Oil-gas pipeline leakage monitoring system based on optical fiber

A technology for oil and gas pipelines and monitoring systems, which is applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., and can solve problems such as unsatisfactory long-distance monitoring and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

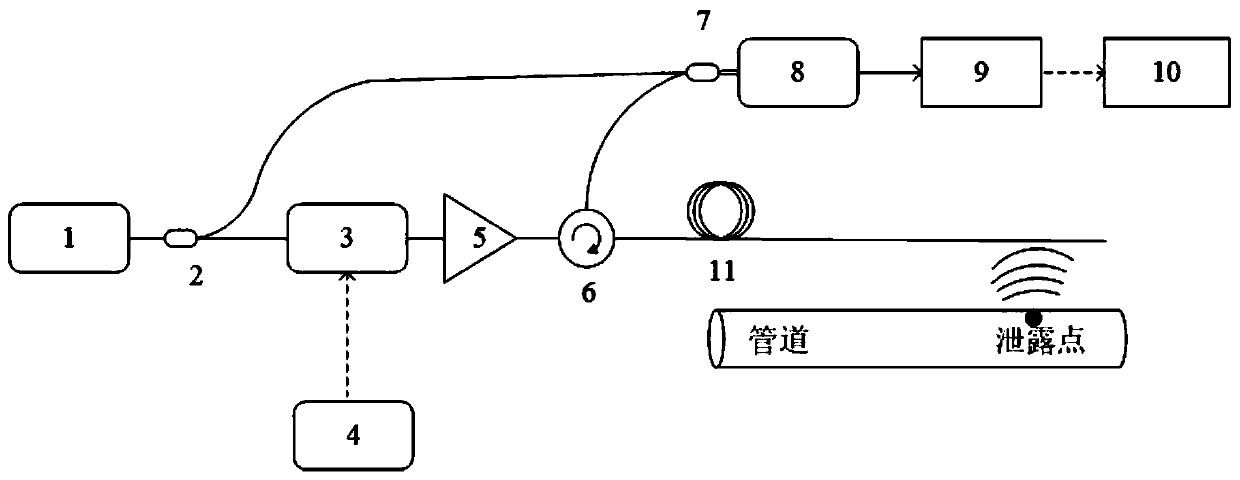

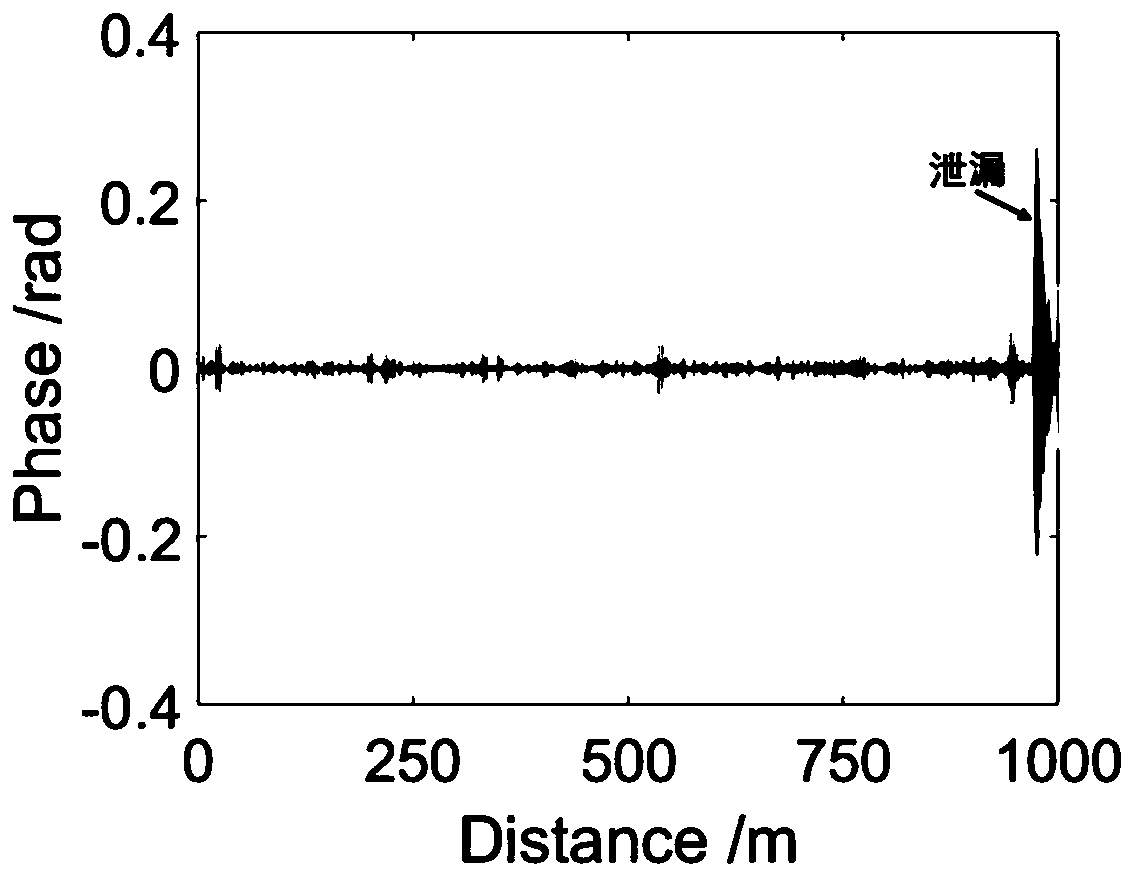

[0020] This example figure 1 and figure 2 As shown, the pipeline leakage simulation experiment is as follows: a small hole with a diameter of 4.2mm is drilled on a metal pipeline with a length of 12m and a diameter of 32mm as a leakage hole. One end of the pipeline is sealed, and the other end is connected to the pressure tank through a transmission pipe. superior. Fill the pipe with soil until it is covered to simulate a buried pipe. After filling a certain thickness of soil, lay a 50m armored optical fiber to be tested on the soil, such as figure 2 As shown, continue to fill the cable with soil to completely cover the cable. The armored optical cable is connected to the DAS demodulator after passing through about 950m of transmission optical cable. For each experiment, the pressure parameters on the pressure tank are changed first, and gases of different pressures are sent to the pipeline to simulate the strength of the pipeline leakage.

[0021] Such as figure 1 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com