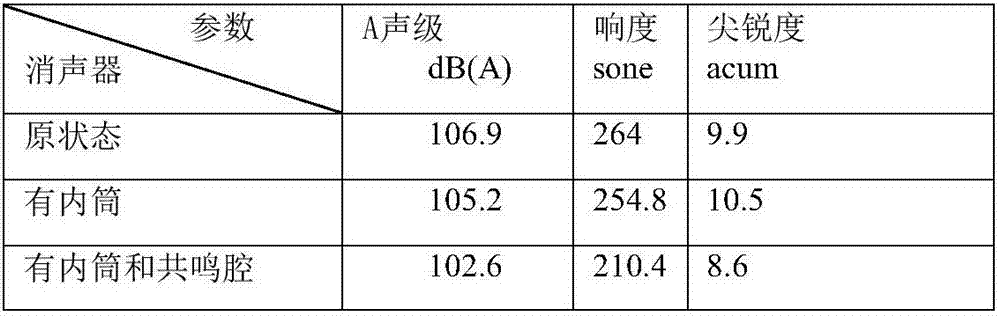

A muffler and resonance technology, applied in exhaust devices, mufflers, gas passages, etc., can solve the problems of complex processing technology, poor economic benefits, low production efficiency, etc., to reduce costs, improve timbre, and reduce loudness and sharpness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

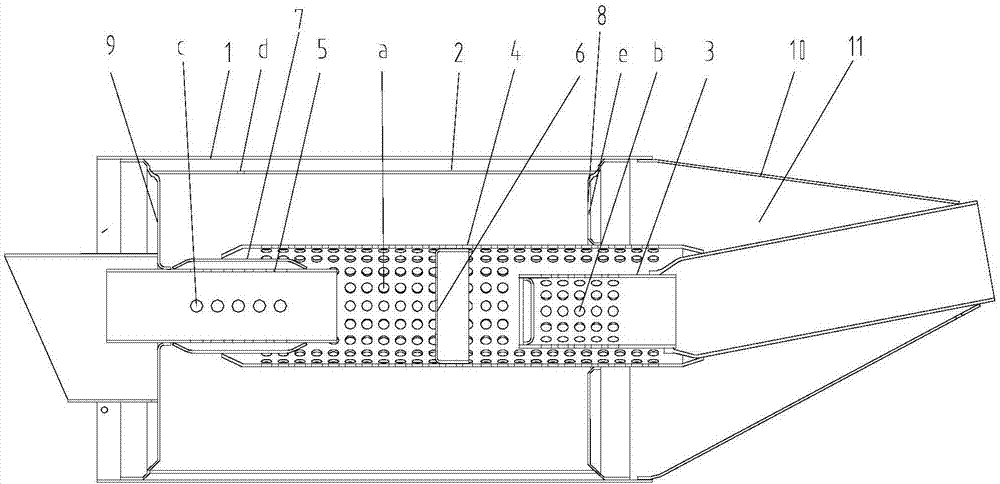

[0017] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure, the exhaust resonance type muffler in this embodiment; includes the muffler cylinder 1 and the inner connection pipe assembly for introducing and extracting exhaust gas arranged in the muffler cylinder 1, so The inner connection pipe assembly includes a front pipe 3, a middle pipe 4 and a tail pipe 5, the middle pipe 4 is provided with a perforated partition 6 for separating the inner cavity of the middle pipe 4 into front and rear chambers and the side of the middle pipe 4 The wall is provided with a plurality of first through holes a; the front pipe 3 and the tail pipe 5 are partially arranged in the front and rear chambers respectively, and the front pipe 3 includes a front pipe section and a rear pipe section 3a arranged front and back, and the front pipe section is located in the middle pipe And its side wall is provided with second through hole, described rear pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com