Optical fiber beam expanding contact based on self-focusing lens

A self-focusing lens and contact technology, used in optical components, light guides, optics, etc., can solve problems such as high processing accuracy requirements, limited parts processing accuracy, unfavorable on-site removal and repair, etc., to improve maintainability, The effect of improving production efficiency and reducing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below.

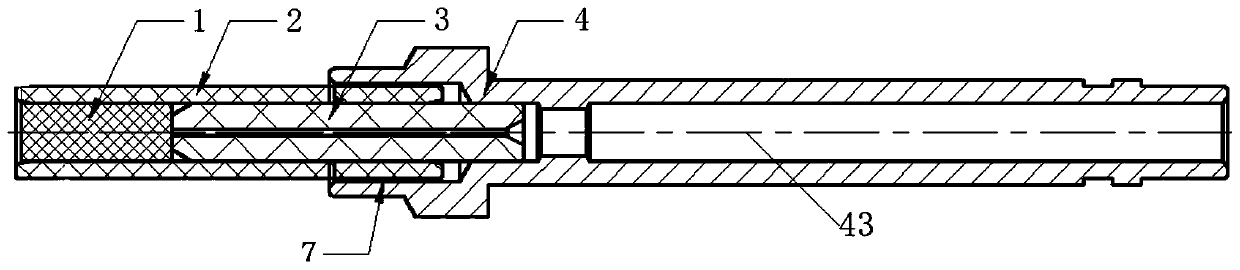

[0022] Such as Figures 1 to 3 As shown, the present invention provides a fiber beam expansion contact based on a self-focusing lens, including a ceramic sleeve with a lens, and a pin flange with a ceramic pin;

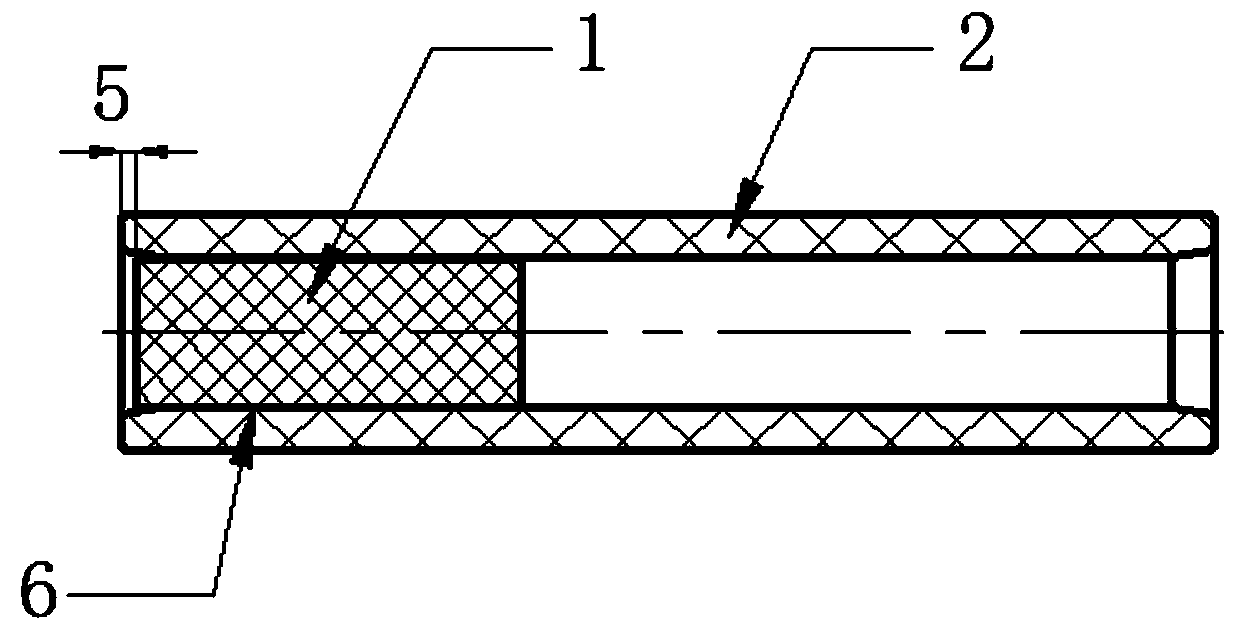

[0023] Such as figure 1 As shown, the ceramic sleeve with lens includes a self-focusing lens 1 and a ceramic sleeve 2, the self-focusing lens 1 is bonded in the left end of the ceramic sleeve 2 by 353ND or equivalent adhesive, and the self-focusing lens There is a gap 5 between 1 and the left end surface of the ceramic sleeve 2; the ceramic sleeve 2 is a closed sleeve, that is, the cross section is O-shaped.

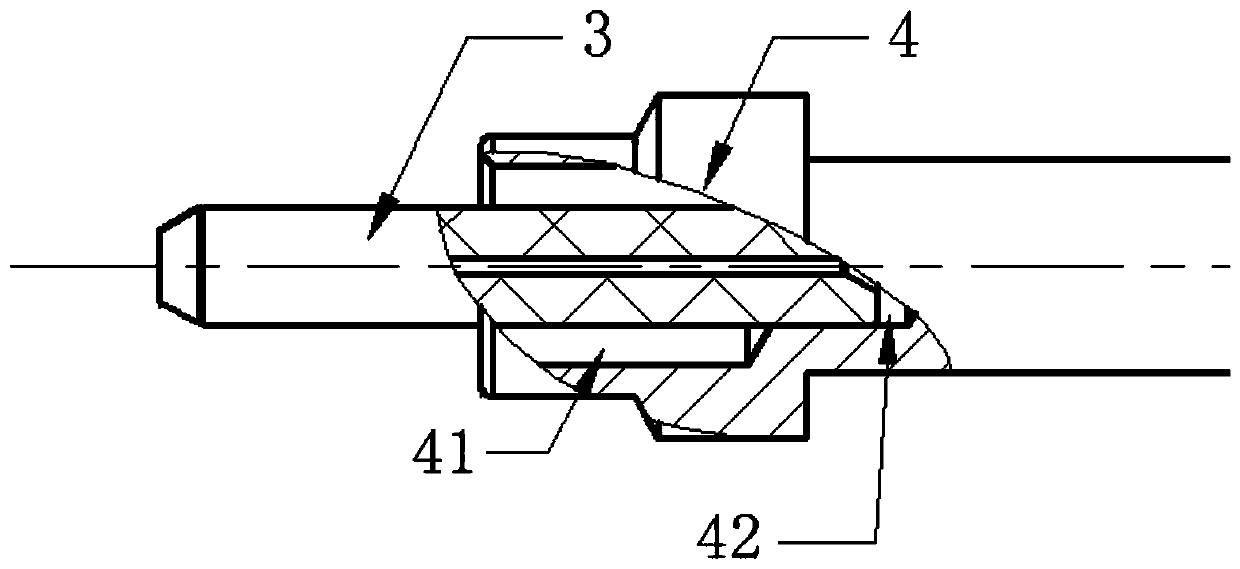

[0024] Such as figure 2 As shown, the pin flange with ceramic pins includes ceramic pins 3 and pin flanges 4; the pin flange 4 includes a first-level stepped hole 41 and a second-level stepped hole 42; in the ceramic pin The bare optical fiber is inserted, and the optical fiber is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com