Conical spring stiffness adjusting method and structure

A technology of conical spring and adjustment method, applied in the field of rail transit, can solve the problems of partial cracking of rubber, affect the performance, affect the stiffness of the conical spring, etc., and achieve the effects of increasing nonlinearity, prolonging service life, and increasing vertical stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

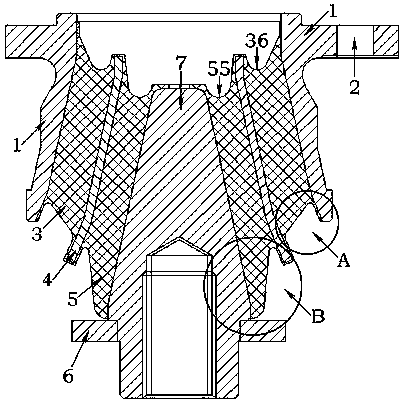

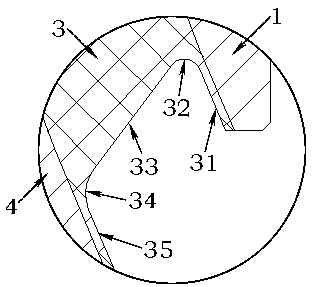

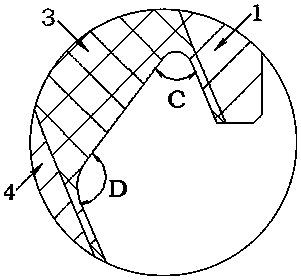

[0028] The conical spring is a rotating body, such as figure 1 As shown, the conical spring includes an outer jacket 1, a rubber body, a partition 4 and a mandrel 7, wherein the outer jacket 1, the partition 4 and the mandrel 7 are all made of metal, and the rubber body connects the outer jacket 1, the partition 4 and the mandrel 7 vulcanized into a whole. The rubber body is provided with partitions 4 distributed vertically, and the partitions 4 are embedded in the rubber body to divide the rubber body into an outer rubber body 3 and an inner rubber body 5 . Have vertical installation hole 2 on the overcoat 1, pass installation hole 2 with bolt, conical spring can be installed on the vehicle. A flange 6 is provided outside the lower end of the mandrel 7 to limit the movement of the lower end of the inner rubber body 5 when the conical spring bears a large load, thereby increasing the vertical stiffness.

[0029] Such as figure 1 and Figure 4 As shown, in order to further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com