Liquid pipeline dead oil section pressure relief device and method

A technology for liquid pipelines and pressure relief devices, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as personal and property damage, safety accidents, seepage, etc. and property safety, timely alarm speed, high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

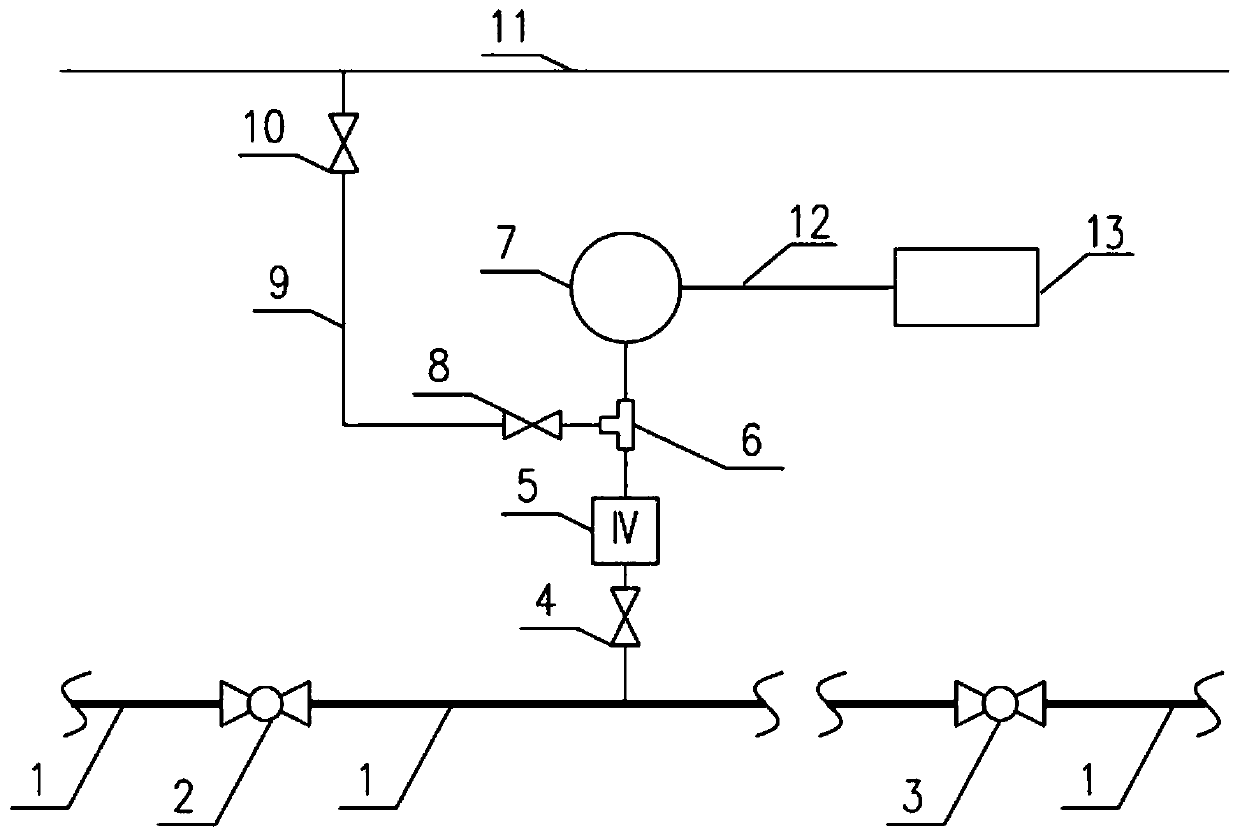

[0031] Such as figure 1 As shown, what is described in the embodiment of the present invention is a pressure relief device for the dead oil section of a liquid pipeline, which includes:

[0032] A liquid pipeline 1 is provided with a first valve 2 and a second valve 3 sequentially from upstream to downstream;

[0033] A pressure monitoring and alarming device 7, which is located on the liquid pipeline 1 between the first valve 2 and the second valve 3, and the pressure monitoring and alarming device 7 is connected to the liquid pipeline 1 through the instrument valve 5;

[0034] Tee 6, which is located between the instrument valve 5 and the pressure monitoring alarm device 7, the instrument valve 5 is connected to the first connection end of the tee 6, and the pressure monitoring alarm device 7 is connected to the second connection end of the tee 6;

[0035] The third valve 8, its inlet end is connected with the third connection end of the tee 6, and the outlet end of the thi...

Embodiment 2

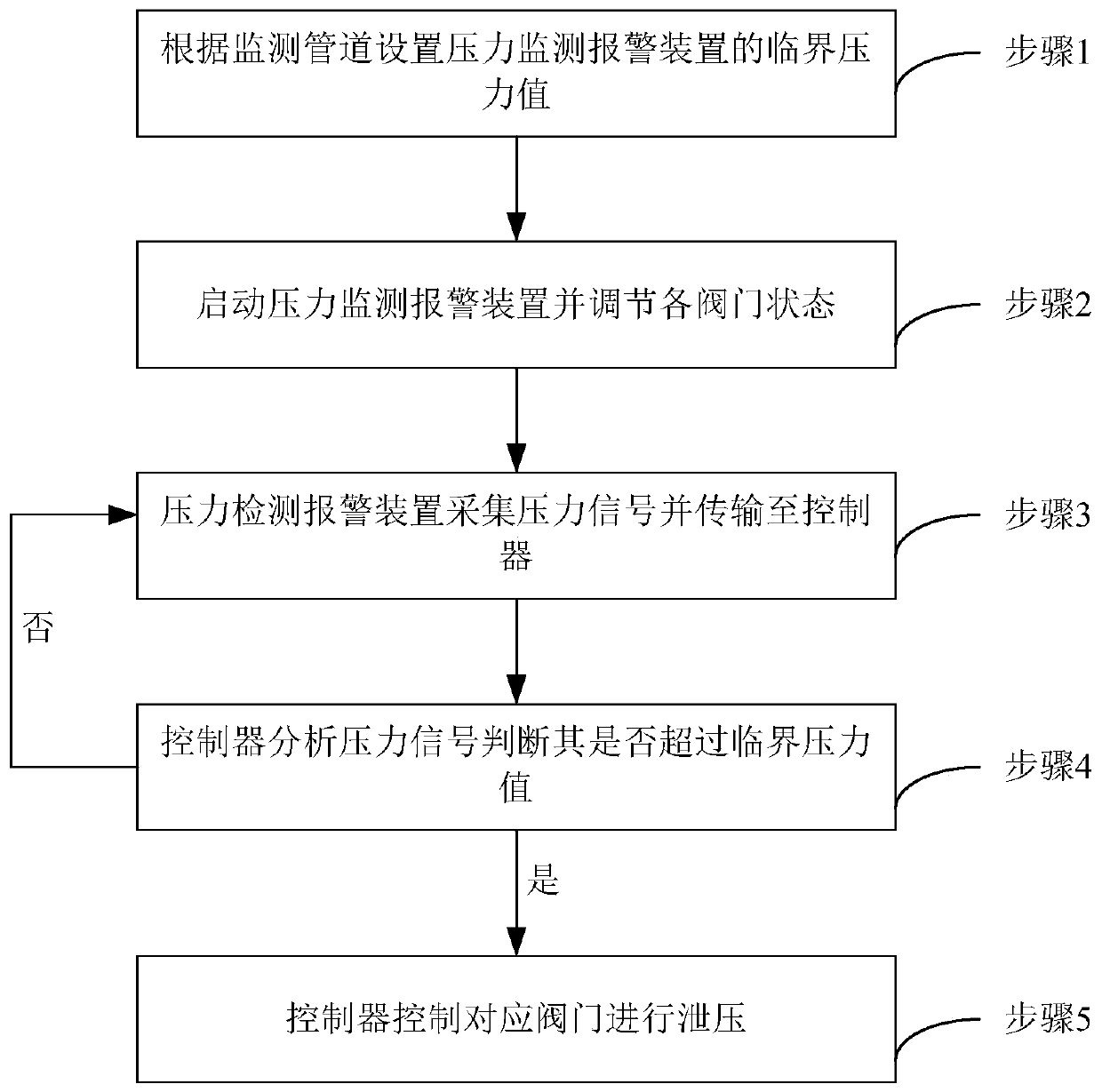

[0045] Such as figure 2 As shown, what is described in the embodiment of the present invention is a method for releasing pressure in a dead oil section of a liquid pipeline, the method comprising:

[0046] Step 1, setting the critical pressure value of the pressure monitoring alarm device 7 and the controller 13 according to the monitored liquid pipeline 1;

[0047] Step 2, start the pressure monitoring and alarm device 7 and make the first valve 2, the second valve 3, the third valve 8 and the fourth valve 10 all in the closed state;

[0048] Step 3, the pressure monitoring and alarming device 7 collects the pressure of the liquid pipeline 1 between the first valve 2 and the second valve 3 in real time, and transmits each collected pressure signal to the controller 13;

[0049] Step 4, the controller 13 analyzes the received pressure signal, and when the pressure signal value exceeds the critical pressure value in step 1, execute step 5, otherwise execute step 3;

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com