Brake

A brake and brake bottom plate technology, which is applied in the direction of hydraulic drum brakes, brake parts, brake actuators, etc., can solve problems such as insufficient lubrication of steel wires, brake failure, and soft brakes, so as to improve effective performance and ensure Driving safety, adjusting friction plate wear gap and thermal expansion gap timely effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

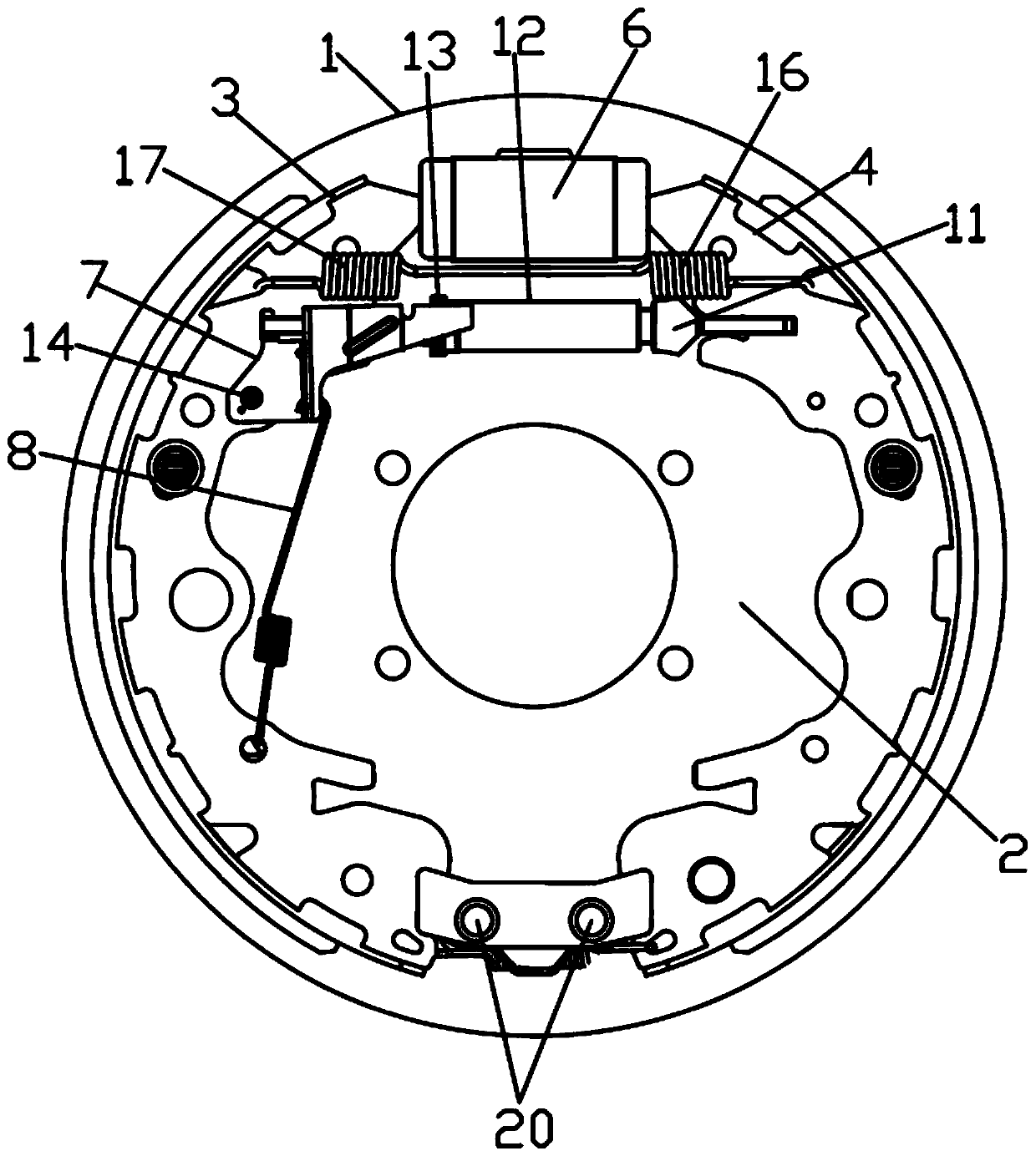

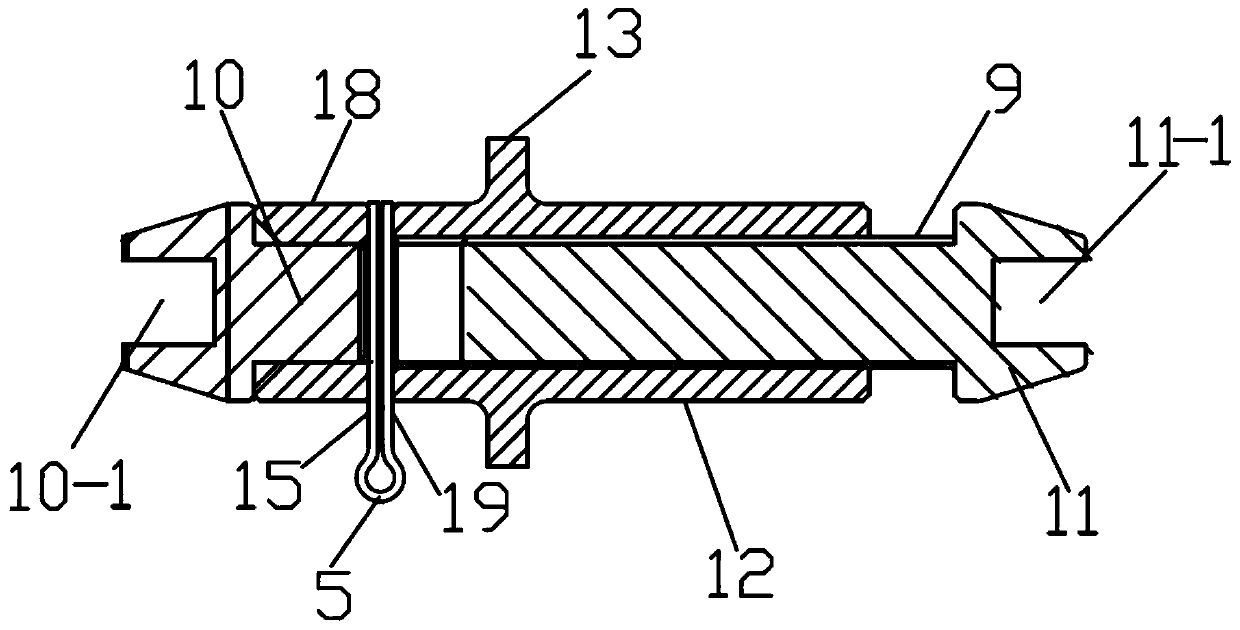

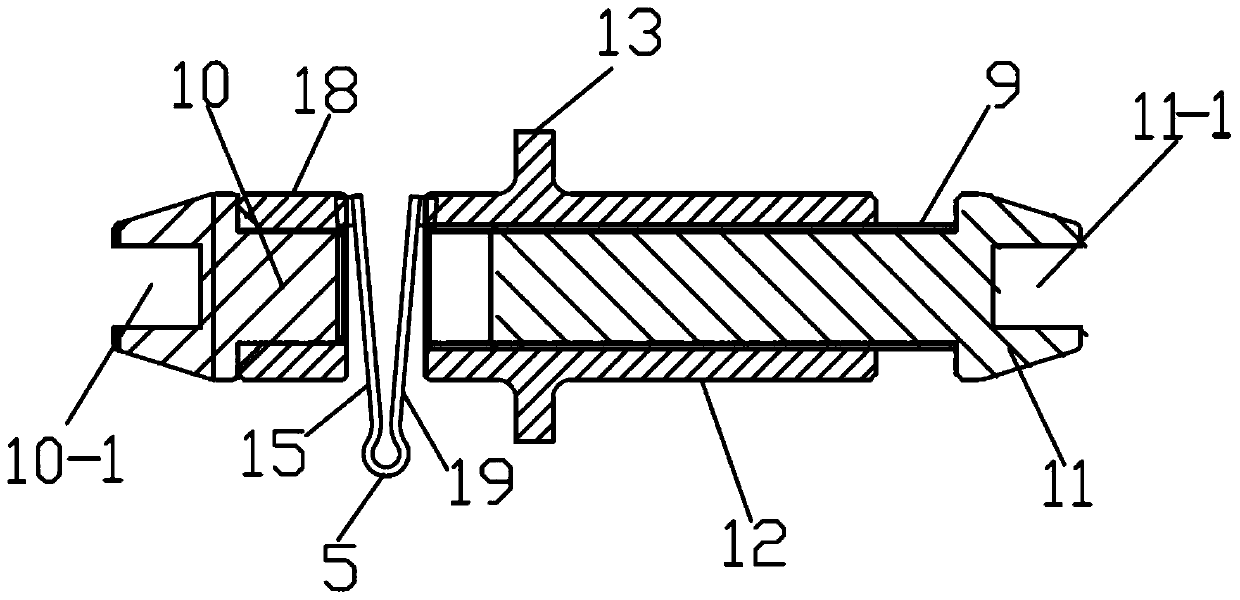

[0021] Depend on Figure 1-4 As can be seen from the illustrated embodiment, this embodiment includes a brake drum 1 with an inner circular friction surface, and the brake leading shoes 3 and the brake slave shoes 4 are symmetrically arranged on the brake bottom plate 2 from left to right, so that the brake leading shoes The arc-shaped friction plates of the brake shoe 3 and the brake slave shoe 4 correspond to the inner circular friction surface of the brake drum 1, and the lower ends of the brake leading shoe 3 and the brake slave shoe 4 are respectively connected to The brake base plate 2 is hinged, and the brake base plate 2 is also provided with a hydraulic cylinder 6 for pushing the upper ends of the brake leading shoe 3 and the brake slave shoe 4 to move to the left and right respectively, and the brake lead shoe 3 and the brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com