Device and method for weighing ballast at a crane and corresponding crane

A crane and ballast technology, applied in the field of ballast weighing equipment, can solve problems such as inability to simply call data, errors, etc., achieve good protection and reduce the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

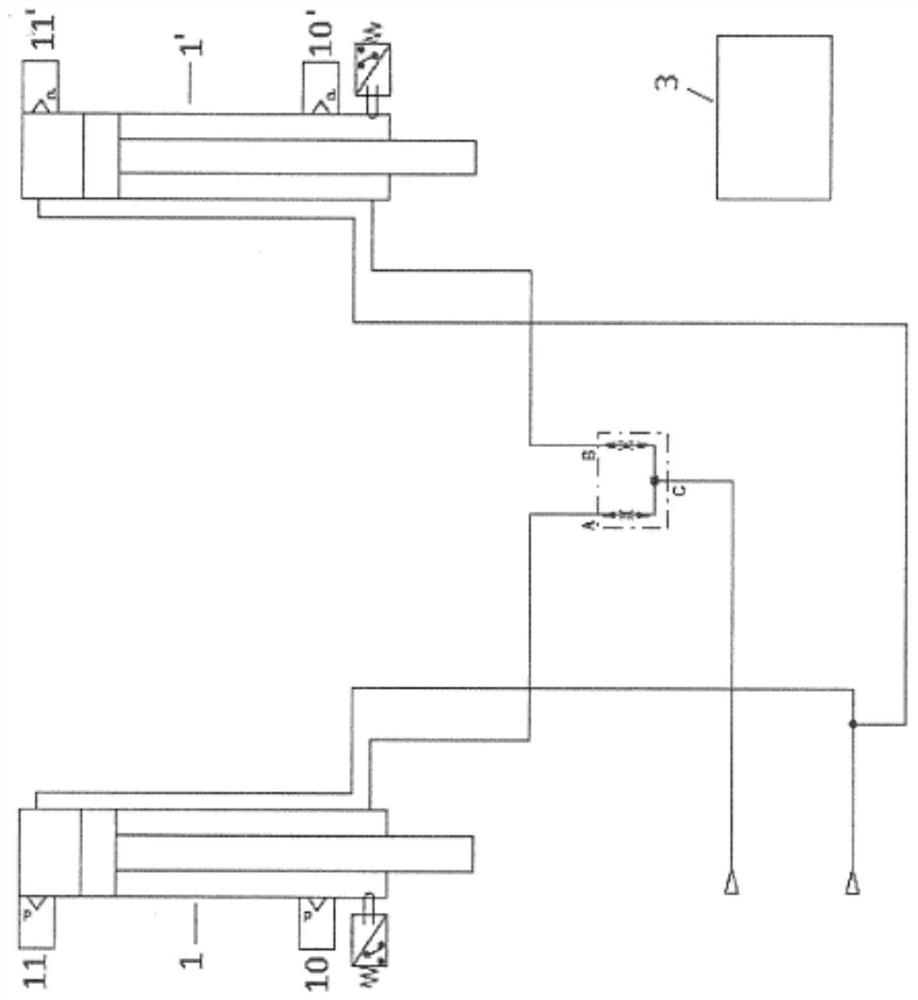

[0037] Figure 1a A schematic diagram showing a device according to the invention for weighing ballast at a crane. Shown here is a left ballast cylinder 1 and a right ballast cylinder 1' for lifting ballast 2 not shown in detail. The ballast cylinders 1, 1' each comprise at least one pressure sensor 10, 10', which are respectively arranged in the piston-side and / or rod-side region of the ballast cylinders 1, 1'. Further pressure sensors 11, 11' can be arranged at the piston side of the ballast cylinders 1, 1'. Depending on whether there is an embodiment with one pressure sensor per ballast cylinder 1 , 1 ′ or an embodiment with two pressure sensors, two pressure sensors at the ballast cylinder 1 , 1 ′ can be determined or used according to the invention differential pressure between or absolute pressure measured at a single pressure sensor.

[0038]Pressure sensors 10 , 11 ; 10 ′, 11 ′ can be coupled to evaluation unit 3 . The evaluation unit 3 is designed to calculate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com