In situ automatic acquisition system for the whole growth cycle of green leafy vegetable phenotypic characteristics

A growth cycle and automatic collection technology, applied in the agricultural field, can solve the problems of low degree of automation and inability to achieve continuous collection and extraction of phenotypic characteristics throughout the growth cycle, and achieve the effect of high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

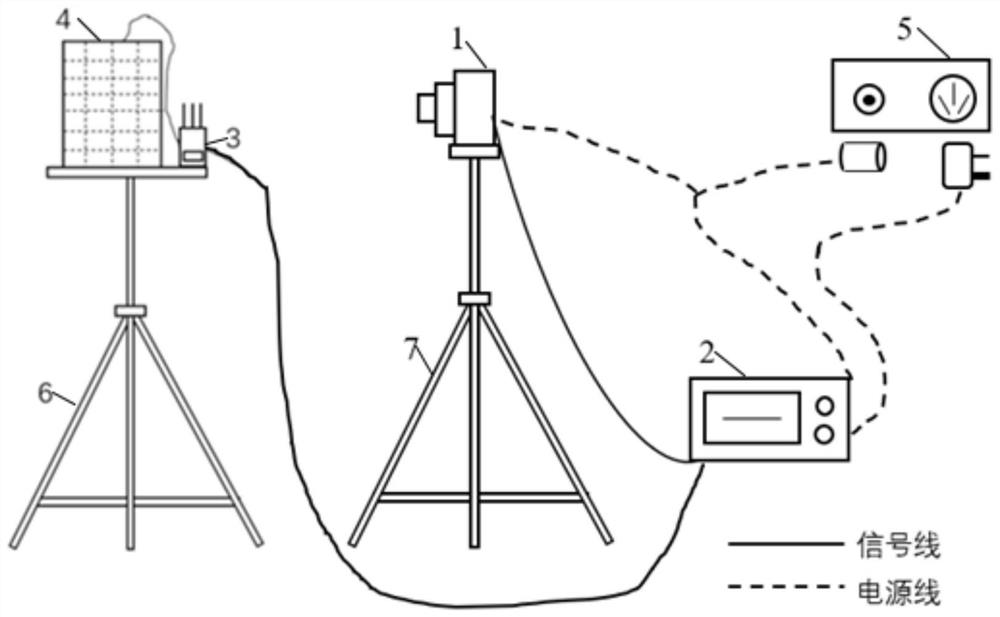

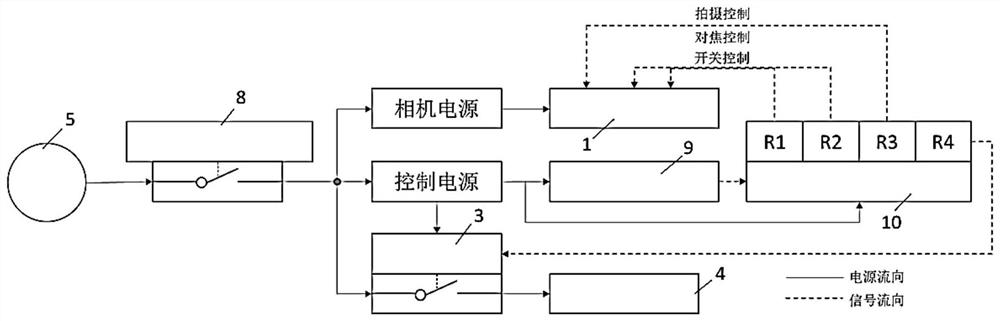

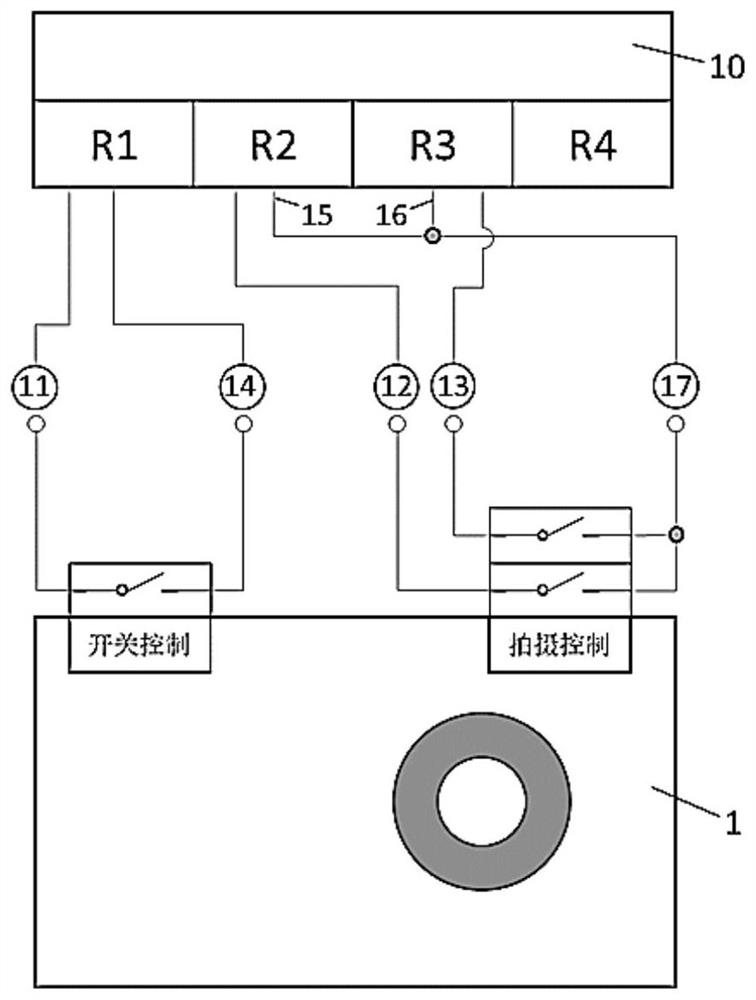

[0018] Such as figure 1 with figure 2 As shown, the present embodiment includes: a digital camera 1 as an image acquisition module, a light metering sensor 3, a supplementary light source 4, a total control box 2 and a power supply module 5, wherein: the power supply module 5 communicates with the programmable time control module 8 respectively The digital camera 1, the total control box 2 and the light metering sensor 3 are connected to transmit the information of power supply on-off of the power supply module 5, the digital camera 1 is connected to the total control box 2 through a control cable, the light metering sensor 3 is connected to the supplementary light source 4 and Transmit supplementary light signal to reduce the illumination difference during image acquisition, the total control box 2 is connected with the digital camera 1 and transmits shooting, focus or switch control information, the total control box 2 is connected with the light metering sensor 3 and colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com